Transcription

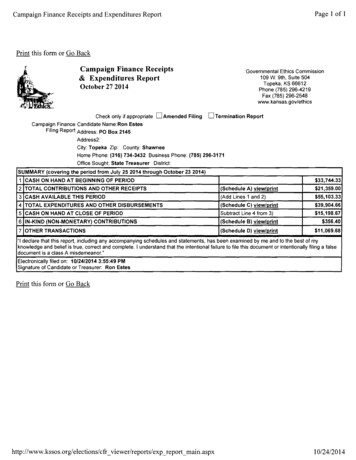

NEWSLETTERVolume 29, Issue 6June 2013FVWWC General MeetingJune 4, 2013 ProgramIN THIS ISSUECalendar of Events – Page 2and May Program ReviewDave Dockstaderand the Shopsmith SIGShopsmith ApplicationsFVWWC Officers and Committees –Page 3Shop Tours and Raffle Results –Page 4Dave and the Shopsmith SIG guys will be presentingShopsmith application ideas for our program thismonth.Library Notes – Page 5Howard’s Corner – Page 6Shaker Box Workshop Report – Page 7Editor’s Woodfiller – Page 8Show and Tell – Page 9 - 10Hot Dog Grill NightEd and John will fire up the grill around6:00pm. Come early to the meeting forhot dogs, chips, and soda.Hands-On DemoLee Nye will be demonstrating anddiscussing router templates and jigs atthe June 4 Hands-On Demo atapproximately 7:00pm.2012Don’t have a Shopsmith and don’t think you willever want one? Well, I said that a few years agowhen I sold my dad’s Mark V Shopsmith stuff lock,stock, and barrel and have since had regrets. At theleast, it would have been a much better lathe than my35 year old Taiwan special. You won’t be turninghuge bowls on a Shopsmith, but I am told that it is anexcellent lathe for general turning projects. And, thevariable speed control is much nicer than the beltpulley arrangement on my old lathe. It is certainly waybetter than no lathe. In addition, while you might notwant it to replace your table saw, they make nice disksanders and drill presses, too.Okay, but they are too expensive. Maybe not. Irecently spoke to Rich Rossio and he has five usedShopsmith’s for sale and he says his prices arenegotiable. The SIG guys can advise you onnavigating the different vintages.Still not convinced? Come to the meeting for the hotdogs and the opportunity to heckle Dave!FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org1

Calendar of EventsJune 2013DateJune 4(Tues)June 4(Tues)June 4(Tues)June 4(Tues)June 19(Wed)Time6:00 PM6:30PMEventHOT DOGGRILL NIGHTHand Tool SIG7:00PMHands On Demo7:30PMFVWWC GeneralMeetingFVWWC BreakfastClubRed AppleRestaurant414 S. Schmale Rd9:00AMMay 7, 2013 Program ReviewBill MorseSeat CaningBill Morse reviewed caning history and styles.He demonstrated techniques and displayedsamples of types seat weaving. Although notwoodworking as such, his presentation wasinteresting and generated a lot of questions. Ilearned that an old sagging cane chair seatcan sometimes be tightened by application of adamp towel to the cane area. Thanks Bill.July 2013DateJuly 2(Tues)July 2(Tues)July 17(Wed)Time6:30PMEventHand Tool SIG7:30PMFVWWC GeneralMeetingFVWWC BreakfastClubRed AppleRestaurant414 S. Schmale Rd9:00AMHands-On DemoThe next Hands-On Demo is at the June 4meeting, but we still need more demonstrators.Have a favorite technique, tool or jig you wouldlike to share with members? These demosneedn’t be anything elaborate – just somethingof interest to woodworkers.Volunteers should contact Mike Brady,at 630-879-6051.2012Seat Weavers is Bill Morse’s chair restorationbusiness in Elgin, IL. He works with chaircaning, rush, splint, binder cane, and more.He is a member of The SeatWeavers' Guild,Inc.DPWWC Tool AuctionOur friends in the DuPage Woodworkers Clubare having their annual tool auction onSaturday, July 27. The auction starts promptlyat 9 am and everyone is invited. Setup willbegin at 8 am. Even if you aren’t selling, youmay want to be there early to look through theitems for sale. If you are just starting out inwoodworking or are a tool junkie, this is theevent for you. There will be bargains galore!More info will be posted in the July newsletter.FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org2

FVWWC Officers & StaffPresident:Past President:John Gesiakowskipresident@fvwwc.orgTom SharpFVWWCSpecial Interest GroupsShopsmithSIG Chair:Dave Dockstader(630) 851-8118Hand Tool SIGChairmen:Mike Bradymbrady25@comcast.netMike l.netVice President:Mike Bradymbrady25@comcast.netTreasurer:Doug Pfaffdhpfaff@gmail.comSecretary:Ed Schalksecretary@fvwwc.orgProgram Committee:Dave BurkKrub411@yahoo.comShop Tour Organizer:Norm MusurMembership:Steve FoxEmail Us:dcnfox127@gmail.comNewsletter Editor:FVWWC Websitehttp://fvwwc.orgwoodworkers@fvwwc.orgLee Nyeroadbiker123@gmail.comDirector of Communication /Webmaster:Mark Dreyerwoodworkers@fvwwc.orgResources Chair:Dave DockstaderHELP WANTEDresources@fvwwc.orgRaffles:Gail MaddenNorm MusurPhotographer:openShow & Tell MC:Rich RusselShow Chairman:openToy DriveMike & Gail MaddenMember-at-Large:Mike MaddenAudio/Visual Tech:Dave BurkHost:Gail MaddenGreeter:Dave Burk2012FVWWC has an opening for Show Chairmanand Photographer in 2013. If you areinterested, contact John Gesiakowski.Also, if you are interested in anothercommittee or board position that is currentlyfilled, consider volunteering as a backup.Learn the ropes from the current committeechair and be available to sub when theperson is absent. For example, thenewsletter editor needs a sub to cover themeetings he is unable to attend. This wouldinvolve taking notes on the program, gettingshow and tell project sheets, raffle results,and taking some photos. Contact thenewsletter editor if you are interested.FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org3

SHOP TOURSWould you like to show off your workshop to a few of your fellow club members? I'mlooking for volunteers who would be willing to have 15 to 20 FVWWC members come toyour home on a Saturday morning to take a look at how you do woodworking (spousesinvited). You could show us your equipment and answer questions about how you use itand your likes or dislikes about it. You could show us any finished projects you have andanswer questions about the material or process you used in building it. Shop layout,lighting or dust collection are all topics for discussion. We could all learn from seeing "howthe other guy does it". And I'm sure you would get at least one, maybe two opinions onyour layout (sarcasm) !How do you set it up? Contact me (info below). We will set up a date agreeable to you ona Saturday morning. We usually start at 9am and finish about 11 or 11:30. After that,those who want to can get together for lunch at a local restaurant in your area fordiscussion about woodworking and how to solve the world's problems (sarcasm, again).Norm Musur 630 584-8669Raffle Winners:Mark DreyerDoug PfaffSherm TaylorDave DockstaderSherm TaylorSilent Auction:Steve FoxMike Madden2012Box Joint JigIrwin Marples saw bladesIrwin Quick GripParts Ogranizersanding beltswoodworking plans132” sanding beltsBall plungersFVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org4

LibraryNotesMissing A Magazine From Your Library?If you are missing an issue of a particular magazine from your library, chances are the club library hasit digitally. Below is a list of magazines we have on disc:American Woodworker Magazine (1985 - 2002)American Woodworker Magazine (2003 - 2010)Fine Woodworking (1975 - 2012)Shopnotes Magazine (1992 - 2012)Today's Woodworker (1989 - 1998)Wood Magazine (1989 - 2012)Woodsmith Magazine (1979 - 2012)Woodwork Magazine (1989 - 1994)Woodwork Magazine (1995 - 1999)Woodwork Magazine (2000 - 2004)Woodwork Magazine (2005 - 2011)Woodworker's Journal (2010)2012FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org5

Howard's Cornerwith Howard Van ValzahAka: The WoodorkerI am finished with my latest major projectand it is in place at our church.Now I am working on a new project at therequest of a Coffee Shop run by the Lutheranchurches in Rockford. They need a housing forwaste containers much like fast food shopshave, but they need three types of waste:recycle, trash, and dishes. They pretty muchleft the design up to me so I have decided tomake the exposed portion of the cabinet out ofwalnut "shorts" which I received free byreworking a sizable pile of walnut that wasdonated to the Klehm Arboretum in Rockford.As donated, it was in no condition to resell or touse without a significant loss. I volunteered togo through it piece by piece to eliminate defective segments. I was allowed to keep the majority ofthe good stuff while returning a good amount to the Arboretum for their use. That left me with a lot ofshort pieces less than 18" long by approximately 3/4" thick. The coffee shop agreed to pay for thewood, but I decided I would donate the wood if they would pay for the router bits to make the shortpieces tongue and grooved. That was agreeable so I bought the type that puts a small V groove onthe mating edges. 125 delivered.Then a new problem arrived which I did not expect. I do not have a conventional router tablewith a fence because I buy all my bits with a bearing wheel on top. The new Grizzly bits came asordered, but I learned quickly that they could not cut to full depth in one pass. I had to add a fence toget the job done in three passes, which was easy for me to do because my router is installed in mytable saw table top. First I pushed the work through the router as I normally did and the routerdecided it wanted to pull the board away from the fence, so I moved the fence to the other side wherethe router would push the work against the fence. This worked just fine until the router decide I wasn'tfeeding fast enough and pulled the board out of my hand and shot it through and across the shop.And surprisingly it cut almost perfectly while doing it. A second pass went through just fine. Ofcourse a better way would be to have a fence that could slide over the bit, but it might be better toclamp a 2 x 4 on to my fence and hollow out space for the bit.Well now, I'm into production and finding it takes a huge amount of tongue and groove woodshorts to make large door and side panels. I never liked production work ever since running a punchpress as a 16 year old in 95 degree weather at Western Electric. It's boring tedious work and subjectto easy accidents if you don't pay attention. A big 1.35 an hour was really great for my age, but I wassurrounded by others who were doing it for a living. My how things have changed?2012FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org6

Shaker Box Workshop ReportOn May 24 and 25, fourteen woodworkers from both the DuPage Woodworkers Club and FVWWCparticipated in a workshop making Shaker oval boxes. Our instructor was John Wilson who conductsthese workshops all over the country. John has been leading these classes for 30 plus years and hisbusiness, The Home Shop, supplies the box making trade. John writes for Popular Woodworking,Fine Woodworking, and WoodenBoat magazines. He has recently released a new book calledMaking Hand Tools which covers construction of a number of planes and other tools, benches, andtool boxes. In the book, John provides directions so that you can temper and harden your ownblades with standard steel stock and quite ordinary equipment.Shaker box making is a bit different from construction of furniture or wood turning in part because itinvolves bending wood using a hot water bath. John and his colleague Eric Pintar, provided thematerials, tools, and instruction leading each participant to construct five nesting oval boxes. Alongthe way in explaining how to make a Shaker box, John covered some history of box making, woodscience, his wood selection and milling process, acquisition and operation of 150 year old tackmaking machines, and his rather novel way of doing business. It was a very interesting, enjoyableday and a half.Pictured here is our enthusiastic class posed with John and his display boxes. (These all nest intothe largest box.) You’ll have to wait for show and tell to see some of our finished work.2012FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org7

Editor’s Woodfiller“Winter” Project Update #3Back in October and last March, I wrote about progress on mylong delayed Period Secretary Desk. The project is based onLonnie Byrd’s “18th Century Pennsylvania Secretary” articlesfrom Fine Woodworking Magazine. While winter is officially over,the lower desk is far from completion. Still, progress has beenmade as you can see (right photo).I should know by now that woodworking tasks often take a lotlonger to complete than one expects.I was a little intimidated by thescrolled and ogee contoured bracketfeet. These are made from stockalmost 2 inches thick, constructed with miters, splines, and corner blocksfor strength. The bracket outline and ogee contour are cut on thebandsaw. It turned out being far easier to do than I thought and the result,I think is good.What turned out to be very fussy and challenging for me was the desk lid. The desk lid is a showsurface and I used my best figured cherry material. It has breadboard ends with mortise and tenonjoinery to keep the wide surface flat and to allow seasonal movement. Construction of the lid itselfwas easy and straight-forward. One of the first installation tasks wasto mortise the hinges to the desk and lid. I used a simple router jig(rectangular cutout) and a pattern following bit to precisely mortise thehinges. I use double-sided tape to fix the jig in place. The first hingemortise was perfect. I decided to reuse the tape for the second hinge –bad idea! The jig slipped and the router cut a nasty divot outside themortise. Repair of this mistake took me most of a day.Once corrected, a lot of time was spent fitting the rabbeted lid tothe case so it would close properly. This is complicated somewhatbecause the top edge of the lid is rabbeted at an angle of about 75degrees consistent with the slope of the case. Fortunately, the lock(Horton Brasses) is designed for this application and comes withthe proper angle. Fitting it to the lid was easy. Unfortunately, thelock strike plate they sent was a simple thin flat brass plate. It wasnot designed to fit the double bevel of the case top and was tooloose to hold the lock for a nice tight lid closure. I had to designand construct a new lock strike plate from brass sheet stock. Ifinally got a good fit on the second plate I made.While I spent maybe 8 hours total making the bracket feet, I think Ispent 8 days getting the lid and hardware right. Drawerconstruction is next – should be straight-forward, right? We’ll see.Lee2012FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org8

SHOW AND TELLPaul DehnertProject: Intarsia Rock BassWeather StationWood:Finish:Jeff SmithProject: CNC & Laser ArtWood:Finish:Cory HauserProject: Toy TrucksWood:Finish: paint2012FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org9

SHOW AND TELLSean LambProject: Zen GardenWood: Tiger MapleFinish: clearNote: not for cats2012FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org10

FVWWC General MeetingJune 4, 20137:30 pmDave Dockstader and the Shopsmith SIGShopsmith ApplicationsHand ToolSIGJune 4, 2013The Hand Tool SIG meets,January through November, at6:30 pm, before the regularmeeting at Bethany Lutheran inthe lower conference room. Anyone interested inthe use of hand tools is welcome to join us fordiscussion of this fascinating area ofwoodworking.ShopSmithSIGJuly 2, 2013The ShopSmith SIG meetsquarterly. The next meeting willbe in July.If you own or are interested in learning about theShopSmith, please stop in. Join us and shareyour Shopsmith experience and find out whatthe rest of us have been up to with ourmachines.We will learn by sharing the experiences of usingand caring for traditional hand tools.Hope to see you there!Mike Bradymbrady25@comcast.netMike Bridgerbridger.mike@gmail.com2012Dave Dockstader630-851-8118sourceror@sbcglobal.netFVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org11

Fox Valley Woodworkers ClubGeneral Meetings held at:Bethany Lutheran Church8 S Lincoln St. - Batavia, ILOn the 1st Tuesday of each Month at 7:30 pmDoors Open at 6:30 p.m.Visitors Always Welcome!2012FVWWC - PO BOX 1041 - BATAVIA, IL 60510-1041http://www.fvwwc.org - woodworkers@fvwwc.org12

If you are missing an issue of a particular magazine from your library, chances are the club library has it digitally. Below is a list of magazines we have on disc: American Woodworker Magazine (1985 - 2002) American Woodworker Magazine (2003 - 2010) Fine Woodworking (1975 - 2012) Shopnotes Magazine (1992 - 2012) Today's Woodworker (1989 - 1998)