Transcription

Andover Continuum CyberStationHVAC Essentials Guide

2010, Schneider ElectricAll Rights ReservedNo part of this publication may be reproduced, read or stored in a retrieval system, ortransmitted, in any form or by any means, electronic, mechanical, photocopying, recording,or otherwise, without prior written permission of Schneider Electric.This document is produced in the United States of America.Product Names are trademarks of Schneider Electric. All other trademarks are the property of their respective owners.Title: Andover Continuum CyberStation HVAC Essentials GuideRevision: CDate: October, 2010Part number: 30-3001-1000Software application version number: CyberStation Version 1.92The information in this document is furnished for informational purposes only, is subjectto change without notice, and should not be construed as a commitment by Schneider Electric. Schneider Electric assumes no liability for any errors or inaccuracies that may appearin this document.On October 1st, 2009, TAC became the Buildings Business of its parent company SchneiderElectric. This document reflects the visual identity of Schneider Electric. However, thereremain references to TAC as a corporate brand throughout the Andover Continuum software. In those instances, the documentation text still refers to TAC — only to portray theuser interface accurately. As the software is updated, these documentation references willbe changed to reflect appropriate brand and software changes. All brand names, trademarks and registered marks are the property of their respective owners.Schneider ElectricOne High StreetNorth Andover, MA 01845(978) 975-9600Fax: (978) s

Andover Continuum CyberStationHVAC Essentials Guide30-3001-1000Revision COctober, 2010

ContentsChapter 1Chapter 2About this Manual .9What’s in this Manual .Related Documentation .Symbols Used .91011Getting Started .13Planning a Building Control System .Overview of Building Control Networks .Andover Continuum Product Description .Andover Continuum Hardware Products .Andover Continuum System Architecture .Single-User Configuration .Multi-User Configuration .Network Controllers .Infinet Controllers .BACnet Controllers .Workstations .Networks .NetController I/O Modules .Controller Expansion Modules .CyberStation Software .141819191920212223232323242526Configuring an HVAC System .29Task 1: Open Continuum Explorer .Open Continuum Explorer .Infinity vs. BACnet Viewing Options .More About Continuum Explorer .Task 2: Create a Network and a Controller .3030313132Andover Continuum CyberStation HVAC Essentials Guide5

Containers and Parent/Child Objects .32Create a Network .33Web Configuration for Controllers .34Create a Controller .36More about Networks and Controllers .38Task 3: Configure IOU Modules .39Creating an IOU Module Object .39General Tab – IOUModule Editor .40Commissioning an IOU Module .42More about Commissioning an IOU Module .42Task 4: Configure Controller Comm Ports .43More about Configuring Controller Comm Ports .43General Tab – CommPort Editor .44Default Modes .45More about the General Tab - CommPort Editor .47Viewing the Status of an XDriver Device .48Settings Tab – CommPort Editor .49Field Bus Controllers Tab – CommPort Editor .51More about the Field Bus Controllers Tab - CommPort Editor .52More about the CommPort Editor .52Task 5: Create CyberStation Points .53Create an InfinityInput Point .53Create an InfinityOutput Point .62Create an InfinityNumeric Point .63Create an AnalogOutput Point .65More about Points .66Task 6: Create Schedules .67About Schedule Points .67Create and Configure a Schedule .67More about Schedules .70Task 7: Configure Alarms .71About Event-Notification Objects .71Create an Event-Notification Object .72About Notification by E-mail and Pages .76About Alarm-Enrollment Objects .78Create an Alarm-Enrollment Object .78About Attaching Alarms to Objects .81Attaching Alarms to a Point .81Using the Alarms / Advanced Alarms Tab of an Object Editor .826 Schneider Electric

More about Alarms .86Task 8: Create Graphic Panels and Controls .87About Graphic Controls for HVAC .89More about Graphics Panels and Controls .91Task 9: Configure Reports .92About Report Objects .92Create a Report .92More about Reports .97See “Reports and Report Editor” in the CyberStation onlinehelp. .97Chapter 3Chapter 4Monitoring a Building Control System .99Responding to Alarms .About the Alarm Status Bar .About the Active Alarm View Window .Using Groups .More about Group Objects .Using ListView Windows .About Predefined ListView Objects .About Creating ListView Objects .More about ListView Objects .Using Logs .More about Logs .Loop Configuration for BACnet .HVAC Control Loop .More about Loop Object Configuration .More about BACnet nced Configuration for HVAC Control . 113Introduction to Plain English Programs .More about Plain English Programs .Security Groups for CyberStation Users .About User Objects .About Security Groups .About SecurityLevel Objects .About ControllerUser Objects .More about Users and Security .Andover Continuum CyberStation HVAC Essentials Guide1141141151151161171181187

8 Schneider Electric

About this ManualAbout this ManualWhat’s in this ManualThis manual provides basic, essential information for planning,configuring and monitoring an HVAC system consisting of AndoverContinuum controllers and CyberStation software. This manualprovides the following information:zAn introduction to planning for an HVAC systemzStep-by-step procedures for basic configuration tasks inCyberStationzStep-by-step procedures for monitoring your HVAC system usingCyberStationzAn overview of advanced HVAC features that you may want toimplement in your facilityThis manual is intended to be used with the CyberStation online helpand the documentation that accompanies the controllers. For completeuser-interface details (beyond the scope of the basic tasks in thismanual), you must consult the online help and the other CyberStationdocuments listed in the next section. The procedural information inthis manual assumes that your HVAC hardware and software areinstalled, online, and ready to be configured.Andover Continuum CyberStation HVAC Essentials Guide9

About this ManualRelated DocumentationFor additional or related information, refer to these documents.10 Schneider ElectricCyberStation online helpn/aCyberStation Access Control Essentials Guide30-3001-405CyberStation Installation Guide30-3001-720Continuum Remote CommunicationConfiguration Guide30-3001-814NetController II Operation and TechnicalReference Guide30-3001-995Introducing BACnet - A Guide for ContinuumUsers30-3001-863Andover Plain English Language Reference30-3001-872

About this ManualSymbols UsedThe Notes, Warnings and Cautions used in this manual are listedbelow.Note: Contains additional information of interest to the user.CAUTION or WARNINGType of hazardHow to avoid hazard.Failure to observe this precaution can result in injury or equipmentdamage.DANGERELECTRIC SHOCK HAZARDHow to avoid hazard.Failure to observe these instructions will result in death or seriousinjury.Andover Continuum CyberStation HVAC Essentials Guide11

About this Manual12 Schneider Electric

Chapter 1: Getting StartedChapter 1Getting StartedThis chapter offers guidance on planning your HVAC system andincludes the following topics:zA review of a sample floor plan displaying a variety of commonHVAC devices that the system manages.zA network configuration of controllers, servers, and CyberStationworkstations that provides the HVAC infrastructure for the samplesite.Andover Continuum CyberStation HVAC Essentials Guide13

Chapter 1: Getting StartedPlanning a Building Control SystemSchneider Electric’s products support the full range of HVAC needs:zSmall buildings to multi-site facilitieszControlled regulation of humidity and temperature for individualareas within a larger facilityAs you prepare to implement an HVAC system in your organization,you may want to work from floor plans of your facility to identify thefollowing factors that affect implementation:14 Schneider ElectriczLocations where HVAC specific controllers are neededzLocations where HVAC devices are neededzPersonnel who can adjust the HVAC settings for these areaszHow you want to manage regulating the environment in eachlocation (for example regulating the temperature or humidity in anoffice or a freezer)

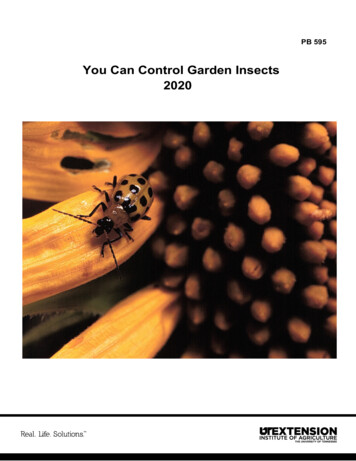

Chapter 1: Getting StartedThe following illustration shows a small warehouse with the mainfacility, an office and a freezer. All of these areas require some form ofHVAC control.The following issues for this sample site determine the HVAC devicesthat are needed and the configuration of the system.zFor the main warehouse how can the humidity be monitored andregulated?zHow will the freezer temperature be monitored and maintained at aconstant below freezing temperature?zHow will the office be monitored and regulated separate from theother two areas?Andover Continuum CyberStation HVAC Essentials Guide15

Chapter 1: Getting StartedzWho will have administrative access to adjust the controllers thatmonitor and regulate all the HVAC devices in the facility?The following illustration shows the same floor plan, with HVACdevices in place.In this floor plan:z16 Schneider ElectricThe Humidity Sensor in the warehouse monitors the humidity leveland sends information back to the appropriate controller(s) if anadjustment is required. A dehumidifying device is then activated,by the controller, to reduce the humidity.

Chapter 1: Getting StartedzThe Temperature Sensor in the freezer monitors any dramatic risein temperature. It also detects if the temperature rises above therequired “constant freezing” temperature. If the temperature doesrise above freezing, then the sensor alerts the controller assigned tothe freezer. The controller then activates the chiller attached to thefreezer, which lowers the temperature back to the proper level.zThe Thermostats in the office and warehouse, monitor and regulatethe temperature (using air conditioning or heating units) forpersonnel in these areas. The regulation of the temperature inthese areas is maintained separately from the regulation of thetemperature in the freezer.Andover Continuum CyberStation HVAC Essentials Guide17

Chapter 1: Getting StartedOverview of Building Control NetworksThis illustration represents a sample Andover Continuum HVACarchitecture.18 Schneider Electric

Chapter 1: Getting StartedAndover Continuum Product DescriptionAndover Continuum is a mixture of hardware and software that isdesigned to monitor and control the various functions of a building.These functions include, but are not limited to, security, access control,lighting, heating, ventilation, and cooling.The hardware consists of equipment controllers, networkcommunication controllers and input and output interfaces. TheCyberStation software is a application program that allows you tocommunicate with, monitor and control the operation of the entireAndover Continuum system.Andover Continuum Hardware ProductsThe Andover Continuum product line encompasses a wide variety ofcomponents including the following:zNetController II, which replaced the NetController, CX9000,CX9200, CX9300 and the CX9500zInfinet bCX1, which replaced the CMX9924, CMX220 and theCMX240zACX (57xx), which replaced the SiteController 9702, ACX780 andACX700These components are networked to create a total building automationsystem.Andover Continuum System ArchitectureDepending upon the complexity of the site architecture, a system canrange from a single-user configuration with one workstation to a large,multi-user configuration with a network of multiple workstations, a fileserver, and numerous controllers.Andover Continuum CyberStation HVAC Essentials Guide19

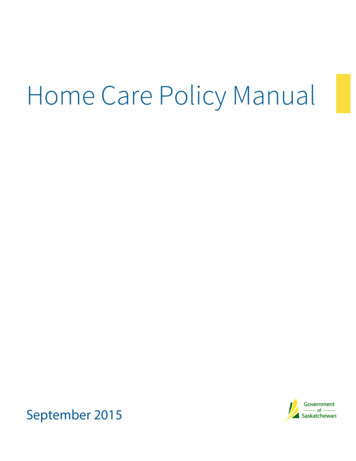

Chapter 1: Getting StartedSingle-User ConfigurationIn single user configurations (also referred to as stand alone systems)the Andover Continuum product line consists of a network controller(NetController II with optional input/output modules), a bCX1 or aACX (57xx) and a CyberStation workstation. The SQL Expressdatabase also resides on the workstation. The NetController.bCX1/ACX(57xx) use Ethernet TCP/IP protocol to communicate with theworkstation. Communication between the network controller and the I/O modules is conducted over a special I/O bus. There are two versionsof the bCX1. One uses Schneider Electric proprietary Infinet protocoland the other communicates using the BACnet protocol. The followingillustration shows a single-user configuration.20 Schneider Electric

Chapter 1: Getting StartedMulti-User ConfigurationThe Andover Continuum system design is based on scalability, soexpansion to a multi-user, larger network configuration in a local areanetwork (LAN) is easily accomplished. The following illustration showssuch a configuration. In this configuration, the network is expanded toinclude another workstation and an SQL database server.Andover Continuum CyberStation HVAC Essentials Guide21

Chapter 1: Getting StartedNetwork ControllersThere are several types of Andover Continuum network controllers:zbCX1 Series Infinet bCX1 BACnet bCX1zNetController II serieszACX (57xx)All are Ethernet TCP/IP compatible. The first four contain at least oneInfinet port to allow communication with Infinet applicationcontrollers.The bCX1 series is a series of Infinet and native BACnet routers andcontroller/routers. The bCX1 Infinet device functions as a Ethernet-toInfinet field bus router. The bCX1 BACnet devices function as BACnet/IP-to-MS/TP field bus routers.The NetController II and ACX (57xx) are powerful CPUs with flashEPROM, providing the central network management functions forAndover Continuum building automation system. These networkcontrollers can be connected to individual IOU modules via a differentproprietary RS-485 protocol called ACC-LON.The ACX (57xx) includes the equivalent of a NetController, a powersupply, and an AC-1 access control module in one small package.22 Schneider Electric

Chapter 1: Getting StartedInfinet ControllersThese controllers include combinations of inputs and outputs for themonitoring and control of local sensors and devices. There is a widevariety of Infinet controllers (including i2 controllers); each device isdesigned for a specific purpose.Infinet controllers are connected to network controllers via theproprietary Infinet network.BACnet ControllersBACnet controllers communicate via the ASHRAE (American Societyof Heating, Refrigerating, and Air Conditioning Engineers) protocol.This open protocol allows controllers to communicate with otherBACnet devices made by different manufacturers.These controllers include combinations of inputs and outputs for themonitoring and control of local sensors and devices. They areequivalent in function to the Infinet i2 Series controllers mentionedabove.BACnet controllers are connected to a bCX1 via the Master-Slave/Token Passing (MS/TP) network.WorkstationsA personal computer (PC) connected to the Continuum Ethernetnetwork runs the CyberStation software and database. The system cancontain a single workstation or multiple workstations, depending onthe site configuration.NetworksInfinet is Andover Continuum’s proprietary high-performance, tokenpassing LAN that allows Infinet application field controllers tocommunicate with each other and to a single network controller. Withrepeaters, it is possible to have 127 Infinet controllers on one InfinetnetworkAndover Continuum CyberStation HVAC Essentials Guide23

Chapter 1: Getting StartedThe LBus is the cable that connects IOU modules to a CX networkcontroller or via the LA-1 to a NetController or NetController II. Onlyone LBus can be connected to a CX network controller. Each LBus canhandle up to 32 IOUs.The BACnet MS/TP network is an RS-485 based industry standardLAN that allows BACnet b3 field controllers to communicate with eachother and to a single bCX1. It is possible to have 127 Infinet controllerson one MS/TP network.Note: For Continuum, It is possible to have 255 Infinet controllers onone MS/TP network (with a maximum of 127 per comm port).NetController I/O ModulesNetController I/O modules are specialized units that receive sensorinputs and activate equipment (valves, fans, chillers, and so on) andperform access control functions.The I/O modules, available in several configurations including input,output, mixed I/O, and display are listed in the following table:TypeInputOutput24 Schneider ElectricModuleUI-8-10UI-10-10VDI-6 ACDI-6 AC LO-2LO-2-OFunctionUniversal Input ModuleAC Digital Input ModuleDigital Input ModuleDigital Input/Output Module(for DIO-20)MilliAmp Input ModuleAnalog Output ModuleAnalog Output Module with overridesRelay Output ModuleRelay Output Module with overridesTriac Output ModuleLighting Output ModuleLighting Output Module withoverrides

Chapter 1: Getting StartedDisplayLB-88-Channel LED Bar Display/w 8 Pushbuttons8-Channel, 3-Digit 7-Segment LEDDisplay/w 16 Buttons2-Line LCD Display/w 12 PushButtonsVoice module for use with touch-tonetelephonesAllows use of LBus IOUs with aNetController or NetController IILS-8LC-1Miscellaneous VT-1LA-1Controller Expansion ModulesExpansion modules extend the I/O capability of certain Infinet i2,BACnet b3, and bCX1 controllers.TypeUniversalExpansionModulexPUI4xPBD4 *xPBA4 *InputOutputxPDI8xPAO2xPAO4xPDO2xPD04DisplayxP DisplayxP Remote DisplayFunction4-Channel Universal InputModule4-Channel Universal Input and4-Channel Digital Output Module4-Channel Universal Input and4-Channel Analog Output Module8-Channel Digital Input Module2-Channel Analog Output Module4-Channel Analog Output Module2-Channel Relay Output Module4-Channel Digital Relay OutputModuleInternal Mounted Keypad/Display Module (920 only)Externally Mounted Keypad/Display ModuleNote: * These modules (xPBD4 and xPBA4) can only be used to expandthe I/O of bCX1 series controllers.Andover Continuum CyberStation HVAC Essentials Guide25

Chapter 1: Getting StartedCyberStation SoftwareA key component of the Andover Continuum system is a Windowsbased application program called CyberStation that runs on a PCworkstation and interacts with the control system. AndoverContinuum’s other key software component is the database that storesall the vital information pertaining to the building automation controlsystem.CyberStationCyberStation provides a graphic user interface that can display andmanage data. This interface allows adjusting schedules and setpoints,acknowledging alarms, tracking temperature and humidity readings,and so on.Andover Continuum allows you to connect several CyberStationworkstations simultaneously to provide for the most flexibleconfiguration/control and monitoring operation available.26 Schneider Electric

Chapter 1: Getting StartedDatabaseThe information that describes the structure and operation of yourbuilding is stored in the CyberStation database. The values of eachpoint in the system, the settings for limits, the configuration of thehardware, the personal data of the personnel granted access to monitorand adjust a buildings HVAC systems, and more, are contained in thedatabase.The database engine that CyberStation uses is either Microsoft SQLExpress server or Microsoft Date Engine (MSDE) 2000.ObjectsThe components associated with your site (networks, workstations,controllers, sensors, and so on) are created, monitored, and controlledas objects in CyberStation. For example, for every controller you havein a building, CyberStation stores a controller object. When you havecreated an object for a piece of hardware, you can monitor, disable,change the settings for, and enable that equipment using that object inCyberStation. Objects represent every aspect of Andover Continuum’sbuilding control system, whether it is building security, lighting, orHVAC control.AttributesAn attribute is a characteristic of an object. All objects have attributesassociated with them. In most cases, there are several attributes thatdescribe an object. (Attributes are known as properties in BACnetobjects.)Andover Continuum CyberStation HVAC Essentials Guide27

Chapter 1: Getting Started28 Schneider Electric

Chapter 2: Configuring an HVAC SystemChapter 2Configuring an HVACSystemThis chapter contains step-by-step procedures for configuring an HVACnetwork in CyberStation, using NetController II controllers. Thechapter presents basic configuration tasks in the sequence that youwould typically perform them.So that you can more readily understand how the elements of an HVACnetwork work together, the procedures in this chapter cover basic setuptasks for a simple network. Each procedure provides cross references tothe CyberStation online help so that you can obtain complete, detailedinformation about all the options associated with a configuration task.Andover Continuum CyberStation HVAC Essentials Guide29

Chapter 2: Configuring an HVAC SystemTask 1: Open Continuum ExplorerObjects are the building blocks of your HVAC network. InCyberStation, objects are categorized by class. Areas, Schedules, andControllers are examples of object classes. An object’s attributes aredetermined by its object class, although the attribute values arespecific to the individual objects.Objects may represent:zPhysical devices, such as a controller or a workstationzFolders that are storage locations for objectszData, such as points, alarms and schedulesWhen you configure a network in CyberStation, you create the objectsthat correspond to the devices, folders, and data in your network, andyou specify their attribute values. Continuum Explorer is the tool thatyou use to configure and manage your network.Open Continuum Explorer1. Open CyberStation if it is not running on your workstation, andlogin.Note: You can also open CyberStation by clickingStart Programs Continuum Continuum Explorer.2. At the CyberStation main menu, click Explorer.Continuum Explorer opens. The navigation pane does not yetcontain any network objects or controllers. However, otherpredefined objects, created for you during installation, aredisplayed.3. Proceed to “Task 2: Create a Network and a Controller” on page 32.30 Schneider Electric

Chapter 2: Configuring an HVAC SystemInfinity vs. BACnet Viewing OptionsWhen you open Continuum Explorer, to view various folders anddevices, you can select one of several views. The views are InfinityController and BACnet Device, Infinity Controller Only andBACnet Device Only.The Infinity Controller and BACnet Device view allows you toview both Infinity and BACnet devices. The Infinity Controller Onlyview shows only Infinity devices in Continuum Explorer, while theBACnet Device Only view displays BACnet devices only.To change views in Continuum Explorer:1. From Continuum Explorer, select View Show TAC BACnetDevice As.2. Select one of the three choices from the drop down menu.More About Continuum ExplorerSee the topic, “Continuum Explorer” in the CyberStation online help.Andover Continuum CyberStation HVAC Essentials Guide31

Chapter 2: Configuring an HVAC SystemTask 2: Create a Network and a ControllerA network is a logical organization of controllers that are linked to eachother and have the ability to exchange data.Containers and Parent/Child ObjectsEach network in CyberStation has a hierarchical structure of objects.Many objects can be containers for other objects. For example, anetwork object contains all the controllers in that network.A container object is also called a parent object. All objects within thecontainer are child objects that are “owned” by the parent object. Theserelationships are important for organizing the many objects that makeup a network. They are also significant because you can apply settingsto container objects that affect all the child objects within them.32 Schneider Electric

Chapter 2: Configuring an HVAC SystemCreate a NetworkWhen you configure an HVAC network, the first object you create is thenetwork itself.1. In Continuum Explorer, right click Root, select New, and thenselect Network.2. Enter a name for the network for Object Name, and click theCreate button.3. In the Network editor, enter the Universal Time Coordinate(UTC) offset in minutes for Time Zone.The UTC offset is the difference between your local time andGreenwich Mean Time (GMT). Enter - if local time is behind GMT.Note: “-300” minutes is an example of the Time Zone offset forEastern Standard Time.4. Click OK.Andover Continuum CyberStation HVAC Essentials Guide33

Chapter 2: Configuring an HVAC SystemWeb Configuration for ControllersNetController II devices are commissioned and configured using yourPC’s Internet Browser.IP-configurable NetControllers are shipped with default IP addressesand Subnet Mask values. These values must be changed to new values,which are assigned by your local IT personnel.The default values for all Andover Continuum IP-configurablecontrollers are: IP Address: 169.254.1.1 Subnet Mask: 255.255.0.0Prior to changing these values, the PC being used to commission thecontrollers must be configured to communicate with the controllers.The setup values are: IP Address: 169.254.1.(191-254) Subnet Mask: 255.255.255.01. From Microsoft Internet Explorer, in the Address field, enter thecontroller’s default IP address.The Andover Continuum Embedded WebServer page appears.2. From the left hand menu, select Controller ConfigurationOptions.The Controller Configuration login dialog displays.3. In the login dialog enter: Username: acc Password: acc4. Select OK.The Controller Configuration screen appears.5. From the left hand menu, select Controller Configuration.34 Schneider Electric

Chapter 2: Configuring an HVAC System6. In the Configurable Properties section

These functions include, but are not limited to, security, access control, lighting, heating, ventilation, and cooling. The hardware consists of equipment controllers, network communication controllers and input and output interfaces. The CyberSta