Transcription

SolutionSmartPlantEnterpriseProcurement, Fabrication& Construction

BALANCINGACTProcurement, fabrication, and construction represent a complexbalancing act between profit-making and risk-taking that requireseffective planning and control. Otherwise, it could severely hinder acompany’s ability to supply a product, design and construct a plant,and start up a facility on time and within budget. In today’s highlycompetitive environment, time to market is of highest priority, whichresults in the major project phases – engineering, procurement, andconstruction – overlapping more than ever before, adding furthercomplexity to this precarious balancing act.Frequent changes in market conditions, global sourcing, geographically distributed plant design and engineering, and remote locationsof construction sites all make the project life cycle increasinglydynamic by nature. It requires a great deal of communicationand supervision to successfully achieve project completionfor all stakeholders.1

Considering that for a typical industrial facility,10 to 15 percent of the total cost is for engineering design and 50 to 60 percent of thecosts are related to material, it is obvious thatsurplus materials caused by ineffective materialsmanagement, even to levels of only five percent,can result in the loss of millions of dollars on anaverage capital project.Without continuous management and projectperformance, it is difficult to take the appropriatecorrective action to prevent schedule delays.These delays can often be even more costlywhen they affect the owner’s ability to produceand sell the product. Effectively managing thesecomplicated business processes in an integratedenvironment throughout all phases of the projectlife cycle is vital.SolutionIntergraph ’s Procurement, Fabrication &“Construction solution is made up of SmartPlant The ability to handle allmaterial managementprocesses, from establishing a corporate materialstandard to quantification,procurement, and controlof material on-site in oneintegrated environment,helped us to significantlyimprove efficiency andminimize risk.“Shuji NaganoGeneral Manager, Engineering ITChiyoda CorporationChiyoda has also extended the solution globally foruse with joint venture partners and suppliers.2Materials, SmartPlant Reference Data, SmartPlantConstruction, and SmartPlant Spoolgen . Thesolution uses the latest technology to provideefficient, accurate cost and material control forplant owner operators and EPC companies.Our Procurement, Fabrication & Constructionsolution includes all disciplines and partners,such as the client, suppliers, freight forwarders,and subcontractors, spanning the completeproject execution life cycle: Estimating, budgeting, and cost tracking Engineering – materials quantifications withchange management Procurement, expediting, and shipping Construction – receiving, inventories, forecasts,reservations, and material issuing

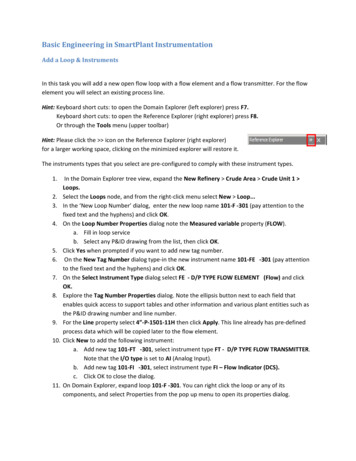

warning systems. Additionally, you can basereference datamanagementPowered bysmartplantreference dataexception reports on data from the entire supplySmartPlant Reference Data offers rule-drivenchain, and more quickly identify potential problemsand change control mechanisms for definingthat might arise in the future. The ability to performand maintaining reference data used later inupfront risk assessment and proactive risk avoid-design and purchasing processes. This referenceance offers a significant savings potential. As adata consists of item descriptions, dimensionleading expert in this area, Intergraph holds approxi-tables, specifications, client mappings, and bestmately 45 percent of the materials managementpractices – all stored at the corporate or projectmarket, and is committed to ensuring that thelevel. This reference data is the common base fortrue power of materials management and projectdownstream EPC processes.With materials information from the completeproject execution life cycle residing in a singledatabase, organizations can establish informationfor quick, effective decision support and earlycontrols are brought to your projects. Intergraph’ssolution enables you to: Lower engineering, procurement, and construction labor costs Reduce material surpluses and shortages Integrate engineering with corporate enterpriseMaterialsManagementPowered bySmartPLantMaterialsresource planning (ERP) Increase the visibility of project costs/performance through earned value analysis Reduce project risksLink Engineering with ProcurementMaterial take-off quantities from the SmartPlantEnterprise will be regularly collected and thencompared to previous project phases, enablingTake advantage of earlier, more accurate materi-you to analyze project trends and make betterals purchase to optimize cash flow and eliminatedecisions. The quantity data will be summarizedoverspending. This directly reduces CAPEX andby pre-defined templates into rule-based requisi-confirms the materials procured are exactlytions. Depending on your workflow needs, you canmatched to the project’s engineering andperform a variety of tasks:construction requirements. Our Procurement, Make quantity adjustmentsFabrication & Construction solution combines Attach documents stored in the SmartPlantbetter estimating, detailed tracking of material andcosts, and smarter budget-driven purchasing toensure “right price, right time, right place” on-sitedelivery of materials. It enables effective construction planning by identifying a continuous materialEnterprise to requisitions Define and approve additional vendordata requirements Release these requirements to theprocurement departmentstatus, such as purchasing, shipping, and arrivalon-site dates.3

ProcurementSmartPlant Construction promotes betterSupplier management is an integral part of pro-planning and management by incorporating thecurement. It enables you to define elements suchdynamic inputs from engineering, procurement,as supplier qualifications, addresses, rating, andfabrication, site materials management, andproject short lists. Accessing historical informationcraft labor plans into a solution specificallyfor suppliers based on their performance rating orfor construction.purchase order history in previous or current projects will help you make better decisions during theTo enhance flexibility and interoperability,negotiation phase. All users can take advantage ofSmartPlant Construction offers full integration withconsistent data in the purchasing cycle (inquiries,the industry-leading SmartPlant Enterprise suite ofbids, and purchase orders) to promote effectiveproducts. Take advantage of data interfaces anddata management throughout the workflow. Thetrue integration. The solution builds on the proveninquiry cycle time is greatly reduced by involvingSmartPlant Enterprise portfolio by offering a widethe suppliers directly in the process by giving themvariety of functionality provided by SmartPlantsecure online access via the Internet.Enterprise solutions.Expediting, inspection, and logisticsSmartPlant Construction benefits the entirePurchasing information and modifications canengineering, procurement, construction, andbe reused in expediting. SmartPlant Materials’operations value chain:change management functionality ensures your Owner operators can improve CAPEX effi-data is always reliable and up to date, even duringciency by consistently managing engineeringrevisions. You can remotely access the Expediting/information from concept through operationsInspection/Logistics module through the Internetand maintenance.by third parties such as suppliers, freight forwarders, or inspectors.StreamlinedconStruction andengineering Powered by SmartPlantconStructionSmartPlant Construction meets the specific needsof construction companies, project managementreal-world construction plans. Constructors can increase profits with improvedvisibility on project plans, accelerate their abilityto re-plan dynamically in response to real-worldchanges, and take advantage of enhancedintegration with engineering, procurement, andfabrication to optimize both engineering andconstruction decisions. Engineering firms can optimize engineeringoffices, fabricators, and owners in managingdecisions based on construction status, andconstruction resources, materials, and sched-vice versa.ules. SmartPlant Construction helps companiesrealize significant savings throughout the life of aconstruction project.4 Fabricators can provide direct input to facilitate

AUTOMATIC PIPINGISOMETRICSpowered BYSMARTPLANTSPOOLGENSmartPlant Spoolgen is specifically designed forpiping fabricators who need to add fabrication andconstruction information to design isometrics delivered by EPCs, generated from 3D models heldin plant design systems. Fabricators can use thesoftware to easily split complete pipeline isometricdrawings into spool drawings, which are thenused to fabricate pipe spools in the workshop.SmartPlant Spoolgen automatically generates allnecessary drawings and reports.Intergraph SmartPlantMaterials is positioned toplay an important role inClough’s business initiative to provide integratedglobal collaboration systemsfor project execution. Weanticipate it will significantlycomplement Clough’s wellknown logistical strengths.We are also looking tothe future in that we arereplacing in-house systemswith what is increasinglyrecognized as an industrystandard product that willgrow and develop with ourcompany.Simon HighCEOClough Services6““The product provides a fast return on investment,is simple to use, and requires minimal training.SmartPlant Spoolgen significantly reduces: Labor hours Fabrication costs Project schedules Rework Construction errors Waste

Measuring thereturnThe power of Intergraph’s Procurement, Fabrication& Construction solution translates into significantbusiness savings. Customers have reported: Reduced surplus materials to less thanone percent Reduced total installed cost by up tothree percent Reduced engineering hours by up to 15 percentThe integratedSmartPlant FamilyBeyond standalone use, Procurement,Fabrication & Construction is also part of theSmartPlant Enterprise. SmartPlant Enterpriseoffers best-in-class applications and a low-risk,step-wise implementation approach to realizinga truly integrated engineering enterprise.SmartPlant Enterprise includes: 3D Modeling & Visualization Engineering & Schematics Information Management Procurement, Fabrication & Construction SmartPlant Alliance ProgramNext stepsThe Procurement, Fabrication & Constructionsolution is fully supported by Intergraph Process,Power & Marine’s global service network andcan be tailored to meet your specific requirements. To discover how this solution can saveyou money and help you gain you a competitiveedge, contact us today.7

ABOUTINTERGRAPHIntergraph is the leading global provider of engineering and geospatialsoftware that enables customers to visualize complex data. Businessesand governments in more than 60 countries rely on Intergraph’s industryspecific software to organize vast amounts of data to make processesand infrastructure better, safer, and smarter. The company’s softwareand services empower customers to build and operate more efficientplants and ships, create intelligent maps, and protect critical infrastructure and millions of people around the world.Intergraph operates through two divisions: Process, Power & Marine(PP&M) and Security, Government & Infrastructure (SG&I). IntergraphPP&M provides enterprise engineering software for the design, construction, operation, and data management of plants, ships, and offshorefacilities. Intergraph SG&I provides geospatially powered solutions tothe public safety and security, defense and intelligence, government,transportation, photogrammetry, and utilities and communicationsindustries. Intergraph Government Solutions (IGS) is an independentsubsidiary for SG&I’s U.S. federal and classified business.Intergraph is a wholly owned subsidiary of Hexagon AB, (Nordicexchange: HEXA B) and (Swiss exchange: HEXN). For moreinformation, visit www.intergraph.com and www.hexagon.se.9

www.inter gra ph. c o mIntergraph, the Intergraph logo, SmartPlant, andSpoolgen are registered trademarks of IntergraphCorporation. Other brands and product namesare trademarks of their respective owners. 2011 Intergraph Corporation.01/11 PPM-US-0027C-ENG

SmartPlant Reference Data offers rule-driven and change control mechanisms for defining and maintaining reference data used later in design and purchasing processes. This reference data consists of item descriptions, dimension tables, specifications, client mappings, and best practices – all stored at the corporate or project level.