Transcription

Alan Ford HSE Professional ConstructionConsultant MSc, B.Eng., Grad IOSH, MIIRSMFrom Liverpool UKStarted Working Life in the Royal Navy10 Years Offshore (Brent Field North Sea) Rigger with-in a Diving Team3 Year BSc in Civil Engineering3 Years as CAA Firefighter with Airbus UK18 Years as HSE Professional (NEBOSH General, NVQ4, MSc)Grad IOSH (1997) MIIRSM (2016)

CRANES & LIFTING OPERATIONS!

THINGS DO GO WRONG!

TYPES OF LIFTING EQUIPMENT(Cranes ) Mobile TelescopicCrawler LatticeAll TerrainTruck al/Helicopter Overhead e GantryTower/Derrick Hammer HeadStiff-leg Derrick

Tower Cranes

Mobile Cranes

Barge Mounted Cranes

HIAB Lorry Mounted Cranes

Gantry Cranes

Spider Cranes

TYPES OF LIFTING ACCESSORIES

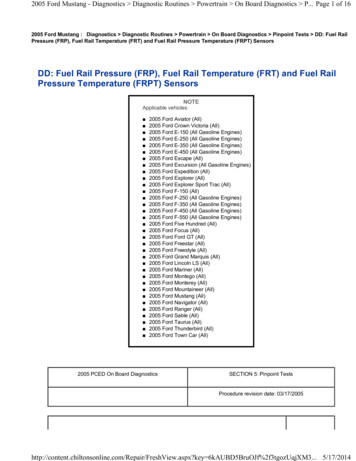

LEGISLATION & STANDARDSOSHAConstruction - Cranes & Rigging 1926.1400-1442 - Cranes Subpart CC 1926.251 - Rigging equipment for material handlingMarine Terminals - Cargo Handling Gear and Equipment 1917.45 - Cranes and derricks (see also 1917.50) 1917.50 - Certification of marine terminal material handling devicesGeneral Industry - 1910 Subpart N - Materials Handling andStorage 1910.179 - Overhead and gantry cranes 1910.180 - Crawler locomotive and truck cranes 1910.181 - Derricks 1910.183 - Helicopters 1910.184 - Slings

LEGISLATION & STANDARDSUKLOLER 1998 Lifting Operations Lifting Equipment RegulationsLOLER ACOP L113.BS7121 British Standard Part 1 1989 Safe use of Cranes General Part 1 2006 Safe use of Cranes Part 2 Inspection, Testing & Examination Part 3 Mobile Cranes Part 4 Lorry Loaders Part 5 Tower Cranes Part 11 Offshore Cranes Part 12 Safe use of Crane recovery of Vehicles & Equipment

QATAR LEGISLATION LOLER & BS7121 are incorporated into QCS 2014

LEGISLATION (Main Elements of the L113ACOP)Regulation 1 Citation and commencementRegulation 2 Interpretation 5Regulation 3 Application 8Regulation 4 Strength and stability 18Regulation 5 Lifting equipment for lifting persons 21Regulation 6 Positioning and installation 26Regulation 7 Marking of lifting equipment 29Regulation 8 Organization of lifting operations 32Regulation 9 Thorough examination and inspection 43Regulation 10 Reports and defects 51Regulation 11 Keeping of information 53Regulation 12 Exemptions for the armed forces 54Regulations Revoked!Regulation 14 Amendment of the Docks Regulations 1988 55Regulation 15 Repeal of Provisions of the Factories Act 1961 55Regulation 16 Repeal of Section 85 of the Mines and Quarries Act 1954 55Regulation 17 Revocation of instruments 55Schedule 1 Information to be contained in a report of a thoroughexamination 56Schedule 2 Revocation of instruments 5

LEGISLATION (Easy) Strength & Stability (Reg, 4) Lifting Equipment for Lifting of Persons(Reg, 5) Positioning & Installation (Reg, 6) Marking of Lifting Equipment (Reg, 7) The Planning for Safe Lifting operations& safe operation of equipment. (Reg, 8) Thorough examination & inspectiondeals with the initial & continuingintegrity of equipment. (Reg, 9)

BS 7121 Main Points Emphasis on safe Planning & operation Covers specific types of Cranes with-in eachsection Crane Appointed Person Crane Supervisor Crane Operator Riggers Banksman Types of Cranes required & Adequacy ofCranes Crane Installation, set up, Operation &Dismantle or de-rigging

Types of Crane Lifts (Routine, Tandem, UsingExcavators, Critical, Specialized & Complex.

Safe & Controlled OperationSTAGECONTROLRESPONSIBILITY1.Assess clearly what is required (Load fromwhere to where?)Crane Appointed person2.Identify all hazards associated with theOperation & implement adequate controlCrane Appointed person3.Have Clear understanding of Load, weight &dimensionsCrane Appointed person4.Ensure the Correct type of Crane is selected forthe task & Wind speed is considered.Crane Appointed person5.Ensure Ground bearing capacity is adequateCrane Appointed person6.Method Statement, Risk Assessment, ApplicablePermits & Lifting Plan are compiled andadequate. All Lifting Accessories are adequateCrane Appointed person7.All relevant personnel are aware of their dutiesCrane Supervisor8.All personnel are briefed on the Hazards &adopted controlsCrane Supervisor9.Area is restricted to non-essential personnelCrane Supervisor10.Commence Lifting operations in controlledmanner. However also consider emergencysituationsCrane Supervisor, Crane Operator &Rigging team11.On Completion of Lifting Operation. De-rigCraneCrane Supervisor, Crane Operator12.Re-instate area & close permitsCrane Supervisor who also informs APof Completion

Itinerary utilized to ensure adequate controlLoad Chart & GBP-GBCconsideredTPC is valid &Competent personsMS & RAPTW & Lift Plan

Document:Size:BS71218.42MBL133 ACOP2.69MBPresentation1.61MBIND G 422141MBLift Plan460KB

Alan Ford Tel:5054 0787alan.ford@dorsch.comThank you all! Any Questions?

Part 3 Mobile Cranes Part 4 Lorry Loaders Part 5 Tower Cranes Part 11 Offshore Cranes Part 12 Safe use of Crane recovery of Vehicles & Equipment. . Crane Supervisor, Crane Operator & Rigging team 11. On Completion of Lifting Operation. De-rig Crane Crane Supervisor, Crane Operator 12. Re-instate area & close permits Crane .