Transcription

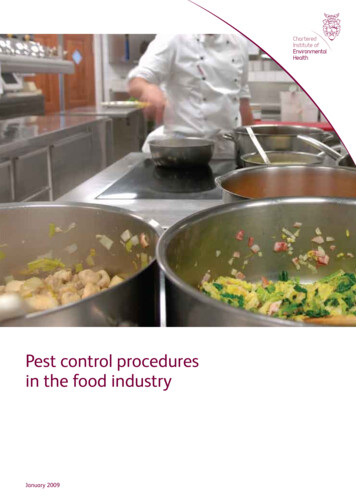

Pest control proceduresin the food industryJanuary 2009

ContentsIntroduction3Food safety4 Rodents8Cockroaches10 Flies12 Ants14 Stored product insects16Birds and other vertebrates20 Inspection and auditing of food premises22 Pest prevention28 Non-chemical control methods37Chemical control methods40 Pest control contracts46Acknowledgements50Useful addresses512

1IntroductionThe presence of pests in food production andpreparation areas has always been unacceptable.Yet while the pest management industry has seenmany advances in monitoring and baiting techniquesin the past 30 years, some of the practices in the foodindustry have not kept up with these new techniques.Concerns for the environment and the requirementsby regulators for improved practices in the industryhave meant that new methods to control pests havehad to be devised.The Chartered Institute of Environmental Health(CIEH) has assessed these developments andfeels that now is the time to consider whether thetechniques that have been common in the foodand pest management industries need to be revised.Since many of the people involved in maintainingand regulating food safety are environmental healthpractioners (EHPs), the CIEH has taken the lead indevising the standards which it believes should nowoperate in the food industry.These guidelines have therefore been drawn up bythe National Pest Advisory Panel (NPAP) of the CIEHafter full consultation with all those involved in foodproduction, preparation and retailing, together withrepresentatives of the pest management industry.Advice has also been sought from governmentagencies involved in research and enforcement,as well as the main bodies which lay down auditingstandards.These guidelines are aimed at the food manufacturingsector. While the principles are the same for production(farmers and growers), raw material and ingredientsuppliers, warehousing, distribution and retail, thelevel of pest control contract specification will vary.The CIEH would like to thank all those who havecontributed to the preparation of these draftguidelines.Dr Stephen BattersbyCIEH President3

2Food safety2.1OverviewThe presence of pests in any food handlingpremises is unacceptable. The risks posed bypests include:Article 5 of the regulation requires that theprocedure or procedures be based upon theHACCP (Hazard Analysis Critical Control Point)principle. The spread of disease – pathogens aretransferred from the gut or external surfaceof the pest Damage to property Contamination of work surfaces andfoodstuffs Adverse public opinion and loss ofreputation Prosecution and closure Poor staff relationsHowever, it does not necessarily constrain foodbusiness operators to implement a HACCPsystem if this is not appropriate.The objective of the Pest ManagementProgramme should be to prevent, as far aspracticable, the introduction of pests onto thesite and to reduce the conditions that mayencourage their presence.2.2Food Hygiene Regulations2.2.1 Regulation (EC) 178/2002 of the EuropeanParliamentThis regulation lays down the principles andrequirements of food law.Article 14 of Regulation (EC) 178/2002 dealswith unsafe food. It is an offence not tocomply with article 14 under the General FoodRegulations 2004. Food shall be deemedunsafe if it is considered to be injurious tohealth or unfit for human consumption.2.2.2 Regulation (EC) 852/2004These regulations lay down general hygienerequirements for all food business operatorsand state that: The layout, design and construction of foodpremises are to permit good food hygienepractices including protection againstcontamination and in particular, pest control. Adequate procedures should be in place tocontrol pests2.3 HACCP – Hazard Analysis CriticalControl PointAccording to EC Regulation No 852/2004 onthe hygiene of foodstuffs, with the exceptionof activities at the level of primary production,food business operators are required to put inplace procedures, which manage food safetywithin their establishment.4Pest management is part of the GoodManufacturing Practices (GMP) for foodbusinesses, which is a prerequisite for theHACCP-based procedures in place. As anintegral part of the GMPs, it should becarried out with due diligence and properlydocumented.2.4 Pest Management Standards in theFood IndustryFood safety audits may be carried out byauditors from within the company or froman independent organisation. The audit isgenerally based on a series of criteria set outto ensure the highest standard of compliancewith a specific aspect of food safety. Thesection which deals with pest managementwill usually require zero infestation andconformity with criteria covering type of pestmanagement programme; permitted materialsand techniques and record keeping.Care is essential when setting criteria to ensurethat they achieve the required result. Over–prescriptive criteria may place unnecessaryrestrictions on the pest managementprogramme, extending the period beforecontrol is achieved.2.4.1 Risk-based standardsIf standards and guidelines for pest controlare to achieve the aim of promoting bestpractice they must be practical and flexible.The standard should be risk-based in order toaddress the issues raised by the following:Risk to public health due to activities of pestsPests are known to carry a range of pathogenswhich can be transmitted to humans eitherthrough contaminated food or their presencein the environment.Risk to food safetyThis will be the priority for all engaged in theproduction, storage, transport, processing andsale of food. The risks include:

P hysical contamination of product by rodentdroppings, insect parts or other foreignbodies Introduction of micro organisms Damage to product or packagingRisk to public safety and the environmentThe irresponsible or inaccurate use ofpesticides may present a hazard to technicians,site staff and members of the general public,as well as to the environment throughcontamination of water, damage to plants andthe effect on non-target species of animals. P resence of non-target species. Are thererecords or reported sightings of protectedspecies of birds or mammals? Are thereareas away from the buildings where thepresence of toxic rodenticide baits maypresent a risk of secondary poisoning?2.4.3 Environmental management andpesticide reductionThere should be an increased reliance onenvironmental management and inspectionof the site to reduce the attraction to pests.Pest management programmes should aimto reduce the use of pesticides, particularlyoutdoors, by enhanced prevention programmesbased on proofing and hygiene.2.4.2 Application of standardsWhen applying the relevant standard to pestmanagement such as rodent control, referenceshould be made to the following: A re rodents active on site at the time of theinspection? (Evidence of, or bait taken by,field mice or voles away from the buildingsshould not constitute an infestation) Past history of site. Is there documentedevidence that rodents have been active inthe last two years? Site potential for infestation. Does thelayout, construction, manufacturing process,hygiene practices or product lend the siteliable to infestation? Are there water courses,railways, amenity sites nearby. Is the sitesituated within or adjacent to a high riskarea? Status of neighbouring properties. Arethe activities of adjacent properties orbusinesses liable to attract pests into thevicinity?2.5For example, reliance on toxic rodent baitsoutdoors as a permanent indicator of ratactivity is no longer acceptable. Knowledge ofthe site, its history and potential for infestationthrough regular and thorough inspections willreplace perimeter baiting as the first line ofdefence.Pest Awareness and Staff TrainingTraining should be given appropriate to thepersonnel concerned, for example using theCIEH DVD Pests on the Menu.As a minimum all departmental personnelshould be aware of the pests that they are likelyto encounter in their part of the process andthe importance of pest prevention. Particularattention should be given to incoming goodssuch as raw materials or packaging.5

Pests and their habitsTraining on the identification and habits ofthe more common pests of the food industrycan be given by the pest control contractor orthrough independent consultants. This is bestachieved in the form of a brief presentationrather than distribution of literature, andwhere appropriate can be tailored to particularindustry segments for example, bakery orconfectionery.Pest preventionThe importance of pest prevention throughgood hygiene, stock management andexclusion practices should be emphasised. Sitepersonnel have the day to day responsibilityof ensuring a pest management programme ismaintained.Information postersIn addition to training sessions the postingof information at individual workstationsor sensitive locations such as rest areas andgoods-inwards doorways can act as a reminderof the requirements of the Pest ManagementProgramme. These can remind staff of pestrelated risks and preventive measures such as: D oor and window disciplines Hygiene and housekeeping Stock storage and rotation2.6 Reporting and Record KeepingThe organisation of a reporting system andmaintenance of records is essential if GoodManufacturing Practice (GMP) status is to beachieved.Records must be kept for the following reasons: o highlight any recommendationsT To demonstrate compliance with legislation To monitor pest management processes As evidence of compliance to third partyauditors2.6.1 Pest sightings logA record should be kept of any pest sightings,including those made by personnel other thanthose involved in pest management. This canbe in the form of a book or a folder where thefollowing information can be logged: ame of person making reportN Date and time Location Pest seen Any other relevant informationIn addition to entering the sighting in the book,the sighting must be reported to the appointedmanager in charge of pest management whowill decide on further action.Where a pest control contractor is employedthe sighting will normally result in a requestfor service. In the case of an on-goingriddance programme the reports will provideinformation on the success of the treatment.6The pest sightings record should be checkedand signed on each contractor visit to the siteand daily where an in-house programme is inplace. The contents of the pest sightings recordshould be part of the management reviewprocess.2.6.2 Pest control reportInspection reports must be concise and legibleand stored in an easily accessible binder.A typical pest control report will contain as aminimum: T reatment date Details of the pest control contractor andname of technician servicing the site Details of the customer and name of thecontact person on site Type of visit: scheduled, follow-up, callout, etc Pests found Action taken Pesticide used Location of baits and monitors (this may bein the form of a checklist or plan) Quantities used Risk assessment Post treatment precautions Recommendations on proofing, hygiene andstorage Details of follow-up inspectionsIndividual specifications may includeadditional reports such as analyses and trendsfor each bait or monitor.The report must be signed by the pest controltechnician and the customer.Where anticoagulant rodenticides are usedoutdoors the following additional recordsshould be kept: A site plan identifying areas where bait hasbeen laid Details of the active ingredient, formulationand quantities used Inspection reports, which demonstrate thetreatment frequency to check and replacebaits and to search for and remove deadrodent bodies where appropriate Reports of any effect on non-target speciesand action taken to reduce risk Reports of any interference or removal ofbaits Reports on conditions, which may adverselyaffect treatment and remedial actions Evidence that control has been achievedwithin the prescribed timescales2.6.3 Other records Safety Data Sheets (SDS) for pesticides usedon site COSHH Risk Assessments* Site Risk Assessments* Environmental Risk Assessments* Qualifications, insurance membershipand accreditation documents* These may not be relevant for each siteor may be in a combined form.

7

3Rodents3.1 RatsIn Britain, there are two species of rat; theNorway or brown rat (Rattus norvegicus)and the ship or black rat (Rattus rattus). TheNorway rat has largely replaced the ship ratover the past 100 years.Norway rats eat on average one tenth of theirbody weight each day. They are consideredomnivorous but if available, cereals arepreferred. Rats must drink water daily unlessthe food source is extremely moist. Due to theirwater requirements, runs to a water sourcemay be evident and give an indication ofharbourages.They explore locations quite freely buthave a fear of new objects. This is known asneophobia and should be taken into accountwhen baits are checked initially after atreatment.On farms, stored animal feed and crops,bedding, even animal waste will presentan ideal environment to support rodentinfestations. Rats living and feeding outsidemay enter buildings with the onset of thewinter months.Ship rats are very good climbers and areusually found indoors, often high up. Althoughthey are rare in the UK, they are still found insome port areas.3.28MiceThe house mouse, Mus domesticus, is thecommon pest in urban environments, althoughfield mice (wood mice and yellow-necked mice,Apodemus spp) can be a problem in autumnand winter. Where these enter premises,control is the same as for house mice.3.3SquirrelsIn the UK the grey squirrel (Sciuruscarolinensis) is regarded as a pest species. Thered squirrel (Sciurus vulgaris) is fully protected.The grey squirrel was introduced into the UKin the mid 19th century and has now becomea major pest of forestry. In addition they mayenter buildings in search of food and shelterresulting in damage to products and structures.Under t

2.6.2 Pest control report Inspection reports must be concise and legible and stored in an easily accessible binder. A typical pest control report will contain as a minimum: Treatment date Details of the pest control contractor and name of technician servicing the site Details of the customer and name of the contact person on siteFile Size: 1MBPage Count: 52