Transcription

Non-destructive Testing of Concrete- Methods of TestLecture No. 26

Rebound Hammer (IS 13311( Part 2 ) : 1992)The rebound hammer method could be used for:i) Assessing the likely compressive strength of concretewith the help of suitable corelations between reboundindex and compressive strength,ii) Assessing the uniformity of concrete,iii) Assessing the quality of the concrete in relation tostandard requirements, andiv) Assessing the quality of one element of concrete inrelation to another

Rebound Hammer(IS 13311( Part 2 ) : 1992)Principle of Test : When the plunger of rebound hammer is pressed against thesurface of the concrete, the spring- controlled mass reboundsand the extent of such rebound depends upon the surfacehardness of concrete. The surface hardness and therefore therebound is taken to be related to the compressive strength ofthe concrete. The rebound is read off along a graduated scaleand is designated as the rebound number or rebound index.

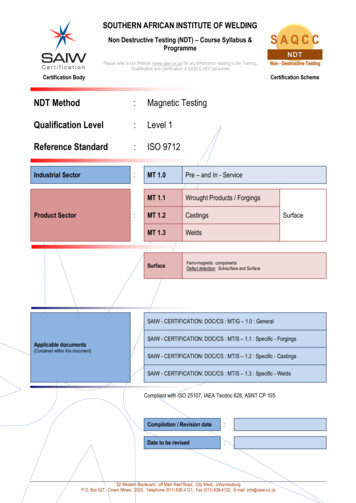

Rebound Hammer(IS 13311( Part 2 ) : 1992)The Rebound Hammer : It consists of a spring controlled mass that slides on a plungerwithin a tubular housing. The impact energy required forrebound hammers for different applications is given in Table 1.

Rebound Hammer(IS 13311( Part 2 ) : 1992)

Rebound Hammer(IS 13311( Part 2 ) : 1992)

Rebound Hammer(IS 13311( Part 2 ) : 1992)

Rebound Hammer(IS 13311( Part 2 ) : 1992)Checking of Apparatus : It is necessary that the rebound hammer is checked againstthe testing anvil before commencement of a test to ensurereliable results. The testing anvil should be of steel anufacturer of the rebound hammer should indicatethe range of readings on the anvil suitable for different types ofrebound hammers.

Rebound Hammer(IS 13311( Part 2 ) : 1992)ProcedureofObtainingCorrelationCompressive Strength of Concrete andNumber : BetweenReboundThe most satisfactory way of establishing a correlationbetween compressive strength of concrete and its reboundnumber is to measure both the properties simultaneously onconcrete cubes. The concrete cube specimens are held in acompression testing machine under a fixed load,measurements of rebound number taken and then thecompressive strength determined as per IS 516 : 1959.

Rebound Hammer(IS 13311( Part 2 ) : 1992)PROCEDURE: For testing, smooth, clean and dry surface is to be selected. Ifloosely adhering scale is present, this should be rubbed of witha grinding wheel or stone. Rough surfaces resulting fromincomplete compaction, loss of grout, spalled or tooledsurfaces do not give reliable results and should be avoided. The point of impact should be at least 20 mm away from anyedge or shape discontinuity.

Rebound Hammer(IS 13311( Part 2 ) : 1992)PROCEDURE: For taking a measurement, the rebound hammer should beheld at right angles to them surface of the concrete member.The test can thus be conducted horizontally on verticalsurfaces or vertically upwards or downwards on horizontalsurfaces. If the situation demands, the rebound hammer can beheld at intermediate angles also, but in each case, the reboundnumber will be different for the same concrete. Around each point of observation, six readings of reboundindices are taken 2nd average of these readings after deletingoutliers as per IS 8900 : 1978 becomes the rebound index forthe point of observation.

Rebound Hammer(IS 13311( Part 2 ) : 1992)The rebound numbers are influenced by a number of factors liketypes of cement and aggregate, surface condition and moisturecontent, age of concrete and extent of carbonation of concrete.

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992)The ultrasonic pulse velocity method could be used to establish:1.The homogeneity of the concrete,2.The presence of cracks, voids and other imperfections,3.Changes in the structure of the concrete which may occurwith time,4.The quality of the concrete in relation to standardrequirements,5.The quality of one element of concrete in relation to another,and6.The values of dynamic elastic modulus of the concrete.

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992)Principle of Test : The ultrasonic pulse is generated by an electroacousticaltransducer. ,When the pulse is induced into the concrete froma transducer, it undergoes multiple reflections at theboundaries of the different material phases within theconcrete. A complex system of stress waves is developed which includeslongitudinal ( compressional ), shear ( transverse ) and surface( rayleigh ) waves. The receiving transducer detects the onsetof the longitudinal waves, which is the fastest.

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992)Principle of Test : Because the velocity of the pulses is almost independent of thegeometry of the material through which they pass anddepends only on its elastic properties, pulse velocity method isa convenient technique for investigating structural concrete. The underlying principle of assessing the quality of concrete isthat comparatively higher velocities are obtained when thequality of concrete in terms of density, homogeneity anduniformity is good.

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992)Principle of Test : In case of poorer quality, lower velocities are obtained. If thereis a crack, void or flaw inside the concrete which comes in theway of transmission of the pulses, the pulse strength isattenuated and it passes around the discontinuity, therebymaking the path length longer. Consequently, lower velocitiesare obtained. The actual pulse velocity obtained depends primarily upon thematerials and mix proportions of concrete. Density andmodulus of elasticity of aggregate also significantly affect thepulse velocity.

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992) The apparatus for ultrasonic pulse velocity measurement shallconsist of the following: a) Electrical pulse generator, b) Transducer - one pair, c) Amplifier, and d) Electronic timing device.

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992)

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992)

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992)

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992)

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992) Influence of Test Conditions Influence of Surface Conditions and Moisture Content ofConcrete Influence of Path Length, Shape and Size of the ConcreteMember Influence of Temperature of Concrete Influence of Stress Effect of Reinforcing Bars

Ultrasonic Pulse Velocity(IS 13311( Part 1 ) : 1992) The quality of concrete in terms of uniformity, incidence orabsence of internal flaws, cracks and segregation, etc, indicativeof the level of workmanship employed; can thus be assessedusing the guidelines given in Table 2,

Ultrasonic Pulse Velocity (IS 13311( Part 1 ) : 1992) The ultrasonic pulse velocity method could be used to establish: 1. The homogeneity of the concrete, 2. The presence of cracks,voids and other imperfections, 3. Changes in the structure of the concrete which may occur with time, 4