Transcription

sl'f/ o0702 February 2007RevisionI of 34[For smaller container sizes:]ISec attached booklet for First Aid Statements. I[Pecl back tab for First Aid and Precautionary Statements.Directions for Use. and Storage & Disposallnstructions.1Serenade" ASO Master Lab,MASTER LABELSerenade@ ASO[Alternate Name: Serenade BiofungicidelAn Aqueous Suspension BiofungicidePRECAUTIONARY STATEMENTS-Agricultural Use10ptional/Aiternate Statement:"NOP Logo: For Organic Production"l[Optional/Alternate Statement: "NOP Logo: Can beUsed for Organic Production"lHAZARDS TO HUMANS & DOMESTIC ANIMALSCAUTIONHarmful if inhaled. Avoid breathing spray mist. Removecontaminated clothing and wash clothing before use.[USE INDOORS AND OUTDOORS)[USE IN FIELD APPLICATIONS. GREENHOUSES. NURSERIES.SHADE HOUSES. LANDSCAPES. INTERIORSCAPES. SEEDLINGPRODUCTION SITES, FOREST Sf EDLING PRODUCTION SITES.)[USE IN TANK MIXES OR ROTATIONAL ALTERNA TlNG SPRAYPROGRAMS WITH OTHER CROP PROTECTION PRODUCTSI[lJSE IN RESISTANT MANAGEMENT PROGRAMS)[USE GROUND, AERIAL, CHEMIGATION AND HAND APPLIEDEQUIPMENT]PERSONAL PROTECTIVE EQUIPMENT (PPE)Applicators and other handlers must wear: I.ong-sleeved shirt and long pants Waterproof gloves Shoes plus socks NIOSH approved respirator with any N, R, P or HEfilter[FOR USE ON ORNAMENTALS, TREES, SHRUBS, TURF. l.A WNS,FolluwSOD, GOLFCOlJRSES (GREENS. TEES, FAIRWAYS ANDROUGHS), SEEDLINGS, CONIFlORSImainlaining PPE. If no such instructions arc available. usedetergent and hot water for washables. Kecp and wash PPEseparately from other laundry.[USE IN PRODUCTION OF CONIFERS FOR REFORESTATION)ACTIVE INGREDIE:-.ITQST 713 strain of Bacillus sublilis. . . . . 1.34%INERT INGREDIENTS . 9X.66%Total . 100.00%Contains a minimum of 1 x AL STATEMENT:ENGINEERING CONTROLS: When handlers useclosed systems, enclosed cabs, or aircraft in a mannerthat meets requirements listed in the Worker ProtectionStandard (WPS) for agricultural pesticides 140 CFR170.240 (d) (4-6)1, the handler PPE requirements may be: "::"""i,ju :ed or modified as specified in the WPS.ISAFETY RECOMMENDATIONSshould:EPA Est. No.:hands before eating, drinking, chewing gum, using"'bacc:o or using the toilet.I.emelve clothing/PPE immediately if pesticides get inside.695926754566728wash thoroughly and put on clean clothing.MEX·IAZ-IGA-2': ;.u :I: PPE immediately after handling this product. Wash[Superscript corresponds to last digit of 101 number stampt.'rl 0-;; container]outside of gloves before removing. As soon as possible.washandinto cleanU.S. Patent Nos. 6,060,051, 6.103,228,6,291,426, andEPA Reg. No. 69592-126,417,163 on QST 713 strain of Bacillus suh/ilisNet contents: [16 fluid ounces OR 20 fluid ounces OR 24fluid ounces OR 32 fluid ounces OR 1.0 gallon. OR 2.5gallons OR 3 gallons OR 5 gallons OR 30 gallons OR IIIlgallons OR 250 gallons]KEEP OUT OF REACH OF CHILDRENCAUTIONFIRST AID -Agricultural OseIF INHALED: Move persot! to fresh air. If person is notbreathing, call 911 or an ambulance, then give artificialrespiration, preferably mouth-to-mouth if possible. Call adoctor or poison control center for further treatment advice.Have the product label with you when calling a doctor 0"poison control center.ENVIRONMENTAL HAZARDS - Agricultural UseDo not apply directly to water or to areas where surfacewater is present, or to intertidal areas below the mean highwater mark. Do not contaminate water when disposing ofequipment wasnwaters.Do not apply when weatherconditions favor drift or runoff from treated areas.DIRECTIONS FOR USE - Agricultural UseIt is a violation of Federal law to use this product in amanner inconsistent with its labeling. For any requirementsspecific to your state or Tribe. consult the State agencyresponsible for pesticide regulation.Do not apply this product in a way that will contact workersor other persons. either directly or through drift. Onlyprotected handlers may be in the area during application.

02 February 2007Revision2 of 34STORAGE AND DISPOSAL - Agricultural UseDo not contaminate water, food, or reed by storage andSerenade ASO Master LabelFor emergencies such as leaks or spills, call 24-hour toll-freeCHEMTREC hotline at 1.800.424.9300.disposal.AGRICULTURE USE REQUIREMENTSUse this product only in accordance with its labeling andwilh the Worker Protection Standard 40 CFR Part 170.This Standard contains requirements for the protection ofagricultural workers on fanns, forests, nurseries andgreenhouses and handlers of agricultural pesticides. Itcorltains requirements for training, decontamination,notification and emergency assistance. It also containsspecific instructions and exceptions pertaining to thestalements on this label about personal protectiveequipment (PPE), and restricted entry intervals. Therequirements in this box only apply to uses of thisproduct that are covered by the Worker ProtectionStandard.Do not enter or allow worker entry into treated areasduring the restricted entry interval (REI) of 4 hours.PPE required for early entry to treated areas that ispermitted under the Worker Protection Standard and thatinvolves contact with anything that has been treated,such as plants, soil or water is: coveralls, waterproofgloves, shoes plus socks.Exception: if the product is soil injected or soilincorporated, the Worker Protection Standard, undercertain circumstances, allows workers to enter the treatedarea if there will be no coil tact with anything that hasbeen treated.NON-AGRICULTURAL USE REQUIREMENTSThe requirements in this box apply to uses that are NOTwithin the scope of the Worker Protection Standard foragricultural pesticides (40 CFR Part 170). The WPS applieswhen this product is used to produce agricultural plants onfarms, forests, nurseries or green houses.Post harvest treatment of commodities do not faU within thescope ofthe WPS. PPE for applicators and handlers oftreated commodities; waterproof gloves. Keep unprotectedpersons from handling commodities until sprays havedried.STORAGE: Store in a dry area inaccessible to children. Store inoriginal containers only. Keep container closed when not in use.PESTICIDE DISPOSAL: Wastes resulting ITom the use of thisproduct may be disposed of on site or at an approved wastedisposal facility. Do not contaminate water when disposing ofequipment rinsate.CONTAINER DISPOSAL: For I.O-gallon, 2.S-gallon, 3-gallon,5-gallon, or 30-gallon plastic containers - Triple rinse (orequivalent). Then offer for recycling or reconditioning, or punctureand dispose of in a sanitary landfiIl. or by incineration, or, ifallowed by state and local authorities, by burning. If burned,stay out of smoke. For llO-gaIlon or larger returnablemini-bulk containers - Return em ty container for reuse.GENERAL USE INFORMATION - Agricultural UseSerenade ASO is a broad spectrum, preventativebiofungicide for the control or suppression of manyimportant plant diseases.Serenade ASO is an idealresistance management tool given its unique, multiple modesof action. It may be applied as a foliar spray alone, inalternating spray programs or in tank mixes with otherregistered crop protection products. For maximumeffectiveness, apply Serenade ASO prior to or in the earlystages of disease development. When conditions areconducive to heavy disease pressure, use Serenade ASO in arotational program with other registered fungicides.Serenade ASO may be applied with spray equipmentcommonly used for making ground or aerial applications andsprinkler/irrigation systems commonly used for chemigation.Serenade ASO can be used for organic production.[OPTIONAL STATEMENT: Serenade ASO is mosteffectively used in a preventive disease managementprogram. For improved performance use Serenade ASO in atank-mix or rotational program with other registeredfungicides. When using Serenade ASO alone for the firsttime a rate of 4 quarts per acre is recommended. Dependingupon disease pressure the rate can be increased and/or sprayintervals decreased. To enhance performance it isrecommended that a surfactant [such as Biotune], known tobe safe to the target crop, be added to the spray tank toimprove penetration and coverage of above-ground portionsof the plant.]INTEGRATED PEST MANAGEMENT (IPM)For disease resistance management, Serenade ASO can beintegrated into an overall disease and pest managementstrategy whenever fungicide use is necessary. Followpractices known to reduce disease development. Consultlocal agricultural authorities for specific IPM strategiesdeveloped for your crop(s) and location.Be sure use of this product conforms to resistancemanagement strategies, which may include rotating andlortank-mixing with other products with different modes ofaction.

O:!2 F e:!:b::.:ru a:!.ryL2:;:O:::O!.!7""R:::e Vi sl ·o::.:n .::S eC!re nade"' ASO Master LabelUSE RATE DETE&'VIINATION Agricultural UseCarefully read and follow all label directions. use rates andrestrictions. Apply Serenade ASO prior to or in the earlystages of disease development. Use maximum label ratesand shortened spray intervals for conditions l:onducive torapid disease development. For proper application.determine the number of acres to be treated, therecommended label use rate and select appropriateapplication volume to give good canopy penetration andcoverage of plant parts to be protected. Prepare only theamount of spray solution required to treat the measuredacreage. Accurate spray equipment calibration is essentialprior to usc.PREHARVEST INTERVAL- Agricultural UseSerenade ASO can be applied up to and including the day ofharvest.APPLICATION INSTRUCTIONS - Agricultural UseGENERAL: Avoiding spray drift at the application site isthe responsibility of the applicator. The interaction of manyequipment-alld-weather- related factors detennine thepotential for spray drift. The applicator and thegrower/treatment coordinator arc responsible for con.-'.,ideringall of these factors when making decisions. Where stateshave more stringent regulations. they should be observed.Note: This section is advisory in nature and does notsupersede the mandatory label requirements.GROUND: Be sure to maintain agitation during mixing andapplication to assure uniform product suspension. Thoroughcoverage of all foliage is essential for effective diseasecontrol. Serenade ASO can be applied in commonlyused ground equipment. hose-end. pressurized, greenhouse,and hand-held sprayers. To achieve good coverage useproper spray pressure, gallonage per acre, nozzles, nozzleConsult spray nozzle andspacing and ground speed.accessory catalogues for specific infonnation on properequipment calibration.AERIAL: This product can be applied by aerial application.Refer to the Aerial Drift Reduction Advisory Infonnationsection of this label for general directions and precaution,.Use the application rate indicated for the appropriate crop insufficient water to achieve thorough coverage, or a minimumof 3 gallons of water per acre.30f34fill the spray tank with clean water and beginagitation. Add the specified amount of Serenade ASO to thetank. Finish filling the tank to the desired volume to obtainthe proper spray concentration. It is critical that the spraysolution be agitated during mixing and application to assurea unifonn suspension. Do not allow spray mixture to standovernight or for prolonged periods. [Optional Statement:Maintain a spray solution pH between 4.5 and 8.5[.Serenade ASO may be tank mixed with other registeredpesticides to enhance plant disease control. Do not exceedrecommended dosage rates. This product cannot be mixedwith any product with prohibition against such mixing. Useof the resulting tank mix must be in accordance with themore restrictive label limitations and precautions,COMPATIBILITY: Do not combine Serenade ASO in thespray tank with pesticides. surfactants or fertilizers if therehas been no previous experience or use of the combinationto show it is physically compatible. effective and noninjurious under your use conditions.Serenade AS() is compatible with many commonly usedpesticides, fertilizers. adjuvants and surfactants but has notbeen fully evaluated with all of these. To ensurecompatibility of tank-mix combinations they should beevaluated prior to use, as follows: Using a suitable containeradd proportional amounts of product to water. Add wettablepowders fIrst. tollowed by water dispersible granules. thenby liquid flowables and lastly. emulsifiable concentrates.Mix thoroughly and let stand for at least five minutes. If thecombination stays mixed or can be remixed, it is physicallycompatible. Test the combination on a small portion of thecrop to be treated to ensure that a phytotoxic response willnot occur as a result of application. [OPTIONALSTATEMENT: Do not use with penetrant-typeadjuvants.[ADDITIVES: Serenade ASO is compatible with a wideSince the product is primarily arange of additives.protectant. thorough coverage of all above-ground plantparts is required for etIective product perfonnance. Toimprove plant surface coverage. add a non-phytotoxicadjuvant [such as BionmerMJ to spray tank.CHEMIGATlON DIRECTIONS FOR USEGeneral Requirements:CHEMIGATION: This product can be applied throughsprinkler or drip type irrigation systems. including a centerpivot, lateral move, end tow, side wheel roll, traveler, solidset, and hand move. Refer to the Chemigation Directions forUse section of this label for general directions andprecautions. Usc the application rate indicated for theappropriate crop as specified in the Use Recommendationssection of this label.MIXING INSTRUCTIONS - Agricultural Us.MIXING: Serenade ASO must be diluted with water forspray applications and may be used in spray equipmentcommonly used for making ground applications. Partially1)2)3)4)Apply this product only through sprinkler or drip typeirrigation systems including center pivot, lateral move.end tow, side wheel roll. traveler, solid set or handmove systems. Do not apply this product through anyother type of irrigation system.Crop injury or lack of effectiveness can result Irom nonuniform distribution of treated water.Ensure that the irrigation ,ystem used is properlycalibrated and If you have questions. call the StateExtension Service specialists or the equipmentmanufacturer or other experts.Do not connect an irrigation system (includinggreenhouse systems) used for pl!sticide application to a

02 February 2007RevisionS."enade" ASO Master Labelpublic water system unless the pesticide labelprescribed safety devices for public water systems art' in5)place.A person knowledgeable of the chcmigation system andresponsible for its operation, or under the supervision ofthe responsible person, shall shut the system down [mdmake any necessary adjustments should the need arist:.4 of 34system. Flush with clean water. Failure toprovide a clean tank, void of scale or residues maycause product to lose effectiveness or strength.2)Do not combine Serenade ASO with pesticides.surfactants or fertilizers for application throughchemigation equipment unleRS prior experience hasshown the combination physically compatible. effectiveand non-injurious under conditions of use.2)such system has at least 15 service connections orregularly serves an average of 25 individuals daily atCenter-pivot,least 60 days throughout the year.Chemigation systems connected to the public waterIrrigation Equipment (Use only with electric or oil hydmulicdrive systems which provide a unifonn water distribution):systems must contain a functional. reduced-pressure Determine size of area to be treated.zone (RPZ). backflow preventer or the functional Determine the time requircd to apply no more than 1/4inch of water (6.750 gallons water per acre) over theequivalent in the water supply upstream from the pointof pesticide introduction. As an option to the RPZ, thewater from the public watcr system should bedischarged into a reservoir tank prior to pesticideintroduction. There shall be a complete physical break(air gap) between the outlet end of the fill pipe and thetwice the inside diameter of the fill pipe.4)5)The system must contain a functional check valve,vacuum relief valve. and low pressure drain prevent water source contamination from back flow.The pesticide injection pipeline must contain afunctional, automatic, quick closing check valve to prevent the flow of fluid back towards the injectionpump. irrigation system is either automatically or manuallyshut down.The irrigation line or water pump must include afunctional pressure switch which will stop the waterpump motor when the water pressure decreases to thepoint where pesticide distribution is adversely affected.7) The system must contain functional interlocking controlsSolid-set. Side (wheel) Roll. and Hand Move IrrigationEquipment: adversely affected.Systems must use a metering pump, such as a positive9)area intended for treatmentApplication Instructions:1)Remove scale, pesticide reSidues, and other foreignmatter from the chemical supply tank and entire injectorDetennine acreage covered by sprinkler.Fill injector solution tank with water and adjust flowrate to use contents over a lO- to 30-minute interval.Determine the amount of Serenade ASO fungiciderequired to treat area.when the water pump motor stops. or in cases wherethere is no water pump, when the water pressuredecre3.'\cs to the point where pesticide distribution 18displacement injection pump (e.g . diaphragm pumpl,effectively designed and constructed of materials thatare compatible with pesticides and capable of beingtitted with a system interlock.Do not apply when wind speed favors drift beyond thoMaintain constant solution tank agitation during theinjection period.Stop injection equipment after treatment is completed.Continue to operate the system until Serenade ASOfungicide solution has cleared the sprinkler head.to automatically shut off the pesticide injection pump8)Runsystem at 80 to 95% of manufacturer's rated capacity.Using only water. determine the injection pump outputwhen operated at normal line pres:-.ure.Detennine the amount of Serenade ASO fungiciderequired to treat area.Add required amount of Serenade ASO fungicide andsufficient water to meet the injection time requirementsof the solution tank.The pesticide injection pipeline must also contain afunctional, nonnally closed. solenoid-operated valvebeing withdrawn from the supply tank when the6) located on the intake side of the injection pump andEnd Tow, and Travelerrecommended by the equipment manufacturer.appropriately located on the irrigation pipeline toconnected to the system interlock to prevent tluid fromLateral Move.area to be treated when the system and injectionequipment are operated at nonnal pressurestop of the overflow rim of the reservoir tank of at least3)SerenadeASO has not been fully evaluated for compatibility withall adjuvants or surfactants. It is advisable to conduct aspray compatibility tcst if mixture with adjuvants orsurfactants is planned.Equipment Requirements:I) Public water supply means a system for the provision tothe public of piped water for human consumption if Add the required amount of Serenade ASO fungicideinto the same quantity of water used to calibrate theinjection equipment.Maintain constant solution tank. agitation during theinjection period.Operate system at normal pressures recommended bythe manufacturer of the injection equipment and usedfor the time interval established during calibration.Inject Serenade ASO fungicide at the end of theirrigation cycle or as a separate application to maximizefoliar fungicide retention.Stop injection equipment after treatment is completed.Continue to operate the system until Serenade ASOfungicide solution hao.; cleared the last sprinkler head.

O:"2:F:e.::b ru:::a;,ory:.;2;;.:O O 7 R:;:e Vi:;:S::;io:.:n s::;e::re;::n,ade ASO MasterAERIAL DRIFT REDUCTION ADVISORYINFORMATIONGeneral: Avoiding spray drift at the application site is theresponsibility of the applicator. The interaction of manyequipment-and-weather-related factors determine thepotential for spray drift. The applicator and the grower areresponsible for considering all these factors when makingdecisions. Where states have more stringent regulations,they should be observed. Note: This section \5 advisory innature and does not supersede the mandatory lubel requirements.INFORMATION ON DROPLET SIZE: The mosteffective way to reduce drift potential is to apply largedroplets. The best drift management strategy is to apply thelargest droplets that provide sufficient coverage and control.Applying larger droplets reduces drift potential, but will notprevent drift if applications are made improperly, or mperature and Humidity, and Temperature Inversions),CONTROLLING DROPLET SIZE: Volume - Use highflow rate nozzles to apply the highest practical sprayvolume. Nozzles with higher rated flows produce largerdroplets. Pressure -Do not exceed the nozzle manufacturer'srecommended pressures. For many nozzle types lowerpressure produces larger droplets. When high flow rates areneeded, use higher flow rate nozzles instead of increasingpressure. # of Nozzles - Use the minimum number ofnozzles that provide unifonn coverage. Nozzle Orientation Orienting nozzles so that the spray is released parallel to theairstream produces larger droplets than other orientationsand is the recommended practice. Significant deflectionfrom horizontal will reduce droplet size and increase driftpotential. Nozzle Type - Use a nozzle type that is designedfor the intended application. With most nozzle types,narrower spray angles produce larger droplets. Considerusing low-drift nozzles. Solid stream nozzles orientedstraight back produce the largest droplets and the lowestdrift.BOOM WIDTH: For aerial applications, the boom widthmust not exceed 75% of the wingspan or 90% of the rotaryblade. Use upwind swath displacement and apply only whenwind speed is 3 -- 10 mph as measured by an anemometer.Use medium or coarser spray according to ASAE 572defmition for standard nozzles or VMD for spinning(itomizer nozzles. If application includes a no-spray zone,do not release spray at a height greater than 10 feet abovethe ground or the crop canopy.APPLICATION HEIGHT: Do not make application at aheight greater than 10 feet above the top of the largest plantsunless a greater height is required for aircraft safety.Making applications at the lowest height that is safe reducesexposure of droplets to evaporation and wind.SWATH ADJUSTMENT: When applications are madewith a crosswind, the swath will be displaced downward.Therefore, on the up and downwind edges of the field, tll :applicator must compensate for this displacement byadjusting the path of the aircraft upwind. Swath adjustmenrLabel5 of34distance should increase, with increasing driftpotential (higher wind, smaller drops, etc.).WIND: Drift potential is lowest between wind speeds of 2 10 mph. However, many factors, including droplet size andequipment type determine drift potential at any given speed.Application should be avoided below 2 mph due to variablewind direction and high inversion potential. NOTE: Localterrain can influence wind patterns. Every applicator shouldbe familiar with local wind patterns and how they affectspray drift.TEMPERATURE AND HUMIDITY: When makingapplications in low relative humidity, set up. equipment toproduce larger droplets to compensate for evaporation.Droplet evaporation is most severe when conditions are bothhot and dry.TEMPERATURE INVERSIONS: Do not apply during atemperature inversion because drift potential is high.Temperature inversions restrict vertical air mixing, whichcauses small, suspended droplets to remain in a concentratedcloud. This cloud can move in unpredictable directions dueto the light variable winds common during inversions.Temperature inversions are characterized by increasingtemperatures with altitude and are common on nights withlimited cloud cover and light to no wind. They begin toform as the sun sets and often continue into the morning.Their presence can be indicated by ground fog; however, iffog is not present, inversions can also be identified by themovement of smoke from a ground source or an aircraftsmoke generator. Smoke that layers and moves laterally in aconcentrated cloud (under low wind conditions) indicates aninversion, while smoke that moves upward and rapidlydissipates indicates good vertical air mixing.SENSITIVE AREAS: The pesticide should only be appliedwhen the potential for drift to adjacent sensitive areas (e.g.residential areas, bodies of water, known habitat forthreatened or endangered species, non-target crops) isminimal (e.g. when wind is blowing away from the sensitiveareas). Do not allow spray to drift from the application siteand contact people, structures people occupy at any time andthe associated property, parks and recreation areas, non target crops, aquatic and wetland areas, woodlands, pastnres,rangelands, or animals.CONDITIONS FOR SALE AND WARRANTYAgraQuest warrants to those persons lawfullypurchasing this product that at the time of the first saleof this product by Seller that this product conformed toits description and was reasonably fit for the purposesstated on the label when used in accordance with Seller'sdirections. Buyers and users of this product assume therisk of any use contrary to such directions. EXCEPT ASPROVIDED ELSEWHERE IN WRITINGCONTAINING AN EXPRESS REFERENCE TO THISWARRANTY AND LIMITATION OF DAMAGES,SELLER MAKES NO OTHER EXPRESS ORIMPLIED WARRANTY OR GUARANTY,INCLUDING ANY OTHER EXPRESS OR IMPLIED

02 February 2007RevisionS43renade"J ASO Master La .Serenade I., is a registen:d lrademark of AgraQuest.WARRANTY OF FIT:-iESS OR OFMERCHANTABILITY A:-iD NO AGE:-iT OF SELLERIS AUTHORIZED TO DO SO. Except to the extentprohibited by applicable law, AgraQuest offers thisproduct with the following conditions: \) buyers anelusers of this product assume the risk of any storage,handling or use contrary to AgraQuest's label anddirections and 2) AgraQuesl's liability shall in no caseexceed the purch se price of the applicable Agr.Questproduct.c1Copyright AgraQuest. Inc., 2007Made in MexicoAgraQuc,t. Inc.1530 Drew AvenueDDVis. (' dlifomia 95618www.agraqucst.com60f34

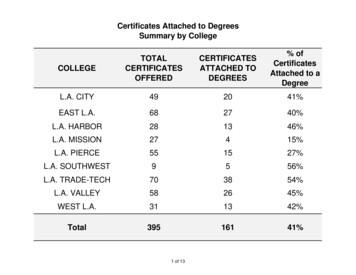

02 February 2007Revision7 of34Serenade'!! ASO Master Lal. .Recommended Application Rates for Selected Crops - Agricultural Use(Serenade ASO has a O-Day PreHarvest Interval for all crops contained on this label)Under moderate to severe disease pressure, for improved performance, increase rates and reduce spray intervals oruse Serenade ASO in a tank mix or rotational program with other registered fuugicides.CropsDiseaseArtichokePowdery MildewLeveillula taurica,Elysiphe cichoracearumGray MoldBotrytis spp.Bacterial Crown RotErwinia chrysanthemiRustPuccinia mparagiBotrytis BlightBotrytis rella 'pp.BerriesMummy BerryMonilinia vacciniicorymbosiAnthracnose Fruit RotColletotriclzumgloeosporiodesColletotrichum acutatumBotrytis BlightBotrytis cinereaLeaf RustPucciniastrum vacciniiPowdery MildewMicrosphaera alniSooty MoldMisc. fungiAlternaria Fruit RotAlternaria tenuissirnaBacterial CankerPseudomonas spp.Downy MildewPeronospora sparsaPhomopsisPhomopsis erryBushberryand otherberry cropsRateOts.!acre1- 61- 6Application InstructionsBegin application when conditions are conducive to diseasedevelopment. Repeat on 7 to 10 day intervals or as needed.Serenade ASO may be applied up to and including the day of harvest.Begin application soon after emergence and when conditions areconducive to disease development. Repeat' on 7 to 10 day intervalsSerenade ASO may be applied up to and includingor as needed.the day of harvest.1-6Begin application when leaves tirst appear and repeat on 7 to 2l dayintervals or as needed. The addition of an approved emulsifiable oil to spraysolutions will improve performance.1- 6Murmny Berry - For suppression, begin application at the bud breakstage of development and repeat on a 7 to 10 day intervals or asneeded. For improved performance, use Serenade in a tank mix orrotational program with other registered fungicides for mnmmy berrycontrol.Bacterial Canker - Apply before fall rains and again duringdormancy before spring growth.For all other ·diseases - Begin application prior to diseasedevelopment and repeat on 7 to 10 day intervals or as needed. Forimproved performance of Serenade ASO, add a surfactant [such asBiotune1to the spray tank to improve coverage.Cranberries - Make application to non-flooded fields only.Serenade ASO may be applied to fluit up to and including the day ofharvest.

Serenade Jl ASO Master La .02 February 2007RevisionCropsDiseaseRate8 of34Application InstructionsOts.!acreBrassicavegetables(Cole Crops)Pin Rot ComplexAltcrnarialXanthomonasBacterial Leaf SpotPseudomonas syringaeBroccoliBacterial Soft RotCabbageErwinia / PseudomonasCauliflowerBlack RotBrusselsXanthomonas campestrisXanthomonas Leaf SpotSproutsCollardsXanthomonas campestrisAlternaria Leaf SpotKaleAlternaria umand otherhigginsianumbrassicaCercospora Leaf SpotcropsCercospora hrassicaicolaDowny MildewPeronospora parasiticaPeronospora spp.Powdery MildewElysiphe polygoniSouthern BlightSclerotium rolrsiiBotrytis Neck RotBulbVegetablesBotlytis spp.Botrytis Leaf BlightBotlytis squamosaOnionOnion Purple BlotchGarlicShallotsAlternaria porriandother Onion Downy MildewPeronospora destructorbulbvegetablesDowny MildewPeronospora spp.Powdery MildewErysiphe spp.White RotSclerotium cepivorumI· nPin Rot - For suppression. begin application when environmentalconditions arc conducive to disease development and repeat on 7 to10 day intervals or as needed. For improved perfonnance,

May 04, 2007 · ISec attached booklet for First Aid Statements. I [Pecl back tab for First Aid and Precautionary Statements. . For emergencies such as leaks or spills, call 24-hour toll-free STORAGE AND DISPOSAL -Agricultural Use CHEMTREC hotline at 1.800.424.930