Transcription

Chapter 10Global Standards for Supply Chain Managementin Consumer Packaged Goods IndustryVirgil PopaAdditional information is available at the end of the chapterhttp://dx.doi.org/10.5772/501001. IntroductionThe Global Standards Management Process (GSMP) is the global process establishedinitially by Global Commerce Initiative (GCI) and continued by GS1 for the developmentand maintenance of global standards and implementation guidelines, which are part of theGS1 System.The Global Standards (GS) is a comprehensive set of methods and rules allowing the usercommunity and affected industry groups to submit and influence the creation andmaintenance of globally agreed standards and guidelines. Since the needs of the communityas a whole and the vertical industry groups are constantly changing, the GSMP structureneeds to reflect changes to allow maximum process efficiency.The Efficient Consumer Response (ECR) movement, Voluntary Interindustry CommerceStandards (VICS) and other industry associations have developed Global Standards andBest Practices for CPG (FMCG) industry based on collaboration. These include for exampleCategory Management and Collaborative, Planning, Forecasting and Replenishment(CPFR). To date the industry has struggled to implement these processes widely. Astandards based foundation brings: Scalability (expansion from a pilot to an enterprise-widesolution); Portability (roll-out across internal divisions and regions); Affordability (increasein scale without proportional increase in cost) to these processes. [1]Emerging technology brings new e-business and e-service opportunities to the marketplace.e-Procurement, e-auctions and e-communication over the internet through XML will all bemore efficient if developed on a common standards based platform. If internationalmanufacturers, retailers and solution providers (including exchanges) are forced to supporta myriad of local ‘standards’ then the incremental cost incurred will impact the entiresupply chain, including national players. 2012 Popa, licensee InTech. This is an open access chapter distributed under the terms of the CreativeCommons Attribution License (http://creativecommons.org/licenses/by/3.0), which permits unrestricted use,distribution, and reproduction in any medium, provided the original work is properly cited.

234 Globalization – Education and Management AgendasThe Global Commerce Initiative established the Global Upstream Supply Initiative (GUSI)in order to provide a standard framework for consumer goods manufacturers and theirsuppliers of ingredients, raw materials and packaging to better integrate across a number ofsupply chain processes.Without Internal Data Alignment, for example, Global Data Synchronization (GDS) willdefinitely not improve business performance and will, in fact, magnify the negative impactof poor quality data. What’s more, collaborative initiatives such as those included inEfficient Consumer Response (ECR) and Collaborative Planning, Forecasting andReplenishment (CPFR) will not be economically deployable on a wide scale without theconsistently accurate and available information that will result from an Internal DataAlignment program.GDS is based on a global network of data pools, or electronic catalogues, which are all interoperable and compliant with the same business requirements and standards.Interoperability means that a manufacturer can publish a product and partner data on onesingle Data Pool without having to worry about the fact that customers may select differentData Pools to access the data.The need for an internal organizationThe success of Global Standards, and therefore the realization of the benefits, will comethrough achievement of critical mass. Widespread adoption, though, does not mean thatcompanies cannot gain competitive advantage through optimal implementation of standards.Leading companies that strive for this position have aligned relevant internal functions andprocesses with the external standards development and management environment and arebuilding standards implementation into their internal business processes.It is clear that standards development requires business involvement. Industryrepresentation is critical. Leading businesses understand this and engage with the standardsprocess.In addition to working with the GS1 - GSMP and with GCI, most major manufacturers andretailers engage with trade associations such as Association Internationalle de Marque(AIM), CIES – The Food Business Forum, Food Marketing Institute (FMI) and GroceryManufacturers Association (GMA), and with associations such as the regional and nationalECR and GS1 organizations. Most companies do not co-ordinate their activity across thesebodies allowing regional or national managers to engage with a regional or local perspectiverather than a global perspective.Lack of alignment of these activities in a global company results in inefficient use ofresources, duplication of activity and confusion within and outside the organization.Companies that have coordinated across these activities report increased efficiency (areduction in the resource applied against these activities) but coupled with a significantincrease in effectiveness. Less people doing a better job.

Global Standards for Supply Chain Management in Consumer Packaged Goods Industry 235The GS1 Business Plan includes expansion of the GS1 System into targeted sectors. In orderto accommodate new sectors, GSMP must balance the need for individual sector needs witha consistent overall process. In terms of recognition and governance, the GSMP allows theformation of a User Group for a specific sector based on the GS1 Business Plan.The Nestlé GCI/GSMP networkNestlé implemented a GCI/GSMP internal network to co-ordinate the approach to standardsdevelopment and drive the standards implementation. The organization is built around 4units: One Expert Network per subject; Subject Matter Owner; Central coordination role;Nestlé GCI/GSMP Steering Group.Nestlé created an Expert Network for each subject in which they are involved in GCI/GSMPworking groups. In general, the Experts could be anyone, who is working on the respectivesubject. They contribute their subject knowledge during standards development andcommunicate the decisions made back to their base (e.g. Market, Regional Center).2. Overview of Global Data Synchronization (GDS)2.1. Information sharing in the supply chainInformation sharing can address three key areas in a product life cycle: Greater sharing ofinformation about consumer trends and market trends between trading partners can lead togreater insights into consumer behavior, enabling both partners to better serve theconsumer. Sharing information about real demand between two trading partners can enablethe development of products that better meet consumers’ needs. Sharing of accurate, realtime operational information between the two trading partners can lead to better use ofassets in the supply chain. This can improve product availability and consumer satisfactionat the point of purchase. Accurate information is the basis of any commercial enterprise.This is particularly true in the fast-moving, quick-response world of manufacturing andretail. [2]New ways of working together is about developing new ways for vertical trading partnersto work together – including sustainable changes in culture, collaborative business planningand new measures and rewards. For a bilateral trading partner relationship, it offers anintegrated roadmap for getting alignment and commitment on four key strategic choices inthe collaboration of trading partners, which can ultimately lead to more satisfied shoppersand the elimination of waste, both of which should, in the end, produce better businessresults.Some of the changes that need to be made with regard to information sharing will affect thewhole industry; others will be bilateral arrangements between individual trading partners,as each company finds out “what works for us”. The reforms needed are in systems, inpractice and in philosophy, and cover, for example, a common vision of the value to becreated by sharing information across participants in the value chain or changing the way

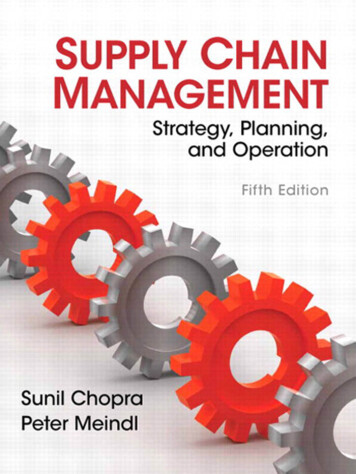

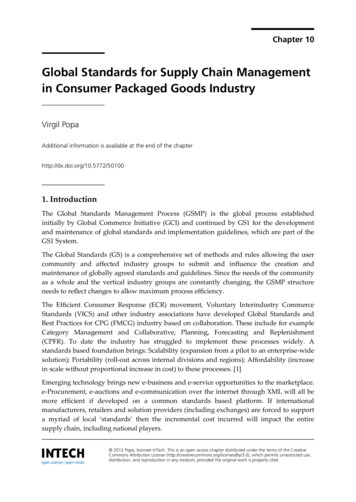

236 Globalization – Education and Management Agendasdata is exchanged. A GCI group worked on the development of data flows linked to theprocess of new product introduction, identifying what the information needs would be in2018, as well as possible solutions, like a POS data sharing platform. The group analyzed thecurrent situation and outlined the action needed to move the industry forward. A number ofgroup members are now working to establish pilots on information sharing across severalsteps of the new product introduction process. [3]2.2. Global commerce initiative vision for Global Data Synchronization (GDS)Data synchronization is the process of sharing master data between trading partners (detailsof materials for sale within a market). GDS is based on a global network of data pools, orelectronic catalogues, which are all inter-operable and compliant with the same businessrequirements and standards. Interoperability means that a manufacturer can publish aproduct and partner data on one single Data Pool without having to worry about the factthat customers may select different Data Pools to access the data. A Global Registry controlsthe flow of information within the network. Obviously , perfect alignment of Master Data isa necessity to support advanced collaborative practices, but the effort of undertaking such aproject is worth it : exchange of master data through data pools is the most efficient andreliable method to implement modern collaborative practices.Strategic directionTo support and implement the GCI vision for GDS is the strategic direction formanymultinational companies. Under the Global Commerce Initiative was developed the firsttruly global approach to Data Synchronization.A known best practice in the area is always to collaborate with customers or suppliers withconfirmed GDS commitment while aligning internally to create the readiness for efficientand effective large scale implementation of GDS, in terms of organization, processes, dataand systems.Buyers and sellers would be able to focus on building sales rather than on correctingmisaligned information. When a new product is launched the data will be exchanged in aseamless and streamlined way through the supply chain, allowing the right amount ofgoods to become available at the right place and at the right time – and faster!This is the vision that GDS enables through providing the fundamental infrastructure for theseamless flow of product information through the supply chain.This GDS vision is delivered by the GDS Network. The network (Figure 1.) consists of: Interoperable, certified Data Pool,A Global Registry; provided by GS1,A set of EAN.UCC Standards (European Article Numbering – United Code Council),ensuring that all supply chain partners use common product descriptions andclassification and the same message structures to exchange the data.

Global Standards for Supply Chain Management in Consumer Packaged Goods Industry 2372. The Data Pool registers a product in the GS1Global Registry and sends very basicinformation about the item.3. The GS1 Global Registry holds this basicinformation about all items and the location of eachitems’ source Data Pool.RegistryManufacturer1. A manufacturer will: Align data internally Prepare data for externalpublication in linewithEAN.UCCstandards Publish item informationto the source DataPool Synchronize changes tothis date Approve retailer requeststo subscribe to date.DataPoolDataPoolRetailer5. The trading partnerssynchronise the iteminformationbetweentheir respective DataPools.6. The same processapplies for synchronisingPartyinformation,published by manufactureror retailer, based on theGLN.4. A retailer will: Search the GS1Global Registry, via aselected Data Pool, foran item (by GTIN orby description) – theRegistry returns thedetails of the items tothe Data Pool Request subscriptionto manufacturer data Receive data and anysubsequent changes Align data withinternal data.Source: An integrated view of the Global Data Synchronization network on the Electronic Product Code Network, GCIand IBM, 2004 [4]Figure 1. GCI vision for GDSThese elements of the GDS Network collectively support the synchronization of productdata between trading partners.The GS1 Global Registry and the interoperable Data Pools are at the heart of the GDSprocess. Their roles and functions are distinct but complementary. The key role of the GS1Global Registry is to ensure that original data is registered once, at one place. Data Poolsprovide for the publication of certified standard data and subscription to this data.The Network works with the following principles: The GS1 Global Registry and the Data Pools will be EAN.UCC certified,There is interoperability among all Data Pools and the GS1 Global Registry,One single point of entry into the Network by all participants,Only the Data Pools will communicate with the GS1 Global Registry,Only GDS EAN.UCC Business Messages will be used within the Network.2.3. Master data synchronizationMaster Data Synchronization (or alignment) through data pools is recognized as the mostefficient way to support the master data sharing between trading partners. The benefit ofdata pools is that the use of their services mandates the adoption of standards. Thedevelopment of most national data pools in the world are claimed to be based on GS1standards such as the Global Trade Item Number (GTIN) for the unique identification ofitems, GS1 messages such as PRICAT and PARTIN, etc. Although many data pools supportGS1 standards, their development appears having been mainly focused on national

238 Globalization – Education and Management Agendasrequirements. This has led to the implementation of different structures and designs. Inorder for global data synchronization to be viable, data pool inter-connection and interoperability is essential.Key business components and requirements of the global data synchronization process are: Leveraging data pools in order to benefit from the potential they offer,The registration of all items and locations to facilitate sharing of master data,The implementation of standardized information flow to support the data registrationand synchronization.In order to meet these requirements, the following is needed: Implementation of a Global Registry to control the registration of items and locations,Amendment and further development of data pools in order to comply with the GCIspecifications (master data dictionary (GCI / Data dictionary), rules, principles,synchronization process, etc.),Development and implementation of standardized messages between data pools andthe Global Registry,Development and implementation of standardized messages between data pools andusers (companies) based on the GCI / Data dictionary,Establishment of a Neutral Body for the governance and certification of the GlobalRegistry,Establishment of a Neutral Body for the Technical Certification of data pools.The initial implementation of the GDS vision is focused around Master Data for ‘Item’ with‘Location’ intended to follow soon after. Master Data is the set of data describing thespecifications and structure of each Product (or Item) and Location (or Party) involved inSupply Chain Processes, based on the key identifiers, the Global Trade Item Number (GTIN)and the Global Location Number (GLN).The Master Data is an Information Alignment that can be divided into Neutral andRelationship Dependent Data.Neutral Data is that which is generally shared between multiple parties and which isRelationship Independent. This can be split into three categories: Core Product Data – Core Data Attributes that apply to all instances of any product (e.g.description, brand name, packaging, dimensions, etc),Category Specific Data – Data Attributes that only apply to specific product categories(e.g. the color, grape and strength of a bottle of wine),Target Market Data – Data Attributes that are specific to product in a particular market(e.g. packaging indicators in a specific country).Relationship Dependent Data – Data Attributes that concern all terms bilaterally agreed andcommunicated between trading partners such as marketing conditions, price informationand discounts, logistics agreements and more.

Global Standards for Supply Chain Management in Consumer Packaged Goods Industry 2392.4. Global Upstream Supply Initiative (GUSI)The Global Upstream Supply Initiative (GUSI) was formed to define a common way formanufacturers of consumer products and their suppliers to provide tighter integration of their supplychains, without the need for costly and time-consuming IT integration projects with every customeror supplier. The UIM (Upstream Integration Model) developed by GUSI comprises a set of agreedbusiness processes and information flows supported by electronic message exchange based on GS1standards.[6]The GUSI Working Group first established an Upstream Integration Model (UIM), whichdefined a number of standard business processes and information flows for differentscenarios. These scenarios covered different situations where consignment stock was or wasnot involved and covered the case where the manufacturer initiated the order (TraditionalOrder Management) or where the supplier initiated the order (Supplier ManagedInventory).In both cases, greater supply chain integration is achieved by improving visibility of bothinventory and demand throughout the supply chain.The GUSI Working Group decided to adopt the GS1 XML message standards toexchange information between the trading partners in support of these supply chainprocesses.It is important to highlight that each business case must be tailored to the actual situationdepending on the individual supplier and manufacturer, the industry, the products, etc. Thestarting point for the companies will also be different. The business case for companies thathave already invested in collaborative supply chain solutions will focus on the cost to adoptthe GUSI model vs. the benefits gained from extending their collaboration community,while the case for a company introducing collaborative solutions for the first time will focuson the initial investment vs. the benefits gained from collaboration based on the GUSImodel.The potential benefits can be categorized as: Hard benefits (tangible),Likely benefits (quantified) (tangible),Qualitative benefits (non-tangible),Stretched benefits (non-tangible).Tangible benefits are those associated with a monetary saving, e.g. from collaboration whichcan give reduced inventory, material cost reduction, reduced errors, optimized productionplanning, reduced paper handling (e.g. e-billing) etc.Non-tangible benefits refer to all those that cannot directly be put into monetary terms,e.g. improved data quality, increased flexibility and reliability towards customers.Although difficult to quantify, intangible benefits can be significant and add weight to anROI study [5].

240 Globalization – Education and Management Agendas2.5. Business rationaleThe current situation in the upstream supply chain of the CG industry is that allmanufacturers and suppliers are faced with different business processes and datainterchanges when they move into more integrated relationships. Different businessprocesses and approaches create a barrier to the scalability of integration efforts whilst alsoimposing many costs: the time and money spent making transactions; the delays caused bythe need for corrections; plus inevitable information gaps and misunderstandings. Bothparties should obtain benefits from integration, among them improved visibility of demandand demand changes and reduced inventory. Today, to access these benefits, each programbetween manufacturer and supplier has to establish its own framew

2.2. Global commerce initiative vision for Global Data Synchronization (GDS) Data synchronization is the process of sharing master data between trading partners (details of materials for sale within a market). GDS is based on a global network of data pools, or electronic catalogues, which ar