Transcription

NORSOK STANDARDCOMMON REQUIREMENTSMATERIAL DATA SHEETS FOR PIPINGM-CR-630 Rev. 1, December 1994Please note that whilst every effort has been made to ensure the accuracy of the NORSOK standards neither OLF norTBL or any of their members will assume liability for any use thereof.1 FOREWORDThis standard has been developed by the NORSOK standardisation work group and agreed by theNorwegian industry for the widest possible national and international application.Note: Materials of Type 6Mo and 25 Cr duplex manufactured prior to 01.01.95 can be acceptedprovided the following is satisfied:- Corrosion tests have been carried out with acceptance criteria for pitting and weight loss accordingto NORSOK MDS’es at 40 C.- The microstructure is free from all grain boundary carbides and intermetallic phases.2 SCOPEThis Standard is a collection of the Piping Material Data Sheets (MDS) applicable to selectedmaterial standards and grades for use in piping systems. The scope for the MDS's is as follows:The materials shall be delivered in accordance with the standard referred to. In addition the MDSspecifies the selected options in the referred standard and additional requirements which shall beadded or supersede the corresponding requirements in the referred standard.3 NORMATIVE REFERENCESAs stated in the individual data sheets.M-CR-630, Rev. 1, December 1994page 1

4 DEFINITIONSMDSMaterial data sheetSMYSSpecified minimum yield strengthCarbon Steel Type 235 Carbon steel with SMYS 220MPa and not impact testedCarbon Steel TypeCarbon steel with SMYS 220 MPa and impact tested at - 46 C235LTCarbon Steel TypeCarbon steel with SMYS 350 MPa and impact tested at - 46 C360LTStainless Steel Type 316 Alloys with approx. 2.5 % Mo of type AISI 316Stainless Steel TypeAlloys with 6 % Mo and PRE 406MoStainless Steel TypeAlloys with 22 % Cr according to UNS S3180322Cr duplexStainless Steel TypeAlloys with 25 % Cr and PRE 40, often also referred to as "super25Cr duplexduplex"5 COLLECTION OF MATERIAL DATA SHEETS5.1 GeneralThe material selection menu for material standards and grades relevant for the piping systems isshown in table 1. The actual grades to be used with respect to piping design shall be stated on thepiping class sheet.The actual types of materials covered are as follow:CDNPRSTXCarbon steels; Type 235, Type 235LT, Type 360LTFerritic/Austenitic Stainless Steels; Type 22Cr, Type 25CrNickel base alloys; Type 625Polymers including fibre reinforcedAustenitic Stainless Steels; Type 6MoAustenitic Stainless Steels; Type 316TitaniumHigh strength low alloyed steels.M-CR-630, Rev. 1, December 1994page 2

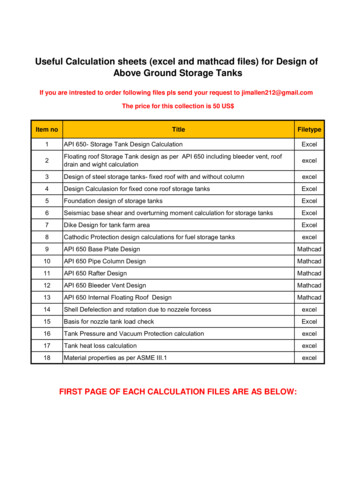

Table 5.1 - Material Selection Menu for Piping SystemsProductCarbonsteelType235 60LTimpacttestedStainlesssteelType 316StainlesssteelType6Mo2)StainlesssteelType 22CrDuplexStainlessNickelsteelalloyType 25CrDuplexTitaniumPipesSeamlessA 106Grade BA 333Grade 6API 5LGradeX52A 312Grade TP316A 312UNSS31354A 790UNSS31803A790UNSS32550A790UNS S32750A790UNS S32760B775UNSN06625B 337Grade 2PipesWeldedAPI 5LGrade BA 671GradeCC60Class12, 22A 671GradeCC70Class12, 22A 312GradeTP316A 358Grade 316Class 1, 3,4A 358UNSS31254Class 1, 3,5A 358UNSS31803Class 1, 3,5A358UNS S32550A358UNS S32750A358UNS S32760Class 1, 3and 5B775UNSN06625B 337Grade 2FittingsA 234GradeWPBA 420GradeWPL 6A 860GradeWPHY52A 403Grade WP316Class S,W, WXA 403Grade WPS31254Class S,W, WXA 815UNSS31803Class S,W, WXA815UNSS32550A815UNS S32750A815UNS S32760Class S,W, WXB366UNSN06625B 363GradeWPT2WB 363GradeWPT2ForgingsA 105A 350GradeLF2A 694GradeF52A 182GradeF316A 182A 182A182Grade F44 Grade F51 UNSS32550A182UNS S32750A182UNS S32760B564UNSN06625B 381Grade F2M-CR-630, Rev. 1, December 1994page 3

PlateA 516Grade60, 70A 516Grade70A 516Grade70,A 240A 240Grade 316 UNSS31254A 240UNSS31803A240UNSS32550A240UNSS32750A240UNS S32760B443UNSN06625B 265Grade 2CastingsA 216GradeWCBA 352GradeLCCA 352GradeLCCA 351GradeCF8MA MCClass 1B 367Grade C2A 351CK3MCuNNOTE 1) Type 235 should be used in piping systems with minimum design temperature above orequal to -15 C and thicknesses less than 30 mm.NOTE 2) The grades UNS N08367, N08925 and N08926 are considered equivalent to UNSS31254. The grade CN-3 MN is considered equivalent to CK-3MCuN.5.2 Referenced Standards and Corresponding MDSMDS No.Rev. No.Standard and GradeProductsCarbon Steel Type 235C01C01C01C01C01C02111111A 106 Grade BAPI 5L Grade BA 234 Grade WPBA 105A 516 Grade 60A 216 Grade WCBSeamless pipesWelded pipesWrought fittingsForgingsPlatesCastingsCarbon Steel Type 235LTC11C11C11C11C11C12111111A 333 Grade 6A 671 Grade CC60, CC70A 420 Grade WPL 6A 350 Grade LF 2A 516 Grade 70A 352 Grade LCCSeamless pipesWelded pipesWrought fittingsForgingsPlatesCastingsC21C21C22111Carbon Steel Type 360LTA 694 Grade F52A 860 WPHY 52API 5L Grade X52ForgingsWrought fittingsSeamless pipesM-CR-630, Rev. 1, December 1994page 4

Ferritic/Austenitic Stainless Steel Type 22Cr DuplexD41D42D43D44D45D46D47D4811111111A 790 UNS S31803A 358 UNS S31803A 815 UNS S31803A 182 Grade F51A 240 UNS S31803A 890 UNS J92205A 276 UNS S31803A 289 UNS S31803Seamless pipesWelded pipesWrought stenitic Stainless Steel Type 25Cr DuplexD511A 790 UNS S32550A 790 UNS S32750Seamless pipesA 790 UNS S32760D521A 358 UNS S32550A 358 UNS S32750Welded pipesD531A 358 UNS S32760A 815 UNS S32550Wrought fittingsA 815 UNS S32750A 815 UNS S32760D541A 182 UNS S32550A 182 UNS S32750ForgingsA 182 UNS S32760D551A 240 UNS S32550A 240 UNS S32750PlatesA 240 UNS S32760D56D5711A 890 UNS J93380 and UNS J93404A 276 UNS S32550A 276 UNS S32750CastingsBarsA 276 UNS S32760Nickel Alloy Type 625N01N01N01N01N01N02111111B 366 UNS N06625B 775 UNS N06625B 564 UNS N06625B 443 UNS N06625B 446 UNS N06625A 494 Grade CW-6MCM-CR-630, Rev. 1, December 1994Wrought fittingsPipesForgingsPlatesBarsCastingspage 5

Polymers including fibre reinforcedP011UK00AGRP pipes and fittingsAustenitic Stainless Steel Type 6MoR11R12R13R14R15R16R17R1811111111A 312 UNS S31254A 358 UNS S31254A 403 UNS S31254A 182 Grade F44A 240 UNS S31254A 351 Grade CK-3MCuNA 276 UNS S31254A 269 UNS S 31254Seamless pipesWelded pipesWrought fittingsForgingsPlatesCastingsBarsTubesAustenitic Stainless Steel Type 316S01S01S01S01S01S02S02111111A 312 Grade TP 316A 358 Grade 316A 403 Grade WP 316A 182 Grade F 316A 240 Grade 316A 351 Grade CF8MA 351 Grade CF3MSeamless & welded pipesWelded pipesWrought fittingsForgingsPlatesCastingsCastingsTitanium Grade 2T01T01T01T02T01T01T01111111B 337 Grade 2B 363 Grade WPT2/WPT2WB 381 Grade F2B 367 Grade C2B 265 Grade 2B 348 Grade 2B 338 Grade 2Seamless & welded pipesWrought fittingsForgingsCastingsPlatesBarsTubesLow Alloy Steel Type AISI 4130X02X0311A 788 AISI 4140A 487 Grade 2B, 2DM-CR-630, Rev. 1, December 1994ForgingsCastingspage 6

MATERIAL DATA SHEETMDS - C01, Rev. 1TYPE OF MATERIAL:Carbon Steel Type 235PRODUCTSTANDARDGRADEACCEPT. CLASSSUPPL. REQ.Wrought fittingsWelded pipesSeamless pipesForgingsPlatesASTM A 234API 5LASTM A 106ASTM A 105ASTM A 516WPBBB60--SCOPEThis MDS specifies the selected options in the referred standard and additional requirementswhich shall be added or supersede the corresponding requirements in the referred standard.MANUFACTURINGPROCESSHEATTREATMENT/Welded pipes to API 5L:Stress relieving when the nominal thickness t 19 mm.DELIVERYCONDITIONCHEMICALCOMPOSITIONC 0.22 %; Si 0.10 %; Mn 0.50 - 1.35 %; S 0.025 %; P 0.030 %;CE C Mn/6 0.04 0.43.TENSILE TESTINGEXTENT OFTESTINGTEST SAMPLINGDIMENSIONALTOLERANCESFittings to A 234:Fittings with reference to MSS-SP-75 shall have maximum wall thickness undertolerance of0,3 mm.Flanges to A 105:Flanges to MSS-SP-44 shall have a maximum wall thickness under tolerance of 0,3 mm for thehub at the welding end.NONDESTRUCTIVETESTINGPipes to API 5L:RT of weld seam or RT at ends and US/Eddy Current of the remaining weld.SURFACE FINISHREPAIR OFDEFECTSCERTIFICATIONEN 10 204 Type 3.1BM-CR-630, Rev. 1, December 1994page 7

MATERIAL DATA SHEETMDS - C02, Rev. 1TYPE OF MATERIAL:Carbon Steel Type 235PRODUCTSTANDARDGRADEACCEPT. CLASSSUPPL. REQ.CastingsASTM A 216WCB-S4, S5SCOPEThis MDS specifies the selected options in the referred standard and additional requirementswhich shall be added or supersede the corresponding requirements in the referred standard.MANUFACTURINGPROCESSHEAT TREATMENT/DELIVERYCONDITIONCHEMICALCOMPOSITIONC 0.22 % and CE C Mn/6 0.04 0.43 for castings with butt weld ends.TENSILE TESTINGHARDNESSIMPACT TESTINGEXTENT OFTESTINGTEST SAMPLINGFor castings with weight 250 kg and above the test coupons shall be integrally cast with thecasting.NON DESTRUCTIVE Magnetic particle examination:Supplementary requirement S4 shall apply to 10 % of delivered castings in pressure classTESTING150/300 psi and to 100 % of delivered castings in pressure class 600 psi and above. Allaccessible surfaces, of the given percentage or minimum two off, of the castings from thesame pattern and the same batch shall be examined.The acceptance criterias shall be ASME VIII, Div.1, Appendix 7.Radiographic examination:Supplementary requirement S5 shall apply to:- critical areas as per ANSI B16.34 of the pilot cast of each pattern- Class 600 and 900 psi; all butt weld ends- Class 1500 psi and above; all critical areas according to ANSI B16.34.The acceptance criteria shall be to ASME VIII, Div. 1, Appendix 7.SURFACE FINISHREPAIR OFDEFECTSCERTIFICATIONEN 10 204 Type 3.1BM-CR-630, Rev. 1, December 1994page 8

MATERIAL DATA SHEETMDS - C11, Rev. 1TYPE OF MATERIAL:Carbon Steel Type 235LTPRODUCTSTANDARDGRADEACCEPT. CLASSSUPPL. REQ.Wrought fittingsWelded pipesSeamless pipesForgingsPlatesASTM A 420ASTM A 671ASTM A 333ASTM A 350ASTM A 516WPL 6CC60, CC706LF270t 19 mm: Class 12t 19 mm: Class 22-S4S2, S7S2, S7S7S5SCOPEThis MDS specifies the selected options in the referred standard and additionalrequirements which shall be added or supersede the corresponding requirements in thereferred standard.MANUFACTURINGPROCESSHEAT TREATMENT/DELIVERY CONDITIONCHEMICALCOMPOSITIONC 0.22 %; Mn 0.50 - 1.35 %; S 0.025 %; P 0.030 %;CE C Mn/6 0.04 0.43.TENSILE TESTINGHARDNESSIMPACT TESTINGPlates to A 516:Supplementary requirement S5 shall apply.Pipes to A 671: Supplementary requirement S2 shall apply.All products:The test temperature shall be - 46 C. The minimum absorbed energy for full sizespecimens shall be 27 J average and 20 J single. Reduction factors for subsize specimensshall be: 7,5mm - 5/6 and 5 mm - 2/3.EXTENT OF TESTINGTEST SAMPLINGWELDINGDIMENSIONALTOLERANCESFittings to A 420:Fittings with reference to MSS SP-75 shall have maximum wall thickness under toleranceof 0,3 mm in accordance with standard.Flanges to A 350:Flanges to MSS SP-44 shall have a maximum wall thickness under tolerance of 0,3 mmfor the hub at the welding end.M-CR-630, Rev. 1, December 1994page 9

NON DESTRUCTIVETESTINGFittings to A 420:Supplementary requirement S4, magnetic particle examination, shall apply to the weldarea of 10 % of all fittings. The acceptance criteria shall be to ASME VIII, Div. 1,Appendix 6.Forgings to A 350:Supplementary Requirement S7.1, magnetic particle examination shall apply to 10 % ofall forgings with NPS 2. The acceptance criteria shall be to ASME VIII, Div. 1,Appendix 6.SURFACE FINISHREPAIR OF DEFECTSWeld repair of base material is not acceptable.CERTIFICATIONEN 10 204 Type 3.1BM-CR-630, Rev. 1, December 1994page 10

MATERIAL DATA SHEETMDS - C12 Rev.1TYPE OF MATERIAL:Carbon Steel Type 235LTPRODUCTSTANDARDGRADEACCEPT. CLASSSUPPL. REQ.CastingsASTM A 352LCC-S4, S5SCOPEThis MDS specifies the selected options in the referred standard and additional requirementswhich shall be added or supersede the corresponding requirements in the referred YCONDITIONCHEMICALCOMPOSITIONC 0.22 % ; S 0.025 %; P 0.030 %;CE C Mn/6 (Cr Mo V)/5 (Cu Ni)/15 0.43TENSILE TESTINGHARDNESSIMPACT TESTINGThe minimum absorbed energy for full size specimens shall be 27 J average and 20 J single.EXTENT OFTESTINGIf quenched and tempered heat treatment is applied, tensile and impact test is required for eachmelt and heat treatment load. Test blocks shall be heat treated with the castings they represents.TEST SAMPLINGFor castings with weight 250 kg and above the test coupons shall be integrally cast with thecasting.NONDESTRUCTIVETESTINGMagnetic Particle Examination:Supplementary requirement S4 shall apply to 10 % of delivered castings in pressure class150/300 psi and to 100 % of delivered castings in pressure class 600 psi and above. Allaccessible surfaces, of the given percentage or minimum two off, of the castings from the samepattern and batch shall be examined.The acceptance criteria shall be to ASME VIII, Div. 1,Appendix 7.Radiographic examination:Supplementary requirement S5 shall apply to:- critical areas as per ANSI B16.34 of the pilot cast of each pattern- Class 600 and 900 psi; all butt weld ends- Class 1500 psi and above; all critical areas to ANSI B16.34.The acceptance criteria shall be toASME VIII, Div. 1, Appendix 7.SURFACE FINISHREPAIR OFDEFECTSCERTIFICATIONEN 10 204 Type 3.1BM-CR-630, Rev. 1, December 1994page 11

MATERIAL DATA SHEETMDS - C21, Rev. 1TYPE OF MATERIAL:Carbon Steel Type 360LTPRODUCTSTANDARDGRADEACCEPT. CLASSSUPPL. REQ.Wrought fittingsForgingsASTM A 860ASTM A 694WPHY F52F52Seamless and welded-SCOPEThis MDS specifies the selected options in the referred standard and additionalrequirements which shall be added or supersede the corresponding requirements in thereferred standard.MANUFACTURINGPROCESSHEAT TREATMENT/DELIVERY CONDITIONCHEMICALCOMPOSITIONForgings to A 694:C 0.20 %; Mn 0.90 - 1.60 %; Si 0.10-0.50 %; S 0.025 %;P 0.035 %; Ti 0.05 %; Nb 0.04 %; Al 0.06 %;N 0.015 %; V Nb Ti 0.07 %; CE C Mn/6 (Cr Mo V)/5 (Cu Ni)/15 0.43 .TENSILE TE

Fittings with reference to MSS-SP-75 shall have maximum wall thickness undertolerance of 0,3 mm. Flanges to A 105 : Flanges to MSS-SP-44 shall have a maximum wall thickness under tolerance of 0,3 mm for the hub at the welding end. NON DESTRUCTIVE TESTING Pipes to API 5L : RT of weld seam or RT at ends and US/Eddy Current of the remaining weld. SURFACE FINISH REPAIR OF DEFECTS