Transcription

OPERATION&MAINTENANCEMANUALElectronic Tabletop AutoclavesModels EZ9, EZ10, EZ10KCat. No. MAN205-0263001EN Rev. E Tuttnauer USA Co., Ltd., 25 Power Drive Hauppauge, NY 11788 USA, : (800) 624 5836, (631) 737 4850, Fax: (631) 737 0720e-mail: info@tuttnauerUSA.com

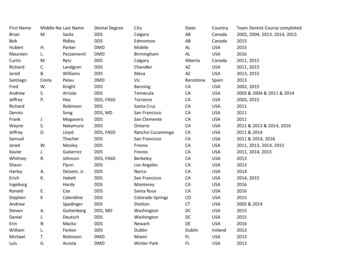

TABLE OF CONTENTSPARAGRAPH1.2.3.4.5.6.7.8.PAGE NO.GENERAL.41.1 Incoming Inspection.41.2 Warranty .41.3 Warranty Statement.4TECHNICAL DATA.62.1 Introduction .62.2 Standby Heating Mode .62.3 Environmental Emission Information .72.4 Operating Conditions .72.5 Utilities .72.6 Construction .72.7 Symbol Description.82.8 Electrical Data .92.9 Specifications .102.10 Technical Specifications .112.11 Standards .112.12 Water Quality.12KEYBOARD (Keys and Display).153.1 Indicator Light Description.163.2 Description and Functions of the Control Panel Keyboard .173.3 Description of the Display Panel .193.4 Description of Displayed Messages and Safety Measures .19STERILIZATION PROGRAMS .224.1 PROGRAM 1. Unwrapped Instruments .224.2 PROGRAM 2. Wrapped Instruments and Porous Loads .234.3 PROGRAM 3. Glassware .244.4 PROGRAM 4. Accessory (Dry Only) .24PRINTER (Optional) .255.1 Printer Operation.255.2 Printer Handling .27INSTALLATION INSTRUCTIONS .286.1 Electrical .286.2 Water Filling.296.3 Lifting and Carrying.306.4 Loading and Unloading the Device .306.5 Filling the Water Reservoir.31PREPARATION BEFORE STERILIZATION.32OPERATING INSTRUCTIONS .351

TABLE OF CONTENTS (Cont.)PARAGRAPHPAGE NO.9.MAINTENANCE INSTRUCTIONS.389.1 Preventive and Scheduled Maintenance.389.2 Replacing the Air Filter.399.3 Draining the Reservoir .409.4 Cleaning the Air Jet.419.5 Replacing the Door Gasket .429.6 Checking the Safety Valve.439.7 Replacing the Fuse .449.8 Cleaning Water Outlet Strainer .459.9 Cleaning Tabletop Autoclaves with Chamber Brite .469.10 Water Sensor Cleaning.4810. TROUBLESHOOTING FOR THE OPERATOR .492

TABLE OF CONTENTS (Cont.)DRAWINGSPAGE NO.Front View.13Rear View .14Front Panel Keyboard.153

1.GENERALRead the Operating Instructions carefully, before beginning any operationon the autoclave!1.1 Incoming InspectionUpon receiving your Tuttnauer Autoclave, carefully inspect the outsideof the shipping carton for signs of damage. If any damage to the carton isfound, note the location with respect to the autoclave and check that areaof the autoclave carefully once it is fully unpacked. Observe packingmethod and retain packing materials until the unit has been inspected.Mechanical inspection involves checking for signs of physical damagesuch as: scratched panel surfaces, broken knobs, etc.If any damage is found, contact your dealer as soon as possible sothat they can file a claim with the shipping carrier and also notifyTuttnauer.All Tuttnauer products are carefully inspected prior to shipment and allreasonable precautions are taken in preparing them for shipment toassure safe arrival at their destination.Note: Lifting and carrying should always be done by two people.1.2WarrantyWe certify that this instrument is guaranteed to be free from defects inmaterial and workmanship for two years against faulty components andassembly.This warranty does not include routine cleaning and preventivemaintenance, to be performed according to instructions insection 9.1 (Preventive and Scheduled Maintenance).Tuttnauer warrantees all new autoclaves for a period of two full years,covering both parts and labor. This two year warranty covers defects inmaterials and workmanship on every part in the autoclave except doorgaskets and HEPA filters (they are wear items).Tuttnauer warrantees all chambers for a period of ten (10) years againstdefects in materials and workmanship. This chamber warranty wentinto effect January 1997.This warranty does not apply to any instrument that has been subjectedto misuse, neglect, accident or improper installation or application, norshall it extend to autoclaves that have been repaired or altered outsidethe factory without prior authorization from Tuttnauer.Tuttnauer’s obligation is limited to the repair or replacement of partsfor the autoclave. This warranty will be void if the unit is not purchasedfrom an authorized Tuttnauer dealer. No other warranties or obligationsare expressed or implied.The Autoclave should only be used in a manner described in thismanual!1.3Warranty StatementTo activate the warranty, the registration card must be completed andreturned to Tuttnauer within fourteen (14) days of purchase or you maycall our customer service department at the number listed below.No product will be received or accepted for repair without prior returnauthorization from Tuttnauer. All transportation charges to and fromTuttnauer must be paid by the owner of the autoclave. During the first90 days after purchase of an autoclave, Tuttnauer will pay shippingcosts on an individually evaluated basis and ONLY with pre-approval.4

Note:If you have any questions or there are any difficulties with this instrumentand the solution is not covered in this manual, please contact your dealer orTuttnauer USA Co. Do not attempt to service this instrument yourself. Tuttnauer USA Co., Ltd., 25 Power Drive Hauppauge, NY 11788, USA : (800) 624 5836, (631) 737 4850, Fax: (631) 737 0720e-mail:info@tuttnauerUSA.com.5

2.TECHNICAL DATA2.1IntroductionThis tabletop autoclave is designed for the sterilization of wrapped andunwrapped instruments and related items found in dental, medical andveterinary clinics, first aid rooms, hospitals, laboratories, etc.This autoclave is an electrically heated sterilizer using steam as thesterilizing agent. A computerized control unit ensuring a fully automaticsterilization cycle, control and monitoring of physical parameters and aclear documentation of the sterilization cycle controls the autoclave.The autoclave has three automatic programs, according to the materialto be sterilized, and one auxiliary drying program. The autoclave isequipped with an air compressor that, during the drying stage draws airthrough a HEPA filter (0.2µm). It pushes the air through the heatedchamber to remove moisture and facilitate the drying operation. Dryingis performed with the door closed.On all models, a water pump is installed between the water reservoirand the chamber. This pump guarantees fast and accurate filling of thechamber every time. Entry of water may be accompanied by a noise forapproximately 30 seconds. This is normal noise generated by regularoperation of the pump.The control system provides adequate protection, to ensure the safety ofpersonnel and reliable operation with a minimum of shutdown time.On all models, a printer is an optional addition to the autoclave. Theprinter prints the preset and actual parameters of the cycle (temperature,time and pressure).This manual is intended for the user and gives the user a generalunderstanding of the instrument and the best ways to operate and takecare of it, in order to obtain optimum effective results.After reading this manual, operating the autoclave will be easy.However, since this instrument is built with high technology sensitivecomponents, no attempt should be made by the user or any otherunauthorized person to repair or recalibrate it.Only technical personnel, having proper qualifications and holdingtechnical documentation (including a technician manual) andadequate information, are authorized to service the apparatus.2.2Standby Heating ModeThe autoclave provides an option of heating the chamber in standbymode between cycles, with a very low power, in order to reduce totalcycle time (1.6% of the total power only). The autoclave turns offautomatically if the interval between the sterilization cycles is morethan 2 hours. This feature is standard on model EZ10K and optional onEZ9 and EZ10 models.6

2.32.4Environmental Emission Information1.The peak sound level generated by the autoclave is less than 70 dBAwith background noise of 60 dBA.2.The total heat per hour transmitted by the autoclave is 100 Wh forall models.Operating ConditionsThis device is to be used for indoor use.This autoclave is intended for NORMAL environment conditions asfollows: Altitude up to 2000m. Room temperature range 5ºC to 40ºC. Installation Category II. Pollution Degree 2. Maximum relative humidity 80% for temperature up to 31ºCdecreasing linearly to 50% relative humidity at 40ºC. Mains supply voltage fluctuations up to /-10% of the nominal voltage.The sterilizer should be loaded only with autoclavable material.Caution!Waste water should be brought into the public net in accordance withthe local rules or requirements, i.e.ONLY NON-HAZARDOUS LIQUIDS SHALL BE DISPOSED INPUBLIC SEWAGE!2.5UtilitiesUtilitiesUnitPower supply (as appropriate)ValueV-A 1ph, 120V – 16A,50/60 HzV-A 1ph, 230V – 16A,50/60 HzAttention:The electrical net must be protected with a current leakage safety relay.The electrical network must comply with local rules or regulations.2.6ConstructionThe main parts of the autoclave are made of materials as indicatedbelow: Chamber is electro-polish and built of stainless steel 316 L. Door is made of stainless steel CF8. Trays are made of stainless steel 304. Water reservoir is made of hard plastic material. Door handle is made of hard plastic material, which is safe to touchand thermo-insulated. Covers are made of aluminum sheet, coated with Epoxy paint.7

2.7Symbol DescriptionCaution! Consult accompanying documents.Caution! Hot surface.Caution! Hot steam.Protective earth (Ground).Standby8

2.8Electrical DataEZ9EZ10EZ10K669.6Ampere (A) at 120V11.711.7 Watts (W)140014002200Ampere (A) at 230/240VFrequency50 / 60 HzDegree of protection by enclosureIP31AUTOCLAVE TYPEDESCRIPTIONEZ9, EZ10EZ10K120V230V230VCircuit breaker (A)151015Air pump fuse (A)2.01.251.25Water pump fuse (A)1.251.251.259

2.9SpecificationsOverall DimensionsModelDimensionsOverall DimensionsMaximumDimensions (dooropen)Distance BetweenSupporting LegsEZ9EZ10, 1.8F142216.642216.6G502.0502.0H40015.840015.83 lit.0.8 gal.3 lit.0.8 gal.0.8 lit.0.21 gal.0.8 lit.0.21 gal.Reservoir VolumeMinimum Water Volume inReservoirMax. Allowable WorkingPressure (MAWP)Load No. Counter102.76 bar (40 psi)Counting from 0 to 250 and nullifies.

2.10Technical SpecificationsModelsEZ9EZ10, EZ10K9.4 cu.ft.(0.27m3)79 lbs.(36 kg)9.4 cu. ft.(0.27m3)106 lbs.(48 kg)YesYesHalf23Full23346.7" x 16.3" x 0.8"(17 x 41.5 x 2cm)0.66 US gal.(3.0 liters.)5 US gal.(19 liters )9" x 18"(23 x 47 cm)6.7" x 16.3" x 0.8"(17 x 41.5 x 2cm)0.66 US gal.(3.0 liters.)6 US gal.(23 liters)10" x 19"(25.4 x 47.5cm)Shipping VolumeShipping WeightPrinterNo. of IMS Cassettes(Optional)No. of TraysTray Dimensions W X D X HVolume of Mineral FreeWater ReservoirVolume of ChamberChamber Dimensions DIA x D2.11StandardsThe autoclaves are FDA cleared and comply with the followingStandards:2.11.1 Technical Standards1.A.S.M.E. Code, Section VIII div.1 for unfired pressurevessels.3.UL61010-1 Safety for Electrical Equipment for Measurement,Control, and Laboratory Use, General Requirements.4.UL61010-2-041 Particular Safety for Autoclaves.2.11.2 Quality Standards1.EN ISO 9001:2008– Quality System2.ISO 13485:2003 – Quality systems – Medical devices .11

2.12Water QualityThe distilled or mineral free water supplied to the autoclave shouldhave the physical characteristics and maximum acceptable level ofcontaminants indicated in the table below:Physical Characteristics and Maximum acceptable contaminantslevels in steam for sterlizersElementCondensate – allowable contentSilicium oxide. SiO2 0.1 mg/kgIron 0.1 mg/kgCadmium 0.005 mg/kgLeadRest of metals except iron,cadmium, leadChloride (Cl) 0.05 mg/kg 0.1 mg/kgPhosphate (P2O5) 0.1 mg/kgConductivity (at 20 C) 3 µs/cm 0.1 mg/kgpH value (degree of acidity)5 to 7Colourless clean withoutAppearancesedimentHardness (Σ Ions of alkaline earth) 0.02 mmol/lCompliance with the above data should be tested in accordancewith acknowledged analytical methods, by an authorizedlaboratory.Attention:The use of water for autoclaves that does not comply with the tableabove may have severe impact on the working life of the sterilizer andcan invalidate the manufacturer’s warranty.12

FRONT VIEWNo.DescriptionNo.Description1Reservoir water drain valve9Air relief valve2Ring for drain valve10Panel base3Door closing device11Front panel key board4Door switch (under door)12Printer5Autoclave cover13Main switch6Water reservoir cover14RS232 port cover7Water reservoir – assembly15Completion to panel8Safety valve13

REAR VIEW14

3.KEYBOARD (Keys and Display)FRONT PANEL KEYBOARDNote: See section 3.2 for a description of the Keyboard buttonsNote: See section 3.2 for a description of the Keyboard buttons15

3.1Indicator Light DescriptionProgramsIndicatorsShows the selected programSTARTShows the system is running a program.HEATThe system is currently in the Heating stage.STEThe system is currently in the Sterilization stage.EXHThe system is in the Exhaust stage.DRYThe system is in the Dry stage.FAILShows the system has failed as a result of either amalfunction, or the STOP key was pressed. Amessage is displayed on the screen; the reason forfailure.ADD WATERThis indicator lights if there is a lack of water in thereservoir.DOORCLOSEDThis indicator lights showing the door is in theclosed position.16

3.2Description and Functions of the Control Panel Keyboard3.2.1Program keys(1) Unwrapped Instruments(2) Wrapped Instruments(3) Glassware (slow exhaust, no drying)Pressing one of the above program keys determines thechosen program. The program parameters are displayed andthe program indicator lights.(4) Dry OnlyPressing this key allows inclusion of the Additional Dryingprocedure for a period of time determined by the operator.Time range is 0-99 minutes.3.2.2Other keys(5) TEMP.Pressing this key places the marker under the temperaturedisplayed on the display. To raise or lower the programsterilization temperature, press UP or DN keys. To store thenew value in the memory, as the nominal setting, completethe changing of the parameter by pressing TEMP. key again.The permitted temperature range for proper sterilization is250ºF-274ºF (121ºC-134ºC).Note:In no case should the temperature be set higher than 274ºF(134ºC)(6) STE. TIMEPressing this key places the marker under the sterilizationtime displayed on the display. To raise or lower the programsterilization time, press the UP or DN keys. To store the newvalue in the memory, as the nominal setting, complete thechanging of the parameter by pressing STE. TIME key again.Time range is 3-99 minutes.Note:It is important to properly coordinate the STE. TIMEwith the sterilization temperature.(7) DRY TIMEPressing this key places the marker under the drying timedisplayed on the display. To raise or lower the programdrying time, press the UP or DN keys. To store the new valuein the memory, as the nominal setting, complete the changingof the parameter by pressing DRY TIME key again. The timerange is 0-99 minutes. This key does not allow any change ofthe dry time for the Glassware program, for which it ispermanently set to 00 minutes.(8) UPPressing this key in combination with TEMP. (5), STE TIME(6), DRY Time (7) and CLOCK (9) increases these values.17

(9) DNPressing these keys in combination with TEMP. (5), STETIME (6), DRY Time (7) and CLOCK (9) lowers thesevalues.(10) CLOCKPressing the CLOCK programming key displays the date,with the cursor under the day. Pressing the UP or DN keyschanges the date. Pressing the CLOCK key again moves thecursor to the month, then year and then time (hour, minute,second). At this point the display shows the currently set dateand time. If no key is pressed during a 10-second interval, thesystem exits the clock-programming mode and returns to thecurrent program display.(11) Water InletPressing this key continuously, allows for manual filling of thechamber with water. Once the key is released the water pumpstops, the fill valve closes and water stops entering thechamber.(12) STARTPressing this key starts the sterilization (or DRY ONLY)process according to the selected program. Water flowsautomatically into the chamber, HEAT and STE. stagescommence and the respective LED indicator lights up.On completion of the sterilization program the Exhaust stagewill automatically begin, at the end of which a Drying stage(if previously programmed) will initiate. The respective LEDindicators light up, indicating which stage is operating. Onceall stages have been completed, the final indicatorextinguishes and the screen displays the “Cycle Finished”message.The process will not start if: The door is not closed and the DOOR CLOSEDindicator is off. The “DOOR UNLOCK” message is displayed.Note:Due to inherent elasticity of the door gasket, the CLOSEDOOR indicator may be illuminated green before acomplete seal is made between the door and the chamber.Therefore, in order to ensure the door is fully sealed,tighten the door bolt until ‘hand tight’. Do notovertighten the bolt as this may result in damage to thegasket. Should the autoclave fail to reach sterilizingtemperature/pressure, always check first if the door isfully sealed. If not, tighten the door further, as describedabove, until completely sealed. There is not enough water in the reservoir, (the redADD WATER indicator lights and the “ADDWATER” message is displayed).18

(13) STOPThis key issues the only command accepted by the systemduring the running of a program. Pressing this key for over 1second causes the program to immediately cease running andenters the EXHAUST stage, at the end of which the “MAN.STOP” message will be displayed. This key has no functionwhen the system is not in operation and its only use is tomanually stop a cycle. In normal working conditions oncompletion, the system automatically terminates the cycle,without use of this key.The STOP key does not function in EXH stage.3.3Description of the Display PanelThe display is comprised of 16 characters in one row and is divided into 4sections.The first section to the right, continuously shows the actual pressure withinthe chamber. This happens whether the system is running a program or not(provided the main power switch is turned on).The three other sections are designated to show the parameters of theselected program, or operating messages. When the system is running asterilization program, the sterilization temperature will be displayed abovethe TEMP key. Sterilization time will be displayed above the STE. TIMEkey and the drying time for the selected program will be displayed abovethe DRY TIME key.If the program is aborted as a result of parameters exceeding the controlledlimits (high, low pressure or temperature etc.) or a manual STOPcommand, a message is displayed on the left side of the screen. When amessage is displayed, pressing any key erases the message and redisplaysthe selected program screen.When the system is running a program, the screen displays the currenttemperature within the chamber and the remaining time for sterilization ordrying. The current real pressure inside the chamber is always displayed onthe screen.3.4Description of Displayed Messages and Safety MeasuresDoor Unlock Message is displayed and the DOOR CLOSED LEDindicator remains unlit, if the door is improperly closedwhen the START button is pressed. If the door accidentallyopens during any stage of the cycle, the same messageappears, the DOOR CLOSED LED indicator will turn off,and the system reacts as if the STOP key was pressed.Man. Stop Message will be displayed and the FAIL indicator will lightafter the STOP key is pressed for longer than 1 second.Add WaterMessage is displayed and the respective red LED indicatesinsufficient water in the water RESERVOIR. After water isadded to the reservoir, the START button must be pressedagain in order to start the required sterilization cycle.Water Inlet During the automatic water fill, the message WATERINLET is displayed as information to the operator.19

Message is displayed and sterilization does not start if theautoclave has not reached sterilization temperature afterheating for 50 minutes while in the Wrapped or Unwrappedprograms (80 minutes in the Glassware program).Possible causes: A clogged Air Jet (see cleaning the Air Jet sec 9.4). No power to the heating elements. Low line voltage delaying heat up.Low PresMessage is displayed, fail indicator lights, and the programis aborted if the pressure drops 4 psi (0.27 Bar) below therequired sterilization pressure.Possible causes: Insufficient water in the chamber (see Low Watermessage) A damaged heating element. A damaged pressure transducer.High Pres. Message is displayed, fail indicator lights up, and theprogram is aborted if the pressure rises 10 psi (0.6 Bar)above the required sterilization pressure.Possible causes: A damaged solid state relay. A damaged heating element.Low Temp. Message is displayed, fail indicator lights and cycle isaborted, if the temperature drops 2.5 C (4.5 F) below therequired sterilization temperature.Possible causes: Insufficient water in the chamber (see Low watermessage). Sterilization time has been set for too long a period. A bad temperature sensor.High Temp. Message is displayed, fail indicator lights and program isaborted if one of the following occurs: The temperature rises to 3 C (5 F) above the requiredsterilization temperature during the sterilization stage. This message appears during the HEAT stage, if thetemperature sensor is damaged.Possible causes: A damaged solid state relay. A damaged heating element. A damaged temperature sensor.Low Water Message is displayed if during the Water Inlet stageinsufficient water enters the chamber. In units with waterpumps, the pump will try three times to fill the chamberwith water, if unsuccessful the cycle is aborted and themessage LOW WATER is displayed.Low Heat20

Message is displayed, if during a normal heat up stage thesystem determines that there is insufficient water in thechamber to complete the cycle. This determination is madeby the combined input of two sensors, the Water Electrodeand the Safety Thermostat. Also, if a power failure occursduring the heat or sterilization stage after the power returns,the system will check the Water Electrode to see if there issufficient water in the chamber in order to resume the cycle.If not, the cycle will be aborted, the message LOW WATERwill be displayed, and the Cycle Fail indicator will light.Possible causes: A dirty or shorted Water Electrode. A clogged water pump or water pump filter. A clogged water line. Unit is improperly leveled. The Air Outlet Valve is stuck closed. A leaky door gasket, door bellows, solenoid valve, safetyvalve, or the air jet is allowing steam to escape at ahigher than normal rate. A power down has occurred and on power up the waterelectrode tip is dry.Power Dn. If a power failure occurred during the running of a cycle,when power resumes a POWER DN message is displayedfor several seconds; if a printer is installed it will printPOWER DN. In addition, the system automatically attemptsto complete the STERILIZATION stage if the followingparameters are met:a. If the temperature drop is less than 4.5 F (2.5 C),sterilization resumes automatically.b. If the temperature drop is more than 4.5 F (2.5 C),the cycle fails, POWER DN message is displayed andprinted and LOW TEMP message is displayed.c. If the pressure drop is more than 4 psi (0.27 Bar), thecycle fails, POWER DN message is displayed andprinted and LOW PRES message is displayed.If a power failure occurred during the HEAT stage, heatingresumes, provided enough water remains in the chamber. Ifnot, the cycle is aborted, the message “LOW WATER” isdisplayed. If a power failure occurs during the dry andexhaust stages, the unit will automatically resume operationonce the power is back on.If a power failure occurs during the GLASSWAREPROGRAM, the system does not allow fast exhaust (sincethe exhaust valve is normally closed).CYC Finish When the cycle has been completed successfully themessage CYC FINISH is displayed.21

4.STERILIZATION PROGRAMSThe autoclave offers 3 sterilization programs, at temperatures of up to 274 F(134 C), with or without a drying stage and 1 accessory (dry only) program.A. Three sterilization programs:1. Unwrapped instruments.2. Wrapped instruments and porous loads.3. Glassware.B. Accessory program:1. Dry onlyNote: The nominal data of the program (default settings) can be changed to fitthe needs of a particular office. This is done by means of the TEMP,STE.TIME, DRY TIME, keys in combination with the UP or DNkeys, as described in sec 3.2.2.4.1PROGRAM 1. Unwrapped InstrumentsFor unwrapped instruments and materials, when the manufacturerrecommends autoclaving at temperatures between 250 F and 274 F(121 C and 134 C) no preset drying stage required.Nominal parameters default settings Sterilization temperature: 273 F (134 C). Sterilization time: 3 minutes. Dry time: none.Operations Sequence Heating by actuation of electrical heaters until the sterilizationtemperature is reached. Sterilization temperature is maintained constant for the presetsterilization time. Fast exhaust, steam is exhausted out of the chamber at a fast rate untilpressure drops to zero.TEMPERATUREPRESSURE (kpa)Note:The sterility of instruments processed in unwrapped cycles cannot bemaintained if exposed to a non-sterile environment.Ambient Pressureand TemperatureTIMEt1t2 Pressure Temperature22t3t1 Steam generation staget2 Sterilization staget3 Fast exhaust stage

4.2PROGRAM 2. Wrapped Instruments and Porous LoadsFor wrapped instruments and materials, when the manufacturerrecommends autoclaving at temperatures between 250 F and 274 F(121 C and 134 C) with a drying stage.Nominal parameters default settings Sterilization temperature: 273 F (134 C). Sterilization time: 7 minutes. Dry time: 30 minutes.Operations sequence: Sterilization temperature is maintained constant for the presetsterilization time. Fast exhaust, steam is

OPERATION & MAINTENANCE MANUAL Electronic Tabletop Autoclaves Models EZ9, EZ10, EZ10K Cat. No. MAN205-0263001EN Rev. E Tuttnauer USA Co., Ltd., 25 Power Drive Hauppauge, NY 11788 U