Transcription

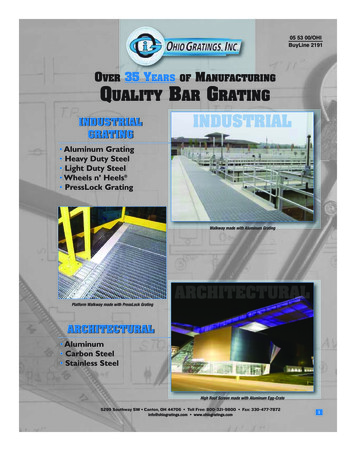

2191 01.qxp:2191 0810/19/077:48 AMPage 105 53 00/OHIBuyLine 2191OVER 35 YEARSOFMANUFACTURINGQUALITY BAR GRATINGINDUSTRIALGRATING Aluminum Grating Heavy Duty Steel Light Duty Steel Wheels n’ Heels PressLock GratingWalkway made with Aluminum GratingPlatform Walkway made with PressLock GratingARCHITECTURAL Aluminum Carbon Steel Stainless SteelHigh Roof Screen made with Aluminum Egg-Crate5299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872info@ohiogratings.com www.ohiogratings.com1

2191 02.qxp:2191 0810/19/077:54 AMPage 2OHIO GRATINGS, INC.Standard Details Water Reclamation FacilityAlum Creek, OH1/4 ClearanceBetween Ends ofCross Bars on RectangularGrating or Rivet Heads onRiveted GratingStandard Grating SpacingsGRATING SPACING CODE13/16 19- -419 – Identifies Bearing Bar spacing in/16 , (thus 19/16 on center)4 19- -413/16 SPAN4 15- -4/16 15– Identifies Grating Series (like ADT,SG, )SPAN/16 15/16 11Note: 8-4 spacing available on some Grating Series.SPAN2 11- -2* 11/16 SPAN* Denotes GRATER AccESS spacing conformingwith ADA when installed with the elongated opening perpendicular to the dominant direction of travel.4 11- -4*2 15- -2SPAN4 – Identifies Cross Bar spacing ininches, (thus 4 on center)2 19- -27- -47* /16 SPAN4 7- -27* /16 2 SPANSPANADA GuidelinesADA Accessibility GuidelinesThe ADA establishes accessibility requirementsfor new construction and alterations of State andlocal government facilities, and places of publicaccommodation and commercial facilities. Itstates that “openings in floor or ground surfacesshall allow passage of a sphere not more than 1/2inch (13 mm) diameter Elongated openingsshall be placed so that the long dimension is perpendicular to the dominant direction of travel.”2ADA Note: As of the publication date of this catalog, OhioGratings’ products having a1/2 maximum opening conform with the Americans WithDisabilities Act AccessibilityGuidelines (ADAAG) and the ADAAGNotice for grating when installed with theelongated opening perpendicular to thedominant direction of travel.5299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872info@ohiogratings.com www.ohiogratings.com

2191 03.qxp:2191 0810/19/077:54 AMPage 305 53 00/OHIBuyLine 2191OHIO GRATINGS, INC.Pressure Locked DesignPressure Locking DefinedThe most common method of manufacturing aluminum bar grating isthrough a process known as pressure locking. Pressure lockedgrating as defined by the ANSI/NAAMM Metal Bar Grating Manual isgrating in which the “.bearing bars are locked in position by cross bardeformation instead of riveting or welding.” We have taken advantage ofthe most modern technology available to produce a permanentlyattached pressure locked joint which will provide long lasting life undernormal service conditions.Pressure Locked Aluminum GratingADT SERIESAluminum Dove TailPlain SurfaceWidthSpan13/16 4 Traditionally designed, dove tail slot pressure lockedgrating introduces our line of pressure locked aluminumbar grating products. Bearing bars and cross bars areprecision slotted, assembled in egg-crate fashion, andhydraulically pressed together to form a tightly locked,rigidly stable panel grid. Bearing bars range from 1 x 1/8 through 21/2 x 3/16 in 1/4 increments. A wide variety ofbearing bar/cross bar spacings is available. A serrated surface can be specified for areas requiring slip resistancedue to the presence of moisture or oily substances.This first generation pressure locked design involvespressing the cross bars into the main bars under hydraulicpressure, forcing 1/16 of cross bar material laterally into“dove tail” slots in the main Serrated Surfacebars. Each piece is thenhSpanidtgenerally end banded toWprovide panel stability, andoutside bearing bars and crossbars are intermittently tackwelded to ensure integrity.Maximum walking surface, cosmetic appeal, economy ofshop fabrication, and ease of field alteration make theALUMINUM FLUSH TOP Series the premier choicewhen pressure locked aluminum grating is being specified. Bearing bars range from 1 x 1/8 through 21/2 x 3/16 in 1/4 increments. A serrated surface can be specified forareas requiring slip resistance due to the presence ofmoisture. All popular bearing bar spacings, as well ascross bar spacings of 4 or 2 are available.Aluminum “Flush Top” grating from Ohio Gratingscombines the sure lock reliability of swage-locked gratingwith the cosmetic appeal and added walking surface oftraditional pressure locked grating. By taking advantage of theswage-lock manufacturing process, Aluminum “Flush Top”grating offers a cost savings over traditional pressure lockedgrating while at the sameSerrated Surfacetime allowing banding to beSpanhidtan option rather than aWrequirement. Field cutting isalso possible.2 19-ADT-219-ADT-4SGF SERIESAluminum Flush TopPlain SurfaceWidthSpan4 13/16 19-SGF-413/16 2 19-SGF-2SG SERIESThe most widely used aluminum pressure locked grating is the Rectangular BarAluminum Rectangular Bar SG Series. The square cross bars are assembled through punched diamond shapedholes in rectangular bearing bars, and are permanently locked in place by swaging.Plain SurfaceBearing bar sizes range from 1 x 1/8 through 21/2 x 3/16 in 1/4 increments. A serhSpanidtWrated surface can be specified for areas requiring slip resistance due to the presence of moisture. All popular bearing bar spacings, as well as cross bar spacings of4 or 2 are available.4 13/16 Serrated SurfacehidtWSpan13/16 2 19-SG-213/16 19-SG-4How to Specify:Refer to Ohio Gratings website forGuide Specifications which follow theCSI Three-Part Section Format.19-SGI-48-SGI-2SpanWidthThe I-Bar Series uses an extruded “I” shape as the mainload bearing member. Square cross bars are assembledthrough punched diamond shaped holes in the web section of the I-Bar, and then permanently locked in place byswaging. Bearing bars range from 1 x 1/4 through 21/2 x1/4 in 1/4 increments. Bearing bar spacings of 13/16 , 15/16 ,11/16 , 8/16 and 7/16 c.c. and cross bar spacings of 4 and 2 are available.SpanWidthSGI SERIESAluminum I-Bar13/16 4 / 1 4/ 8 162 / 1 4/ 3 16SGLi SERIESSame specifications as above except for 3/16” flanges. Ideal forlightweight applications because it’s 20% lighter than comparablegrating products, yet strong and durable.5299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872info@ohiogratings.com www.ohiogratings.com/ 1 163

2191 04.qxp:2191 0810/19/078:03 AMPage 4OHIO GRATINGS, INC.Aluminum Plank GratingPlank SeriesAluminum FramesAs an alternative to bar grating,Aluminum Plank is structurallysound and cosmetically attractive. The surface can be providedunpunched, or with a variety ofpunch/patterns for the passageof air, light, heat or moisture.The interconnecting webs offera flush top walking surface forAvailable for use with all types of ished condition or with a coataluminum grating is an extrudedof bituminous paint on surfacesframe for embedded concretewhich will come into contactapplications. This frame features awith concrete.continuous ledge to accommoDIM “B”1 4date plank fasteners, grating/ clamps, or self-tapping screwsfor other types of fasteners. TheContinuouscontinuous anchor can be usedAnchoralone, or in conjunction with supplementary anchor straps. Angle1 4/ frame is available fabricated perdrawings with mitred and weldOptional Anchored corners, or in long lengths( / x 1 )with prefabricated corners forinstallation in the field. Framescan be provided in the mill fin- Section View of Grating Framemaximum foot contact andcomfort. Plank is available in 6 wide plain sided sections 3/4 through 21/2 high, or 1 highinterlocking sections. Individual6 sections can be bandedtogether to form standard panelwidths for ease of handling andinstallation.SpanRaised Transverse Rib(Upset Patterns)/32 19.062 TYP1 4 SlotWidth3/4 thru21/2 1.20 1.20 6.00 DIM “A”Aluminum Plank1 4thWidADA-15*Sectional View*Denotes percentage of open areaGreater Access Steel Grating InformationWheels n’ Heels Heavy Duty Steel1/4 A type of heavy duty welded steel grating which satisfies both the vehicleloading requirements of AASHTO and the pedestrian comfort requirements of the Americans With Disabilities Act. The Short Span Series ismade from 1/4 thick ASTM-A36 bearing bars ranging in size from 1 to 2 ,in 1/4 increments, suitable for H15/H20 loads up to 34 clear span. TheLong Span Series utilizes 21/2 x 1/4 up to 5 x 1/4 bearing bars, withintermediate 3/16 filler bars, for vehicle spans of up to 8 feet. Both Seriesoffer either a 1/4 or a 1/2 opening. The Long Span Series may be specifiedas serrated, or a slip resistant surface may be applied to either type ofgrating. Wheels n’ Heels is ideal for parking garages, sidewalks, andpedestrian accessible roadways where ventilation or drainage is required.Wheels n’ Heels is the latest product addition to the Heavy Duty SteelGrating line of Ohio Gratings. For grating spans 3 and under, bearing barsmade from 1/4 thick ASTM A-36 steel are arranged at 1/2 or 3/4 centers.Bearing bars are joined by welding to 3/8 cross rods on 4 centers. Theresulting panel grid provides a grating surface which will carry AASHTOH15/H20 roadway traffic, or forklift traffic. In addition, the close spacing ofthe bearing bars offers a pedestrian friendly 1/4 opening for the 8-WHSeries, or a 1/2 opening for the 12-WH Series. (Note: 2 maximum panelwidth suggested for ease of handling.)hidtW4 Span8-WH-4 (1/4 open)44 Span1/2 Ctrs(1/4 Open)12-WH-4 (1/2 open)1/2 nSpa2-5/8 cc2-3/4 ccWidthWidth44-WH-4 (1/2” open)42-WH-4 (1/4” open)Wheels n’ Heels Long SpanWheels n’ Heels Short SpanhidtWanSp3/4 Ctrs(1/2 Open)The Long Span Series utilizes 3 -1/2” x 1/4” up to 6” x 1/4” bearing bars withintermediate 3/4” x 3/16” filler bars, for vehicle clear spans of up to 8 feet.The “Redesigned” Wheels n’ Heels Long Span Series II should be specifiedfor spans up to 24’ (clear spans 8’ max) where both ADA compliance and HeavyLoading are required. The structure is composed of bearing bars made fromheavy duty, ASTM A-36 steel, bearing bars spaced on 1-3/4”, 2-1/16”, 2-5/8” or2-3/4” centers welded to cross bars on 4” centers in combination with a Swagedsteel filler panel of 3/4” x 3/16” bearing bars. The resulting assembly provides agrating that will carry AASHTO H15/H20 roadway or forklift traffic with ADAcompliant bar spacing. The close bar spacing of the filler panel offers a pedestrianfriendly 1/4" opening between bars with 28-WH Series and 42-WH Series or1/2" opening between bars with 33-WH Series and 44-WH Series.Many existing sidewalk and roadway gratings are manufactured from 3/16 thick pressure locked or riveted A1011steel bar which is not AASHTO rated. Others present openings from 3/4 to 1 , which are not pedestrian sensitive.Wheels n’Heels offers both a vehicle safe grating, aswell as a grating which conforms to the spacing requirements of the Americans With Disabilities Act.5299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872info@ohiogratings.com www.ohiogratings.com

2191 05.qxp:2191 0810/19/078:04 AMPage 505 53 00/OHIBuyLine 2191OHIO GRATINGS, INC.Pressure Locked Steel GratingDT Series Steel Dove Tail7-DT-4 (1/4 open)11-DT-4 (1/2 open)WidthWidthFor those steel applications which call for the smooth, rectilinear profileSpanSpanof pressure locked grating, we offer the Steel Dove Tail DT Series.Bearing bars and cross bars are precision slotted, assembled in egg-cratefashion, and hydraulically pressed together to form a tightly locked, rigidlystable panel grid. Bearing bars range from 3/4 x 3/16 through 21/2 x 3/16 in1/4 increments, suitable for pedestrian spans up to 12 feet. GRATERAccESS spacings include 7/16 c.c. (1/4 open), and 11/16 c.c. (1/2 open),4 with cross bars on 4 or 2 centers. Where skid resistance is desired, a4 7/16 serrated surface or an applied skid resistant surface may be requested.11/16 Traditionally designed Dove Tail slot pressure locked grating offers thehigh strength and stiffness of welded steel grating, along with theAlso available in stainless steel as DTSS Series. Consult factory for information.smooth, clean lines of a flush top rectangular cross bar.SGCS Series Swaged Carbon11-SGCS-4 (1/2 open)WidthSpan7-SGCS-4 (1/4 open)SpanWidthElectroforge welded steel grating has been the standard industrial footwalkproduct for many years. Inherent in this grating, however, is the jaggedweld flash which accompanies the welding process. Additionally, the heatgenerated as a part of electroforging, limits how close together the barsmay be placed. By taking advantage of the most modern technology available, Ohio Gratings is now able to offer Swaged Carbon Steel Grating.Bearing bars range from 3/4 x 3/16 to 21/2 x 3/16 in 1/4 increments, suitablefor pedestrian spans up to 12 feet. GRATER AccESS spacings include7/16 c.c. (1/4 open) and 11/16 c.c. (1/2 open), with cross bars on 4 or 2 centers. Where skid resistance is desired, a serrated surface or an applied skidresistant surface may be requested. This manufacturing method offerssmooth surfaces and clean lines free from the warping and weld flashinherent in the electroforging process. Swaged Carbon Steel is especiallysuited to field fabrication.4 4 / 11 16/ 7 16SGSS Series Swaged StainlessSpanWidthSpan4 / GratingDepth3Grating with shimbar at panel ends(Anchor Strapnot shown)/4 1 11/4 11/2 13/4 2 21/2 3 31/2 4 41/2 5 / 7 164 11 16Steel Angle FrameIn conjunction with both Light and Heavy Duty steel grating, Ohio Gratings offers a welded steel grating frame forembedded concrete applications. This frame features welded anchor straps which hold the frame firmly into the concrete trench. Steel angle frame is available fabricated perdrawings with mitred and welded corners, or in longlengths with prefabricated corners for installation in thefield. Some grating sizes may need to be shimmed in orderto accommodate standard angle dimensions (see tableright). Frames can be provided mill finished, galvanized orwith a coat of manufacturer’s standard black paint.7-SGSS-4 (1/4 open)11-SGSS-4 (1/2 open)WidthElectroforge welded stainless steel grating has been the standard industrialfootwalk product for severe corrosion applications for many years.Inherent in this grating, however, are the warping, discoloration and jaggedweld flash which accompany the welding process. Additionally, the heatgenerated as a part of electroforging limits how close together the barsmay be placed. By taking advantage of the most modern technology available, we are now able to offer Swaged Stainless Steel Grating. Bearing barsrange from 3/4 x 3/16 to 21/2 x 3/16 in 1/4 increments, suitable for pedestrian spans up to 12 feet. GRATER AccESS spacings include 7/16 c.c.(1/4 open) and 11/16 c.c. (1/2 open), with cross bars on 4 or 2 centers.Where skid resistance is desired, a serrated surface or an applied skidresistant surface may be requested. Type 304 & 316 stainless are available.Please contact the factory for the suitability of Swaged Stainless in foodservice or pharmaceutical applications. The swaging process eliminates thewarping, twisting and burn marks which are characteristic of welded stainless. It is ideal for many industrial caustic and acidic environments.StandardAngle Size111 /2” x 1 x /4 (LLH)13/4 x 11/4 x1/4 (LLH)11/2 x 11/2 x1/4 13/4 x 13/4 x1/4 2 x 2 x1/4 12 /2 x 2 x1/4 (LLV)3 x 21/2 x1/4 (LLV)31/2 x 21/2 x1/4 (LLV)4 x 3 x1/2 (LLV)5 x 3 x1/2 (LLV)5 x 3 x1/2 (LLV)6 x 31/2 x1/2 (LLV)Dim“A”3/4 1 11/4 11/2 13/4 21/4 23/4 31/4 31/2 41/2 41/2 51/2 SHIMSIZEDim“B”11 /4 11/2 11/4 11/2 13/4 11/4 x 1 /4 13/4 1/4 x 2 21/4 1/4 x 2 21/4 21/2 1/2 x 2 21/2 21/2 13 /2 x 2 Dim“C”1/4 /4 /4 1/4 1/4 1/4 1/4 1/4 1/2 1/2 1/2 1/2 11Grating with anchor block5299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872info@ohiogratings.com www.ohiogratings.com5

2191 06.qxp:2191 0810/30/073:12 PMPage 6OHIO GRATINGS, INC.Strong Structural.SolutionsLight Duty Steel GratingOhio Gratings offers a wide variety of light duty steel grating styles including electroforgewelded, dove tail pressure locked, riveted and swaged.Electroforge welded grating is the more traditional industrial product, while dove tailpressure locked, riveted and swaged offer smoother lines and a more pleasing appearance than thetypical welded grating. These products appeal to the architectural market and offer a different lookand can be used not only for industrial applications but also commercial applications where alighter profile product might be desired. The dove tail and swaged products are also part of ourGRATER AccESS line of products conforming to ADA standards.Heavy Duty Steel GratingWelded carbon heavy duty steel grating is the most popular choice where high strength is theprimary grating requirement.The main bars are slotted and assembled with cross bars which are welded with one fillet weldat every joint. Stainless steel can also be provided for those high corrosive applications. This productmeets the demanding vehicle loading requirements of AASHTO and is geared to handle heavy rollingloads. Slip resistant surfaces are available. The typical markets for heavy duty steel grating include: ramps,docks, industrial flooring, industrial cover trenches, airfield ramps & trenches, airplane landing mats,machinery support trenches, bridge decking, bridge sidewalks, bridge trenches and many moreapplications.Aluminum Provides a Unique Combination of Properties.which makes it one of the most versatile engineering and construction materialsavailable today!As a natural resource, aluminum is our most abundant metallic element. Its lightweight mass(about a third the weight of copper or steel), unmatched strength-to-weight ratio and excellentcorrosion resistance under the majority of service conditions makes it an excellent material forthe manufacturing of bar grating.Aluminum can be recycled and as a result makes it an environmentally friendly material unlikesome other grating material. Aluminum is durable and will offer years of service withoutshowing wear or decay. It is also non-toxic so it can be easily cleaned and does not absorbbacteria sustaining particles. As a result it is a good candidate for food processing facilities. Thematerial is also resilient; it can deflect under loads and then spring back.All these attributes make aluminum grating an ideal solution for some specialgrating applications such as: sewage and waste water treatment plants, off-shore drilling rigs,the chemical process industry, the paper mill industry and marine superstructure applications.Because of its natural attractiveness, aluminum grating is also used in many architectural andcommercial applications including sun screens, ceiling tiles, vent grills, fencing, building facades,fountains, nature and wildlife walkways and entranceways.We RecycleFor Information or Catalog:65299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872info@ohiogratings.com www.ohiogratings.com

2191 07.qxp:2191 0810/19/078:11 AMPage 705 53 00/OHIBuyLine 2191OHIO GRATINGS, INC.PressLock GratingPressLock grating is manufactured from carbon or stainless steel. Thebearing bars are notched and then locked with the cross bar at very highpressure. This particular production method guarantees a uniformprecision mesh size. The edge of the press lock grating is banded eitherwith a T-shaped special section or flat bar. This process (i.e. where thebanding is welded at right angles to and flush with the grating surface) isdone with an automatic resistance welding process.PROBLEMSOLUTIONWhy have this issue with 1" x 1/8" 19W4 weld forgeWhen carts can roll smoothly over our new 21PL7PROBLEMSOLUTIONHigh heels caught in the opening oftraditional 19W4 grating.Specify ADA compliant 21PL7 press lock grating whichallows high heels to stay on walking surface.21PL21Both the bearing bars and cross bars are spacedat 1-5/16" center to center. This spacing isappropriate when pushcarts & pallet jacks are notused on the mezzanines.The cross bar is inserted in the notches of the bearing bar and press lockedinto a stable structure at a force of 500 tons.OPTIMAL MAXIMUM PANEL WIDTH72"MAXIMUM PANEL SPANIn practice the length will be predetermined bystatistical requirements and unit weights.END MESHINGPanel width and span edges must be equaldimensions.5299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872info@ohiogratings.com www.ohiogratings.com7

2191 08.qxp:OGI Sweets Catalog-Page 87/23/0811:25 AMPage 8OHIO GRATINGS, INC.PressLock GratingTECHNICAL INFORMATIONT21PL7 16 inchesF721 16 inchesFT7PL21 16 inches15 16 inches7The 7PL21 (left) is the designation forbearing bar spacing (7/16") and cross barspacing (21/16"). The 21PL7 (left) is thedesignation for bearing bar spacing (21/16")and cross bar spacing (7/16"). The meshsize on Press Lock Grating allows eitherbearing bars (T) or cross bars (F) to bespread in increments of 7/16". This providesa great deal of flexibility in design.CROSS BARSBANDING BARSBEARING BARSANGLE COLLARAt right angles to the bearingbars, the cross bars connect thebearing bars with one another inthat they are pressed at the intersection points.Grating is usually banded allaround by a flat bar, T-shapedsection or U-shaped section.In parallel with one another, thebearing bars are the load carryingflat bars set out perpendicularly.Angles can be welded on to oneor several edges. Angle heightshould be at least the same as thebearing bar.ADVANTAGES A lighter weight steel option Offers flexibility Bar spacings are available in increments of 7/16" in eitherdirection Can be assembled closer together for greater foot comfort Allows for a smoother rolling surface for pushcarts whichare often used in distribution centers and warehouses Wider panel sizes availableAPPLICATIONS Airports Architectural Automotive Parts Centers Distribution Centers Logistic Operations Military Bases Marine Warehouses Racking Systems Shelving Mezzanine Flooring ADA Walkways Treads Industrial Flooring Platforms Facades Railing Infill Panels Fencing Sun Screens Security BarriersFor Information or Catalog:see us at85299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872info@ohiogratings.com www.ohiogratings.com.com

†Wheels n’ Heels † PressLock Grating 2191_01.qxp:2191_08 10/19/07 7:48 AM Page 1. 5299 Southway SW Canton, OH 44706 Toll Free: 800-321-9800 Fax: 330-477-7872 2 info@ohiogratings.com www.ohiogratings.com W