Transcription

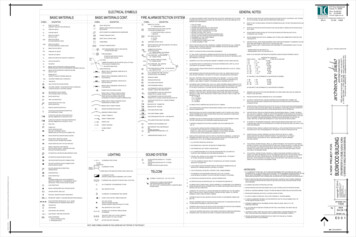

1EX-FLUORESCENT LIGHT FITTINGS23456EX-LIGHT FITTING eLLK 92. – MAIN FEATURES2.20EX-LIGHT FITTING eLLK 92.2.12EX-POLE MOUNTED LIGHT FITTING eLLM 92.2.14EX-EMERGENCY LIGHT FITTING eLLK 92. NIB2.18EX-RECESSED CEILING LIGHT FITTING eLLB 20.2.26EX-RECESSED CEILING LIGHT FITTING RLF 250.2.38EX-d LIGHT FITTING AB 12 AND EVF.2.46EX-LIGHT FITTING nLLK 08. FOR ZONE 22.56EX-EMERGENCY LIGHT FITTING nLLK 08. N FOR ZONE 22.62EX-PHOTOCELL2.68LIGHTING MOUNTING SYSTEMS2.70789101112

IField of applications and main featuresIThe best choice for an economicalThe advantages of fluorescent lampssolution for the illumination of probablein light fittings:explosive environments is the fluores - worldwide availabilitycent lamp. low cost very good colour reproduction immediate starting easy handling long service life with EVG-Technology immediate restart standardised disposalof the fluorescent lampsEVF.eLLK 92.Depending on the proposed usagethere is a variety of groups to choosefrom: eLLK/M 92.:Surface and pole mounted foruse in the Zones 1, 2, 21 and 22 nLLK 08.:Surface mounted for use innLLK 08.the Zones 2, 21 and 22 eLLB 20 and RLF 250 .:Recessed ceiling mountingfor use in the Zones 1, 2, 21 and 22 AB 12./EVF.:Flameproof surface mounted for usein the zones 12, 2 and 22eLLB 20.2.2RLF 250.COOPER CROUSE-HINDS GMBHAB 12.

IField of applications and main featuresI12one sidedthrough-wiringType 1/6Fluorescent light fittings of the serieseLLK 92. / nLLK 08. are equippedwith a single-end through-wiring 1/63double sidedthrough-wiringType 2/6as standard. Here there are 2 cableentries M25 for cable sizes Ø 8-17 mm,4where as one of these is fitted witha certified blanking plug (red) as astopper.The 2/6 version is fitted with a cableentry M25 for cable sizes Ø 8-17 mmand a certified blanking plug (red) as5stopper on both ends. The mainsterminal block has 6 clamps enablingwire of up to 2 x 6 mm 2 (solid) or2 x 4 mm 2 (multi wire) to be connected.This allows for a comfortable and6problem free wiring (L, L1, L2, L3, Nand PE) and installation.The 2/6 version is fitted with a secondmains terminal block of 6 clamps onthe opposite side. The required internalwiring of the light fitting has been rated7for 16 A.The standard screwable terminal blockallows single sided connecting withouthaving to bend the wire. Simply pushthe hinged cover shut and you alreadyhave protection against contact accor-8ding to BGV A2.9101112COOPER CROUSE-HINDS GMBH2.3

E X - L I G H TF I T T I N G STechnical Special Featureson hand of the eLLK 92Standard – two mouldedplastic or brass (optional)cable entries for one-endedthrough-wiringThe fluorescent lamp series eLLK 92.,eLLM 92., nLLK 08. and in some partsthe eLLB 20. have in their architecture,the same characteristics, which we showhere on hand of the eLLK 92-Series.Double thread (MS)for reliable PE contacting of metal gland (optional)MaterialsThe eLLK 92 light fitting is made of highgradeplastics that, in addition to the excellent mechanical properties, also feature a high stabilityagainst many chemicals found in industrialStandard terminal block with6 terminals for conductors up to 2 x 6 mm2Optional double-endedthrough-wiring for cable connectionplants. All the materials used for the light fittingEnclosure made of polyesterreinforced with glass fibreCombination of high resistant materialsprovide are effectively protected againstSpecial Ex-EVG in the type of protection Ex dto meet high requirementscorrosion and have already been successfullytried and tested in chemical and off-shoreinstallations.Locking bolt for operating thelight fitting locking mechanism on both sidesOptimizedSealing systemSealing systemBowl made of transparent,impact-resistant polycarbonateThe bowl and the enclosure form a labyrinth,that protects the seal against jet water. Thecontinuous seal is extremely elastic and, inconjunction with the locking mechanism,ensures that the light fitting is sealed tightly forSockets for the hingesof protective bowl – on both sidesa long time. As was also confirmed by an ERAtest, this is the only way to reliably maintain thedegree of protection IP66 for a longer period.Internal sealing system for IP66Aptitude testsThe eLLK 92 light fitting has already passedboth tests with lateral thrusts due to wind upto 12 Bft and the ERA 1) test specified for Britishoff-shore installations. Here, for example, thesealing qualities and the resistance to vibrationSpecial lamp socket in the type of protectionEx e for bi-pin lamps to IEC 81are tested.Moulded plastic or brass cable entries fordouble-ended cable connection (optional)1)ERA-Test UK-test institutefor offshore technology2.4

12CEAGCost reduction with single-end through-wiring3Standard version for two cablesThe standard version of the eLLK 92is designed for a single-ended throughwiring. According to the verdict inan independent expertise, together4with the easily accessible terminalcompartment, this connection methodresults in a time saving of up to 30%compared to conventional light fittingsEasy lamp replacementusing the classical through-wiringmethod.light fittings that were installed at a5later point in time. The fact that thegenerously dimensioned terminalcompartmentsPlastic cable entriesInstallationof the eLLK 92/nLLK 08locking mechanism can be operatedWhether it is mounted on rails orbowl is hinged on both sides, meanssuspended from the sealing, the lion’sthat there is plenty of scope for theshare of the overall costs is taken uparrangement of light fittings. The bowlby the installation and electrical con-can simply be swung open in the re-nection of the light fitting. Here, duespective direction without tools – thisto the standardized fixing clearancesis made possible by the hinge fastenersand the generously dimensionedfitted on both sides of the light fittingterminal compartments, the eLLK 92housing. A quarter turn of the lockingprovides a high saving potential. Thebolt and the bowl opens up down-terminal compartment can be openedwards. The hinges on the cover arewithout removing covers or reflectors,fixed in such a way that the replace-thus permitting the easy connection ofment lamps can be safely deposited incables.the bowl, thus saving time when repla-on both sides and that the protective7cing lamps. The bowl cannot fall down,Three ways – one solution6even in wind and rain.Depending on the type of installation,8different cable entries could be requiredfor the connection of the light fitting.Available for all types are the following:9 M25 x 1.5 Plastic cable entriesMetal thread M20 x 1.5 Earthed metal threadfor metal cable entries non-metric threads, for exampleMyer Hubs 3/4” NPT-Thread10Lamp replacement made easyIrrespective of how the light fitting isinstalled, the locking mechanism canbe operated on either side – this meansthat there are no future surprises with11Myer Hubs (for Conduit-System)12COOPER CROUSE-HINDS GMBH2.5

Catch points protective bowlopening of bowlclosing of bowlClosing system using the ”strongbox principle“ guarantees a correct sealingLocking mechanismLampsThe housing and the protective bowlAll the light fittings in the eLLK 92/are securely locked by means of anLLK 08 /eLLB 20 and RLF 250. serieslocking mechanism according to thehave been developed and certified for„strongbox principle“ on both sides thatØ 26 mm bi-pin fluorescent lamps withfeatures as many as 24 latch points .a G 13 lamp cap in accordance with:This new type of locking system featu-IEC 60081 – page 22/20 (18 W)res stainless steel springs that regulateIEC 60081 – page 24/20 (36 W)the pressure applied to the seal, thusIEC 60081 – page 21/22 (58 W)guaranteeing the tightness of the lightThis means that the lamps, that arefittings, even in the event of changesavailable all over the world, can bedue to the ageing of the sealing materialused for both hazardous and non-and variable climatic influences.hazardous areas. Not only does thissimplify stock-keeping, but the operatoralso benefits from all the technicaladvantages in conjunction with EVGoperation. Compared to the oldØ 38 mm single-pin fluorescent lamps,the luminous power of the system isInternational Ø 26 mm bi-pinfluorescent lamp and the oldØ 38 mm single-pin fluorescentlampincreased by a factor of 2.2. Specialthermo-lamps with 38 mm diametercan be used in all bi-pinlamp holder of CEAG fluorescent light fittings. Thisallows an economical useof fluorescent lamps evenbelow ambient temperaturescompulsory N/C contactsafeguarded against contactof –5 CLighting engineeringDouble the safety is betterDue to the various fields ofThe regulations require the automaticapplication light fittings aredisconnection of the supply voltageequipped with a large varietywhen the light fitting is opened.of lamps and reflectors.The built-in compulsory NC contactThe criteria for the selectionis safeguarded against inadvertentof the types of lamps andoperation and, as soon as the lockingreflectors are basicallymechanism of the light fitting is opera-determined by the type ofted, it de-energizes all parts thatlighting required (illuminationcan be touched. A second interlockof surfaces or objects, etc.)switch increases the safety level forand the economic efficiency.the operator. Therefore, even if theWhen planning a lighting installation,lock of the light fitting is actuatedthe polar curves of the luminouswhile the protective bowl is still open,intensity of the light fittings beingthe switch cannot be operated, as, inused are required in order to calculatethis case, the circuit for the light fittingthe illumination distribution.CEAG products are constanly beingadvanced and tested in the company’sown lighting laboratoryremains disconnected.2.6COOPER CROUSE-HINDS GMBH

Polar curveslighting properties of all explosionprotected light fittings are tested inthe Cooper Crouse-Hinds GmbH lighPolar curve eLLK 92018/18eLLK 92036/36909040757580606012045451603015200150C 0C90l/cd/klmfluctuating mains voltage– safe lamp ignition at low and highambient temperatures– longer service life for lampsting laboratory. In this– AC/DC operation possibleway it is ensured that– Standard dual channel ballast,the reflectors, as wellthat means on failure of one lampas the protectivethe second lamp will continue inbowls for fluorescentoperation independent from thelight fittings are opti-failed one.23mized down to theof the light fittingsEOL (END OF LIFE) –What is it?eLLK 92., nLLK 08.,As with all other lamps, the lifetime ofeLLB 20 andevery fluorescent lamp is limited. Userslast detail. In the case301– Regulation of luminous flux withDuring the development phase theRLF 250. series of Cooper Crouse-of all Ex fluorescent light fittings repor-Hinds GmbH has succeeded in optimi-ted on some critical situations where,zing both the illumination of surfacesafter being in operation for longer peri-with the largest possible light distribu-ods, they overheated or even caughttion and the illumination of objectsfire. It is not possible to say for certainwith the highest possible axial lightto what extent the EOL effects wereintensity. The polar curve of each lightthe cause of this. At the request of thefitting can be found in the technicalGerman Manufacturers Association thedata and can be used together withPhsyikalisch-Technische Bundesanstaltthe other lighting values to calculate(PTB) in Braunschweig carried outthe illuminance. All lighting designan independent investigation of thisdata can be downloaded from ourphenomenon. The results of this latestWeb page: www.ceag.deinvestigation have been published andcan be found on the Internet pages of456the PTB.Extract from this report:„In the more recent past, luminairesused in conjunction with these fluores cent lamps have been found to fail as7a result of local overheating of the lampcap and the lamp socket. There aredifferent kinds of faults that may haveled to these failures. One possibleexplanation is the end-of-life effectElectronic ballasts (EVG)(EOL) of the lamp, which will occur onlyNowadays it is not possible to imaginein exceptional cases at the end of themodern light fittings for fluorescentlamp lifetime. It is for the time being notlamps without the EVG technology.possible to reproduce this EOL effect inFeatures such as immediate starting,the laboratory in a conclusive manner,the absence of flickering during opera-but it may be described as follows intion or the minimal heat rise are onlyqualitatively terms .“89possible with this technology. With theCEAG EVG technology, fluorescent lightfittings for use in hazardous areas also10provide decisive advantages:– possibility of a lamp-sparing coldstart– use of bi-pin lamps, Ø 26 mm– use with various mains voltages from110 V up to 254 V 10 %1112COOPER CROUSE-HINDS GMBH2.7

The solution for Zone 1applications – CEAG EVG 09The advantages for you:All the EVGs (electronic ballast’s) Latest lamp circuit monitoring as ansupplied by CEAG since 1988 featuremonitoring of the lamp circuit, detection Time-tested and reliable technologyadditional safety factor Meets all requirements of theThe EVG 09 in practice:Explosion protected luminaireswith trademark CEAGAll these functions are just one component in the extensive safety concept ofof the rectifier effect, as well as astandard draft IEC 60079-7 forthe CEAG EVG 09. The use of high im-shutdown of the circuit in the eventluminaires with fluorescent lamps inpact resistant plastic materials for thethat the lamp does not strike. There -“Increased Safety” (EOL)encapsulation in the type of protectionfore, the CEAG EVGs already ensured EVG designed specially for roughEx-de, as well as the additional unita high level of safety at the serviceoperating conditions of Zone 1 – notfuses for the event that a fault occurslife of the lamps long before the discus-just an encapsulated industrial EVGrounds off the whole package.sions on EOL ever started. The new Thermally optimised circuitry for longCEAG EVG 09 also fulfils the relevantservice life, even in high ambientThe new CEAG EVG 09 will becomeEOL requirements of the industrial stan-temperaturesstandard for our fluorescent lightdard IEC 61347-2-3 (§ 17.2 and 17.3),as well as those laid down in the latestdraft of IEC 60079-7 Ed. 4 7/2006 Wide input voltage range and DCoperation for universal use Two separate lamp circuits (autarkic(Electrical Apparatus in the type of pro-switching) provide more safety fortection Increased Safety), for luminairesyour employees and installationsfor use in potentially explosive atmospheres Zone 1. Thus, the CEAG EVG 09,which is certified to: BVS 09 ATEX E 054 U,meets the latest findings and thenewest standards.fittings series:eLLK 92 ./. , eLLM 92 ./ . NIBas well as fort he recessed ceilingluminaires eLLB 20 and RLF 250 Practically insensitive to networkharmonics and over-voltageinfluences Isolation of one lamp circuit for usein emergency lighting installations(economic battery use)Which protective circuits doesthe new EVG 09 have?The standard DIN EN 61347-2-3(VDE 0712-33), which was issued inFebruary 2005, only stipulates a per manent monitoring of the lamp circuitfor EOL effects for T4 and T5 lamps(16 mm and thinner). The draft versionof the standard IEC 60079-7, whichwas derived from this standard, laysdown the test requirements for Ex-elight fittings with cold start EVGs for T6(26 mm) fluorescent lamps.Unlike industrial luminaires with EVGs,Ex-e luminaires shall fulfil all of therelevant conditions of this standard.2.8COOPER CROUSE-HINDS GMBH

123to ensure a constant good quality.Cooper Crouse-Hinds GmbH has beenmanufacturing EVGs for more than25 years and has the necessary knowhow. In addition to the routine verifi cations and tests carried out on allapparatus, stress tests are carried out4on individual batches to ensure safefindings with regard to componentspecifications.5Computer-aided finalinspectionsThe uncompromising safety of theexplosion-protected eLLK 92 lightfittings is maintained throughout theEVG-Capsulationvarious production stages and includesRobust technology for extremeapplicationsthe final inspection. Each light fittingThe operation of explosion-protectedprogram. All data relating to thelight fittings places high requirementsmanufacture and safety is stored andon the reliability and durability of thecan still be called up years later. This iscircuits being used. In addition to tem-where the Cooper Crouse-Hinds GmbHperature, moisture and mechanicalquality assurance system, that is certi-stress, mains contamination or voltagefied to ISO 9001:2000, clearly makespeaks can affect the light fittings.it mark.6is tested in detail by a computer test7Here the EVGs specially developed by8Cooper Crouse-Hinds GmbH providesafe protection against harmful influences. Whereas conventional industrialDirect or alternating voltage?EVGs are designed for an ambientConventional ballasts only work withtemperature of the light fittings ofan alternating voltage and can onlyup to 30 C, the CEAG EVGs arebe used with group or central batterydesigned for an ambient temperatureinstallations under certain conditions.of 50 C. The large-scale printedCooper Crouse-Hinds GmbH, as thewiring board layouts ensure an evenleading manufacturer of emergencyheat distribution, through-connectionslighting installations, offers an explo-and encapsulation of sensitive compo-sion-protected ballast that can benents provide mechanical protection.operated with alternating and directA hermetically sealed enclosure pro -voltages.910vides protection against undesirablesubstances that could cause damageQuality cannot be left to chanceto the PCB.Extensive testing and a highly automated production process are necessary1112COOPER CROUSE-HINDS GMBH2.9

Ex-emergency light fitting with self-containedbattery system eLLK 92036/36 NIBEmergency lighting –central or decentralThe new CEAG series of emergencyAppertaining to Emergency Lightingbattery systems eLLK 92 NIB,in hazardous explosive areas, theireLLB 20. NIBare two general philosophies. Thathave all the necessary self-controlof the supply assurance, the testfeatures needed and does the requiredand maintanance effort and that offunctionality and operating time teststhe economic efficiency.automatically. Hereby the batterylight fittings with self-containedlifespan is optimized.Emergency light fittings with aself-contained battery systemcontained battery systems provideCentrally controlledemergency lighting systemswith CG-Modulesthe required Emergency lighting decen-A centrally controlled emergency lighttral, independant from central systems.system using the CEAG group supplyThat means the battery, the chargerand a central battery system is installedand the electronics are integrated in thewhen a large number of emergencylight fitting. Taking the availability andlights are conglomerated and can bethe redundance into consideration, thisused as a system emergency lighting.system has with respect to the supplyThese battery systems are generally,assurance in safety-engineering sensi-not installed in the hazardous areas andble areas a very high standard. Takingtherefore do not have to cope with thethe economic efficiency into considera-same environmental conditons as thetion, the required effort of testing,light fittings themselves. This usuallymaintance and the environ mental effectresults in an extended life span of theon the battery life span of eachself-batteries with a minimized maintanancecontained battery system has to beeffort. One must of course take intotaken into account. Taking the aboveconsideration that the cable laying frominto consideration it is without reasonthe central battery to each light fittingthe best solution when emergency lightin the hazardous areas affords anfittings with a self-contained batteryincreased effort.Emergency light fittings with self-system are used in large and spaciousexplosion hazardous areas where thenumber of fittings to be used is limited.CEAG emergency lightingsupply unit for non-hazardousareasOne line, e.g. 3 x 1.5 mm2for both the mains and the emergency power supply12345610Ex-light fittings with CG-S modul and codingswitch with a maximum of 20 light fitting per circuit72.108910111220COOPER CROUSE-HINDS GMBH

1234To be able to run on the CEAGThis combination offers the followingemergency light fittings system weadvantages:can provide the following light fitting– Automatic performance of theseries eLLK 92, nLLK 08 and eLLB 20necessary function test with centralversions with ”CG-S Modules“. Thisrecord-keepingcontrolling module controls amongstother things the data exchange5– Enormous cost savings as manualtesting is no longer necessarybetween the main emergency light– Two-lamp operation with mainsapparatus and the individual lightsupply, single lamp operationfittings per power supply cable andwith emergency power supply,reports all functional errors.therefore cost saving for batteries6and apparatusIn conjunction with the CG-S Modules,it is now possible to connectindividually monitored emergencylight fittings to a CEAG emergencylighting installation with monitoringsystem. Here it is now possible to– High degree of safety of emergencylighting due to constant display ofavailability– Simplified installation:– mains and emergency power supplyhave a common connectionintegrate explosion-protected light– a separate data line is not requiredfittings as system light fittings into the– a maximum of 20 light fittingspractical monitoring system of CEAGgroup or central battery installations.78can be connected to one circuit– automatic performance of thenecessary function tests withcentral record-keeping9101112COOPER CROUSE-HINDS GMBH2.11

EX-LIGHTeLLK 92. 18 W - 58 WAll plastic design for Zone 1 and 21The eLLK 92 Ex-protected light fittings for bi-pinfluorescent lamps are fitted with an electronicballast and conform to the ATEX Directive94/9/EG. The modern economical ballastEVG 09 according to the latest standards(IEC 60079-7: 2006) allows a safe and econo mical operation of bi-pin fluorescent lampsG13 according to IEC 60081. Lamps reachingits end of life will be monitored and securelyswitched off (EOL-effect). The high input voltagerange allows international use. Due to thestandard dual channel architecture (with doublelamp fittings) if one fluorescent lamp fails, theother fluorescent lamp will independently stayin operation. The standard single-sided throughwiring in connection with the variety of possi bilities offers a cost efficient installation. Doublesided lock with 10, 20 or 24 latch points allowsthe protective bowl to be hingeable on bothsides meaning the fitting can be mountedwithout having to pay attention to which side isthe right side. Automatic switch built as a safetydisconnector according to EN 60947 (IEC 664)with an automatic switch ensuring the disconnection of all exposed components when thefitting is opened. The optional CG-S modulerepresents an optimum solution for the individualmonitoring of light fittings connected to CEAGemergency battery systems.Standard dual channel ballastDouble-sided safety lockSafety locking system dueto an integrated forced isolating switchSafety standard IP66Connection to CEAG emergency lightmonitoring systems possibleInternational Approvals2.12FITTINGS

IeLLK 92. (18-58 W)I121 x 36 W2 x 36 W3Technical dataeLLK 92018/18 eLLK 92036 / eLLK 92036/36 eLLK 92058 / eLLK 92058/58Marking to 94/9/ECII 2 G Ex de IIC T4 /II 2 G Ex de mb II T4 (CG-S variant)II 2 D Ex tD A21 IP66 T80 CEC-Type Examination CertificateBVS 09 ATEX E 034IECEx-Certificate of ConformityIECEx BVS 09.0033Marking to IECEx4Ex de mb IIC T4Ex tD A21 IP66 T 80 CPermissible ambient temperature-25 C to 55 C (Un 220 V)-25 C to 50 C (Un 220 V)1)Frequency550 - 60 HzPower factor cos ϕ 0.95CircuitEVG resp. EVG/CG-SConnecting terminalsL1, L2, L3, L, N, PE; max. 2 x 6 mm2 per terminalInsulation classILamp capG13 accd. to IEC 60081Degree of protection accd. EN 60529IP66Cable glands/gland plates/enclosure entry holesEx-e cable glands M25 x 1.5 (plastic) for cables from Ø 8 - 17 mm,6Option: M20 x 1.5 metal threadEnclosure materialGlass-fibre reinforced polyesterProtective cover/protective bowlPolycarbonateeLLK 92018/18eLLK 92036eLLK 92036/36Rated voltage110 - 254 V AC /110 - 254 V AC /110 - 254 V AC /110 - 250 V DC110 - 250 V DC110 - 250 V DCRated voltage CG-S220 - 254 V AC /220 - 254 V AC /220 - 254 V AC /195 - 250 V DC195 - 250 V DC195 - 250 V DC0.18 A0.18 A0.34 ARated current0.19 A (CG-S variant)780.35 A (CG-S variant)Lamp/illuminant2 x T26 / 18 W (T8)1 x T26 / 36 W (T8)2 x T26 / 36 W (T8)Rated luminous flux2)2700 lm3350 lm6700 lmLight efficiency in operation78 %86 %78 %Dimensions (L x W x H)760 x 188 x 130 mm1360 x 188 x 130 mm1360 x 188 x 130 mmWeightapprox. 5.2 kg /approx. 7.2 kgapprox. 7.4 kg /approx. 5.6 kg (CG-S variant)approx. 7.7 kg (CG-S variant)eLLK 92058eLLK 92058/58Rated voltage220 - 254 V AC /220 - 254 V AC /195 - 250 V DC195 - 250 V DCRated voltage CG-S220 - 254 V AC /220 - 254 V AC /195 - 250 V DC195 - 250 V DC0.27 A0.53 A / 0.54 A (CG-S variant)Lamp/illuminant1 x T26 / 58 W (T8)2 x T26 / 58 W (T8)Rated luminous flux2)5200 lm10400 lmLight efficiency in operation83 %72 %Dimensions (L x W x H)1660 x 188 x 130 mm1660 x 188 x 130 mmWeightapprox. 8.2 kgapprox. 9.1 kg / approx. 9.6 kg (CG-S variant)Rated current1)eLLK 92058/58: max. 40 C2)depends on used lamps9101112COOPER CROUSE-HINDS GMBH2.13

IeLLM 92./.IeLLMTechnical dataeLLM 92018/18 e L L M 9 2 0 3 6 / 3 6Marking to 94/9/ECII 2 G Ex de IIC T4II 2 D Ex tD A21 IP66 T80 CEC-Type Examination CertificateBVS 09 ATEX E 034IECEx-Certificate of ConformityIECEx BVS 09.0033Marking to IECExEx de IIC T4Ex tD A21 IP66 T80 CPermissible ambient temperature-25 C to 55 C (Un 220 V)-25 C to 50 C (Un 220 V)Rated voltageFrequency110 - 254 V AC / 110 - 250 V DC50 - 60 HzPower factor cos ϕ 0.95CircuitEVGConnecting terminalsL1, N, PE; max. 2 x 6 mm2 per terminalInsulation classILamp capG13 accd. to IEC 60081Degree of protection accd. EN 60529IP66Cable glands/gland plates/enclosure entry holesEx-e cable glands M25 x 1.5 (plastic) for cables from Ø 8 - 17 mmEnclosure materialGlass-fibre reinforced polyesterProtective cover/protective bowlPolycarbonateeLLM 92018/182.14eLLM 92036/36Rated voltage110 - 254 C AC / 110 - 250 V DCRated current0.18 A0.34 ALamp/illuminant2 x T26 / 18 W (T8)2 x T26 / 36 W (T8)Rated luminous flux1)2700 lm6700 lmLight efficiency in operation78 %78 %Dimensions (L x W x H)1060 x 188 x 130 mm1660 x 188 x 130 mmPole socketØ 44 mm x 150 mmØ 44 mm x 150 mmWeightapprox. 7.0 kgapprox. 9.5 kgCOOPER CROUSE-HINDS GMBH

IeLLK 92. (18-58 W)IeLLM 92./. (18 36 W)I122 x 18 W1 x 36 W2 x 36 W2 x 36 W2 x 18 W3Ordering d double-endedglands3)PlugsOrder No.eLLK 92018/18 (2 x 18 W)1/6-11x6x–2 x M25 x 1.51 x blanking1 2265 875 1012/6-22x6–x2 x M25 x 1.52 x threaded1 2265 875 1031)1x6x–2 x M20 x 1.51 x threaded1 2265 875 1092/6-2 M1)2x6–x4 x M20 x 1.52 x threaded1 2265 875 1111x6x–2 x M25 x 1.51 x blanking1 2265 875 1262/6-22x6–x2 x M25 x 1.52 x threaded1 2265 881 1032/6-2M1)2x6–x4 x M20 x 1.52 x threaded1 2265 881 2111x3––1 x M25 x 1.51/6-11x6x–2 x M25 x 1.51 x blanking1 2263 875 1012/6-22x6–x2 x M25 x 1.52 x threaded1 2263 875 1031/6-1 M1x6x–2 x M20 x 1,51 x threaded1 2263 875 1111x6x–2 x M25 x 1.51 x blanking1 2263 875 1251x6x–2 x M25 x 1.51 x blanking1 2266 875 1011/6-1 M4eLLK 92018/18 (2 x 18 W)Level gauge P2eLLK 92018/18 CG-S2) (2 x 18 W)5eLLM 92018/18 (2 x 18 W)1/6-11 2268 875 101eLLK 92036 (1 x 36 W)6eLLK 92036 (1 x 36 W)Level gauge P3 1/6-1eLLK 92036/36 (2 x 36 W)1/6-12/6-22x6–x2 x M25 x 1.52 x threaded1 2266 875 1031/6-1 M1)1x6x–2 x M20 x 1.51 x threaded1 2266 875 1092/6-2 M1)2x6–x4 x M20 x 1.52 x threaded1 2266 875 111eLLK 92036/36 CG-S2) (2 x 36 W)2/6-22x6–x2 x M25 x 1.52 x threaded1 2266 881 1032/6-2M1)2x6–x4 x M20 x 1.52 x threaded1 2266 881 2111x3––1 x M25 x 1.51/6-11x6x–2 x M25 x 1.51 x blanking1 2264 875 1012/6-22x6–x2 x M25 x 1.52 x threaded1 2264 875 1032/6-2 M1)2x6–x4 x M20 x 1.52 x threaded1 2264 875 1111/6-11x6x–2 x M25 x 1.51 x blanking1 2267 875 1012/6-22x6–x2 x M25 x 1.52 x threaded1 2267 875 1032/6-2 M1)2x6–x4 x M20 x 1.52 x threaded1 2267 875 11178eLLM 92036/36 (2 x 36 W)1/6-11 2269 875 101eLLK 92058 (1 x 58 W)9eLLK 92058/58 (2 x 58 W)10eLLK 92058/58 CG-S2) (2 x 58 W)2/6-22x6–x2 x M25 x 1.52 x threaded1 2267 881 1032/6-2 M1)2x6–x4 x M20 x 1.52 x threaded1 2267 881 2111)M: with metal thread, without cable glandCG-S: design single monitored emergency light fitting for use in CEAG emergency light supply unit3) With dustcover if entry/thread is not closedScope of delivery without lamp and fixing accessories.112)12COOPER CROUSE-HINDS GMBH2.15

IeLLK 92. (18-58 W)IeLLM 92./. (18 36 W)eLLKIeLLMAccessoriesLamp for luminaire eLLK92/eLLM92Type of lampsocket/diameterPowerLuminous fluxlight colourOrder No.Bi-pin socket G13T26/Ø 26 mm (T8)G13-60081-IEC-2220-118 W1350 lm white3 2475 900 001Bi-pin socket G13T26/Ø 26 mm (T8)G13-60081-IEC-2420-136 W3350 lm white3 2475 900 002Bi-pin socket G13T26/Ø 26 mm (T8)G13-60081-IEC-2520-158 W5200 lm white3 2475 900 003Aura-UltimateT26/Ø 26 mm (T8) LonglifeG13-socket18 W36 W58 W1300 lm white3350 lm white5200 lm white3 2475 900 0873 2475 900 088on requestAura Super ExT-HS 26/Ø 26 mm1)Single pin cap Fa618 W36 W58 W1150 lm white3000 lm white4800 lm white3 2475 900 0843 2475 900 085on requestSeries eLLK 92. and eLLM 92.TypeOrder No.Hexagon screw SW 133 2485 000 005Series eLLM 92018/18 and eLLM 92036/36TypeOrder No.Single sided through wiring 2/6 with 2 entries M25, incl. terminals and mounting material2 2218 602 000Fixing materials eLLK 92Type/codeCorrosionprotectionQty.per light fittingOrder No.Eye bolt A2galvanized22 2480 002 000Hexagon screw S4stainless steel22 2480 054 000Ceiling mounting bracket D92incl. screws and washerstainless

Lighting engineering Due to the various fields of application light fittings are equipped with a large variety of lamps and reflectors. The criteria for the selection of the types of lamps and reflectors are basically determined by the type of lighting required (illumination o