Transcription

LIGHTWEIGHTC0NVEYORBELTING –PVC AND RUBBER

FOOD HANDLING MEATS& POULTRY (USDA, FDA) HOT, OILY FOODS (FDA) FROZEN FOODS (SUB-ZEROTEMPERATURES) FRUIT& VEGETABLE PROCESSING (FDA) NUT PROCESSING (FDA) AGRICULTURE INCLINE SERVICE (FDA) POTATO HARVESTING & UTILITY SERVICE HARVESTING EQUIPMENT TUBECONVEYOR AND BUNK FEEDER SYSTEMS COTTONPROCESSING EQUIPMENT PACKAGE HANDLING BELTS FOR INCLINES BELTS FOR STEEP INCLINESOF 45 DEGREES BELTSFOR HORIZONTAL SERVICE LIGHT INDUSTRIAL &AUTOMATION BELTS WHEN OIL IS PRESENT BELTS FOR OIL-FREE SERVICE SPECIAL APPLICATIONBELTS FOOD HANDLING MEATS & POULTRY (USDA,FDA) HOT, OILY FOODS (FDA) FROZEN FOODS (SUBZERO TEMPERATURES) FRUIT & VEGETABLE PROCESSING (FDA) NUT PROCESSING (FDA) AGRICULTURE INCLINE SERVICE(FDA) POTATO HARVESTING & UTILITY SERVICE HARVESTING EQUIPMENT TUBE CONVEYOR AND BUNK FEEDER SYSTEMS COTTON PROCESSING EQUIPMENT PACKAGE HANDLING BELTS FOR INCLINES BELTS FOR STEEP I2 OF45 DEGREES NCLINESBELTS FOR HORIZONTAL SIndexReference Guide . . . . . .Introduction . . . . . . . . . .PVC and Rubber BeltingSuperior Fabrics . . . . . . .Superior Covers . . . . . . .Belting Selection Guide .Food Handling . . . . . . . .Agriculture . . . . . . . . . . .Package Handling . . . . .234678101214Light Industrial Uses . . . . . . .Conveyor Belting &Data Specification Sheet . . .Belt Splicing . . . . . . . . . . . . .Troubleshooting . . . . . . . . . .General Resistance QualitiesPVC Belting Data . . . . . . . .Rubber Belting Data . . . . . . .HBD/Thermoid, Inc. . . . . . . . . . . . . . . 15.16171819202230General Application Use – Quick Reference Guide*FoodHandlingAgriculture& HarvestingPackageHandling Light Industrial& AutomationPVC Conveyor Belt ProductsChevron Cleated InclineGriptite Griptop Korowhite Pack-EZ S/WeaveHerringbone Rubber Conveyor Belt ProductsBig Red SiliconeButyl (Hot’N Cold)Caripack Cleat-Rite “OSM”Diamond InclineGin FlashingGriptop – GumGriptop – NitrileGriptop – RubberHot Stock & WaterNitrile – BlackPack-EZ PremPotato BeltRibflex Ridgetop Sani-Brite SaniWhite SheetingSlide-A-Pack Sliptop Teflon WhiteV-Cleat * NOTE: For complete application use details on each conveyor belt, see pages 8 and 9 for general use detailsand/or refer to the individual conveyor belt product descriptions.Selecting the correct conveyor belt product can be difficult. To help you determine the correct products foryour requirements, please see page 16. If you require any advice or technical assistance, please contact ourcustomer service representatives at 800/367-0420.

. THE LEADING EDGEIN LIGHTWEIGHT BELT TECHNOLOGYHBD/Thermoid , Inc. has been a leadinginnovator in lightweight belt technologyfor decades. Many improvements thathave now become industry standardswere pioneered in our researchlaboratories.We were the first to use 100% polyester and50-50 polyester-cotton blends for greaterstrength and moisture resistance in our lightweight fabrics.the first to use a nitrile rubberto dramatically improve the oil resistance inour food belts. We developed the specialadhesive treatment for synthetic carcassesthat helps keep plies from separating.When it comes to conveyor belt technology,HBD/Thermoid never lets down, which iswhy so many customers look up to us forengineering excellence.UP-TO-DATE MANUFACTURING CONDITIONSThe HBD/Thermoid plant in Oneida,Tennessee, has more than 300,000 squarefeet, and is a modern belt-making plant usingstate of the art equipment. We manufacturea full-line of lightweight rubber and PVCconveyor belting under the cleanestconditions. We’ve invested heavily in thislightweight belting plant because we intend tomake our belts the very best available.SPECIALLY DESIGNED FABRICS ANDCOVERS FOR CONVEYOR SERVICEWe don’t have to rely on commercial fabrics.Instead, our textile engineers develop specialweaves designed to handle a wide range oftensions, loads, pulley sizes and troughingangles. Our cover compounds are developedby our own experienced research chemiststo cope with conditions like oil and grease,heat and cold, chemicals, acids, moistureand abrasion. So every Made-In-USAThermoid belting is designed to give youmaximum service for your dollar.For Assistance: 800/367-0420 or info@hbdthermoid.com3

PVC AND RUBBER BELTINGNo other manufactureroffers both in such acomplete range oftensions and a widechoice of textures.When HBD/Thermoid recommends abelt, you can be sure we have nothingto gain by suggesting any one typeover another. We manufacture bothtypes: PVC and rubber. So you cantrust us to recommend the belt that’sreally best for you.world’s leading laboratories, so they’re easyon the eyes under all types of illumination.Plus we offer special surfaces from extrasmooth to deeply textured. So whateveryour particular requirement, you can find aThermoid lightweight belt to match. Hereare the features that make our belts abetter value.FLEXIBILITYOur Customers can be confident whenusing our belt products in all applications.Our lightweight belting offers lower costplus endurance when used in shortercenters and smaller pulleys.LIGHTWEIGHT CONSTRUCTIONIt takes less power to drive our belts. Thatcan result in savings with today’s highenergy costs.EXCELLENT DIMENSIONAL STABILITYThere’s little need to take-up adjustmentsand few work stoppages. The drop indowntime means a rise in profitability.Thermoid lightweight belting comes in awide variety of tensions, fabrics and covercompounds. Each belt has two things incommon: efficiency and economy. Ourlightweight belting also features colors thatare scientifically developed in one of the4HIGH STRENGTH AND ABRASIONRESISTANCEAdds up to a long, useful service life anda great return on your investment dollar.

SANIWHITE & SANI-BRITE NITRILE – WHITENYLOCK COSDIAMOND INCLINE – BLACK & TANPVC HERRINGBONEGRIPTOP GRIPTOP – BLUE & ORANGE, CARBOXYLATEDNYLOCK – BLACK, SBXSBSLIDE-A-PACK GRIPTITE BIG RED SILICONEFor Assistance: 800/367-0420 or info@hbdthermoid.com5

SUPERIOR FABRICSDesigned and wovenspecifically for ourconveyor beltingproducts.SPECIAL TREATMENT FORSYNTHETIC FABRICSWe apply a special adhesive treatment tomost synthetic fabrics. This increasesadhesion by 50%, so covers and plies resistseparation far better than they would in anuntreated belt. This improves service lifeand increases overall cost effectiveness.(Letter “T” in fabric name designates suchtreatment, as in APT35 or PNT50.)POLYESTERS (AP, APT)These polyester belts are the mostdimensionally stable for wet service.Polyesters won’t shrink, stretch, rot ormildew when exposed to moisture, whichmakes them especially effective wherewetness is a problem. Strong and tough,these polyester belts will hold mechanicalfasteners particularly well.POLYESTER-NYLON (PN, PNT)Polyester warp members runninglongitudinally give this fabric low elongationfor minimum stretch. Resilient nylon fillermembers run transversely to hold fastenerstightly, especially where shock is involved.PN’s perform well under frequent stop-and-goconditions or where products may jam.SPECIAL COTTON-POLYESTERBLENDS (SCP)A 50-50 blend, SCP’s are 40-50% strongerthan cotton belts and more dimensionallystable. They won’t stretch or shrink in thepresence of moisture like cotton or cottonnylon belts and have little or no camber.These fabrics have more bulk than straight6polyesters for customers who prefer aheavier feel. SCP’s can be used withouta cover for a lower coefficient of friction.POLYESTER-COTTON BLENDS (PCB)A heavy-duty version of the SCP, bettersuited for heavier, textured surfaces;50-50 blends of polyester and cotton runboth longitudinally and transversely.PC’s are stronger and tougher than cottonand cotton-nylon fabrics. They also holdfasteners better.NYLOCK Designed exclusively by HBD/Thermoid,Nylock belting has a tough, interwovensingle-ply polyester body, 20% lighter inrelation to its strength than equally-ratedfabrics. Polyester tension filaments areinterlocked with 100% staple polyesterfillers, then these are fully protected with100% staple polyester face and back warps.Nylock belting has excellent resistance toimpact, 6¹ ₂ times more resistance to tearthan belting with ordinary fabrics. It workswell in the most demanding applications.

SUPERIOR COVERSCompounded specially bythe rubber and chemicalexperts at HBD/Thermoid.PVC NYLOCK This is a proprietary premium PVC beltingproduct. This belting has excellent resistanceto chemicals and acids. It cleans easily,doesn’t stain as readily as most other types.It’s available in highly oil resistant tan andwhite, and is USDA-approved for carryingmeat and poultry. It also meets all FDArequirements for food processing.NITRILE RUBBERNitrile rubber belting is our most popularbelting for food handling. Nitrile rubber hasexcellent oil resistance and withstandsgrease, fats and acids. It’s USDA-approvedfor carrying meat and poultry, plus it meetsall the requirements of the FDA. Nitrile rubber belting is available in white, tan, reddishbrown and black (non FDA and USDA).CARBOXYLATED NITRILEAn abrasion resistant rubber that is usedin our blue and orange Griptop belts.This compound also offers good oil andchemical resistance.RUBBERHBD/Thermoid is one of the nation’s mostexperienced rubber compounders. Rubbercovers are especially useful for carryingfrozen goods or in low-temperatureenvironments. Our rubber covers meetFDA requirements and are available inwhite and tan.BUTYLThis all-temperature belt compound is suitable for temperatures as high as 300 F andas low as -65 F. It is particularly suitable forfood processing lines involving both cookingand freezing operations. Available in white.For Assistance: 800/367-0420 or info@hbdthermoid.com7

BELTING SELECTION GUIDEA quick easy-to-readreference for matchingour lightweight conveyorbelts to your particularapplications.FOOD HANDLINGMEATS & POULTRY (USDA, FDA)Saniwhite & Sani-Brite nitrile rubber(all fabrics)Korowhite (125, SMC x F covers& CHV x F)Hot ’n Cold butyl (Polyester fabrics)PVC (Polyester fabrics)Ridgetop NitrileHOT, OILY FOODS (FDA)Saniwhite & Sani-Brite nitrile rubber(all fabrics)Butyl (Hot ’n Cold )TeflonFRUIT & VEGETABLE PROCESSING (FDA)Saniwhite & Sani-Brite nitrile rubber(all fabrics)Rubber, if oil-resistance not required(all fabrics)Korowhite 125, 150NUT PROCESSING (FDA)Nitrile rubber (all fabrics)PVC (Polyester fabrics)AGRICULTUREINCLINE SERVICE (FDA)Griptop for 35 degree inclines(PCB, SCP, PNT fabrics. Tan rubber andreddish-brown nitrile)Korowhite Chevron (USDA & FDA)Korowhite Cleated Incline (USDA & FDA)Ridgetop (USDA & FDA)Korowhite Herringbone (USDA & FDA)for up to 30 degree inclinesKorowhite GriptitePOTATO HARVESTING & UTILITY SERVICEPotato (2-ply synthetic fabrics)PVC Nylock HARVESTING EQUIPMENTFROZEN FOODS(SUB-ZERO TEMPERATURES)Butyl (Hot ‘n Cold )Rubber (Slide-A-Pack and Griptop )8PotatoPVC Nylock Chevron PVC Nylock Cleated InclinePVC Herringbone for 30 degree inclines(USDA & FDA)

TUBE CONVEYOR AND BUNKFEEDER SYSTEMSPVC Herringbone for 30 degree inclines(USDA & FDA)PVC Nylock Chevon PVC Nylock Cleated InclinePVC Nylock low-tempCotton processing equipmentGin flashing materialPACKAGE HANDLINGBELTS FOR INCLINES(1)Griptop — 35 degree inclinesGripper — Light impression for up to20 degree inclinesPVC Chevron and Cleated Incline —Molded pattern helps move loose materialon moderate inclines to 35 degreesdepending on productPVC Nylock for up to 18 degree inclinesat normal temperatures; up to 15 degreeinclines at low temperaturesPVC Herringbone for up to 30 degree inclinesGriptite for up to 20 degree inclinesLIGHT INDUSTRIAL & AUTOMATIONBELTS WHEN OIL IS PRESENTSaniwhite & Sani-Brite nitrile rubber(Polyester, PNT, SCP)Griptop (Nitrile & Carboxylated Nitrile) —for 35 degree inclinesSliptop TeflonBELTS FOR OIL-FREE SERVICEPVC Nylock & Korowhite Hot Stock & WaterCaripack Slide-A-Pack Potato (Utility)SPECIAL APPLICATION BELTSBELTS FOR STEEP INCLINESOF 45 DEGREESBig Red — Hot or Cold Tacky MaterialPlywood processing — TrayLumber service — LumberRubber processing — Hot Stock & WaterCotton gins — Flashing materialDiamond InclineV-CleatRibflexBELTS FOR HORIZONTAL SERVICECaripack Slide-A-Pack Sliptop Sheeting BeltHot Stock & WaterPVC Nylock (1)Smooth surface belts are generally satisfactory forinclines up to 15 degrees.For Assistance: 800/367-0420 or info@hbdthermoid.com9

FOOD HANDLINGFrom fruit to nuts to frozenfish. We can serve up a beltthat’s correct with any typeof food you’re processing.Some foods are oily, greasy or wet. Someare carried frozen, some steaming hot.Many leave juices, acids or particles thatcan stain or contaminate. Some foods grindat a belt cover and wear it away.Because different foods behaveso differently, HBD/Thermoid offersa wide selection of lightweightcarcasses and specially-compoundedcovers designed to deal with a varietyof conditions. All meet the very latestFDA and USDA requirements for food,drugs and cosmetics, with theexception of black nitrile.rubber belts stand up to temperatures from20 F to 212 F. Their smooth cover finishesresist abrasion, chipping and pitting, andhelp make cleaning easy and fast.Saniwhite and Sani-Brite nitrile rubber beltscome with special white covers developedto lower eye strain on inspection lines.Customer can choose fabrics frompolyesters, SCPs and PNs, plus ply andcover constructions for light or medium duty.WHITE TEFLON BELTFor easy product release.Our Teflon covered food belt will conveyfood and confectionary products duringprocessing and prevent them from stickingto the belt. The easy release of hot or stickymaterials from the belt makes it ideal formany light industrial applications as well.KOROWHITE BELTSThe most effective combination of highstrength and maximum resistance foryour most demanding applications.SANIWHITE AND SANI-BRITE NITRILE RUBBER BELTSOur most popular belting for generalfood handling.Saniwhite and Sani-Brite nitrile rubberbelts are a truly all-around belting withexceptional resistance to oil, grease, fats,food acids, alkalies and moisture. Nitrile10A tough, single-ply construction ofinterwoven polyester cords, fully protectedby 100% staple polyester face and backwarps. Korowhite belting is at least 20%lighter than equally-rated belts, yet it hasgreater impact resistance and up to 6¹ ₂times more tear resistance than ordinarybelting. It has very low stretch and won’tcamber in service or in storage. Totallysaturated with a white, premium PVCcompound, it is oil resistant and hasexcellent resistance to moisture, chemicalsand food acids. It’s also stain resistant.thebright white smooth cover cleans up easilywith just a damp cloth and a mild detergent.

HOT’N COLD BELTAll-temperature belt for extreme hotand cold conditions.White butyl belt is designed for hot serviceapplications up to 300 F and freezingcold ones down to -65 F. Its 3-ply APT 35polyester body has excellent fastenerholding power and resists effects of heat,cold and moisture.Hot’N Cold is ideal for food processingplants, dairies or bakeries where extremetemperature conditions exist.GRIPPER BELTThe economical belt for inclinesup to 20 .Gripper is an advanced HBD/Thermoid beltdesign manufactured in fabric impression.Its lightly-textured impression surface isexcellent for carrying products or packagedgoods up inclines up to 20 . It’s normallyconstructed with white nitrile rubber with 2or 3 plies of APT 35 fabric, and is alsoavailable in other carcass constructions.CHEVRON , CLEATEDINCLINE, HERRINGBONE,PVC, AND RUBBERGRIPTOP BELTSFor inclines of 30 and 35 .Chevron has a moldedchevron pattern in the PVCcover for handling inclinesup to 30 , depending uponproducts carried. Thechevrons help resist foodmaterial trapping andcarrying back. They alsodrain off juices or liquidsvery easily. These beltsconform well to either flator troughed conveyors.PVC Cleated Incline belt’sbucket-shaped pattern provides a firmer grip, movingbulk or packaged materialsup inclines as great as 35 ,depending upon productcarried. Flexing providesself-cleaning action andhelps prevent carry-back.Available in white food grade and in black.Herringbone has a molded herringbonecleat pattern in its PVC cover for handlingproduct up to 20 degree inclines.Griptop belting has a deeply-textured surfacewith thousands of tiny fingers that can copewith angles up to 35 . While not availablewith a white cover, Griptop belting doesmeet FDA requirements in tan rubber orreddish-brown nitrile for added oil resistance.RIDGETOP BELTThe incline belt for meatand food products.Ridgetop belting has a molded cleat ¹ ₈"high on 1" centers running across the widthof the belt. The Ridgetop cleat designenables the belt to carry meat and foodproducts up 20-30 inclines. The cleatdesign also prevents wet or moist productsfrom sticking to the belt by allowing theproduct’s surface to rest on the cleats. Anysuction effect between the product and thebelt cover is eliminated.For Assistance: 800/367-0420 or info@hbdthermoid.com11

AGRICULTURECustom orders for theOEM. Replacement beltsfor the farmer. Eitherway, we work withcustomers closely tokeep America’s cropson the move.HBD/Thermoid offers dependable,cost-saving lightweight belts for farmimplements, harvesting equipment,and storage and retrieval systems.designers to draft precise material anddimensional specs. Our sales staff willcoordinate and follow through to be sureyou get exactly what you order.on timeand on budget.In addition, your HBD/Thermoid IndustrialDistributor is within easy reach, providingnot only the lightweight belting you need,but important services like slitting, cleating,splicing and repair.Your distributor usually carries a completestock of the types of belting used aroundthe farm. But if you have a special request,he’ll be happy to order it for you.NYLOCK AND KOROWHITE BELTSGreat strength with moderate oil andexcellent chemical resistance, for thosetough applications that demand both.OEM’s can order through our Oneidalocation. We offer a broad range of fabrics,covers and special cover surfaces to meetnearly all field equipment and systemsneeds. We also offer products to meetUSDA and FDA requirements.If you need a specially-designed, made-toorder belt, our technical staff at Oneida iswell equipped to handle your requirements.Our technical staff can work with your12Strong enough to measure up to harvestingequipment and other heavy-duty implements.Resistant enough for fertilizers, feed andany oily crops you may be handling. Bothbelts have a unique carcass.a specialweave of polyester cords that providesgreater strength for its weight, plus addedresistance to impact and up to 6¹ ₂ times thetear resistance of ordinary belting.The PVC top and bottom covers providesuperior resistance to chemicals, food acidsand moisture. What’s more, both belts areeconomical because they’re reasonablypriced and give long service life. Nylockcomes with black covers; Korowhite withan easy-to-clean white cover. Either canhave a molded chevron or cleated patternadded during manufacture for carrying upinclines to 35 .

CHEVRON , HERRINGBONE ANDCLEATED INCLINE BELTSFor bulk material and tubeconveyor systems.The molded chevron, herringbone or thebucket shaped pattern in the PVC coverhelps move bulk materials like grain, feedand fertilizer efficiently up inclines as steepas 35 . The impressions resist the trappingor carry-back of material and readily drainoff liquids. What’s more, they’re easy toclean. The covers have added abrasionresistance for longer service life with coarsematerials. These belts are made with a thin,tough woven polyester carcass that cantravel flat over head and tail pulleys, yetconform well to deep troughs and tubes toprevent the load from dusting and spilling.POTATO BELTSThe economical belting madeespecially for potato harvesting.Excellent for the harvesting, processing andstorage conveyors that handle potatoes.Potato belts have two plies of syntheticfabrics with black, abrasion-resistant topand bottom covers. For slider beds, they’reavailable with a rubber top cover and atreated duck bottom to reduce the drag overthe slider bed surfaces. The perfect low-costsolution to this specialty application.GIN FLASHING MATERIALThe highest quality and most durableproduct available for gin flashing.The body of this material is three strongplies of cotton fabric protected by a heatresistant cover compound. The all cottonfabric makes the material rigid enough forgood seals and provides excellent boltholding strength.For Assistance: 800/367-0420 or info@hbdthermoid.com13

PACKAGE HANDLINGWe have a belt that canhelp you get a better gripon your business.In every situation, it’s important to weighoriginal cost against expected servicelife to determine which belt will be themost cost-effective. For these reasons,HBD/Thermiod gives you an ample rangeof fabrics, weights and textures.Surface frictionrequirements andeconomics are thebiggest factors in beltselection for packagehandling.For sharp inclines anddeclines, speciallydesigned grippingsurfaces are a mustto keep loads fromslipping. Even flatapplications putspecific demands ona belt, depending on the amount of on-and-offloading and the nature of material handled.PACKAGE HANDLING BELTSCaripack , Slide-A-Pack , Sheetingand Sliptop Belts.These belts have good all-around propertiesfor horizontal handling. The rubber frictionsurface helps keep even slippery packagesmoving along at belt speed. The blackCaripack and tan Slide-A-Pack are goodgeneral purpose rubber belts for slider bedand live roller conveyors where there is no oilpresent. The reddish-brown nitrile sheetingbelt is a good belt for those applicationswhere oil is present. The Sliptop belt ismanufactured with a treated nylon top ply toprovide for easy package release or transferfrom the belt. The tan nitrile compound givesthe Sliptop belt excellent oil resistance as well.SPECIALTY PACKAGE HANDLING PRODUCTSPack-EZ S/Weave belts are approvedand preferred by all major, packagehandling companies. Especiallysuited for slider bed systems,14our rugged PVC, low stretch belts have asingle ply carcass of special S/Weaveinterwoven polyester fabric. Built tough,these belts are designed to resist stretchingand fire. Pack-EZ special S/Weave fabriccomes in various operating tension ratings,including 120#, 150# and 200#.HBD/Thermoid , Inc. manufactures a widevariety of package handling belts. Thesebelts are product engineered to meet yourservice requirements. Our Pack-EZ Prem PHbelts are another very popular package handling product group. Constructed of rubber/monofilament fabrics, Pack-EZ Prem PH beltsdeliver solid performance while standing upto the rough, everyday demands required inpackage handling. These belts resist fire andstretching. The Pack-EZ Prem PH series isavailable in a wide range of product types tomeet the many unique applications requiredin package handling. Choose from theseoptions: 2 Ply 90#, 2 Ply 160#, 3 Ply 1354#and/or 3 Ply 200# with Bare X Bare or LightImpression X Bare.GRIPTOP INCLINE BELTSThe deep textured surface with raised rubberpeaks grips each package and carries it upinclines as steep as 35 . Griptop belts are ourmost popular line of incline belts. They areavailable in black or non-marking tan rubberfor general service and reddish-brown nitrilefor applications where oil is present. Pure gumrubber works best where abrasion, tearing orgouging are problems with the general serviceGriptop belts. For the most severe abrasionapplications choose blue or orange Griptopcarboxylated nitrile belts.STEEP INCLINE BELTSOur full line of molded impression top, steepincline belts are ideal for carrying packages,cases, cartons, luggage and many productsup inclines as steep as 45 degrees. Thesteep incline belts are available in thefollowing three cover impressions: V-Cleat,Diamond Incline and Ribflex . These beltsare available in general service black rubbercompounds, and some are stocked innon-marking tan or pure gum compounds.Our V-Cleat belt is also available in an oilresistant red/brown nitrile construction.

LIGHT INDUSTRIAL USESWhere productivity adds upto profit, our belts can helpyou step up the pace.More and more manufacturers ofautomated equipment are looking toconveyor belts as an integrated part oftheir systems and products. Today’s beltsmust often resist attack by industrialoils, grease and chemicals. They oftenneed to operate effectively in low or hightemperatures. The covers must be builttough enough to stand up to persistentimpact and abrasion from all sizes andshapes of small parts. HBD/Thermoidbelts serve all of these needs.On assembly lines, our belts can move thingsfrom station-to-station as fast or slow asthe schedule demands. Soft but contrastingcolors go easy on the eyes while improvingthe level of quality control at inspection stations. The belts can be slit narrow enough tocarry a single part at a time cost-effectively,or we can make them wide enough to movewhole masses of parts at a steady rate.To satisfy a variety of industry’s needs, weoffer general purpose and specialty beltswith plenty of options.excellent releasecharacteristics. Thesilicone covered topply enables materialsto be conveyed ongradual inclines without slipping back andyet, releasing from thecover at the end. BIGRED has a proventrack record of performing exceptionallywell in difficult applications such as conveying tire and hosestock, and plasticsand vinyl materials.NITRILERUBBER BELTSFor general utility.Nitrile rubber belting offers a good combination of properties for a wide range of industrialuses. The cover offers superior resistance tooils, grease, alkalies, acids and moisture. Itcan withstand high surface temperatures upto 212 F. In the off-white color, it’s well-suitedfor inspection lines and cleans up very easily.Also available in tan, green, black and reddishbrown. Carcass constructions can be chosenfor light or medium duty from the polyesters,SCPs and PNs.GRIPTOP CARBOXYLATED NITRILE BELTSFor those applications where excellentabrasion, oil and chemical resistance isrequired. These belts are commonly usedin the processing of paper and cardboardproducts, and some wood processingapplications. The bright blue and orangecolored impression covers allow for easyidentification when color coding belts forcertain applications in a plant.“BIG RED ” SILICONE COVEREDHOT STOCK & WATER BELTHOT STOCK & WATER BELTS“BIG RED” silicone covered Hot Stock &Water is designed for conveying hot or coldtacky material such as rubber or plasticstock in various stages of manufacturing.This special silicone treatment allows thecover of the belt to withstand material inexcess of 350 F. Another feature is itsConveys the hot rubber stock while it’s cooledwith water in the various stages of rubberprocessing. The bare cotton, silver hard-ducktop ply prevents the hot rubber stock fromsticking to the belt. This belt is also ideal forother general service horizontal conveyorswhere a bare fabric surface is preferred.For Assistance: 800/367-0420 or info@hbdthermoid.com15

CONVEYOR BELTING ANDDATA SPECIFICATION SHEETCustomerDateLocation*ConveyorDATA AND SPECIFICATIONSDrive Details:*Belt Width (inches)Type.Single (S), Tandem (T), Dual (D)*Length (ft.).one of three required:**Motor HorsepowerBelt LengthPulley Surface.Bare (B) or Lagged (L)Conveyor CentersBelt Wrap (Degrees)Horizontal CentersLocation from Head (ft.)ElevationLift (ft.)Slope (Degrees)*Belt Speed (ft./min.)Capacity (tons/hr.):AverageMaximumMaterial Info:or Drop (ft.)TypeWeight (PCF)Maximum Lump Size (inches)Temperature (Degrees F.)Oil.None (N), Some (S), Much (M)Drop to Belt (ft.)Idlers:Pulley Diameters (inches):Degree TroughHeadRoll Diameter (inches)Drive SnubTrough Spacing (ft.)TailTake-upOtherBelt Splice.Vulc (V) or Mech (M)Take-up:Type.Auto (A) or Manual (M)Movement (ft.)Location from Head (ft.)CALCULATIONSMaximum Operating Tension (lbs.)Load Support, Q (lb./ft.)Unit Operating Tension (PIW)Wrap Factor, KHorsepower RequiredCOMMENTSPrevious Belt Spec.Previous Belt Failure.Other.BELT RECOMMENDATIONS*Required information. **Required if either ELEVATION or CAPACITY details are unknown.16

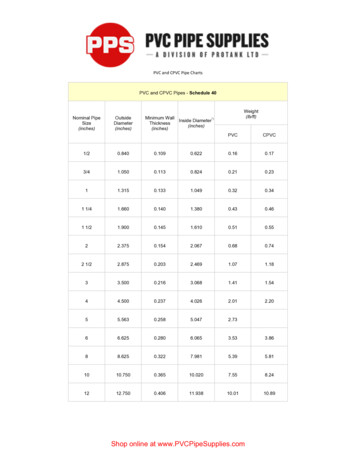

BELT SPLICINGEither vulcanized splices or mechanicalfasteners are recommended forHBD/Thermoid conveyor belts. Thefastening method you select dependson the particular requirements of theconveyor system. Here are somereasons for and against each method–the need for a vulcanizer and can bemade in areas that are not accessiblewith a vulcanizer.One company offering cold splice materialsand instructions is: REMA-TIP-TOP NorthAmerica, 200 Paris Ave., Northvale, NJ.Phone: 201/768-8100.MECHANICAL FASTENERS1. Require the least amount of timefor splicing.2. The splice can be taken apart andrejoined if pin style fasteners are used.This should be considered if there is anypossibility the belt or the system will belengthened or shortened.VULCANIZED SPLICES1. The belt surface is smooth, animportant consideration in manyapplications where other equipmentoperates in conjunction with the belt.2. If fine material is being handled, avulcanized splice is necessary to preventleakage at the joint.3. Vulcanized splices allow the full ratedworking tension of the belt to be utilized.WIDTH TOLERANCESCut Edge BeltsPlus or MinusUp to 24" inc.¹ ₈"Over 24" to 36" incl.³ ₁₆"Over 36"¹ ₂ of 1%THICKNESS TOLERANCESFinished BeltsPlus or MinusOverall GaugeAIR CURING CHEMICAL SPLICESChemical systems of splicing provide analternative to the vulcanized splice. Thisair-curing cold-splice system eliminatesUp to .094 (³ ₃₂).016.095 to .156 (⁵ ₃₂).020.157 to .344 (¹¹ ₃₂).031.345 to .500 (¹ ₂).047For Assistance: 800/367-0420

state of the art equipment.We manufacture a full-line of lightweight rubber and PVC conveyor belting under the cleanest conditions.We've invested heavily in this lightweight belting plant because we intend to make our belts the very best available. For Assistance:800/367-0420 or info@hbdthermoid.com 3