Transcription

TEXAS A&M UNIVERSITY2017ANNUAL REPORTDEPARTMENT OF MATERIALSSCIENCE AND ENGINEERING

FROM THEDEPARTMENT HEADDear Colleagues and Friends,2017 was a dynamic year for the Department of Materials Scienceand Engineering at Texas A&M University. Among the plethoraof exciting events, we are most proud of receiving approval fromthe Texas Higher Education Coordinating Board for the Bachelorof Science degree program in materials science and engineering.This will be the first undergraduate program of its kind at a large,land-grant university in the state of Texas. We will welcome the firstcohort of sophomore students to the department in fall 2018.In addition to welcoming undergraduate students to the department, we reached record enrollment of151 total graduate students in 2017 comprised of 26 master’s and 125 doctoral students.As part of the Air Force Research Laboratory’s Minority Leaders Program, 12 minority doctoral studentsper year will be funded and have the opportunity to train in data driven materials discovery anddesign. Drs. Raymundo Arróyave, Ibrahim Karaman, Dimitris Lagoudas and Patrick Shamberger, areleading the effort for our students. Texas A&M and Georgia Tech University were the two universitiesselected to host the program.With our growing enrollment, we have added a new faculty member in January 2018. Dr. Kelvin Xie cameto us from Johns Hopkins University where he was an assistant research scientist.Our faculty are excelling in many research endeavors while receiving recognition from their peers asprestigious award recipients. Dr. Svetlana Sukhishvili is leading an executive committee to establishand develop an interdisciplinary soft matters facility on our campus to unify research activitiesrelated to soft matter and improve multifunctional polymer-based materials that are used in manyapplications, including energy, health care and transportation.NASA has selected a team of Texas A&M faculty for a five-year, 10 million grant as part of NASAAeronautics’ University Leadership Initiative. Lagoudas, deputy director of the Texas A&M EngineeringExperiment Station, will manage the team, which includes Dr. Darren Hartl as operations director. Thefaculty at Texas A&M, along with collaborators from six other institutions and companies, will researchand design commercially-viable civil supersonic transport aircraft that can modify shape during flightunder a range of conditions to meet noise and efficiency requirements for overland flight.We are excited to announce the large donation of a brand-new FEI Titan Themis 300, double correctedhigh-resolution electron microscope, which will be installed in the Materials Characterization Facilitythis academic year, and will greatly impact materials research on campus.AZZ Inc. has generously established two fellowships in the department for faculty and graduatestudents. The AZZ Inc. graduate fellowship will be used to recruit the best and the brightest domesticstudents in the country to the department, while the AZZ Inc. faculty fellowship will help our youngfaculty to develop into superstars of research, which will positively impact society.2I am honored to present the accomplishments of the Department of Materials Science andEngineering, and would like to offer a sincere thank you to the donors who generously support ourprograms through significant contributions in support of faculty, students and facilities.Sincerely,Dr. Ibrahim KaramanDepartment Head and Chevron Professor I2DEPARTMENT OF MATERIALS SCIENCE AND ENGINEERING 2017 Annual Report

TABLE OF CONTENTS6Faculty News10Research Spotlight:Dr. Michael Demkowicz14Research Spotlight:Patrick Shamberger16Student Spotlight172017 Research PublicationsCover:Porous hallow carbon fibers with antibacterialfillers for multifunctional textiles.Provided by Dr. Mohammad Naraghi,affiliated faculty member in the Departmentof Materials Science and EngineeringTexas A&M Engineering Communications 2018TEXAS A&M ENGINEERING engineering.tamu.edu/materials3

MATERIALIZING OUR FUTUREANNOUNCING BACHELOR OF SCIENCEIN MATERIALS SCIENCE AND ENGINEERINGThe Department of Materials Science and Engineering at Texas A&MUniversity will enroll its first class of sophomores in fall 2018 for thenew bachelor of science degree in materials science and engineering.Our goal is to admit 100 students per year to become one of thelargest materials science and engineering programs in the country.engineering.tamu.edu/materials4DEPARTMENT OF MATERIALS SCIENCE AND ENGINEERING 2017 Annual Report

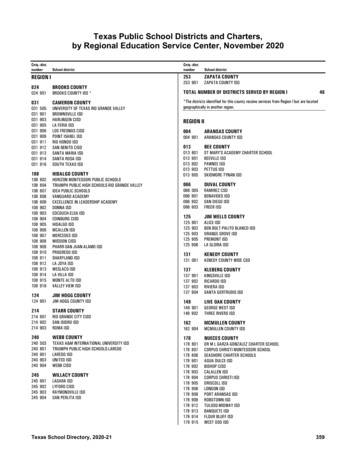

2017 IN ate ProfessorsAssistant ProfessorsProfessors of PracticeAffiliated FacultyNational Academy ofEngineering MembersENROLLMENT 151M.S.Ph.D.26125158431492RESEARCH IMPACTAverage journal articlespublished per faculty member7.4Average journal articles publishedper graduating Ph.D. studentRESEARCH AREASSTUDENT DIVERSITY54% 33% 26%Incoming DomesticGraduate StudentsIncoming MinorityGraduate Students7FemaleEnrollment Advanced structural materials Computational materials scienceand design Corrosion science and engineering Materials for extreme environments Multifunctional materials Polymers and compositesINDUSTRY ADVISORY BOARDTodd AbbottJay HendersonRyland MarekBonnie TullyPioneer NaturalResources, Oil and GasNucor Steel Texas3MEvonik CorporationDr. Scott BeckwithDr. Peter Hong GaoJeffrey PolzerVance Cribb, IIIApplied MaterialsShell Global Solutions US Inc.Dr. Lotus HuangDr. Pratik JoshiBell Helicopter Textron,Aerospace/Aviation OEMThe Dow Chemical CompanySamsung Austin SemiconductorThomas LednickyColleen SchlaefliCFAN- Commercial AerospaceLockheed Martin AeronauticsDr. Calvin LundeenJohn StevensWexco CorporationBaker Hughes GEBTG Composites, Inc.Mark ChrisBell Helicopter Textron, Inc.Bernardo DuranAZZ Inc.Roxanne WarrenArconic/ RTI DirectedManufacturing,Additive ManufacturingTEXAS A&M ENGINEERING engineering.tamu.edu/materials5

TALREJA RECEIVES THE 2017 OUTSTANDING RESEARCHAWARD FROM THE AMERICAN SOCIETY FOR COMPOSITESDr. Ramesh Talreja,Tenneco Professorof Engineering in theDepartment of AerospaceEngineering and theDepartment of MaterialsScience and Engineeringat Texas A&M University,has received the 2017Outstanding ResearchAward in Composites fromthe American Society forComposites (ASC).The ASC describes the winner of the award as “adistinguished member of the composites communitywho has made a significant impact on the science andtechnology of composite materials through a sustainedresearch effort over a number of years.” The ASC’s missionis to provide a communication forum for the engineeringand scientific community and to expedite growth ofknowledge gained from inter-disciplinary engineeringand scientific research in composite materials, as well asto promote the exploitation of the unique properties ofcomposite materials in emerging applications.In 2013 Talreja received the highest honor, the ScalaAward, from the International Committee on CompositeMaterials (ICCM). The award comes with the designationWorld Fellow and Life Member of ICCM.Talreja has published extensively in the field of damagemechanics and fatigue of composite materials. Hehas authored the monograph “Fatigue of CompositeMaterials,” and has edited several major works includingPolymer Matrix Composites, Damage Mechanics ofComposite Materials, Multiscale Modeling and Simulationof Composite Materials and Structures and PMC Fatigue–Fundamentals, and has contributed more than 30chapters to numerous books. His book “Damage andFailure of Composite Materials,” co-authored with C.V.Singh, was published by Cambridge University Press. Heis on the editorial boards of 14 journals, and has servedas associate editor of Mechanics of Materials and as editorin-chief of International Journal of Aerospace Engineering.His current focus is on structural integrity, durability andsustainability of composite materials in aerospace andwind power structures.Prior to joining the faculty at Texas A&M, Talreja was aprofessor of aerospace engineering at Georgia Institute ofTechnology from 1991-2001. His academic career beganat the Technical University of Denmark where he receivedhis Ph.D. and Doctor of Technical Sciences degrees in1974 and 1985, respectively, and served in differentacademic positions until 1991. From 1978-83 he had ajoint appointment at the Risø Laboratory of SustainableEnergy in Denmark.Talreja received his plaque and award of 1,000 atthe awards banquet of the 32nd Annual TechnicalConference, to be held at Purdue University on Oct. 24.CASTANEDA-LOPEZ TO RECEIVE 2018 HERBERT H. UHLIG AWARDThe National Association ofCorrosion Engineers (NACE)has selected Dr. HomeroCastaneda-Lopez, anassociate professor in theDepartment of MaterialsScience and Engineering atTexas A&M University, toreceive the 2018 Herbert H.Uhlig Award.The award recognizesoutstanding youngeducators in postsecondarycorrosion education who have effectively excited theirstudents through outstanding and innovative teaching incorrosion engineering.6DEPARTMENT OF MATERIALS SCIENCE AND ENGINEERING 2017 Annual ReportCastaneda-Lopez is director of the National Corrosion andMaterials Reliability Center at Texas A&M, where the focusis to develop the next-generation leaders in corrosionscience and technology to work in various industriesincluding energy, national defense, auto, healthcare,infrastructure and multiple government agencies.“We work to bridge the gap between fundamentalresearch (science) and technology (engineering),”Castaneda-Lopez said. “We serve as a world-classcorrosion education and research center creatingtomorrow's leaders in corrosion science and engineering.”Castaneda-Lopez will receive the award in April atCORROSION 2018, the world’s largest corrosionconference and exposition.

SRIVASTAVA RECEIVES 2017 HAYTHORNTHWAITERESEARCH INITIATION GRANTDr. Ankit Srivastava, anassistant professor in theDepartment of MaterialsScience and Engineeringat Texas A&M University,was selected as one ofthe four HaythornthwaiteResearch Initiation Grantrecipients by the executivecommittee of the AppliedMechanics Division (AMD)of the American Societyof Mechanical Engineers(ASME). Srivastava receivedhis award during the AMD Honors and Award Banquetat the 2017 ASME International Mechanical EngineeringCongress and Exposition (IMECE) in Tampa, Florida.correlations in multi-phase materials using in-situscanning electron microscope experiments andmicrostructure-based modeling.“The technological need of lightweight structures forweight-critical products, such as aircrafts and long-haultrucks, and to decrease emissions from automobiles,calls for materials with high density-normalized strength,”Srivastava said. “The current materials with highdensity-normalized strength suffer from poor fractureresistance, which limits the performance, reliability andmanufacturability of their components.”As a result, the overarching goal of Srivastava’s projectis to enable the design and discovery of more fractureresistant, high strength structural materials. Theoutcome of Srivastava's project will be presented at the2018 ASME IMECE.This award will provide 20,000 to support Srivastava’swork on investigating microstructure-fractureXIE JOINS MATERIALS SCIENCE AND ENGINEERINGDr. Kelvin Xie has joinedthe Department ofMaterials Science andEngineering at TexasA&M University as anassistant professor.Xie comes to TexasA&M from JohnsHopkins Universitywhere he receivedhis postdoctoraltraining. He earned hisPh.D. in mechanicalengineering and his bachelor degrees in biomedicalengineering and finance all from the University ofSydney, Australia.Xie’s research focuses on understanding anddesigning lighter and stronger structural materials,such as Magnesium alloys, boron carbide and 3-Dprinted ceramics, assisted by advanced nano-scaleand atomic-level characterization techniques.“In the area of ceramic engineering, we revealedthe twinning mechanisms in boron carbide, alight-weight body armor material, as a function ofchemistry and local bonding,” Xie said. “This ability tocontrol twinning is expected to help design the nextgeneration of lightweight body armor, where twininterfaces provide additional strength and toughness.”In the area of metallurgy, Xie and his colleaguessystematically investigated the dislocation and twinstructures in deformed bulk magnesium singlecrystals, which substantially contributed to theunderstanding that explains why Magnesium andMagnesium alloys generally exhibit poor ductilityand formability.Xie will teach fundamentals of materials science andengineering classes this spring.TEXAS A&M ENGINEERING engineering.tamu.edu/materials7

QIAN, WANG FEATUREDIN 2-D MATERIALSElectronic devices have been constantlydecreasing in size and increasing inspeed and efficiency, from miniaturizedpersonal computers to pocket-sized cellphones. Researchers in the Departmentof Materials Science and Engineering atTexas A&M University have discovereda class of two-dimensional (2-D)materials to aid in further reducing thesize and improving the performance ofvarious devices.Dr. Xiaofeng Qian, an assistantprofessor, and Hua Wang, a graduatestudent in the department, werefeatured in a recent issue of 2-DMaterials for their work in 2-Dmultiferroic materials.“Most 2-D materials studied so far haveshown one ferroic characteristic,” Qiansaid. “When we looked into group IVmonochalcogenide layers, we discoveredthat these 2-D materials have two ferroiccharacteristics simultaneously.”Their paper “Two-DimensionalMultiferroics in Monolayer Group IVMonochalcogenides” demonstratesa special class of two-dimensionalsemiconductors. These materialsare special due to their abilityto exhibit a large spontaneouslattice strain called ferroelasticity,and a giant switchable electricpolarization called ferroelectricity.These properties appearingsimultaneously in the monolayer groupIV monochalcogenides lead to 2-Dferroelastic-ferroelectric multiferroicity.“2-D materials with more than oneferroic characteristic can be veryuseful for miniaturized multifunctionaldevices such as sensors and actuators,”Qian said. “However, they are veryscarce in nature.”8DEPARTMENT OF MATERIALS SCIENCE AND ENGINEERING 2017 Annual ReportThis unique class of 2-D multiferroicmaterials could be useful for 2-Dferroelectric memory and ferroelasticmemory that are as thin as onenanometer. In pocket-sized devices, thisnew material could help make the devicesmaller by decreasing the size of thesensors and materials inside the device.They can also be useful for exploringferroelectric excitonic photovoltaicsthat take advantage of both largeferroelectricity and extraordinaryexcitonic optical absorption.“Additionally, these 2-D materials withmultiple ferroic orders provide an idealplatform to demonstrate 2-D nonvolatilephotonic memory with much lowerpower consumption and at a fasterspeed,” Qian said.Currently, the group is working to betterunderstand the microscopic mechanismsof the domain wall motion and discoverother novel 2-D multiferroic materials.“Our ultimate goal in this project is todesign multiferroicity into 2-D materials,”Qian said. “We also want to be able tofine tune and control their multiferroicityfor a variety of electronic, optical andenergy applications.”Results of the duo’s work will providenew opportunities for 2-D multifunctionalmaterials research toward miniaturizedenergy efficient applications.“Many interesting properties and potentialapplications have been discovered in 2-Dmaterials and their hybrid structures.There are a lot of new fascinatingproperties waiting to be discovered,” Qiansaid. “It is so fortunate and exciting towork in this field and understand theirfundamentals and implications for futuredevice and energy technologies.”

TEXAS A&M ENGINEERING engineering.tamu.edu/materials9

CHANNELING HELIUM:RESEARCHERS TAKE NEXTSTEP TOWARD FUSION ENERGYFusion is the process that powers the sun, harnessing iton Earth would provide unlimited clean energy. However,researchers say that constructing a fusion power planthas proven to be a daunting task, in no small partbecause there have been no materials that could survivethe grueling conditions found in the core of a fusionreactor. Now, researchers at Texas A&M University havediscovered a way to make materials that may be suitablefor use in future fusion reactors.The sun makes energy by fusing hydrogen atoms, eachwith one proton, into helium atoms, which contain twoprotons. Helium is the byproduct of this reaction. Althoughit does not threaten the environment, it wreaks havocupon the materials needed to make a fusion reactor.“Helium is an element that we don't usually think of asbeing harmful,” said Dr. Michael Demkowicz, associateprofessor in the Department of Materials Science andEngineering. “It is not toxic and not a greenhouse gas,which is one reason why fusion power is so attractive.”However, if you force helium inside of a solid material,it bubbles out, much like carbon dioxide bubbles incarbonated water.“Literally, you get these helium bubbles inside of themetal that stay there forever because the metal is solid,”Demkowicz said. “As you accumulate more and morehelium, the bubbles start to link up and destroy theentire material.”10DEPARTMENT OF MATERIALS SCIENCE AND ENGINEERING 2017 Annual ReportWorking with a team of researchers at Los Alamos NationalLaboratory in New Mexico, Demkowicz investigated howhelium behaves in nanocomposite solids, materials madeof stacks of thick metal layers. Their findings, recentlypublished in Science Advances, were a surprise. Rather thanmaking bubbles, the helium in these materials formed longchannels, resembling veins in living tissues.“We were blown away by what we saw,” Demkowiczsaid. “As you put more and more helium inside thesenanocomposites, rather than destroying the material, theveins actually start to interconnect, resulting in kind of avascular system.”This discovery paves the way to helium-resistantmaterials needed to make fusion energy a reality.Demkowicz and his collaborators believe that helium maymove through the networks of veins that form in theirnanocomposites, eventually exiting the material withoutcausing any further damage.Demkowicz collaborated with Di Chen, Nan Li, KevinBaldwin and Yongqiang Wang from Los Alamos NationalLaboratory, as well as former student Dina Yuryev fromthe Massachusetts Institute of Technology. The projectwas supported by the Laboratory Directed Research andDevelopment program at Los Alamos National Laboratory.“Applications to fusion reactors are just the tip of theiceberg,” Demkowicz said. “I think the bigger picture hereis in vascularized solids, ones that are kind of like tissueswith vascular networks. What else could be transportedthrough such networks? Perhaps heat or electricity or evenchemicals that could help the material self-heal.”

MATERIALS SCIENCE AND ENGINEERING GRADUATESTUDENT SERVES AS ASM INTERNATIONAL OFFICEROlga Eliseeva, a graduate student in the Departmentof Materials Science and Engineering at Texas A&MUniversity, is serving as one of three student voices onthe board of trustees for ASM International (ASMI).“The mission of ASMI is to connect material engineersfrom research, industry and government, as wellas provide access to reference materials, data andeducational content,” Eliseeva said.She hopes to one day become a member of the boardof directors for a company or larger internationalorganization and credits this experience with providingexclusive opportunities to learn more about largeorganizations and how they function.“I also enjoy meeting individuals leading the cuttingedge companies in the field of materials science andengineering,” Eliseeva said. “This opportunity excitesme because I love learning of people’s stories and howtheir careers have unfolded. This also gives me a betterunderstanding of what to expect in the future.”Satisfying her desire to give back, this position s

Arconic/ RTI Directed Manufacturing, Additive Manufacturing TEA AM ENNEERN engineering.tamu.edu/materials 5. The National Association of Corrosion Engineers (NACE) has sele