Transcription

LE EUROPECANNONDApe, B.V.ts Group EuroCycling SporOldenzaal,27, 7570 GC,torpozenHaNetherlands4879380(Voice): 41 6115 14240com(Fax): 31 54sportsgroup.rope@cyclingservicedeskeuLE UKCANNONDA.comwww.cannondalepGroung Sports 2016 CycliGroup16)ts4/or(0Sp22ngCycli1334,, The FulcrumVantage Way, BH12 4NUPoole, Dorset88(0)1202 73224 4):ceoi(V72336602)12(04 4(Fax):co.uksportsgroup.sales@cyclingSCALPEL SIOWner’s manual Supplementl.ner’s manuale bicycle owur cannondayodanreference.treentumboth for futhis suppledepeaKeR!n.iongatniWarfety informimportant saBoth contain133422ISLEPLASCTSUPPLEMENLAUNAMOWNER’S

133422.PDFAbout This SupplementCannondale Owner’s Manual Supplements provideimportant model specific safety, maintenance, andtechnical information. They are not replacements foryour Cannondale Bicycle Owner’s Manual.This supplement may be one of several for your bike.Be sure to obtain and read all of them.ContentsSAFETY INFORMATION.2TECHNICAL INFORMATION. 3-14Replacement Parts. 15If you need a manual or supplement, or have aquestion about your bike, please contact yourCannondale Dealer immediately, or call us at oneof the telephone s listed on the inside cover of thissupplement.Maintenance . 16You can download Adobe Acrobat PDF versions ofany Cannondale Owner’s Manuals or Supplementsfrom our website: www.cannondale.comYour CannondaleDealerPlease note that the specifications and informationin this manual are subject to change for productimprovement. For the latest product information,go to www.cannondale.comTo make sure your bike is serviced and maintainedcorrectly, and that you protect applicable warranties,please coordinate all service and maintenancethrough your authorized Cannondale Dealer.Explicit DefinitionsNOTICEIn this supplement, particularly importantinformation is presented in the following ways:Unauthorized service, maintenance, or repairparts can result in serious damage and void yourwarranty.WarningIndicates a hazardous situation which, if notavoided, could result in death or serious injury.NOTICEIndicates special precautions that must betaken to avoid damage.The intended use of all modelsis ASTM CONDITION 3, CrossCountry.ASTM F2043For roughoff-road ridingand jumps lessthan 24” (61 cm)1

SAFETY INFORMATIONImportant CompositesMessageInspection & CrashDamage Of CarbonFrames/ForksWARNINGYour bike (frame and components) is made fromcomposite materials also known as “carbonfiber.”All riders must understand a fundamental realityof composites. Composite materials constructedof carbon fibers are strong and light, but whencrashed or overloaded, carbon fibers do not bend,they break.For your safety, as you own and use the bike,you must follow proper service, maintenance,and inspection of all the composites (frame,stem, fork, handlebar, seat post, etc.) Ask yourCannondale Dealer for help.We urge you to read PART II, Section D. “InspectFor Safety” in your Cannondale Bicycle Owner’sManual BEFORE you ride.YOU CAN BE SEVERELY INJURED, PARALYZEDOR KILLED IN AN ACCIDENT IF YOU IGNORETHIS MESSAGE.2WARNINGAFTER A CRASH OR IMPACT:Inspect frame carefully for damage (See PART II,Section D. Inspect For Safety in your CannondaleBicycle Owner’s Manual. )Do not ride your bike if you see any signof damage, such as broken, splintered, ordelaminated carbon fiber.ANY OF THE FOLLOWING MAY INDICATE ADELAMINATION OR DAMAGE:––––An unusual or strange feel to the frameCarbon which has a soft feel or altered shapeCreaking or other unexplained noises,Visible cracks, a white or milky color presentin carbon fiber sectionContinuing to ride a damaged frameincreases the chances of frame failure,with the possibility of injury or deathof the rider.

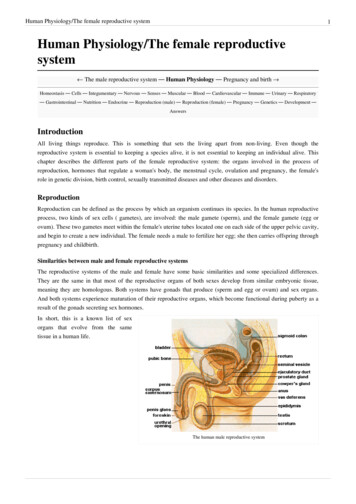

133422.PDFTECHNICAL INFORMATIONGeometryABDEFGHIJKLMNOPBSeat Tube Length (cm/in)Top Tube Horizontal (cm/in)Head Tube AngleSeat Tube Angle EffectiveStandover (cm/in)Head Tube Length (cm/in)Wheelbase (cm/in)Front Center (cm/in)Chain Stay Length (cm/in)Bottom Bracket Drop (cm/in)Bottom Bracket Height (cm/in)Fork Rake (cm/in)Trail (cm/in)Stack (cm/in)Reach (cm/in)PGOADEMKLJIHNMENSWOMENSS 650M 29L 29XL 29XS 650S 650M 25.554.8/21.657.0/22.460.3/23.7D69.5 69.5 69.5 69.5 69.5 HHE73.5 73.5 73.5 73.5 73.5 7/16.043.7/17.2H Indicates same as previousSpecifications subject to change without notice.3

SpecificationsHeadtubeCannondale Si (see also Replacement Parts for conversion kits)Rear Travel100mmSAG: 25%, 12mmEYE-TO-EYE: 190mmSTROKE: 45mmREDUCERS: 30mm (1.180”) x 8mmALLOY: BB30/83, CARBON: PF30/83mm31.6/34.9mmS3 Direct Mount, Side swing142x12mm MaxleFlat mount, 20mm BoltRear ShockBB Shell/ WidthSeat Post Diameter/BinderFront DerailleurDropout SpacingRear BrakeWARNINGPlease read your Cannondale Bicycle Owner’s Manual for more information onthe following specifications:Intended UseMaximum Tire WidthMaximum Fork LengthMinimum Seat Post InsertASTM CONDITION 3, Cross-Country, Marathon, Hardtails.SCALPEL SI 27.5 : 27.5 x 2.30 in SCALPEL SI 29 : 29 X 2.30 inSCALPEL SI 27.5 : 487 mm SCALPEL SI 29 : 500 mm120 mmMaximum Weight Limit (Lbs/Kg)*(Seat Bag Only)RIDER300 / 136LUGGAGE*5 / 2.3TOTAL305 / 138Integrated HeadtubeQSISEAL/BEARING SEALIn carbon models, cups are bonded within the headtube. Cannondale Headshok System Integrationbearings are accepted directly into both type.For 1.5” and 1 1/8” adapter headsets, seeReplacement Parts.XHD169/BEARINGSNOTICEDo not face, surface, or cut the head tube bearingcups. When removing adapters, bearings, or cupfrom, extra care must be used so that the toolused to drive out the bearing is not located onany part a bonded cup.FRAME SIZEWOMENS4FRAME SIZEMENSHEADTUBELENGTH (X)XS, SMSM97mmMDMD109mm-LARGE122mm-X-LARGE134mm

133422.PDFTightening TorquesCorrect tightening torque for the fasteners (bolts, screws, nuts) on your bicycle is very important to yoursafety. The durability and performance of your bicycle. We urge you to have your dealer correctly torque allfasteners using a torque wrench. If you decide to tighten fasteners yourself always use a good torque wrench!DescriptionNmLoctite Shock Mounting BoltsTop Tube PivotPivot Axles155Loctite 242 (blue)Loctite 242 (blue)1.0 - axle3.0 - wedgeLight GreaseRear Derailleur Hanger boltHousing Guides (Maximum)1.13.0Loctite 242 (blue)Light Greaselogo)ASYMMETRIC Integration (Ai)(Ai trademark- RearWheelCENTERLINEOFFRAMEAboutYou must use rear wheels that are compatiblewith the Cannondale Asymmetric Integration(Ai) 6mm offset. OEM wheels built to thisspecification are identified with “Ai” logo, shownat right.6mm Offset /55mm ChainlineThe Ai rear hub is offset 6mm to the drive side.This both aligns the cassette with the Ai frame’s55mm chainline, and aligns the rim/tire withframe’s centerline for correct tire clearance. (Seealso, Maximum Tire Width in SPECIFICATIONS).Ai wheels have equal spoke angles and tensionon both sides (non-dished wheel) which improveswheel stiffness, strength.NOTICE(Ai trademark SSETTECASSETTERIMCENTERHUBCENTEROFFSETWHEEL HUBUSE ONLY “Ai” OFFSET REAR WHEELS.Incorrect wheel offset can damage yourframe.Standard wheel assembled on this frame willresult in insufficient tire clearance leading torubbing and serious frame damage. This kindof damage is not covered by the CannondaleLimited Warranty.Building/Truing a WheelIf you chose to build, or true the wheel, makesure the 6mm offset is present.Consult with your Cannondale Dealer if youhave any questions.WHEEL HUB(Ai trademark 142mmB142mmdropout centerdropout centerKT041/AI Truing Skewer5

SCALPEL Si CARBONBOTTOM BRACKET - PRESSFIT BB30Carbon frames have a 46 mm I.D. bottom bracket bearing system press interface. The shell width is 83mm.MaintenanceIn general, you should inspect the condition of the bearings annually (at a minimum) or anytime the cranksetassembly is disassembled , serviced, or if a problem is indicated.To inspect, when the crankset is removed, rotate the inner bearing race of both bearings; rotation should besmooth, and quiet. Execesssive play, roughness or corrossion indicates a damaged bearing.RemovalTo avoid serious damage to the frame, it is important to remove bearing systems very carefully using propertools indicated by the manufacture’s service instructions. Make sure the bearings(cup or adpater parts) aredriven out squarely and evenly from inside the shell!!! Do not pry components from shell.ReplacementPressFit BB30 bearings are not removable from the adapters or cup systems that are pressed into the framebottom bracket shell. Therefore, damaged bearings must be removed and replaced as new entire sets. Beforeinstalling any new bearing units into the shell, thoroughly clean the inside surface of the bottom bracket shellwith a clean dry shop towel. Also, make sure both bearing units and the BB shell surfaces are clean and dry.Do not apply grease to either.Follow the manufacture’s instruction for assembly and installtion of the bearing system. Use a headset presssuch as Park Tool HHP-2. See HHP-2 Select appropriatepress and adapters to ensure that force is only applied to the cup and not the bearing inside. Press until theboth cup flanges are mated to the BB shell edge.NOTICEConsult with your Cannondale Dealer on the quality and compatibilty of any proposed replacementcomponent.Make sure the PRESSFIT BB30 30 system is intended for use with with a 46 mm I.D. BB shell. Confirmacutal part dimensions with a micrometer.Do not use chemical solvents to clean. Do not remove frame material or use surfacing tools on bottombracket shell.Frame damage, caused by improper components, component installation or removal is not covered by yourwarranty.6

133422.PDFSCALPEL Si ALLOYBOTTOM BRACKET - BB30The bottom bracket shell is compatible with the BB30 Standard. See http://www.bb30standard.com/ .MaintenanceInspect bearing condition annually (at a minimum) and anytime the crankset assembly is disassembled orserviced. With the crankset removed, rotate the inner bearing race of both bearings; rotation should besmooth. No play or movement inside the shell. If the bearing is damaged, replace both bearings with newones.Bearing RemovalRemove the old bearings with the bearing removal tool KT011/.Bearing InstallationTo install bearings, use a headset press and Cannondale tool KT010/. Clean inside of shell apply a high-qualitybicycle bearing grease to the inside surface. Press bearing one at a time. Press each bearing until seated.Following installation, apply a light coating of a high-quality bicycle bearing grease to both sides of eachbearing to help repel moisture.Do not re-use removed bearings. Install both bearings as a new set.NOTICEBEARINGS - Frequent or routine renewal of undamaged bearings is not recommended. Repeated removaland reinstallation can damage the inside BB shell surfaces resulting in poor bearing fit. Do not face, millor machine the bottom bracket shell for any reason. Doing so can result in serious damage and possibly aruined bike frame.Do not cut, face, or use abrasives to clean the inside if the BB shell.We strongly recommend that these procedures be performed by an Authorized Cannondale Dealer.Damage caused by improper installation/removal is not covered under your warranty.7

Rear Shock15 N-m15 N-mSAG25%, 12mmSAGEYE-TO-EYESTROKEREDUCERSSet-Up1. Set the air pressure according to your bodyweight. Follow the shock manufacturer’sinstruction for pressurizing the shock.2. Slide the O-ring against the shock wiperseal.3. Sit on the bike in a normal riding positionwith your hands on the handlebar andfeet on the pedals so that your weightcompresses the rear shock.4. Measure the SAG. Adjust the air pressurein the shock to achieve the correct SAGmeasurement.Add air to decrease sag.Release air to increase sag.Recommended Sag 25% - 12mm825% (12mm)190mm45mm30mm (1.180”) x 8mmWARNINGSELECT ONLY COMPATIBLE SHOCKS AND FORKSFOR YOUR BIKE. DO NOT MODIFY YOUR BIKE INANY WAY TO MOUNT ONE. HAVE YOUR SHOCKOR FORK INSTALLED BYA PROFESSIONAL BIKE MECHANIC Riding with the wrong rear shock candamage the frame. You could have aserious accident. Make sure the totaltravel, eye-to-eye length, and strokelength of the rear shock you selectmeet the SPECIFICATIONS listed in thismanual. When selecting different shocks orforks for your bike, make sure that theshock or fork you select is compatiblewith your bike’s design and how you willuse your bike.

133422.PDFShock LINK(a)4.2.5.2.4.3.6.1.2.2.Carbon Link: Installbearings w/Loctite401 Prism InstantAdhesive *Alloy Link: Install bearings w/Loctite 6097.1.Shock Link4.Spacers 2X2.Bearing 4X5.Frame Pivot3.Frame Pivot Bolt6. & 7.Shock Mounting Bolts - KP433/Composite Link Bearing Installation1. Clean outer race of all bearings and linkbearing bores with denatured alcohol andclean cloth to remove any oil or contamination2. Apply a thin bead of Loctite 401 PrismInstant Adhesive * around inside of abearings bore near the outer edge of thebore.3. Insert a bearing into the bore with adhesiveand ensure it is fully seated on the lip (a) inthe bore.4. Ensure bearing is fully seated in bore.5. Repeat steps 3-5 for the remaining 3bearings.76 Confirm that all 4 bearings are fully seatedin each bore.7. After 45 seconds the adhesive will cureenough for handling8. Wait a 5 minutes before installing link inframe* Required, no substitutions9

PIVOT AXLESTop Tube1.5 N-mShock Link2.1 N-m3 N-mMain Pivot3.1 N-m3 N-m10

133422.PDFLock’RT253.0 N-ma1.M53.2.4.M61.0 N-mClean and applylight grease to allparts.5mmAInstallationRemovalBe sure to inspect the parts for any burrs, scratchesor other damage before assembly. Replace thecomplete axle assembly if any damage is found.The axle removal technique is shown removed fromfor clarity. See inset A. Apply a high-quality bearing grease to all theparts of the assembly before installing intothe linkage. Be sure to coat all threads, wedgesurfaces and expansion areas.Be sure to use the correct length axle andscrew for the specific location. See above.Insert the axle (1) into the link from thenon-drive side. and tighten it with an 6mm hexto 1.0Nm. Do not over-tighten.Insert the threaded wedge (2) into the driveside of the axle and insert the other wedge (3)and screw (4) opposite and tighten screw witha T25 Torx to 3.0Nm.Steps:A. Loosen the screw (4) 4-6 turns using a T25 Torxkey.B. Tap head of M4 screw (4) to un-seat threadedwedge (2).Remove M4 screw (4) and threaded wedge (2)from the axle (1).C.Insert a 5mm hex key to twist the wedge (3)free and remove it (shown). If stuck, insert thelong side of a 6mm HEX key (non-ball end) fromthe threaded end of axle and tap it out.D. Insert a 6mm hex key into the axle and turncounter-clockwise until it can be removed.11

Rear Derailleur Hanger - KP432/1.B3.2.AWheel RemovalHanger ReplacementOnce the rear axle (1) is removed, the hanger (2) andattached rear derailluer will pivot down and backslightly to enable easier removal of the rear wheel.See inset A.Hanger replacement kit is available as Cannondalekit KP432/.12The kit includes the hanger (2) and a new pivot bolt(3). Before installing a new hanger, be sure to cleanany dirt or debris on the dropout with a nylon brush(old toothbrush). Inspect the area for any damage.Lightly grease the dropout surface. Apply Loctite242 (blue) to the pivot bolt (3). Align the hanger onthe opposite side of the dropout and tighten the boltto the specified torque.

133422.PDFShimano DI2 BatteryBUse seat post type Shimano SM-BTR2 battery.The battery holder kit and internalguides are available as Cannondalekit - KP439/.ABInstallation order:1.Attach holder (B) to battery (A)securely with 3mm zip ties (C).2.Remove the rear shock.3.Snap assembled holder/battery over the existingshock spacers (D).4.Connect the battery wire tothe battery.5.Insert the battery and shockinto top tube.6.Installandtightentheshockboltsto 15 N-m.CC15 N-mDD13

Internal Guides4mm5 mm x 25 mm5 4mm4mm4mmUse the guide inserts in openlocations.4Internal Frame Guides:Install plastic spiral wire wrap (5) overDi2 wires (6) passing through internalguide (7).54mmUse the 4mm guide opening for Di2 wire.6145mm75 mm

133422.PDFREPLACEMENT PARTSKP441/ or KP442(Full Sprint)KT041/AXKP421/160 - 160mmKP421/180 - 180mmmm14212xZKP432/Loctite 242 (blue)M5x20mmLoctite 242 (blue)10 Nm (88.5 InLbs)YXZCRBBALLOYZKP312/Z10XSCALPEL SICODEKP432/DESCRIPTIONKIT, HANGER, SCALPEL SI, 142KP436/KIT, CABLE GUIDES MECH,SCALPEL SIXKP437/29KIT, LINK, CARBON, 29, SCALPEL SIXXKP437/27KIT, LINK, CARBON, 27, SCALPEL SIXXKIT,CABLE GUIDES, DI2, SCALPEL SIXKIT, TOOL AI TRUING WHEEL AXLEXKP439/KT041/KP433/CRB ALLOYXXCODECRB ALL0YXXKIT, BEARINGS, PIVOT, SCALPEL SIXXHD169/KIT BEARINGS HEADSET 2 HSHOKXXQSISEAL/KIT, SEAL,UPPER BEARING,58mm ODXXKP119/KIT HEADSET INT HSHOK TO 1.5”XXKP434/KIT, SHOCK BOLTS, SCALPEL SIDESCRIPTIONKIT, LINK, HARDWARE, SCALPEL SIKP435/KP058/KIT HEADSET INT HEADSHOK 1 1/8XXKP205/KIT HEADSET INT H SHOK TO TAPERXXXKP441/KIT, REAR SHOCK, SCALPEL Si, MONARCH FS (Full Sprint version)KF115/KIT GEL DYNAMIC CARBN SEATPOSTXXXKP197/KIT BEARING BB-PRESSFIT 30XXKP442/REAR SHK, SCALPEL Si, MONARCHXXKB6180/KIT BEARING BB SI 2PCSXXKP443/KIT, CSTAY PROTECT, SCALPEL Si CRBXKP421/160KIT, BRAKE MOUNT, FLAT, 160MMXXKP444/KIT, CSTAY PROTECT, SCALPEL Si AlKP421/180KIT, BRAKE MOUNT, FLAT, 180MMXXKF103/KIT GUARD SCUFFGUARD 8PKXXX15

SI HOLLOWGRAM MTN PF30 BB30BB30 - 83mm16.12.7. 11.7.6.4.3.8.10.9.9.13.14.8.19 mmmm140.5mm149mmmmGreasePF30- 83mm40 N-m,Grease40 Nm,(30 FtLbs)Loctite 242 (blue)1.WAVEWASHERKT012/DRIVELoctite 242 (blue)SPACER40 N-m3/8”driveFIXINGBOLTNON-DRIVESPACERSHIELD SHIMWASHERSHIELD10.2.KP308/RH CRANKARM0.5mm4.KP021/9 mm137 mm14 mm83mmLH CRANKARM5.KP352/2X105mm CL Offset104x64 BCDKP354/1X115mm CL Offset76 BCD46.9.0mm47.0mm15.0mm43.1mmNON-DRIVEDRIVE(laser etch)“A2 SRAM 1X CL 55.6”137.0mm(laser etch)“104X64”Grease1640 Nm, (30 FtLbs)20.0mmKP308/ KIT,SPINDLE-SI MTN, 137MM (Spindle only)Loctite 242 (Blue)40 Nm, (30 FtLbs)KT012/

(laser etch)KP308/ KIT,SPINDLE-SI MTN, 137MM (Spindle only)“104X64”133422.PDFLoctite 242 (Blue)40 Nm, (30 FtLbs)Grease40 Nm, (30 FtLbs)KT012/3/8in driveLoctite 242 (Blue)40 Nm, (30 FtLbs)SPINDLERH CRANKARMSPIDERNO. (QTY)1(2), 2(2)451(2), 2(2),6, 7(2)8(2),9A(2),9B(2)10, 11(3),12, 13CODEDESCRIPTIONKP251/BLKKIT,CRANK BOLTS,H-GRAM SL2,(2)NO. (QTY)KP296/KIT,SPIDER-SI MTN,XX1KP128/KIT,SPIDER,SI MTN,SRAM 80/120BCD BLTKP241/KIT,SPIDER,SI MTN,SRAM 64/104BCD BLTKF355/KP021/LOCKRINGKIT,SPIDER-SI MTN,TRIPLE 64/104BCD 4BLTCODEDESCRIPTION--KP218/KIT,LOCTITE 609 BEARING,BB-BB30 (SKF#68062RS /SRI2 /90% FILL)8(2)8(2), 9A(2) KP197/KIT,BEARING,BB-PF30CU4041AI30MTB SPIDERING SL 30T X-SYNC Ai OFFSET7(2)CU4041AI32MTB SPIDERING SL 32T X-SYNC Ai OFFSET10KP308/KIT,SPINDLE-SI MTN, 137MMCU4041AI34MTB SPIDERING SL 34T X-SYNC Ai OFFSET11QC617/KP021/KIT,LOCKRING-SL --REQUIRES KT012/KIT,SHIMS-PLASTIC, BB-SI; INCL 5SHIMS12QC618/KIT,WASHER-WAVE, BB-SIKT010/KIT,TOOL-BB BEARING-SI;KT011/KIT,TOOL - BEARING REMOVAL SI;KT012/KIT,TOOL-LOCK RING-SIKP306/KIT,BB,CDALE SI,68/73X137 BB30/PF3016KP249/BLKKIT,BEARING SHIELD,BB-SL2KT013/KIT,CRANK EXTRACTION TOOL;2 PIECESRIGHT CRANKARM - 3TYPESISL2HOLLOWGRAM 72R175mmKP246/175RKP305/175RKP423/175RHOLLOWGRAM SICANNONDALESILEFT CRANKARM - 175mmKP246/175LKP305/175LKP423/175L17

SI HOLLOWGRAM MTN16.12.7. 11.7.6.4.3.8.10.9.9.13.14.8.0.5mm19 mm14 mmRIGHT CRANKARM - 3Loctite 242 (blue)TYPEGrease40 N-m,KT012/1.3/8”driveLoctite 242 (blue)40 N-m10.2.KP308/RH CRANKARMSISL2KP021/137 mm5.NO. (QTY)1(2), 2(2)451(2), 2(2),6, 7(2)8(2),9A(2),9B(2)10, 11(3),12, 1318CODEDESCRIPTIONKP251/BLKKIT,CRANK BOLTS,H-GRAM SL2,(2)KP296/KIT,SPIDER-SI MTN,XX1KP128/KIT,SPIDER,SI MTN,SRAM 80/120BCD BLTKP241/KIT,SPIDER,SI MTN,SRAM 64/104BCD BLTKF355/KIT,SPIDER-SI MTN,TRIPLE64/104BCD 4BLTKP366/28MTB SPIDERING SL 28T X-SYNCKP366/30MTB SPIDERING SL 30T X-SYNCKP366/32MTB SPIDERING SL 32T X-SYNCKP021/KIT,LOCKRING-SL --REQUIRES LLOWGRAM SICANNONDALESILEFT CRANKARM - 14TYPE4.HOLLOWGRAM mKP246/175LKP305/175LKP423/175LNO. (QTY)CODEDESCRIPTION--KP218/KIT,LOCTITE 609 KIT,BEARING,BB-BB30 (SKF#68062RS /SRI2 /90% FILL)8(2), 9A(2) KP197/7(2)KP249/BLKKIT,BEARING,BB-PF30KIT,BEARING SHIELD,BB-SL210KP308/KIT,SPINDLE-SI MTN, 137MM11QC617/KIT,SHIMS-PLASTIC, BB-SI; INCL 5SHIMS12QC618/KIT,WASHER-WAVE, BB-SIKT010/KIT,TOOL-BB BEARING-SI;KT011/KIT,TOOL - BEARING REMOVAL SI;KT012/KIT,TOOL-LOCK RING-SIKIT,BB,CDALE SI,68/73X137 BB30/PF3016KT013/KIT,CRANK EXTRACTION TOOL;2 PIECES

133422.PDFMAINTENANCEThe following table lists only supplemental maintenance items. Please consult your Cannondale BicycleOwner’s Manual for more information on basic bike maintenance. Consult with your Cannondale Dealer tocreate a complete maintenance program for your riding style, components, and conditions of use. Follow themaintenance recommendations given by the component manufacturers for the various non-Cannondaleparts of your bike.ITEMFREQUENCYHOUSING AND CABLES - Your bike has been supplied with smalladhesive frame protectors - KF103/. Place this material on the theframe between where cables and housing rub due to movement.Overtime, cable rubbing can wear into the frame itself causing veryserious frame damage.BEFORE FIRST RIDENOTE: Damage to your bike caused by cable rubbing is not acondition covered under your warranty. Also, adhesive frame guardsare not a fix for incorrectly installed or routed cables or lines. If youfind that applied guards are wearing out very quickly, consult withyour Cannondale Dealer about the routing on your bike.DAMAGE INSPECTION - Clean and visually inspect entire bike frame/swingarm/linkage assembly for cracks or damage. See “Inspect ForSafety” in your Cannondale Bicycle Owner’s Manual.BEFORE AND AFTER EACHRIDECHECK TIGHTENING TORQUES - In addition to other componentspecific tightening torques for your bike. Tighten according to theTIGHTENING TORQUES information listed in this supplement.EVERY FEW RIDESINSPECT BEARINGS, REPLACE WORN OR DAMAGED PARTS : SHOCK LINK ASSEMBLY PIVOT AXLES FRAME PIVOTBEARINGSIN WET, MUDDY, SANDYCONDITIONS EVERY 25 HRS.IN DRY, CONDITIONSEVERY 50 HRS.FORK - Please consult the manufacturer’s owner’s manual for maintenance information for your fork.WARNINGANY PART OF A POORLY MAINTAINED BIKE CAN BREAK OR MALFUNCTION LEADING TO AN ACCIDENTWHERE YOU CAN BE KILLED, SEVERELY INJURED OR PARALYZED. Please ask your Cannondale Dealerto help you develop a complete maintenance program, a program which includes a list of the parts on yourbike for YOU to check regularly. Frequent checks are necessary to identify the problems that can lead to anaccident.19

LE EUROPECANNONDApe, B.V.ts Group EuroCycling SporOldenzaal,27, 7570 GC,torpozenHaNetherlands4879380(Voice): 41 6115 14240com(Fax): 31 54sportsgroup.rope@cyclingservicedeskeuLE UKCANNONDASCALPEL SIl.ner’s manuale bicycle owur cannondayodanreference.treentumboth for futhis suppledepeaKeR!n.iongatniWarfety informimportant saBoth contain133422.comwww.cannondalepGroung Sports 2016 CycliGroup16)ts4/or(0Sp22ngCycli1334,, The FulcrumVantage Way, BH12 4NUPoole, Dorset88(0)1202 73224 4):ceoi(V72336602)12(04 PLEMENLAUNAMOWNER’S

Unauthorized service, maintenance, or repair parts can result in serious damage and void your warranty. abouT ThIs supplemenT Cannondale Owner’s Manual Supplements provide important model specific safety, maintenance, and technical information. They are not replacements for