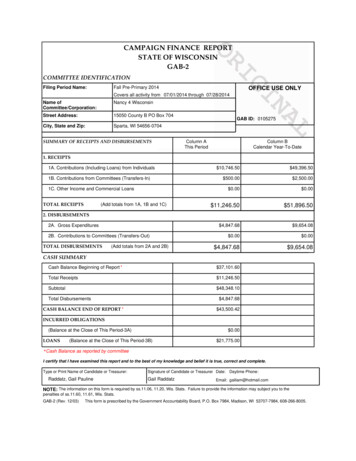

Transcription

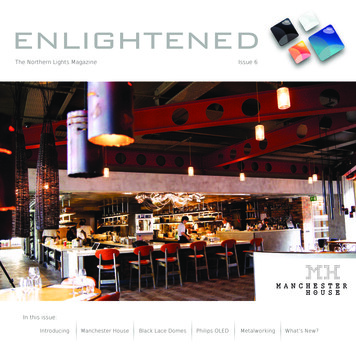

enlightenedThe Northern Lights MagazineIn this issue:IntroducingManchester HouseIssue 6Black Lace DomesPhilips OLEDMetalworkingWhat’s New?

Contents246101416182023enlightenedIntroducing:Meet the new members of the Northern Lights team including our new Managing DirectorProject Focus:An in-depth look at Manchester HouseProduction Focus:A four metre diameter fret-cut ‘lace pendant’ for Izel in the Conrad Hotel, DubaiSupplier Spotlight:Philips show you the future with OLEDFactory Feature:We take a look at our in-house metalworking team and how they turn your ideas into realityNorthern Lights in Dubai:A look at how we are working on projects in DubaiWhat’s New:Highlights from Light Building 2014 and a new finishing techniqueLighting Trends:Our Technical Lighting Design Manager Michael Jackson on new lighting trends

WelcomeFirst of all we would like to apologise for the delay insending out this, our latest magazine. We have hardlyhad time to think since our return to work after theChristmas holidays. The whole year has gone by in ablurWe ended 2013 on a high note with like for like salesfor the last 6 months of the year increasing by 28%.2013 started out looking like it was going to be atough year but there was a dramatic upturn mid-yearleading to a really positive end of year and start of2014. As we rapidly approach the middle of this yearthe positive outlook continues and we are as busy aswe have ever been.It’s almost 27 years now since John and I startedNorthern Lights and we have now decided to takemore of a back seat handing over the day-to-dayrunning of the company to Paul. We will both remainas shareholders and will still be involved, albeit a bitmore removed than we have been. We are bothlooking forward to having more free time to pursuepersonal interests but our main interest will alwaysbe Northern LightsWe are all very positive about the changes and arelooking forward to the potential opportunities thatshould ensue.We have some exciting projects on at the momentincluding a complete refurbishment of our officeswhich have been sadly neglected over the last fewyears. The staff are really excited about the newdesign and have promised to make more of an effortto keep it tidy!We’re also in the process of updating and refreshingour traditional catalogue as well as working on a newhotel / restaurant catalogue. We are currently lookingat some great new products for both catalogues andwe’re sure that you will find these interesting.It has indeed been a while since our last edition andthis is partly due to some exciting organisationalchanges here at Northern Lights, the most exciting ofwhich is the appointment of a new ManagingDirector, Paul Wade. Paul joined the company in Apriland you can find out a little more about him overleaf,along with some of the other people who have joinedour growing team.Frances ConlonDirectorNorthern Lights (Chesterfield) LtdJohn FlemingDirectorNorthern Lights (Chesterfield) Ltdenlightened3

Paul WadeIntroducing.Northern Lights new Managing DirectorI am delighted to join the team at Northern Lights. The company hasbeen designing and manufacturing wonderful decorative lighting for ahuge variety of customers for over 25 years and John and Frances havecreated a very sound base from which to grow. I look forward tocontinuing to work with them both over the months and years to come.I would like to build on these firm foundations by continuing to find waysof offering the combination of quality and flexibility that our customershave come to expect - speed and strength of response has never beenmore important and we will be building on our already strong reputationfor great service.This ability to respond is helped enormously by our UK manufacturingbase here in Chesterfield. Manufacturing is important to the UK economyand vital to our local area here too, and whilst clearly we need strongmanufacturing supply links in other parts of the world, there is little moresatisfying than seeing a high quality light fitting designed, manufacturedand shipped from a factory in the UK - long may we continue to fly theflag!As I get to understand the business more, much of my time will be spentmeeting customers and working with you to understand what you needfrom Northern Lights, so that we can make what we offer even better.I look forward to meeting you - however until then I am contactable viaany of the channels under my photo - if you would like to, please do nothesitate to get in touch.Finally, thank you for your support of Northern Lights. we appreciate it!Paul WadeManaging DirectorNorthern Lights (Chesterfield) Ltd4enlightenedContact Tel: 01246 858 750Mob: 07792 782 563E: paul.wade@northern-lights.co.uk

Introducing.Allan Terry our newLighting DesignerAllan joins our talented lightingdesign team. Allan is an LIA(Lighting Industry Association)certified designer with extensiveknowledge of materials andmanufacturing techniques.Using his various productdevelopment skills, especially in3D product modelling, he hasalready worked on some inspiringand challenging projects such asthe new installation at The MarriottHotel - Paris, transforming theclient's vision in to a stunning lobbycentrepiece.Introducing.Katy Walker our newInternal AccountManagerKaty joins us as a Trainee InternalAccount Manager strengtheningour very busy Sales Team.Katy is already overseeingprojects from the first quotethrough to despatch for brandssuch as PizzaExpress and is also providing administrativesupport to the rest of the sales team on large scale hotelprojects.With her outgoing personality Katy has already madequite an impression within the sales team and we lookforward to seeing her continued success and progressionwithin the Northern Lights team.Introducing.Mark Watson our newFabrication AreaSupervisorMark has joined our manufacturingteam to oversee the craftsmen inour fabrication departmentconcentrating mainly on thesheet metal area.Mark brings with him over 30 yearsexperience in the production of bespoke metalworkoperations and has already started to implement newworking proceedures and guidelines, ensuring the smoothtransition of fittings from the drawing board through themetalwork department.Introducing.Bina Lakahni our newAccounts ClerkBina has recently joined theAccounts Department. She will beresponsible for all our day-to-dayaccounts and payroll.She brings over 20 years ofaccounts experience and a happydisposition to the job.Introducing.Colton Lee our newTechnical IT SupportColton joins our IT Departmentand will help maintain our ITsystems and improve ourin-house technical programming.enlightened5

When you approach Tower 12 inSpinningfields Manchester, it lookslike a very normal city tower don’tbe fooled. Inside lies a very specialexperience for both food lovers andlovers of a life with a view. Twostunning independently differentenvironments. The Restaurant byAiden Byrne on level 2 and theLounge on level 12.Welcome to Manchester House.Manchester House is the joint creation of Aiden Byrne,the youngest chef ever to win a Michelin star and LivingVentures, the operator of some of the most excitingbrands in the UK restaurant and bar market. The projecthas two areas, a restaurant on the second floor and alounge bar at the top on the 12th floor with apanoramic view over Manchester. In the restaurant areathe interior design and brand consultancy Keane Brandscreated a very individual space by mixing metal beamswith modern upholstery and contrasting strikingcolours with a muted background colour. Workingalongside Keane Brands, Northern Lights supplied awide range of decorative lighting.From minimalist barelamp ceiling lights at the entrance to the dramatic fibreoptic ceiling feature at the Chef's Table to pendantsusing wicker shades, they all work together to enrichthe unique dining concept of Manchester House –making fine dining accessible.6enlightened

Fibre optic chandelierA loom of 240 end illuminatedfibre optic strands form the coreelement of this feature locatedabove the Chef’s Table. The fibrescurve gracefully from the centreof the framework to each ofthe 20 articulated dishes wherethey conclude as pinpoints oflight.Private dining pendantAn interesting example of acollaboration with a third party:we don't just wrap shades inspecialist fabric. We supplied theouter shade frame for thispendant which was wrapped inLara Vose Elegant Cluttermaterials, which also featured inother areas on site.“Manchester House lives it upin a kind of dressed downway. Fine cooking served inan informal, fun and funkyway. For us it’s about thecustomer loving their timewith us. Eating well, tryingnew things and enjoying abit of what they love.We also thought it was vitalthe place had a properdrinking bar too, so you canpop in whenever you’re intown, whether you want toeat or not”Aiden Byrne - Head Chef

“Northern Lights - they weregreat to work with becausethey realised my creativeintent. I found them verysupportive and it was great towork with a company that areso design literate.”“They were able to understandthe vision and were great atnailing down the detail andwere not prepared tocompromise.”“The brief was not easy.I needed them to help createan ambience of honey colouredsoft lighting, which wouldcounteract the grey drizzle ofManchester and they deliveredon this in a short period of timeand on budget.”Tim Merrifield, Head of Interiors at Keane Brands8enlightenedThe honeycomb lattice light raftThe feature light is a merging patternarray of hexagonal profiles with lampdrop centres located at the patternintersections. The intended ‘rust’ effectfinish and exposed lamps emphasise theraw industrial style intended for thisspace.Scaffold pole lamp featureTo accentuate the industrial themescaffold poles from a construction sitewere employed for this luminaire.Bespoke hand-made frame enclosureswere formed to house decorativefilament lamps, suspended from anarray of coloured braided flexes

The lounge and privateterraces on Floor 12 havethe look and feel of amovie star’s pad. It’s slick,monochromatic dramaticand designed to bedecadent, with wowwraparound views ofManchester. Make it yourCity address every day.The Bullrush featureThe bullrush feature is a complex jigsaw assembly offloor plates which interlock and follow the profile ofthe external seating area. It was necessary to havebespoke fibre optic projectors manufactured toindividually illuminate the 'bullrushes' to eachsectional unit. The fibre strands are threaded throughthe plates and the corresponding hand-formed tubestems. Each strand has a glass end optic whichpunches light into the glass globes, highlighting thedelicate internal glass strands within the spheres.Client: Living VenturesInterior Design: Keane Brandsenlightened9

Izel, Conrad Dubai -The Stunning Black Lace PendantAnother prestigious site enhancedby Northern Lights bespoke fittingsWe were tasked with supplying custom made public areafeature lighting and pendants for the Izel Restaurant and Bar;a place to 'dine and enjoy authentic Latin American flavourswhilst embracing the energy of authentic Latin beats in thelargest supper club in Dubai'.Working with Vann FID Interiors, we were asked to create ascheme to engineer lighting solutions fitting to the brand andsurroundings. Decadent and opulent finishes were essential tocomplement the five star environment, so we focused on handfinishing most items, especially the rectangular wall lights tothe back bar. We combined a gold leaf panel with a handrusted steel to give a stunning contrasting effect. These walllights were back-lit with dimmable LED strips which providedevenly distributed illumination to the wall. This option is longlasting, energy-efficient and allows control with electronicdimmer systems.The largest, probably most impressive feature is the hugefretwork dome pendants. We supplied three domes in total two with a 3Mtr diameter and one with a 4Mtr diameter - whichwere suspended from gold leaf coffer areas. Northern Lightsdon’t just manufacture lighting. In fact these feature pendantsdid not require any integral lighting, just a decorative structurewas required to enhance the coffer areas. On the specificationdocument, we were supplied with a brief of: 'Circular domeshaped chandeliers with lace pattern in black resin', and givena sample image of the pattern to use. We were then left tocome up with proposals for what we could achieve within thelead time specified. Our design team applied their skills toengineer the large domes to appear as delicate as possible, butwith the structural integrity to be safely suspended on site.Gold leaf and rust wall lightenlightened11

We explored a vast range of options to create thedomes: the main problem was creating a rigid shape.We could not produce within budget a totally ‘domed’structure, as this would involve complex formingtechniques, possibly fibreglass. Our in houseworkshop is better suited to metalwork fabrication, sothe possibility of a steel/aluminium structure wassuggested and we set about splitting up the shapeinto manageable sections that we could laser cut, roll,and weld together.We knew the material would have to be thick enoughto maintain rigidity, but thin enough to be a weight12enlightenedthat could be suspended. Our 3D CAD softwarehelped us estimate the total weight of the structure todetermine what would be appropriate and weproduced a full size prototype section to evaluate therigidity. Initially, the client was concerned that theshape would look too ‘bulky’. We reduced the amountof support ribs to the smallest number and thethinnest possible width to create the shape. Weldingthree sections of rolled fretwork together with supportribs at each end. The support ribs ended up beingapproximately 40-50mm wide – minute consideringthe vast overall size.

enlightened13

The Future.Available now!Luminescent carpets and ceilings. Windows thatprovide bright daylight even when it's dark outside.Glimmering luminescent clothes. When designersand scientists start talking about organic lightemitting diodes (OLEDs), their creativity knows nobounds. Indeed, the future holds in store infiniteways of using OLEDs. But even today, theseultra-flat light sources have already raised light toa brand new level.The OLED is just setting out on its journey to fameas a new source of light. It is set to completelytransform the way in which we perceive light,allowing new and exciting applications to see lightof day, which were, until today, only a figment ofour imagination.“Lumiblade OLEDs willrevolutionize the designand atmosphere of livingand working spacesLighting will fit perfectlyinto its setting.“

OLEDs benefits at a glance:OLEDs are the first full surface lightsource ever and are blend freeOLEDs do not get warmer than 30degrees and need no coolingOLEDs are very thin - between 0,7 mmand 1,8 mmOLEDs provide a beautiful, all-roundhomogeneous lightOLEDs are extremely energy-efficientand energy-savingOLEDs are free from harmful substancesand are re-usableHere at Northern Lights, weare extremely excited aboutPhilips OLED and the designopportunites it presents.We are looking for aninnovative designer to workwith on our first PhilipsLumiblade OLED luminiareproject.If this collaborationopportinuty excites you,please get in touch

FactoryFocusMetalworkingAn essential part of your bespoke lighting manufacture.This time in ‘Factory Focus’ we’re going to take a look atwhat we consider one of the most crucial aspects of whatwe do here at Northern Lights - metalworking.Most of our customers don’t realise that we have over 30skilled metal workers based in our Chesterfield factory.These are the people who cut, bash, bend and weld themetals we use to produce our fantastic bespoke lightfittings and features.Metalwork was one of those subjects some of you willremember taking at school where you learned how to workwith and manipulate various types of metal, hopefullyending up with a useable item at the end of your course.We are going to reveal some of the materials andprocesses that we use here at Northern Lights whenturning your design drawings into real world light fittings.As you may already know, the main types of materialswe are able to work with are metals such as mild andstainless steels of various grades (including marine gradesfor outdoor areas), brass, copper and aluminium.Each of these materials gives unique properties to afitting but also can bring with it issues to watch out for.An example would be cross contamination of mild andstainless steel - meaning that we have to keep two setsof tools, one for working in mild steel and one forstainless steelWe’ll now run through some of the processes used in thefactory during the manufacture of your light fittings andbespoke features.Before any assembly work takes place (such as welding)you may need to cut the materials. This is done witheither manual or automatic saws for things like solid bars,flats and tubes or large industrial guillotines for cutting16enlightened

sheet metals into manageable sized parts. We might need to roll materials toform simple curves or complete circles - this is done using the appropriatesized industrial rollers. We can roll most types of materials - tubes, solid barsand sheets.You may also need to put holes into sheets or flat bars and we would do thisusing one of our punching machines. With these machines we have varioussets of punches and dies that allow us to punch almost any size and shapeholes. We also use a ‘notcher’ which lets us remove the corners from sheetmaterials to allow them to be formed into pans and boxes.Once you have your component parts completed and rolled or formed youmight have to join several of them together. Like any other manufacturingprocess using metals, different types of welding are normally employed forthis purpose.For steels we use either TIG (Tungsten Inert Gas) welding which uses anelectrode to heat the metals forming the bond or MAG (Metal Active Gas)welding which uses a consumable wire between the work pieces to create anelectric arc which then forms the bond. We can also use a type of MIG welding(another electric arc type) for bonding aluminium parts together.If we are joining brass and copper parts, this is normally done by solderingrather than welding. Hard (or Silver) soldering uses a rod containing silverwhich is heated with a torch, fluxed and melted into the joint. Soft solderinguses a rod containing lead and tin which melts at a lower temperature to formthe joints. Hard soldering gives more structural strength to a joint where softsoldering would be used if the items are less structural and more decorative.As you can see, there is an awful lot of work still done by hand that goes intoalmost every bespoke fitting we produce here at Northern Lights. Metalworkingis a very important part of turning any design into a real product and withoutthe skilled engineers in our factory, we wouldn’t be able to offer such acomprehensive and flexible service.enlightened17

Dubai is not just any city.– it is a tourism, trade and travel hub servicing the MENASA region and it justhappens to be a first class destination home to some of the most iconic hotels,hospitality and leisure establishments in the world. With a serious growthstrategy in place, Dubai leads the world in hotel build and development.Northern Lights in Dubai.Having worked in the interior design field for more than 12years; 5 years of which have been in Dubai, we always facedchallenges when it came to lighting. A shared challengeamong the design community is a huge need for a lightingcompany which can work closely with the interior designersand architects to deliver creative yet functional lightingsolutions and to be able to bring their visions in to reality.“Northern Lights” is a perfect match to fill this gap.Sample productsfrom Waldorf AstoriaPalm Jumeirah withbespoke ‘brightbronze’ finishNorthern Lights is a bespoke one-stop lighting serviceprovider for hotels, pubs, restaurants and the retail sectorwith manufacturing facilities in the UK and a “nothing isimpossible” attitude.Launching “Northern Lights” in Dubai was a huge success.We have been involved in many prestigious projects in avery short time. We have successfully handed over Izelrestaurant in Conrad Hilton, Conrad All day dining,Waldorf Astoria Palm Jumeirah rooms, presidential suitesand all the front of house areas and many more We arenow involved in many 4 and 5 star properties and areworking closely with some of the most well known interiordesign and contracting companies in the region.We provide comprehensive lighting solutions to theHospitality and Retail Sectors. Vann FID is proud to represent“Northern Lights” in the UAE and Middle East Markets.Together we provide our prestigious clients with:Lighting ConsultationLighting DesignLighting ManufactureProject Management18enlightenedIzel Restaurant Conrad Hilton, Dubai

The Hotel Show Dubai.The Hotel Show in Dubai is the largest hotel, resortand restaurant exhibition and the foremost businessto-business event in the MENASA region. In 2013, 560global suppliers from 80 countries showcasedthousands of brands covering every aspect of hoteldevelopment, to more than 16,700 worldwideattendees.Interiors, Lighting and Design at The Hotel Showattracted the best in the industry, and saw 249premium exhibiting brands in 2013. This popular areaat the exhibition allows for designers, architects andinterior consultants to keep abreast of the latestdesign trends, to launch brand new products and tomeet with distributors of some of the world’s leadinginterior brands.We participated in the show with a remarkable andoutstanding stand to make our mark as a one-stopbespoke lighting solution provider in the region.The stand itself was designed to meet the twodifferent most desired styles from opposite ends ofthe spectrum of lighting design; modern glamour andindustrial chic. The stunning chandeliers and dramaticstand generated a lot of interest, while productsdisplayed showcased our capability to meet all lightingrequirements for different sectors and styles.Our stand was a huge success attracting most of thebranded hotel chains and hospitality main players.68% of our visitors were director level or above and77% of visitors were from Hotels & Resorts in theMENA region. We met clients and potential clientsgiving us the opportunity to discuss their concerns andrequirements face to face.I believe that we conveyed the messageto designers and architects that“.if you can imagine itwe can produce it.”enlightened19

What’s New.from Light Building 2014I think we all know just how big Light Building at the MesseFrankfurt is, but after literally walking a marathon around theplace, it’s amazing just how many new and exciting things wefound with every single step!While industrial themed pendants with filament style light bulbsand glass pendants of all kinds still populate many of the standsat the show, it would appear that lots of construction materialssuch as concrete and wood are being incorporated into newlighting designs,Chainmail and mesh pendants were also on show along with alarge and vibrant range of fabric shades in all shapes and sizes.We also saw a lot of brightly coloured and flexible silicone rubberpendants which appear to be turning quite a few heads at themoment.We’ve put together a few images for you in this ‘show review’and some of what you see here may soon be available topurchase through Northern Lights. We are working with both newand existing suppliers to bring their ranges to our customers.20enlightened

Switch to a new era of LED lamp and preventreplacement costs – switch to the LED e-line.ADVERTORIALKeep your decorative luminaire styling withouthaving to compromise on the latest technology.LED solutions offer savings other light sources cannot provide.They are energy efficient and achieve a very long life time. This ofcourse helps to cut energy bills and reduce maintenance costs.Used within decorative light fittings however, many common LEDapplications only provide low and cold light levels, which result in apoor unwelcoming atmosphere. Technologies such as LED retrofitlamps can partially offer a better light scheme, but they are notprotected against ‘unauthorized removal’. This often is an unwanted side effect of using LEDs in the hotel and hospitality sector.Serving the lighting industry for more than 100 years, Germanmanufacturer BJB has now developed an effective solution the LEDe-line. This innovative LED lamp creates a welcomingatmosphere through a warm and natural light colour, whichultimately helps to create customer satisfaction and maintain loyalty.The single unit LED e-line is designed with the same dimensions asa standard E27 lampholder, which means that it can be specifiedat the luminaire manufacture stage in place of a conventionallampholder. The lamp becomes part of your luminaire andtherefore provides a theft-proof and robust energy efficient LEDsolution. The LED e-line can also be easily embodied in existingluminaires as part of on-site refurbishments.Keep your decorative luminaire styling without having tocompromise on the latest technology and switch to the LED e-line.KEY BENEFITS:Reduced lighting related energy costs up to 90%Increased sustainabilityReduced environmental impactReduced maintenance costsImproved customer satisfaction by implementing a ‘green solution’All data and statistics provided by BJB.enlightened21

A new bespoke finishnow available.Aqua-PrintingNorthern Lights are now pleased to offer a truly uniqueand bespoke finishing technique to their range of metalproducts. Aqua printing is a specialised technique wherebythe product, such as a lamp shade, is dipped through aprinted film that is placed on the surface of a water bath.As the shade passes through the film and into the water,the print coats the contours of the shade and gives a trulyunique finish. There is a wide range of patterns available,from carbon fibre effect to animal prints such as snakeskinand tiger print and other patterns such as woods, marblesand grasses. There are also more off the wall patternssuch as tattoo skulls and American Dollar bills!Due to the nature of the process no two shades will evercome out identical - which is why we are calling this a trulyunique finishing technique!Snakeskin effectTattoo skullsIf you are interested in using this technique or would liketo know more about the process or the available patterns,please call our sales team on 01246 858 750 or emailsales@northern-lights.co.ukAutumnal reeds (matt finish)Black / silver carbon fibre22enlightened

Lighting TrendsOur Lighting Design Manager Michael Jackson shares histhoughts on the current trends in hospitality lighting design,how Northern Lights can help designers realise their vision.What is the trend inhospitality lightingdesign now?We have observed that trendswithin the hospitality sector forbespoke lighting do not follow aspecific path and it is apparent thatvariety really is the spice of life.There is no set formula for adecorative lighting scheme withproduct varying in material, finish,scale, colour and function, fromproject to project. With theexception of retaining brandidentity the key to a successfulscheme is in offering a solutionwhich is new and original.The wide range of bespoke lightfittings we have developed forclients over the last year hasreflected this trend - from statementchandeliers and industrial pendants,to ceiling lights inspired by Chineselanterns and pendants usingreclaimed items. Architects anddesigners are challengingconventional production techniquesand material applications toproduce totally unique designs,with engineering principles andprocesses having to be adapted ininnovative ways to achieve this.How can Northern Lightshelp designers realisetheir vision?Here at Northern Lights we offera comprehensive developmentservice where we will work withthe designer from concept stagethrough to production to ensurethe client's visions are accuratelyreproduced.To ensure that we can reactquickly and effectively to ourcustomers' requests we havecontinued to invest in the latestComputer Aided Design (CAD)software. This enables us topresent accurate design proposalswhich can be reviewed andapproved prior to commencementof manufacture. In 2013 we alsoprocured additional ComputerNumeric Control (CNC) systemswhich provide us with acomprehensive scope ofmanufacturing works. Thismachinery brings more processesin-house enabling us to havecomplete control over productionthus keeping reaction times to aminimum.What to expect fromNorthern Lights in thenear future?We are continuously working on manynew projects for clients frominternational hotel groups to regionalrestaurant chains. The manufactureof decorative feature lighting isbecoming increasingly demanding.We will always keep investing in ourfacilities and our people to meetthese challenges.2013 was our best year to date forexport sales and we are already setto beat this in 2014. Our innovativedesigns, superb craftsmanship andon-time delivery have led us to workon projects in the UAE, Israel, Russia,Australia and Singapore. We expectto further increase our export saleswith a more efficient supply chainand streamlined internal procedures.Lighting is such a powerful andversatile decorative tool. We lookforward to working with designersand clients to experiment withdifferent materials, finishes andlighting sources to deliver creativeyet functional lighting solutions,setting the trend for the future.enlightened23

Interact with us on social media:Northern Lights (Chesterfield) LtdHardwick View Road, Holmewood Industrial Estate,Holmewood, Chesterfield, S42 5SAT: 01246 858750 F: 01246 858751W: www.northern-lights.co.uk E: sales@northern-lights.co.ukIf you do not wish to receive further issues of this magazine please email: editor@northern-lights.co.ukE & OE Disclaimer StatementWhilst every effort has been made to ensure the accuracy of the information supplied here

Philips show you the future with OLED . at some great new products for both catalogues and we’re sure that you will Tnd these interesting. It has indeed been a while since our last edition and . lights were back-lit with dimmable LED