Transcription

NOTICETHIS DOCUMENT HAS BEEN REPRODUCED FROMMICROFICHE. ALTHOUGH IT IS RECOGNIZED THATCERTAIN PORTIONS ARE ILLEGIBLE, IT IS BEING RELEASEDIN THE INTEREST OF MAKING AVAILABLE AS MUCHINFORMATION AS POSSIBLE

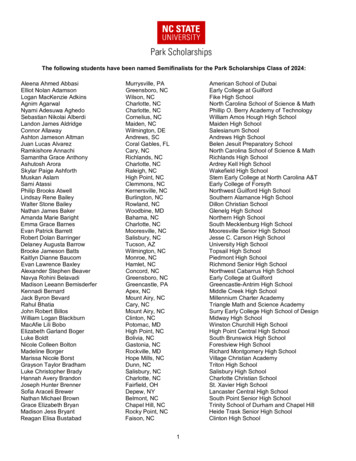

jr ' DOE/NASA CONTRACTORDOE/NASA CR-161731REPORTSOLAR HEATING AND Hr'.TWATER SYSTEM INSTALLED ATCHARLOTTE MEMORIAL HOSPITAL, CHARLOTTE, NORTH CAROLINA:Prepared from documents furnished byFerebee, Walters and Associates5672 International DriveCharlotte, NC 28211Under Contract DOE-EX-76-C- 01 -2394Monitored byGeorge C. Marshall Space Flight Center, Alabama 30812National Aeronautics and Space Administration*ror the U. S. Department of Energyw , ir41?''B1U.S. Department of Energy rSolar Energy

TABLE OF CONTENTSUgeI CDescription of Building & Function1A.Building Description1B.Design Philosophy1C.Solar System Design Overview1D.Solar Component Selection Process7IIControl logic & Modes of Operation27IIIAcceptance Test Plan33IVEquipment Schedule34VProblems Encountered,Solutions & Recommendations38AppendixA.Pictures of InstallationA-1B.DrawingsR-1rW

I. DESCRIPTION OF BUILDING AND FUNCTIONA.BUILDING DESCRIPTIONThe Area Health Education Center at Charlotte Memorial Hospital andMedical Center is a combination administration and continuing educationfacility. The purpose of the building is to provide staff office space,classrooms, and resources to maintain a program for undergraduate, graduateand continuing education aimed at improving the quality, quantity andRdistribution of healt'" manpower and education with a nine county area ofNorth and South Carolina, of which Charlotte is the center,The development of the building was made possible by a State of NorthCarolina Capital Fund Grant administerk d under the Area Health EducationCenter Program through the University of North Carolina and CharlotteMemorial Hospital and Medical Center.The six story building provides a two story multi-media center, 14classrooms, approximately 55 offices for faculty, secretarial personneland administr a tion personnel. A television studio and photographic laboratory is also provided. A one story annex to the building houses thehospital outpatient clinic reception area.B.DESIGN PHILOSOPHYThe installation of solar on the project was a retrofit to a projectialready under construction. The goal was to implement solar space heatingand domestic water heating with minimal impact on the existing structure,Imechanical systems, and appearance of the overall building design.C. SOLAR SYSTEM DESIGN OVERVIEW1. General DescriptionThe solar system is an array of flat plate collectors, undergroundstorage tank, domestic hot water heat exchanger, heating system heat-1-

exchanger, pumps, piping systems, instrumentation, etc. to make a complete and operating system.The solar system is integrated into the building systems in thefollowing manndrs (1) All domestic hot water flows through the domestichot water heat exchanger prior to entering the building electric waterheaters, (2) The heating coil in the solar energy circuit is installedin the building perimeterheatingsystem airunit upstream of the electric'heating coil. The control system is integrated to first use the heatavailable in the solar energy heating coil and then in sequence make upany heating deficit with the building electric heating coil.Theheating andair conditioning systems in the building consist oftwo basic systems.The core of the building is served by an all air variable volumeconstant temperature airmode and is onlysystem.This system operates in a cooling onlyoperational during the occupiedhours.All of the out-side ventilation air requirements are introduced through this systemthereby, the ventilation load isingandnot imposed upon the building as a heat-tax.The exterior perimeterof the building is served by a constant volume,variable temperature heating and cooling system. This is the system intowhich theIsolar system was integrated.Solarization was not included in the original building concept. Siteorientatien was conducted with primary considerationparameters such asfor conventionaltopography and surrounding structures, The superla-tive insulative characteristics of this multi-story 65,000 sq. ft. structure,coupled with the selection of superior solar components-2-and the judiciousI

placement ofsolar collectors, has negated an apparent penalty in overallsolar efficiencyresulting from a less than optimum orientation of thebuilding with respect to solarac.umulation.The solar heating and domestic hot 'water system consists of 171General Electric Model P5 collectors, roof mounted in two arrays. Netcollector area totals 4,020 sq. ft. fAwater,'»thylene glycol antifreezesolution is circulated through the collectors to a heat exchanger locatedin a lower level equipment area. Heated water is then supplied primarilyto a heating coil in' ;he perimeter air handleror to the 5,000 gallonthermal energy storage (TES) tank, also located in a lower level equipment area. Domestic; hot water is provided through a secondary heatexchanger and augmented by 12 KW electrical resistance heaters in eachof threemanifolded 15gallon hot water tanks.The schematic shown in Figure C.1-1 reflects the system concept andFigure C.1-2 shows the proposed solar collector arrays.A flexible control system is provided for the solar energy system toenable several operating modes. Control and modulating valves were provided and integrated with the existing system, for use with manual andautomatic controls to regulate solar supplied heating. The basic controlfunctions willbe operated from a self-contained panel located in thebuilding penthouse. The primary operating mode is automatic with overviewmonitoring bybuilding facilities personnel.IThe instrumentation system provides data monitoring and recordingfor evaluation of system performance and for correlation of predicted toreal time data. The instrumentation console will also be locatedpenthouse.inthe

A dedicated solar demonstration and viewing room was added to thepenthouse of teh AHEC building for holding professional and public observations.bI

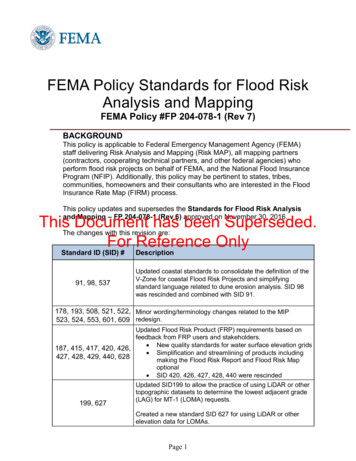

SVANSIONTANKTENT. SENSORSUNLIGHTSPACEHEATINGCOILIgoE ALVZ V4SOLAR ENERGYLDLLECTORVALVE V1PANELSPUNT P12PUN! P1J::fAy—iCOLD WATERSUPPLY'.TEMP. SENSORALVE v2v vCOLLECTOR LOOPKEAT EXCHA.4GERTHERMALENERGYSTORAGETANKDOMESTIC NOT WATERWT WATERHEAT E90WICERSUPPLY4,000 GAL.VALVE VJDRAINsTFIGURE C.1-1 AHEC SOLAR HEATING SYSTEM SCHEMATIC-5-

Q.f'IIN*NLDH44jtl i.it

1. DESCRIPTION OF BUILDING AND FUNCTION (Continued)D. SOLAR COMPONENT SELECTION PROCESSUsing NCC 1II,an analysis program for the determination of peakheating and cooling loads by APEC (Automated Procedures for EngineeringConsultants), the cooling and heating loads for the building were determined. The hot water demand and profiles for the builidng were basedon ASHRAE data. The results of the analysis are shown in Figures 1Iand 2.Modeling the characterization of the ANEC building was performedutilizing General Electric's Building Transient Thermal Loads (BTTC)Program. The corresponding parametric analysis was developed by GeneralElectric's Solar Energy System Simulation (SESS) Program.Conclusions resulting from the analysis are as follows;1.Solar system efficiency, using a TES minimum temper,itureMalin) of 105 O F is predicted to be 30.3% for space heating and 78.6% for domestic hot water - a total annual of45.8%.With a Tmin of 800 F, the total annual solar contribution would be increased to approximately 52.5%.We recommend a 5 0 activation range for the .ES pumpon at 85 0 F and off at 800F.2.Collector tilt should be changed from 500 to 35 0 to minimizecollector shadowing.r3.Storage volume is confirmed at 6,000 gallons.4.Proposed 4" coated urethane TES insulation is confirmed,5.The addition of a second collector cover will result in aIperfoniiance improvement of only 4% and is, therefore, notrecommended.r 7

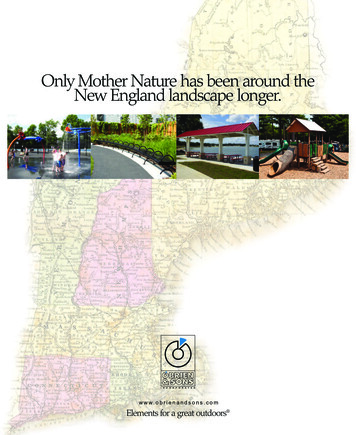

IThe descriptions of the unclosed graphs of the study results are asfollowsThe building usage schedules, shown in Figure 1, reflect FWA inputsused in determining space heat loads. Monthly space and hot water loadsare shown ire Figure 2.The effect of varying TES tank minimum temperatu r e is shown in Figure3. By allowing the TES tank to operate atlower temperatures, it is pos-sible to utilize more of the stored energy, particularly for space heatingwhich is the daninant load, and thereby improve the overall solar energysystem performance. For the most part, the solar energy is used to prebeat the circulated air and cold water supply, with conventional energyproviding the deficit,Two conditions of TES tank minimum were evaluated - re,,Ots areshown in Figures 4 through 13: Thin # 80 O F (Figures 4 through 8) TminIOSo F (Figures 9 through 13). For the design, it is recommended thatthe 80 O F condition be used with a 5 o F dead bank (i.e, the pump in theTES load loop would be turned off when the TEStemperature A80 O F andwould not turn on again until the TES temperature - 850F).The effect of collector tilt angle on solar energy system performanceis shown in Figures 4 and 9. Notice that peak performance can be realizedat 45 0 w 500 tilt when row-to-raw collector shading is eliminated. Thisresult is consistent with the ruleapplications occurs at anof thumb that optimum tilt for heatingangle equal toIthe latitude plus 15 0 . Domestichot water demand tends to reduce the optimum angle somewhat.When thedesign spacing (panel width - 1.5) is implemented, the shading at thehigher tilt anglesXe.become significant andresults in reducedperformance,The recommended tilt angle is 350.-8.r

The performance of the solar energy system is shown in Figures 5 and10 as a function of collector area. The available roof area and the designspacing between rows of collectors constrain Lite number of collectors to171 (3,950 FT2 ). For the Tmin 80O F condition, 52.5% of the total loadis supplied by solar, with 39.5% contributed to space heating and 78.6%to domestic hat water loads. Also, as shown in Figures 5 and 10, theperformance of the FP-1 collector can be enhanc, J 4% to 6% by additionof a second cover.The effect of varying the TES tank capacity was evaluated over therange 4,000 to 8,000 gallons and the performance is shown in Figures 6and 11. Beyond 6,000 gallons, the performance curve is relatively flat.Therefore, 6,000 gallons was selected,The 'TES tank should b,, insulated with a material having a minimumthermal conductivity of .3 BTU-INas measured at a mean temperatureHR-F T2 -OFof 2000 F. The effect of varying insulation thickness on system performance is shown in Figures 7 and 12. A thickness of 4" was selected.As a result of this analytical study, the design features of the solarenergy system have been selected and are suniarized below:Collector Area (Net)3,950 FT2Collector Tilt:350TES Tank. Capacity6,000 Gal,TES Minimum Temperature80OFTES insulation4" Coated Urethane orEquivalentkIf the total load were increased by a factor of 1.5, the overall performance would be reduced to 42.8%; if the total 'load were doubled, theperformance would be reduced to 37.5% (for Tmin 80OF as shown in Figure 8).The corresponding effect of varying load for a Tmin 1050 is shown inFigure 1 3.-9V -

AT 10NA TCENTERBUILDING USEAGE SCHEDULES808000alle756000uC70Q 4000IujI. -4n652000tt04812162002484121620242024HOUR OF DAYHOUR OF DAY160400140120300W100wQWC9200s80x w100i6040!0048. ., .,.121620240481216HOUR OF DAYHOUR OF DAYFIGURE 1,10

T0AREA HEALTH AND EDUCATION CENTERMONTHLY LOADS PROFILE0 1141210.19cappNwL6420Jnnr r- tv f-frrN r7t-r%FIGURE 2Vl- rrVGrV t-

IAREA HEALTH EDUCATION CENTERSUMMARY OF ANNUAL BUILDING LOADSZONESPACE HEAT LOAD, MMBTUM1171.0218.1325.946.056.56358.6DOMESTICSPACE TOTAL486.6HOT WATER TOTAL222.6GRAND TOTAL709.2FIGURE 2-1r

taAREA HEALTH EDUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF TES TANK MINIMUM TEMPERATURES.NOTESf1. COLLECTOR AREA 3950 FT22. YES TANK CAPACITY n 6,000 GAL.3. TES TANK INSUL. THICK. n 4" (K n3-8TU -inHR-FT - F4. COLLECTOR TILT n 3506Qoc5Cm0WH4C0NaoO.J3C.azWVd'Wd2CC08090100TES TANK MIN. TEMP., OFFIGURE 3-13-110120

AREA HEALTH EDUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF COLLECTOR TILTNOTES:1.COLLECTOR AREA 3950 FT22.TES TANK CAPACITY 6000 GAL.3.TES TANK MIN. TEMP. 80 F4.BBTU-114TES TANK INSUL. THICK. 4" (K .3 - TU -114 o )5.- - - —SHADOWING NOT INCLUDEDHR-FT F. 1HADOWNG INCLUDED60wdc50JONcoDM 40CLG.WwQW 30UCGW200020403050COLLECTOR TILT ANGLE, DEG.ritFIGURE 4-14-60

f i AREA HEALTWEDUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF COLLECTOR AREA.NOTES1.TES TANK CAPACITY a6000 GAL.2. COLUCTOR TILT , 360f3.TES TANK MIN, TEMP n 80OF4.TES TANK INSUI L. THICK. n 4" (K5'.I.3'OVERALL PERFORMANCE —SPACE HEATING PERFORMANCEHOT WATER PERFORMANCE----DOMBTU-IN'"n r-r2 celHR-Fr6. THE CURVES REFLECTI COVER COLLECTORS. THE SYMBOL 0 REFLECTS 2 covers.I100 BO600-4Ci.to 40;EiL4.2000I23COLLECTOR AREA, K FT 2FIGURE 5-15-45(AtI GINAL PAGE ISOF Po ()R QUAL17Y

AREA HEALTH EDUCATION, CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF TANK CAPACITY.NOTESI. COLLECTOR AREA - 3950 FT22.COLLECTOR TILT - 3503.TES TANK MIN. TEMP. : 80 F4.g BTUTES TANK INSUL. THICK. - 4" (K - ,)HR-FT - F5.- -- OVERALL PERFORMANCE-- - SPACE HEATING PERFORMANCE-DOMESTIC HOT WATER PERFORMANCE10080 tNmW60Jd.,.Cdi, . - .».V1WC7. ,zW 40V4dd200l01.,.fI-24. . . . .6TES TANK CAPACITY, K GALFIGURE 6-16 .T .4-. 810

7—crAREA HEALTH EDUCAilON CENTERiSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF TES TANK INSULATION THICKNESS.NOTES:1.COLLECTORAREA 3950 FT22.COLLECTOR TILT 3503.TES TANK CAPACITY 6000 GAL.4.TES TANK MIN. TEMP. 80OF5.- -I NTES TANK INSUL. K n .3 BTUHR T -60aC)"'50asWrra.CL.4041-aWVWa.30k2000264TES TANK INSUL. THICK., INCHESFIGURE 7-17-8

AREA HEALTH EDUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF LOAD FACTOR.NOTES1.COLLECTOR AREA - 3950 FT2.COLLECTOR TILT - 3503.TES TANK CAPACITY - 6000 GAL.4.TES TANK MIN. TEMP. - 8005.TES TANK INSUL. THICK. - 4" {K , 3 BTUoHR-FT - F60Tf .50.,. co04 -1w'zwW430 t20 t01.01.5HEAT LOAD FACTORFIGURE 8-182.0

AREA HEALTH EDUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF COLLECTOR TILT.NOTES:1. COLLECTOR AREA s 3950 FT2R. TES TANK CAPACITY 6000 GAL.3.TES TANK MIN. TEMP. - 1050F4.TES TANK INSUL. THICK . 4" (K n .3 BTU-IN5.--- - SHADOWING NOT INCLUDEDHR-FT -- FSHADOWING INCLUDEDFO50craamWHWa40CLNwavc 30WQx2000k2030405060COLLECTOR TILT ANGLE. DEG.FIGURE 9Pr-19-ir

iAREA HEALTH EDUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF COLLECTOR AREA.NOTES:1.2.3.4.5.6.TES TANK CAPACITY- 6,000 GAL.0COLLECTOR TILT 35TES TANK MIN. TEMP - 105 FOTUTES TANK INSUL. THICK. 4" (K * , 3 .--. o)HR-FT - F--- OVERALL PERFORMANCE-- - SPACE HEATING PERFORMANCEQOM. HOT WATER PERFORMANCETHE CURVES REFLECT 1 COVER COLLECTORS. THE SYMBOL G REFLECTS 2 COVERS.a1 OA-800cnm 60vw,JdNpiC7QFW40LiCGW.m200L. .0i1F! .2.Fi3COLLECTOR AREA, K FTFIGURE 10-20-III4a .i. ',.I5

tAREA HEALTH EDUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF TANK CAPACITY.NOTES:1. COLLECTOR AREA 3950 FT22. COLLECTOR TILT n 3503. TES TANK MIN. TEMP. n 1050F.3 BTU, 1n4. TES TANK INSUL. THICK n 4" (K nHR-Ft -OF5. --- OVERALL PERFORMANCE — SPACE HEATING PERF.— -.- DOM HOT WATER PERF.1008060JminJ40G.ddF-W 'cOU OCWCL00264TES TANK CAPACITY. K GALFIGURE 11-21810

AREA HEALTH EQUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF TES TANK INSULATION THICKNESS.NOTES:1.COLLECTOR AREA - 3950 FT22.COLLECTOR TILT - 3503.TES TANK CAPACITY - 6,000 GAL.4.TES TANK MIN. TEMP. - 105 F5.TES TANK INSUL, K - .3 BTU-INHR-FTZ- F60 7Y50 ».,

AREA HEALTH EDUCATION CENTERSOLAR ENERGY SYSTEM PERFORMANCE AS A FUNCTION OF LOAD FACTOR.NOTES:1. COLLECTOR AREA - 3950 FT22.COLLECTOR TILT n 3503.4.5.TES TANK CAPACITY . 6,000 GAL,TES TANK MIN. TEMP. w 1050F'BTU- INTES TANK INSUL. THICK. 4" (K .3HR-FTHR-FT - Fi60S 500H!cQW40J"30HZWCL200G01.01.52.0HEAT LOAD FACTOR.FIGURE 1323i4j

In addition to the parametric analysis and modeling which were donefor the equipment selection, it was necessary to determine the collectorpressure drops with respect to flow and the system temperature balancepoint, with respect to rejected heat versus collected heat. The resultsof these studies ,ire shown on Figures 14 and 15, respectively, whichfollow:-24-

Tt},i r t trk t . . ;;. g,tY » , }}4r.ti,#;} .# :! ,s;Sr4i ft{:.ylt .t sF4.}if" « , .},tr##4r# .ij 3 (4F 7: , :i tk4*' * 3 t r' 4t:tx ji#p3 ya ta t'rkr'! } { {I. }' .r kr .}E-#l,4 t!1tt 4.k1 4ikStS SF F F i} tti{z yi #i» Vr l}fk.t!i} #,# }ct1't Y rR, ! },t. 1'p}M.t " iit!Ar At r'1tr-}t . Ii aR i .T'r . .r4r.}} .D.'iq r'll .i t4rt"r:r tiititt ,''t'c}r:fti k s t .ref.livttis,.w i #1,l 4.titif Iyrirtj4- I ,i r! .rA "T,.t i .f .ik.t t rIl}f.ri r '4;.} .l', " #a t'aj4 i }at err f ii "FYtt' #ffi.}1t,#i b '}Y}4,tr}:if ## {yt.lii i 4#,ttt r j. } ,t}., a« t , rit .t 4r i i'11 .r- 4} ' t, 3x . 333T} iii i r { Cittl r t M { . 1 }lt j ' 44k»R. r it #.yX« R tt.»tr tt , f . 4t.: t #'*ktt ., R }}, ,t 4.r, } 4#'. ,4 :,}r111«k a .l' a,k,. ,} t44 t s. 4t}::d } . . ,ellk.i3.#t: tt af v}*it}4; " { tARtrI 'rel wr t }irt i#} V» -»4b .#k" ,. f4 ef ; 'sl: ?il.Vls Y.,FIGURE 14—25-t h » -ki}ifit'Y#tY r iiey a l.'f ,tt t ,i .1-. ,. f. L.k}l1.R #tt r.,4.r.i r'Y R; .(t4 1 t rt#t #s x. .1"'4.{ . 4 ttr{ trrt'µt}{,#a-11trt kt Y ' #*Mr: h i f # t' ha :F" tf14, *rt i 9t Ytk.t}itfr f"» d s. 7{'Y } I7 }}t' }. .! r } . 4 }» t 'afll ,w ti A.t;„}ll r »i .11},t 1 l t;4. 'ii l T it ww# «t Y.r « ,* .i r('4. ,e t.'t' e}r y} it(tt,}1 tt (t3it f i # ' tr i;# r r , . }41,,, }rk ik » rt . P,:{.» ';;ti Xt' ; t ,e" l : t 4, j ettl r!' "1' ,. Rt.i}ktS t:lwih I} ti.io t t fr }ky tt l j' .t :}.1./ i a l#aw}E ,, l ;.tiVIr».4 # rt t YV tt,} t 'R} tr rttrtLL 4 .!. ik« 4r z ”l rt} 4A1# 1 i .4 tt ";l f:IIat r f #a,}k' ! 44 }4} V ft,.V 4k tlt «t , 'I r :}j yr rf1A yn}/\Ml[a :#f. ia }} .Yiit}fiw.Y. .{j ,l Orr 4 ,ft# . la4.! i , Y IfY4YItetfiS4 j' ,,.4tht ,k,.'4 }t e4#'ti 4} Y 4 tt kRt!s ,Y% iYty', };1Ijx} actY ,i twwl fikt ir A4t, sf t,4 4 . 11r t #.Jt k' j}ttick rr}ti4t ,rt ' {} r.ir 1.'. Rintxar} 4' t'# .«,4A41141 4,is .4*A# 1 f4ti.4?{ 1,rr#'} yj.wl r»wi! .tr . i r4 :y. ',t-t,. f }1 lt»s»I « # . l #MrRkY. t fl {Y.-i.,' '. .t,, J 40 . xr { str r{.iiF,.k tt i ,i !kt it'tt 4RI 't . # ' t4it4fi4 f 4 i' „ .Y , t # .w# 4:.t;.tti#}. }a t .t.r-Rt l.tt ' :k#s t }'" r,Mlat4. i . r.ifYt '4rf ' rr "k1 r'4l ,l»ar R t. y,It# ki !!l# i .i i k}.' .t' i' #.Rifi. i'V 4rt ; .,,. tt}. '4t}4 tx} 4: t4F } if Y. S '. »Y . f.:, [. a r lY :l34!*tlf , }'r 4 r i i l t t tR {4841tftt ! t e11 Fjk j-t #, i t}T rtr rr .M .'1 l.isk# #ttf it} *4 kt F}'i' 4{ yr t!44fyry iyik#. , t *}R: .t fikr4Yrr i1Ill}t}t . yt t4 a t{to t 14'4r *}t : t it}4 yi't'!, 4",c.t't} klirP 4t{{r,, ti }}4 l . ti; . 1{ Aita}yet ya.; tA4 4'-f}tIt}{7 } 4, y }r ff' t l tie4 l i4}l# }}rr r li'4t.»l»1j,rr Pt: } y'.;f.4x I l # r 4r t hi tF, t.} i'rk4!j t l ,t t .,Iii ,r '#.ta-,r,4 .t it.t 4r itIt .rr 4 ttgt;It(i t I*k}II.,i4 !'# ri} x42. l k.j 1 M Y . t t l -#t:tt. aw« ;w t M . i . *rMx t% » tFRI ! }' # Ei r }ic!rM .i4f . t.11 l 4R. : 4F i tt? t : Y'krT'Yt t'i-i rt4 t.}([ i} 1 lY4' . I4 rfy 4 ' r1 }ill r t}i i 4t.,} }. 1fhi L4 1 .ir#tP t'-4's: tl it.4' f i t r iiitk} S p iYa !} w .4 # r,y.' It;atl 'a }ikr}i(yil it!# '.(i4 ir4:'.}kk 77I ik t 4 } a f . iy. 4, :ir ;k.y.#rx »t{. ' 1att 11lrt[(44! Mtr } }tt,qTi } Y i #t , .ki, t.}l4tR 1 titi ;lt t' 1'Rr'i'rt.Y«r{. }.' #i}t sY E} 4at'r R{/ l4 tK trtrr4 x 4rr i43 .i#}} }

SOLAR HEATING AND Hr'.TWATER SYSTEM INSTALLED AT CHARLOTTE MEMORIAL HOSPITAL, CHARLOTTE, NORTH CAROLINA:Prepared from documents furnished by Ferebee, Walters and Associates j 5672 International Dri