Transcription

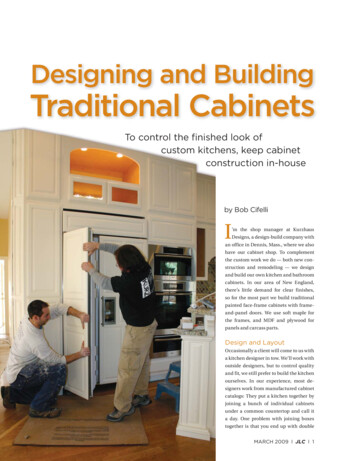

Designing and BuildingTraditional CabinetsTo control the finishfinisheded look ofcustom kitchens, keep cabinetconstruction in-houseby Bob CifelliI’m the shop manager at KurzhausDesigns, a design-build company withan office in Dennis, Mass., where we alsohave our cabinet shop. To complementthe custom work we do — both new construction and remodeling — we designand build our own kitchen and bathroomcabinets. In our area of New England,there’s little demand for clear finishes,so for the most part we build traditionalpainted face-frame cabinets with frameand-panel doors. We use soft maple forthe frames, and MDF and plywood forpanels and carcass parts.Design and LayoutOccasionally a client will come to us witha kitchen designer in tow. We’ll work withoutside designers, but to control qualityand fit, we still prefer to build the kitchenourselves. In our experience, most designers work from manufactured cabinetcatalogs: They put a kitchen together byjoining a bunch of individual cabinetsunder a common countertop and call ita day. One problem with joining boxestogether is that you end up with doubleMARCH 2009 l JLC l 1

Designing and Building Traditional Cabinetsinternal partitions that waste perfectly(see Figure 1). Also, building cabinets tooverall look they’re after, including doorgood storage space, not to mention ply-fit a specific space gets rid of scribe strips,and drawer styles and paint color. Wewood. Plus visually you’re stuck withbolt-on end panels, and various gap mold-then talk about function. Where do theydouble stiles and seams between everyings — all of which make the cabinets lookwant food storage, pots and pans, uten-two cabinets.blocky and take up space that could havesils, containers, appliances, and lighting?been used for storage.Together we outline their dream kitchen.We prefer to build entire runs of cabinets as a unit, which allows us to get ridOn a new kitchen, I begin by reviewingWe find that clients tend to be most spe-of double partitions and to maintain andesign ideas with our clients. We look atcific about what they don’t want, havingequal reveal between every door andtheir magazine clippings and at photoslived with it for so long.drawer, top to bottom and side to sideof our completed work to determine theI then head back to the shop, armedwith the list of dos and don’ts and a fewnice-to-haves. At this point, I draw thekitchen in plan view with a few elevationsand renderings, using KCDw software(508/760-1140, kcdw.com), which is intended specifically for designing kitchencabinets and closet storage (Figure 2).The version I use costs 4,995. If you’veworked with CAD, the program is easy tolearn; it takes about two kitchens to getused to its ins and outs and customize thereporting tools. The program yields notonly cut lists and assembly drawings forthe shop, but also highly realistic 3-D renderings that can help the clients visualizetheir new kitchen before committing.Storage Where It MakesSenseI make sure appliances are paired withFigure 1. Reveals between drawers and doors are uniformly equal, whichgives the cabinetry a distinctive look and a pleasing rhythm. To increasestorage space and make access easier, the interiors are left free ofunneeded partitions.the appropriate storage. For example,under a cooktop I’ll put two 12-inch-tallpot drawers as wide as the unit (see sidebar, page 4). Because we bump the cooktop cabinet depth out as far as 30 inches,Figure 2. Theauthor developsboth design andproduction drawings using KCDwsoftware.these drawers are extra deep.I also try to bring all dish storage withinarm’s reach of the dishwasher. Stockupper cabinets are typically 12 inchesdeep, leaving a scant 11 inches insidefor storage. Dinner plates larger thanthat have to be leaned upright or storedsomewhere less convenient. So I makemy upper cabinets 14 inches deep andkeep them free of inside partitions. If thewall run is 8 feet, I build an 8-foot cabinet with no interior walls and no stilesMARCH 2009 l JLC l 2

Designing and Building Traditional Cabinetsbetween door pairs (Figure 3). The onlyreason I will interrupt a cabinet run is foran appliance, or because a larger cabinetsimply won’t fit through the doorway.Cabinet heights. Stock wall cabinetsusually come in heights ranging from30 to 42 inches and typically get installed54 inches above the floor (or 18 inchesabove a standard 36-inch-high counter).While 42-inch cabinets work fine with8-foot ceilings, with higher ceilings youeither have to build a soffit — a spacewasting detail — or leave a gap at the top.In my kitchens, I keep the 54-inch baseline but build the upper cabinets to suitthe ceiling height, leaving only enoughroom for crown molding (Figure 4). Onerecent kitchen had 64-inch-tall uppersunder a 10-foot-8-inch ceiling.I also build tall floor cabinets in onepiece, fitted to the ceiling and ready forcrown molding. We vary the crown heightaccording to the height of the ceiling. Forceilings under 9 feet, we install a stockFigure 3. Completeruns of wall andbase cabinets aredesigned and builtas single units. Thecabinet shown here,seen finished in Figure 1, fills an 8-footdiagonal wall andcontains continuousadjustable shelvesaccessed by a seriesof doors along itslength.Figure 4. Thesetaller-than-averagewall cabinets aresized to leave a balanced reveal on thetop rail beneath acrown molding (topleft). As long as he’ssure he can bring itinto the house, theauthor will build asingle cabinet tostand full heightunder an 11-footceiling (top right).Crown molding isnormally installedunfinished andpainted on site(bottom left).MARCH 2009 l JLC l 3

Designing and Building Traditional CabinetsEmphasisOn Access12I’m a big fan of monster silverwaredrawers (1) located as close aspossible to the dishwasher. I putthem on soft-closing, full-extensionslides (800/438-6788, blum.com).Below the cooktop, I put twodrawers. Big pots and pans go inthe larger, bottom drawer; lids and4589smaller pots go in the upper one.The top drawer also contains aninner drawer (2) for cooking utensils. Near the oven, I put a verticalflat-pan rack and a knife drawercustomized to suit the clients’collection (3).I almost never install a falsedrawer front under the kitchensink, or one of those drop-down7trays where old sponges go to die.sink area. A bottomless base underdeep as 30 inches (7), for ample,Instead, the doors close on a top railthe drawer makes it easy to serviceeasily accessible storage.that’s the same width as those adja-a kickspace heater (5).cent (4). There’s no stile betweenThere’s no perfect answer toMany kitchens include breakfastnooks. A 42-inch-tall peninsula cab-the doors, and the shelf behindthe corner base-cabinet problem,inet is a good way to separate thisthem is only 16 inches deep. I leavebut Rev-A-Shelf’s (800/857-8721,area from the kitchen (8). Elsewherethe space behind the shelf opencabinetparts.com) quarter-turnalong the countertop, I’ll drop a sec-to the floor for plumbing access.pull-out hardware (6) is one user-tion down to 32 inches for a bakingBeneath the shelf I put a full-exten-friendly option. I also build mystation (9). The marble top shownsion drawer, handy for storing trashown solution: diagonal drawers onhere provides a nice visual break.bags and other items used in thefull-extension undermount slides asA standard 24-inch-deep cabinetMARCH 2009 l JLC l 4

Figure 5. The author provides extra counter spacebehind sinks and cooktops by bumping thesecabinets up to 6 inchesforward of the line; bunfeet add a furniture look.36crown of up to 5 inches tall. Any ceilingover 9 feet deserves a tall, built-up crown,which we mill using a mix of stock andcustom profiles.There are places where the heightabove the counter must change — suchas over the stove — but otherwise, I don’tvary the 54-inch elevation. Some designers feel that varying the baseline heightadds visual interest, but I think it spoils10an eye-soothing horizontal line.Base cabinets are a different story. Ivary the heights and depths of base cabinets to suit the application. I also bumpout my stove and sink bases by as much as6 inches. That way I have plenty of roomfor mounting fixtures behind the sink,and the homeowner has a place to putcooking condiments behind the stove.Varying countertop depths breaks up theotherwise flat surface of a line of cabinets,and also provides a natural place to dividea long run. I often add bun feet or columndoesn’t make for easy access.So I divide the space in a pantrycabinet, putting a third of it onthe door, improving visibility andFigure 6. Face frames are the firststep in the author’s constructionsequence. A frame for a cooktopcabinet with deep drawers flankedby pull-out pilasters is seen in theforeground.legs to these bumped-out cabinets to givethem a furniture-like look (Figure 5).Cabinet ConstructionI make the face frames first using pocketscrew joinery, which allows us to assem-reach (10). To handle the heavyble large, remarkably strong face framesdoor, I may install as many as awithout interlocking profiles or tenonsdozen hinges.(Figure 6). I used to bore the pocketholes with a simple manual Kreg jigMARCH 2009 l JLC l 5

Designing and Building Traditional CabinetsFigure 7. The KregDK3100 can drill up tothree holes at a timeabout as fast as theoperator can positionthe workpiece underthe air-driven clamp.(800/447-8638, kregtool.com), but thisproved way too time-consuming. I nowuse Kreg’s three-head tub-boring machine, which makes short work of thispart of the job (Figure 7). A companion tool, the face-frame assembly table,clamps and holds multiple frame parts inalignment for screwing. Together, the twoitems cost about 6,800.I also use pocket-screws for gussets,back rails, stretchers, and other internalstructural members, including sides andbottoms. For finished partitions and bottoms, we use 3/4-inch furniture-grademaple plywood; for horizontal and vertical bracing, we use 3-inch-wide 3/4-inchArctic birch, glued and pocket-screwed.This plywood is strong and takes cabinetscrews well. The bracing squares the cabinet and provides mounting for drawerrunners and attachment points for thecountertop.Our cabinets are built to stand on theirown and support heavy stone or concreteFigure 8. An island cabinet with pilastersand a raised snack bar takes shape (top left).The contiguous face frames are directly connected to a structural, raised-panel back.Interior bracing, partitions, and bottom panelswill be pocket-screwed from inside. The authorand a helper plot the final position for anotherisland cabinet (bottom left), shown finished inFigure 1. The island above is 9 feet long andweighs more than 1,000 pounds empty. It’ssupported entirely on four bun feet.MARCH 2009 l JLC l 6

Designing and Building Traditional CabinetsFigure 9. The authorcuts and assemblestoekick “ladders” onsite. He levels andfastens them to thefloor first, then screwsdown the cabinets.The rough toekicks arecovered with a prefinished baseboard.tops and commercial appliances. I don’tcabinets on top. This simple approachsion system. We also bought a CA Tech-add backs to base units or uppers thatworks just as well for island cabinets —nologies Cougar AAA (Air Assist Airless)don’t have glass doors. I just make sureand the reduced cabinet height makessystem (888/820-4498, spraycat.com). Wethat the finish wall color is in place beforeit more likely that we’ll be able to get therun air from a large compressor throughI install, or paint it later. I also don’t useunits through the kitchen door.a five-stage air cleaner and dryer insidethe spray room. The compressor suppliessolid bottoms in my drawer bases whenan open frame serves just as well.Finishesair to the AAA pump head at 60 psi, whileFinished ends. I build finished endBefore we had a spray room, we relied onthe system has its own regulator, set atpanels to match the door style or as aa triple-stage HVLP turbine gun to spray45 psi. The gun has twin hoses; one sup-beadboard frame-and-panel. Either way,waterborne finishes. (Because of healthplies paint to the tip at 600 psi and theI attach the panel to the face frame so thatand fire hazards, if you don’t have a sprayother provides air to atomize the fan pat-the cabinet looks like one seamless, inte-booth with a high-volume exhaust sys-tern at around 15 psi. Because it lays a lotgrated unit. This is particularly impor-tem, you pretty much have to use a water-of paint on at once, the AAA system takestant for freestanding island cabinets,borne finish.) HVLP guns lay on a reallya little getting used to.which need to look good from every anglesmooth coat with little overspray. TheWe spray finishes made by ML Camp-(Figure 8, page 6).turbine air is heated, making the finishbell (800/364-1359, mlcampbell.com).My base cabinets don’t have integratedflash over a little faster. Dust control is aFor primer, we use Campbell’s Clawlock,toekicks. Instead, I rip 3 3/4-inch plywoodmust because the paint remains tacky fora two-part catalyzed undercoat that youstrips in the shop and build separate “lad-an hour or so after spraying.mix just before spraying. It has a workingders” on site (Figure 9). I set these onLast year, we expanded the shop and in-time of about eight hours, after which itthe floor first, shim or scribe them level,vested in a spray room with high-volumebecomes too thick to spray and must besecure them with screws, then attach theexhaust and a fire detection and suppres-discarded. Clawlock is made for sealingMARCH 2009 l JLC l 7

Designing and Building Traditional CabinetsMDF, but it works well on maple, too.produces a hard, high-quality finish. ItMagnaMax comes pretinted and has aIt can be applied at a thickness of up toflashes over completely in five minutes;shelf life of about three months.5 mils per coat, and sands nicely.parts can be stacked within 25 minutesFor the top coat, we use Campbell’s(unlike parts sprayed with waterborneCabinet InstallationMagnaMax precatalyzed lacquer, whichfinishes, which can’t be stacked for days).A typical installation takes us two days.I use a RoboLaser RT-7210-1 (robotoolz.com, 800/984-0404) to mark base cabinet height, upper cabinet height, and allplumb lines on the walls (Figure 10). Thelaser displays a level line of dots across thewall, which I can move horizontally witha remote as I install. I watch for the dotsto be split, with the bottom half displayedacross the top front edge of the cabinetand the upper half on the wall line. Thisensures a level plane for the countertop.I shim behind the cabinet’s back railto correct for any unevenness in the wall(Figure 11), then screw the cabinet to theFigure 10. Splitting the laser dots between the front edge of the cabinetand the wall line provides a level reference side to side and front to back.This ensures dead-true support for a stone countertop and eliminatesunsightly shim gaps.studs with 41/2-inch HeadLok screws(800/518-3569, fastenmaster.com). Usingthese may seem like overkill, but I likethem because they self-tap and havelarge heads that don’t sink into the wood.They also provide solid insurance againstshear and pullout when we’re hanginguppers, which can be quite heavy whenthey’re loaded. We always install solidblocking behind the drywall at the topand bottom lines of the upper cabinets.In cases where a visible fastener is objectionable, I countersink and cover with aninlaid patch of edge banding. If the cabinets have glass doors, I use finish washers behind the screws. I nearly always useobscure glass rather than clear glass inthese doors.When the cabinet installation is complete and the last coat of floor finish is dry,I apply a finished facing to the toekick,usually with a small profile routed into itfor a little extra customization. Nail holesin the toekick are hidden with wood fillertopped with latex paint.Figure 11. Here, the author blocks a backless drawer base off the wall toincrease countertop depth, using structural star-drive screws to fasten itto the wall framing.Bob Cifelli is the shop manager at KurzhausDesigns in Dennis, Mass.MARCH 2009 l JLC l 8

keep them free of inside partitions. If the wall run is 8 feet, I build an 8-foot cabi-net with no interior walls and no stiles Figure 1. Reveals between drawers and doors are uniformly equal, which gives the cabinetry a distinctive look and a pleasing rhythm. To increase storage space and make acces