Transcription

Steel HandbookMaterials Reference Book

Dear customerWe hope this book will prove useful to you asa practical steel reference guide. We have alsomade it small enough to comfortably carry aroundwith you. Please just let us know if you would likeadditional copies.Best regards,Stavanger Steel ASStålverksvegen 51N-4100 JØRPELANDNORWAYTel: 47 51 74 34 00www.stavangersteel.noE-mail: post@stavangersteel.noContents of this bookAs well as an introduction to SSA and ourproducts, you will find a lot of useful informationabout steel and stainless steel, corrosion resistance,mechanical properties, heat treatment, welding,casting and forging, testing and standardising.In addition, the conversion tables we haveincluded for units, temperature and mechanicalproperties should be useful too. We have alsopresented an overview of the different steelgrades we supply, and the way they meetinternational and other standards.23

StavangerSteel ASWith our high level of flexibility we can meet allmarket demands with short delivery times andexcellent quality. SSA also offers design andmaterial engineering support provided by highlySSA is part of a long and proud industrial tradition.qualified staff in our technical department.Stavanger Electro Staalverk A/S was establishedSSA organizes the classification and inspectionStavanger AS operated on the same site betweentime. SSA operates a professional laboratoryin Jørpeland, Norway in 1911. Scana Steel1991 and 2015, and now Stavanger Steel AS carries on that tradition as Norway s sole specialized steelworks, and one of Europe s leadingof all components, saving our customers valuableat our production site, which, in addition to beingan important element in our internal quality assurance regime, meets or exceeds the requirements of third party classification agencies.suppliers of forged and cast steel products.We intend to build on this tradition and developBy working closely with reliable partners inand expertise of the company. Our main productall the requirements the market demands. ByNorway and abroad, SSA will be able to meetSSA based on the good standing, performancesegments will continue to be cast and forgedsteel components for a range of different markets.As an exclusive supplier, SSA offers a “one-stopshop” - service to our customers. Through ourcombining over one hundred years of industrialtradition with modern expertise and excellencein all of our activities, we live up to our name– Stavanger Steel AS.partnerships with qualified suppliers we processcomponents from melted scrap steel throughthe entire production process, including heat treatment, machining, NDE, testing of mechanicalproperties, surface treatment and assembly.SSA also offers elements of this process as standalone services.45

Steel propertiesdependson chemicalcomposition andheat treatmentstabilize austenitic structure. Nickel (Ni) is acommon alloying element in stainless steels andis added for stabilizing the austenitic structure.Materials selectionProper materials selection is vital for the lifetimeof the steel. Knowledge about exposure to internalor external corrosive media is a key considerationin making the correct choices. Temperature, pressure, concentration of corrosive media, flow rate,design and physical connection to other materialsare also of crucial importance.Corrosion resistanceBut corrosion resistance is not the only thingIn general terms, steel is said to be stainless whenchromium content is above 10.5 %. Adding moreto consider. Strength, toughness and weldabilityare other important factors. You may find an alloyin our tables of steel grades that meets manychromium, molybdenum and nitrogen furtherof your needs.increases corrosion resistance.Super stainless steel grades may contain 25 % Cr,7 % Mo and some nitrogen, resulting in a PRESSA manufactures a wide selection of forged andcast corrosion-resistant steel alloys. With our wideexperience of many different applications, we canvalue above 40. PRE is an empirical formulahelp you in making the best materials selection.designed for the highest class of stainless steel.Depending on your precise needs, we can alsomanufacture customised steel grades to yourPRE Pitting Resistant Equivalentspecifications. Our highly efficient productionPRE %Cr 3,3 · %Mo 16 · %N.processes enable us to produce anything fromsmall one-off orders to larger batches.Small amounts of Nitrogen (N) have a significanteffect on the corrosion resistance and also67

Mechanical propertiesof stainless steel alloysDuplex stainless steels like S8490 (“duplex”)and S8492 (“super duplex”) have excellentcorrosion resistance combined with high strength,due to their fine grained two-phase structure.Mechanical properties are a consequenceof material structure and are determinedMartensitic stainless steels like S134M andby the type and amount of alloying elementsS165M are tough even though they have beenand subsequent heat treatment. Stainless steelhardened to a high tensile strength of 800-1,000alloys may be grouped into hardenableMPa. The tempering temperature is vital for(martensitic) and non-hardenable (austeniticstrength and toughness. Higher temperatureand duplex) structures.increases toughness and decreases strength,and vice versa. SSA will be pleased to help youAustenitic stainless steels like SSA gradesfind the optimal properties for your application.S316L / S128MIIIsuper have low yield strength,although their hardness and strength can beincreased by adding Cr and Mo (6Mo steel).Austenitic steels are very ductile and tough(impact test at -196 C) and are non-magnetic.89

Heat treatmentarranged by typeSolution annealing describes heat treatmentExcept from billets in some grades steel productsstructure with no detrimental precipitation thatused for austenitic and duplex steel alloys.By heating to about 1,000 -1,200 ºC followed bynever leaves the SSA plant without having beenheat treated, because this is vital for achievingrapid cooling, the alloy will have a homogenousmay cause reductions in corrosion resistanceor toughness.optimal physical properties. Below, you will findan overview of the most common types of heatStress relieving is performed to reduce stresstreatment in steel production:after non-uniform shrinkage caused by cooling,or after welding. Welding causes a localNormalising is a heat treatment performedon carbon-manganese steel by heating to about900 C and cooling in air. The micro structureis named ferrite-perlite. Stress-relieving at about600 ºC for reducing stress after welding to casttemperature rise close to the weld, which resultsin localised expansion followed by shrinkageas the metal cools. This can cause the steelto deform or cracks to appear due to localisedstresses. Stress relieving evens and reducessteel will not affect the structure of normalizedthis stress. It also reduces hardness in thesteel, but will temper hard zones (HAZ) aroundheat-affected zones in the base material closethe weld deposit.to the weld deposit, creating a tougherweld connection.Quenched and tempered (QT) describesa two-step heat treatment process: first heatingAging is also known as precipitation hardening.to about 900 ºC and then fast-cooling in wateror polymer emulsion. The next step is the tempering, with the temperature depending on the steelgrade and the specification of hardness/strengthand toughness. In general terms, low temperatureis used to achieve high strength and low toughness,and vice versa. High alloyed hardenable steel maybe allowed to cool in oil or air to harden.For some stainless steel grades (e.g. 17-4 PH)and some Nickel base alloys (Alloy 718) agingby heat treatment is required. This is a two-stepprocess were the alloy is firstly solution annealedfollowed by rapid cooling, and then held at anelevated temperature for some time to producefine dispersed precipitates (particles that increasesstrength).Solution annealing describes a heat treatment1011

Below, you will find some steel alloys groupedby structure:Carbon steel grades as well as martensiticstainless steel grades are quenched andtempered (QT), gaining a tempered martensiticstructure. The mechanical properties aredepending on the tempering temperature level.Low tempering temperatures result in highstrength/hardness but less ductility andtoughness. On the other hand, high temperingtemperatures result in less strength/hardness butincreased ductility and toughness. (ToughnessHeat treatment arrangedby micro structureis measured by Charpy-V impact testing in Jouleat a specified temperature).SSA supply a range of different stainless steelalloys. Most of these alloy steels require veryspecific and carefully managed heat treatment toobtain the required quality and material structure.SSA has extensive capacity for isothermalannealing, normalising, stress relieving, hardening, quenching and tempering of steelproducts. Furnaces are calibrated according toThanks to their excellent hardenability properties,martensitic stainless steel grades can beNorsok M-650 / API 6A Appendix M.hardened by air cooling. Depending on yourAll heat treatments are documented by graphs.specifications, tempering is an ideal way toachieve the strength and toughness you need.1213

Schaeffler diagram forprediction of structureWe can predict the structure of steel usingchemical analysis. The diagram below has beencompiled on the basis of many tests, in whichmelted steel alloys were rapidly cooled to roomtemperature (simulating a welding deposit). TheDuplex stainless steel grades are quenched,structure is defined by metallographic testing.but are not hardenable by quenching. Theirhardness, strength and toughness are achievedThe diagram is like a “map”. Mapping the percen-and their small grain size. Heat treatment in thishorizontal (Cr) and vertical (Ni) axis will provideby the combination of austenite / ferrite structurescase is solution annealing at 1,000-1,130 ºC, withrapid cooling in water to achieve corrosionresistance and the correct ferrite/austenite ratio.tage of actual elements into the values on theyou with digits to plot into the diagram, givingyou an estimate of the steel’s structure. (ref. 316)Nickel equivalent % Ni 30 · %C 0,5 · %Mn 30 · %N302826Austenit240%Ferrrit6MO5%10%222018316A M1620%40%14A F1210Martensit8S3556Austenitic steel grades are solution annealed40in water to achieve excellent ductility, toughnessand corrosion resistance.024680%A M FM F2at 1,000-1,280 ºC followed by rapid coolingDuplexS165M8Ferrit10 12 14 16 18 20 22 24 26 28 30 32Chrom. equivalent % Cr 1,4 · %Mo 1,5 · %Si 0,5 · %Nb 2 · %TiType and amount of alloying elements are decisive for the structure of the steel.1415

SSASteel productionand productsAOD-converter with a capacity of approximately17 tons. The small heat size and sophisticatedrefining process in our melting shop enables usto produce small heats of grades with customerspecified chemical analysis, that may deviate fromstandard grades or have narrower limits than standard grades. For the production of our StrømhardMelting shopgrade, we utilize a furnace with a capacityThe production is scrap steel based. The scrapIngot dimensionsof approx. 6 tons for both melting and refining.is graded into different classes according to typeand amount of alloying elements. The scrapis melted in an EAF (electric arc furnace), andrefined by an AOD (Argon-Oxygen- Decarburization). By adding different alloying elementsto the molten steel, the desired steel grade canbe produced.The process in the AOD includes reducingthe content of carbon, impurities and dissolvedgases. Controlled nitrogen alloying for ingot(mm)Form(4-8-12 2516608362008306801898122122001100900217081alloyed steel grades is also performed in theAOD converter.Our steelworks is well known for its ability tomanufacture a wide range of high quality low-alloyed, high-alloyed and stainless steel grades.For most of our grades, we utilize a furnacewith a capacity of approximately 12 tons and an1617

Cast or forged steelManufacturing steel is a lengthy process.It begins at the melting shop, where steel meltsare produced in electrical furnaces, and finishingrefining and alloying process in an AOD converter(AOD Argon Oxygen Decarburisation).Steel alloys intended for forging are first castinto ingots. In the forging plant, ingots are heatedto make them ductile for hot forging.If the product is too complex for forging, castingmay be an alternative.Forged steel products are normally more fine-grained compared with cast steel. This may bereflected in the improved mechanical propertiesof forged steel.Due to the different requirements that apply tothe mechanical properties, cast and forged steelneed to meet separate steel 8614071428144914691490C̊EmptyTemperatureY1819

Forged stainlesssteel productsSSA forges different product forms as flat,The forge heats up the ingots to forgingDimensions limited to SSA ingot sizes andsquare and round bars and shafts, and also billets(semi-forged products).temperature. Manipulators then collect the ingotsin the furnaces and bring them to the 1,600tonnes forging press. Here, the products areforged according to the customer’s specification.The products are delivered to our customersrequired reduction grade.Equipment: 1600 t hydraulic free – form press. 6 t forging manipulator.as forged, rough machined, finish machined, or Forging furnaces, gas fired/regenerator burners.grinded billets for further forging, milling, etc.Steel grades:SSA manufactures forged products in stainlessDuplex, super-duplex, austenitic, super-austenitic,steel alloys like duplex, super duplex, austeniticferrittic/martensitic.and martensitic hardenable stainless steel.The ingots are heated up to forging temperaturein the gas-fired furnaces. Furnace temperature iscontrolled, monitored and linked to the computersystem in the forging press. The normal forgingProducts:Round, square and flat bars. Shafts. Round,square and flat billets for further forging/rolling.Other forge products. Dimensions according toingot sizes and reduction requirements.temperature is 1,150-1,250 ºC.2021

QT-steel, manganese steel (Hadfield-steel)for stone crushing, and different stainless steelgrades like duplex, super-duplex, austeniticand martensitic stainless steel. Examples ofapplications for stainless steel products in themarine industry include propeller blades andpropeller hubs, while we also make bodies andparts of pumps and valves for the oil industry.For the chemicals, turbine and wood processingindustries, we manufacture turbine and pumpCast steel productsbodies and parts, impellers, paddle wheels,Casting is a complex process. Working fromSSA also produces steel grades for high-wearwelding flanges and rings.the customer’s specifications, drawings are thentransferred to computer programmes (Solidpurposes, like stone crushers. Alloying elementsin the range of 12-20 % manganese (Mn) andedge, Magmasoft etc.) that help us to assess0-3 % chromium (Cr), often referred to asissues like slip angles, oversizing to allow forHadfield-steel. The steels are initially austenitic,shrinkage during solidification, and where to putchills, feeders and inlets. Working with the resultswe get from this process, the wooden or plasticpattern is then designed and physically finished.but harden effectively via cold deformationwhen in service; an example of this is SSA's“Strømhard” grade.SSA delivers castings in low-alloyed steelThe pattern model is placed into a framefor onshore and offshore purposes, includingand buried in sand mixed with binding agent.nodes for offshore platforms, parts for buoyThe quality of the moulding depends heavily onthe consistency of the sand, good craftsmanshipand the correct casting temperature.mooring systems and pad-eyes. Structural steelcomponents are alloyed to achieve goodweldability.SSA supplies a wide range of cast steel products,including carbon-manganese steel, alloyedOur foundry is well known for high-qualityproducts and our ability to produce complex2223

Linear dimensional tolerancefor dimensional casting tolerancegrade (DCTG)cast products using a wide range of stainlessand structural steel grades. This steel requiresa high level of competence throughout themanufacturing process, which is where webenefit from having all the necessary processsteps in-house. These include casting methoddevelopment and simulation, pattern shop,NominaldimensionsDCTG12DCTG 13 DCTG 14 DCTG 15related to themoulded part (mm)moulding, heat treatment, upgrading/welding,machining and NDE. This allows us tocontrol the entire production process, fromthe melt and engineering to the finished product.Patterns: wood or plasticMould system: chemically bonded Olivinesand and Sodium Silicate Ester.Unit weight: 500 – 10,000 kgto 10 mm4,2---10,1 – 164,4---16,1 – 254,6681025,1 – 405791140,1 – 635,68101263,1 – 100691114100,1 – 1607101216160,1 – 2508111418250,1 – 4009121620400,1 – 63010141822630,1 – 1000111620251000,1 – 1600131823291600,1 – 2500152126332500,1 – 4000172430384000,1 – 6300202835446300,1 – 1000023324050According to NS-EN ISO 8062-3:20072425

Required machiningallowance grade (RMAG)The nature of castingsCasting is a complicated process. About 1,500 Cmolten steel is poured through a ceramic inletsystem into sand moulds which depending on com-Largest overallRMAG HRMAG JRMAG Kdimension (mm)plexity and wall thickness may cause impurities like2porosity, sand or slag inclusions. This is the natureto 40 mm0,7140,1 – 6311,4363,1 – 10022,84100,1 – 160346160,1 – 25045,58250,1 – 4005710400,1 – 6306912630,1 – 100071014Production welding of steel castings1000,1 – 1600811161600,1 – 250091318According to ISO 11970 the definition of Production2500,1 – 40001014204000,1 – 63001116226300,1 - 10000121724tion according to accept levels stated in standardsand specifications. The imperfections are removedby arc gouging and/or grinding, and welded according to WPS (Welding Procedure Specification).welding is “any welding carried out during manufacturing before final delivery to purchaser includingjoint welding of castings and finishing welding”.“Welding procedure tests shall be carried outaccording to this standard, unless additional testsAccording to NS-EN ISO 8062-3:2007are specified by the purchaser or by agreementbetween the contracting parties.”Fillet radii of cast productsWelding is carried out according to WPSs whichrefer to 3rd Party approved WPQR’s tested accord-ing to standards and specifications required for con-According to experience fillet radii of caststruction welding like ISO 15614-1, ASME IX, AWSproducts should be in proportion to the castD1.1, NORSOK M-101 or Classification Companiesthickness to avoid local cast defects:Cast thickness (t) in mmFillet radii (r) in mmt 25 mmr t25 t 75r 25 mmt 75r 1/3 tof many castings. A purchaser will require rectifica-standards and specifications.SSA welders are tested and certified accordingto ISO 9606-1, and are approved for weldingSSA steel grades according to WPS. SSA has implemented quality procedures and instructionse.g. for handling of consumables and heat treatment according to relevant standards.2627

WeldabilityTo calculate the preheat temperature, the weldingengineer needs to know the expected heat inputIn specific terms the weldability of carbon-(Q) calculated from the formulae:manganese steel grades, the CE factor used inpreheat calculations contains chemical elementsincreasing the hardenability of the steel:CE %C %Mn6 %Cr Mo %v5 %Ni %Cu15Q U·I·ĸv · 1000U voltage, I electric current,v welding speed (mm/s) andĸ welding factor (efficiency).Preheat temperature is defined as the localisedtemperature of the base material at the pointwhere you start welding. After a few weld passes,the steel will be hot, and we may have to waitfor the temperature to decrease to the maximuminter-pass temperature before proceeding.In addition, it is necessary to consider localisedhydrogen content (moisture, oil, grease, dust)as well as the thickness of the steel.Welding procedure approval starts by makinga pWPS (preliminary welding procedurePreheating is performed to control the hardnessspecification) for the welding test.in the HAZ (Heat Affected Zone).Excessive hardness may cause reduced ductilityand toughness, or even hydrogen cracks.The welding parameters are logged duringthe welding sequence. The welded test piece iscut into test samples as required, and the testingmay be witnessed by a third party. All test resultsand welding parameters are recorded in aWPQR. The welding engineer provides a WPS(welding procedure specification) for the job orrepair, with reference to the WPQR no.WeldDepositHeat Affected Zone (HAZ)28Base Material29

Quality Controlof productsTesting ofsteel gradesSSA QC department is performing destructiveChemical analysis of ladle (steel melt) and, ifcastings according to relevant standards and1/1000%, documented in the material certificate.and non-destructive testing of forged products and specifications.NDE: Visual (VT), Penetrant (PT), Magnetic powder(MT), Ultrasonic testing (UT)DT: Tensile testing, Impact testing, Bend testing,Hardness testingStructure: Metallographic micro- and macro testingCorrosion: Testing according to Standard testspecified, product analysis to an accuracy ofTension test for measuring yield strength (YS),tensile strength (TS), elongation (A) and reductionof area (RA). Yield strength is often calledRe or Rp 0.2, tensile strength Rm, elongation A,and reduction of area Z.Hardness test, Vickers (HV), RockwellmethodsChemical: Spectrograph analysis for all relevantelements(HRB (ball)), HRC (cone)) or Brinell (HB).Impact test is most often required for hardenableand duplex steels. The measuring unit used is theSSA Technical Department adds value to the testingprocess through high metallurgical competence andlong experience.Joule, and always refers to test body temperature.Test bodies are normally Charpy-V (KV).Corrosion test will be performed if required forhigh alloyed stainless steels (e.g. ASTM G48).NDT (None Destructive Testing) is performedduring the manufacturing process and on finishedproducts, before shipping to the customer.Ultrasonic testing (UT), Magnetic powder (MT),Penetrant (PT) and Visual testing (VT).SSA steel grades are tested eitherby s tandardised methods, or as requiredby the customer.3031

Hire WorkHeat treatmentfurnacesSSA offer hire work like forging, heat treatment,testing, machining and documentation, or partsof this process. Normally including low-alloysteel grades like F22, AISI 8630, AISI 4130/4140,NrWorkingzone-mmTemp. range – CCapasity-T1102000X1300X8300560-115016AISI 4330 etc. All these steel grades will 50X5040470-114017Heat treatment furnaces calibrated 90470-1060152010 / ISO 10423:20091441400X900X5540560-106015purchased from other steel works by SSA or theto Norsok M-650 ed. 4, Appendix B, and API 6A:Size of Quenching bath/water: Length 8000/Width 4000/Depth 2000mm. Pump agitation.3233

MaterialdocumentationSour ServiceAll products are delivered with an inspection"sour service" requirements as specifiedtesting, corrosion testing, etc. Inspection documentsE.g. for carbon and low alloyed steels this impliesthe 3.1 certificate issued by SSA, or the 3.2of 1 % Nickel (Ni) content.If required by Customer, many of our steelgrades can be delivered according to certificate containing test results from mechanicalin ISO 15156/NACE MR0175.are produced in line with EN 10204, and includea maximum hardness of 22 HRC and a maximumcertificate when third party certification is involved.For high alloyed and stainless steel gradesEnclosed a typical inspection certificate.INSPECTION CERTIFICATECustomerCert.no.Page: 1 of 1Stavanger Steel ASStålverksvegen 51NO - 4100 JørpelandNORWAYINSPECTION CERTIFICATECustomerPO No:Specification:Marking:EN 10204 - 3.1SupplierC143/17Date: - 3.1EN 10204SupplierCert.no.Stavanger Steel ASStålverksvegen 51NO - 4100 JørpelandSupplier order no:NORWAYSupplier work-order no:BSA-2017-0005S20017 T14605 001931.03.2017C143/1760016.4000Date:Ø330,2 mm barsrough machined condition31.03.2017ASTM A182 F55,ASTM A276/A479 UNS S32760, EN10088.3 1.4501NACE MR0175-200060016.4000Grade:PO No:BSA-2017-0005Notes:Specification:Marking:S20017 T14605 0019CERTIFIED CERTIFIEDCOMPOSITIONGOODSCHEMICALTestC No Si WeightMnNo. 0,019 0,27 (kg)0,54Supplier order no:Supplier work-order no:DimensionSPCr0,001 0,027 24,98Ni7,27HeatV TreatmentMoCuW0,600,053,55Al0,0100,55Solution annealed 1130 C, 5hrs ;T146051 PROPERTIES453413"ASTM A370WaterMECHANICALTensile test,4 -8 C Rp1.0Test no Sample IdPosDirectionDim. [mm] CoolingTemp temp.Rp0.2 C[MPa][MPa]CHEMICALCOMPOSITION14605TL-5T/6,max ,0010,02724,987,270,60MECHANICAL PROPERTIES Impact test ISO 148MECHANICALPROPERTIESASTM A370Test no SampleIdPosTensile test,DirectionDim. [mm]Test no Sample IdPosDirectionDim. [mm]1460514605IL-5BTL-5T/6,max 50mmT/6,maxss50mmss 50mmT/6,maxLoLo12,50,053,55TempTemp C -60C230,550,010-EAF AOD, ingot casting and4,63 : 1S20017forgingTensile strengthElongationRed.HardnessRm [MPa]A4 %[Z] %HBSSA76grade: 27C0 241S450175839N0,23795J7595T/6,max50mmLoMICRO-7933- 01ss14605TREATMENTIL-5T/6,max 50mmLoHEATssLOT-12304-01Ref. report:Ref.report: -60-110MICROSTRUCTURE EXAMINATIONADDITIONAL INFORMATIONMICRO-7933 - 01Ref. report:CORROSION TESTRef. report:Co0,071,12%Lat.Shearexp71 CORR-13860,74- 01-46-SSA grade: 27C0 S4501ForgingCharge No.ratioCo ProcessPRE0,0740,48N0,237PRE40,48J%Lat.J%Rp0.2 ShearRp1.0exp Tensile strengthShear[MPa]Rm71- [MPa]0,7475 [MPa] 56975814605IL-5Lo-46110ssMECHANICAL PROPERTIES Impact test ISO 148Test no Sample IdPosDirectionDim. [mm]TempJMICROSTRUCTURE EXAMINATIONCORROSION CTEST14605Ref.report: IL-5B1700019Ø330,2 mm barsrough machined conditionProcessForgingCharge No.ASTMA182 F55,ASTM A276/A479 UNS S32760,ratioEN10088.3 1.4501NACEingotMR0175-2000EAF AOD,casting and4,63 : 1S20017forgingCertified goods:Heat TreatmentGrade:Solution annealed 1130 C, 5hrs ;WaterCooling temp. 4 -8 C13"1,12-Lat.J%ElongationRed.expShearA4 % 63 [Z] % 0,7939761,05%Lat.NDTShearexp- J]70-1,1105Ref. report:Smi-9809-01HEATTREATMENTTest locationfrom a prolongation of the bar after heat treatment.LOT-12304-01Ref. report:PT and UT carried out . Report attached.Corrosion testing carried out .Report attached.Microstructure INFORMATIONexamination carried out .Report attached.ADDITIONALsuper-duplex stainless steel.Classification companiesSSA is approved by Det Norske Veritas (DNV GL)Steel Castings and Forgings, Bureau Veritas (BV)and Technisches Überwachungs Verein (TÜV) formanufacturing steel and stainless steel products.Bureau of Shipping (ABS) is an ongoing process.ISO 9000 and 14000Testedwith Geiger-counterand arefoundbe freeradioactive contamination.Testlocationfrom a prolongationof thebartoafterheatfromtreatment.PT and UT carried out . Report attached.Corrosion testing carried out .Report attached.Microstructure examination carried out .Report attached.SSA is approved for and maintains ISO 9001 andTested with Geiger-counter and are found to be free from radioactive contamination.ISO 14001 certification.We hereby declare that the product supplied are in compliance with the orderin which test results are supplied.Manufacturer's authorized representative:SSA is a qualified manufacturer of duplex andLloyds Register of Shipping (LRS) and AmericanNDTCORR-1386 - 01ApprovalsNorsok M-6501700019Certified goods:this often implies an extra heat treatment.Page: 1 of 13.party representative:We hereby declare that the product supplied are in compliance with the orderin which test results are supplied.Stavanger Steel AS, Stålverksvegen 51, NO-4100 JØRPELAND, NORWAY,Org. NO 917 466 564 MVA, Tel: 47 51 7434 00,www.stavangersteel.noManufacturer's authorized representative:3.partyrepresentative:Stavanger Steel AS, Stålverksvegen 51, NO-4100 JØRPELAND, NORWAY,Org. NO 917 466 564 MVA, Tel: 47 51 74 34 00, www.stavangersteel.no3435

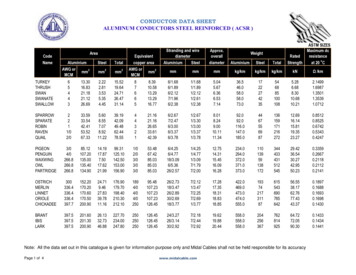

D 256125SE260066007SSA NameSSA no.-A167A890 5AA890 4AA743 CF3MA743 CF3A743 CB6A743 CA6NMA743 CA6NM---A128 gr.AA532 II B 15 % Cr-Mo----A148 115-95A148 90-60A27 70-40A216 -630 MDS D56M-630 MDS D46M-630 MDS S02----------M-122 Grade 460M-122 Grade 420M-122 Grade 310--M-630 MDS C12M-630 MDS C02NorsokCast steel grades – Chemical analysisSSA0,250,09 0,03 0,03 0,03 0,03 0,05 0,05 0,061,481,421,251,202,70 0,30 0,14 0,14 0,140,200,25 0,20 00,800,851,501,451,101,000,601,200,65Mn- 5,5020,009,0021,00 11,0025,5022,0017,50 12,5018,5016,2013,5012,502,802,40 0,75 0,75-15,000,40 0.50 0.20 0.200,651,05 0,15 050,050,040,010,010,010,010,020,030,030,03Max. S Max.

a practical steel reference guide. We have also made it small enough to comfortably carry around with you. Please just let us know if you would like additional copies. Best regards, Stavanger Steel AS Stålverksvegen 51 N-4100 JØRPELAND NORWAY Tel: 47 51 74 34 00 www.stavangersteel.no E-mail: post