Transcription

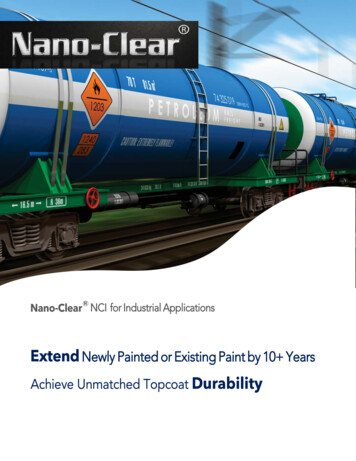

.ANO #LEAR NCI for Industrial ApplicationsExtend Newly Painted or Existing Paint by 10 Years"DIJFWF 6ONBUDIFE 5PQDPBU Durability

Industrial MarketIndustrial asset owners commonly applyprotective topcoatings over steel surfaces tomitigate the effects of environmental exposure tothe sun including oxidation, chemical attackdamage, corrosion and desire for betterappearance. Conventional industrial coatings"alone" are currently very susceptible to; UV degradation weathering acid rain water damage corrosion normal useWhat is needed?An improved surface coating that protectsindustrial assets more thoroughly than anyexisting technology. A permanent surface coatingthat will enhance and extend the surface life offreshly painted or highly oxidized paint by 10 years. Extreme Corrosion ResistanceNo Rust After 4000 Hour Salt Spray Testing %XTREMEȩ!BRASIONȩ2ESISTANCE/NLYȩ MGȩLOSSȩAFTERȩ ȩCYCLES ȩ KGȩȩ EATHERPROOFȩ'LOSS 799% Gloss Retention after 4000 Hours. Xenon WOM ȩ ȩ#OATING ȩ!MBIENTȩ (UMIDITY ȩ#UREDDry-To-Handle in 4 hours; Return to Service in 24 hoursȩ EDUCEȩ2E 0AINTȩ#YCLEȩBYȩ 9 9 2As Documented in Production Case Studies )ȩ MPROVEȩ"RANDȩ!PPEARANCE!CHIEVEȩ EEPERȩ#OLORSȩ ȩ RAMATICALLYȩ(IGHERȩ'LOSS.ANO #LEARȩ.#)/BOP MFBS / I ESBNBUJDBMMZ JNQSPWFT TVSGBDF QSPUFDUJPO BOE braOE JNBHF XIJMF TJHOJGJDBOUMZ SFEVDJOH TVSGBDF NBJOUFOBODF FYQFOTFs INTENANCE4IMEȩ ȩ%XTENDingȩ9OURȩ2ECOAT #YCLEȩ"Yȩ ȩ9EARSx'UARANTEED

What Makes NCI Unique?Nano-Engineering (OPU OBOP QBSUJDMFT)Creates Exceptional Crosslink DensityNano-Clear NCI is manufactured usingproprietary 3D nanostructured polymers producing extreme crosslink density.BMW validated Nano-Clearcoating to have the highestgloss levels and DOI of anyclear coating system theyhad ever tested.NCI provides extreme corrosion resistance,abrasion, chemical & UV resistance andreduced surface maintenance. NCIpenetrates deep into the pores of freshlypainted or highly oxidized paints toenhance color, improve gloss, dramaticallyincrease surface hardness, improvechemical and long-term UV resistance.Nano-Clear is a one-component humiditycured / highly cross-linked polyurethane/polyurea hybrid nanocoating.With this exceptionally high crosslinkdensity, we have the test data to prove thatNCI is the world’s best all-around clearcoatfor resistance to scratches, chips, abrasion,chemicals, weathering, and more. Pleasesee the back cover for test results orhttp://www.nanocoatings.com.BeforeEven with its remarkably high surface hardness (4H),NCI stays flexible. This iron-phosphated steel panel,painted with Macropoxy 646 Epoxy and then coated withNCI, bends in-half without cracking or any other failure tothe coat. Call 810-227-0077 for technical questions.

Why is Crosslink Density So Important?Coatings contain “building blocks” withIXQFWLRQDO JURXSV 7KH FKHPLFDO UHDFWLRQ RI WKHVH JURXSV GXULQJ FXULQJ IRUPV D QHWZRUN ,Q PRVW WUDGLWLRQDO SRO\PHUV the network is a linear chain of moleculeswith low crosslink density.Linear chain of moleculesConversely, we “nano-structured”our clearcoat to have a 3D molecularDUFKLWHFWXUH 7KH ' SRO\PHU QHWZRUN KDV DQ H[SRQHQWLDOO\ KLJKHU QXPEHU RI crosslinked sites. The result is a tightlyNQLW PHVK ZLWK XQSUHFHGHQWHG DMA density. LJK FURVVOLQN GHQVLW\ SURYLGHV KLJKO\ IXQFWLRQDO VXUIDFH SURSHUWLHV LQFOXGLQJ unmatched corrosion resistance, scratchresistance, chemical resistance and UVdurability. It also means low surfaceHQHUJ\ UHSHOOLQJ ZDWHU K\GURSKRELF and aiding in the release of ice, dirt,brake dust, and even concrete dust. PRQWK ƓHOG WULDO withoutNano-Clear NCI ȩMOLECULARȩARCHITECTURE PRQWK ƓHOG WULDO withNano-Clear NCIEven sticky concrete dust releases easily from Nano-Clear NCI

Unrivaled Performance Enhancement for Newly Paintedor Highly Oxidized Coatings&ORȩTHEȩLASTȩ ȩYEARS ȩTHEȩSAMEȩ LINEARȩCHAIN ȩPOLYMERȩTHEMES ȩ!SȩAȩRESULT ADMILL ȩ0AINTING ȩTHENȩWATCHINGȩTHEȩSUBSEQUENTȩOXIDIZATION ȩLOSSȩOFȩGLOSS ȩCORROSION ȩANDȩPAINTȩFAILURExȩREQUIRING ȩINȩTURN ȩLABOR HEȩSAMEȩCONVENTIONALȩCOATINGȩTECHNOLOGY Before0UTȩSIMPLY ȩ.#)ȩRESTORESȩTHEȩCOLOR ȩGLOSS IFEȩOFȩCONVENTIONALȩCOATINGSȩBYȩ ȩYEARS ȩCOATINGȩIS ȩ.ANO �PROVIDEȩUNMATCHEDȩSURFACEȩPROTECTION ȩBACKEDȩBYȩAȩFULLȩ YEARȩWARRANTY .ANO #LEARȩ .#)ȩ ISȩ ALSOȩ DESIGNEDȩ TOȩ ACESȩINCLUDINGȩ ȩEPOXIES ȩ ȩPOLYURETHANESȩANDȩPOWDERȩCOATINGS After withNano-Clear NCI

How Does NCI EnhanceColor & Physical Properties?.#)ȩHASȩAȩLOWȩ ȩCPS ȩVISCOSITY ORESȩOFȩnewlyȩPAINTEDȩORȩOXIDIZEDȩCOATINGS ȩTURNINGȩTHEȩWHITE ȩCHALKEDȩLAYERSȩTRANSPARENT ȩSHOWȩTHROUGHȩWHILEȩFORTIFYING HARDENINGȩTHEȩSURFACE (UMIDITY CUREDȩATȩAMBIENTȩTEMPERATURES TEDȩSURFACE ȩhLOCKING HȩITSȩLONG TERMȩ56ȩABSORBERS 0LEASEȩNOTE RATEDȩINTOȩAȩȩPOWDERED ȩPEELEDȩAND ORȩERODINGȩSTATE ȩȩ.#)ȩISȩNOTȩAȩRUSTȩCONVERTER �AȩHIGHȩSOLIDS ȩTWO COMPONENTȩEPOXies ȩȩPRIORȩTOȩAPPLYINGȩ.#) O #LEARȩ.#)ȩ4ECHNICALȩ ATAȩ3HEETȩHTTP WWW NANOCOATINGS COM NCITDS PDF)NDUSTRIALȩ5SERSȩOFȩȩ.ANO #LEARȩ.#)

Where Could You Use NCI?/Nȩ.EWȩORȩ(IGHLYȩ/XIDIZEDȩ#OATINGS ȩE G ȩ ȩEPOXIES ȩ ȩPOLYURETHANES ȩPOWDERȩCOATINGS ȩPOLYESTERS ȩGELȩCOATS ȩE COATS ȩLATEXES ȩFIBERGLASS ȩANDȩȩANODIZEDȩALUMINUMȩ TOȩPREVENTȩFILIFORMȩCORROSION ȩETC &ORȩ)NDUSTRIALȩ%QUIPMENT ȩE G ȩRAILȩTANKȩCARS ȩFUELȩTANKS ȩHEAVYȩDUTYȩEQUIPMENT ȩEARTHȩMOVINGȩEQUIPMENT ȩSHIPS ȩFLEETȩVEHICLES ȩPLANTȩFLOORS ȩPAINTEDȩBUILDINGȩSTRUCTURES ȩLIGHTȩPOSTS ȩTRANSFORMERȩHOUSINGS ȩPUMPS ȩVALVES ȩȩLIFEBOATS ȩOILȩPLATFORMS ȩPIPELINES ȩȩSHIPPINGȩCONTAINERS ȩETC ȩ0ROBLEM NTȩRESTORATION 3OLUTION VERALLȩIMAGEȩOFȩTHISȩLEADINGȩSODAȩBRAND ȩWHILEȩREDUCINGȩTHEȩRE PAINTȩCYCLEȩANDȩREDUCINGȩFLEETȩMAINTENANCE ȩ3EEȩOTHERȩ.ANO #LEARȩCASEȩSTUDIESȩHTTP WWW NANOCOATINGS COM CASESTUDIES#ALLȩ.ANOVEREȩATȩ ȩTOȩARRANGEȩAȩ.ANO #LEARȩ.#)ȩAPPLICATIONȩDEMONSTRATIONINFO NANOCOATINGS COM

.ANO #LEARLjȩ.#)ȩ#OATINGȩ3PECIFICATIONS3FDPNNFOEFE 6TFT 0O )JHIMZ 0YJEJ[FE 1BJOUT PS 'SFTIMZ 1BJOUFE 4VSGBDFT IFNJTUSZ /BOP 4USVDUVSFE 1PMZVSFUIBOF 1PMZVSFB )ZCSJEPROPERTY/TESTCrosslink DensityTEST METHODRESULTSTESTING SOURCE2.17 (X103 mol/m3)Nippon Paint1.25 lb/gal (150 g/l)1 mil to 2 mils1122 sq ft/gal (at 1 mil)86.0 / 92.2NanovereNanovereNanovereStonebridge Technical ServicesVOCRecommended Dry Film ThicknessCoverageGloss 20 / 60 DMA (DynamicMechanical Analysis)ASTM D3960ASTM D5796NanovereASTM D523Abrasion Resistance (CS-17, 1 kg, 1000 cycles)Pencil Hardness, ScratchScratch HardnessASTM D4060ASTM D3363SASO 28338.4 mg loss4H2500 gmPencil Hardness, GougePendulum Hardness (Persoz)Impact Resistance 18 C Direct in/lbsImpact Resistance 18 C Reverse in/lbsImpact ResistanceImpact StrengthChip Resistance 23 C (2 mils)Chip Resistance -29 C (2 mils)Falling Sand Abrasion 100 litersMar ResistanceASTM D3363ASTM D4366ASTM D2794ASTM D2794SASO ISO 3248ASTM D2794ASTM D3170ASTM D3170ASTM D968ASTM D51785H 250 oscillations50 Pass / 60 Fail10 Pass / 20 Fail1 kg - 160 cm145 kg-cm7A7BPass5.0 kgXenon WOM Resistance 4000 hrsSAE J1960ASTM G155ASTM D4587ISO 2812-2SASO ISO 11997ASTM D 1735-02JIS H8502-7GM9525PABUSE RESISTANCENippon PaintStonebridgeSaudi Standards, Metrology, &Quality Organization (SASO)StonebridgeNippon ebridgeStonebridgeSASOENVIRONMENTAL RESISTANCEQUV 313, 1500 hrsWater Immersion Test 240 hrs @ 50 CSalt Spray, 4000 hrsHumidity, 100% RH, 100 F, 240 hrsCASS 240 hrs @ 50 CThermal Shock (100 F 3 hrs, Freeze3 hrs, Steam Blast 30 sec)100% Gloss Retention99% Gloss Retention100% Gloss RetentionPassExcellentNo loss of adhesion. No change.PassNo loss of adhesion. No Change.StonebridgeNippon PaintNippon PaintNippon PaintSASOAmerican Racing Custom WheelsNippon PaintAmerican Racing Custom WheelsCHEMICAL RESISTANCE10% Sulfuric Acid10% Hydrochloric Acid10% Sodium Hydroxide10% Ammonium HydroxideIsopropyl AlcoholXyleneSkydrol 500 FluidMEK ResistanceASTM D 1308ASTM D 1308ASTM D 1308ASTM D 1308ASTM D 1308ASTM D 1308ASTM D6943-AASTM 4752Adhesion, Direct to MetalAdhesion, Cross CutFlexibility, 1mm MandrelFlexibility, Cylindrical MandrelFlammability: Fire Retardant & Flame SpreadDe-Icing AidASTM D4541SASO ISO 2409SASO 2833SASO ISO 1519ASTM E84 / BS476Coated equipment frozen in20 ft freezerNo effectNo effectNo effectNo effectNo effectNo effectNo effect1500 double , FLEXIBILITY & CLEANINGSelf-Cleaning Properties3 MpaRating 10Passed (Very Good)3 mm Passed (Excellent)Class 1 (Excellent)It was possible to flake off ice bits andmelting was faster.Oil & Dirt Release; Hydrophobic,Brake-Dust ReleaseSASOSASOSASOSASOSASOSchlumbergerNippon PaintAPPLICATION HIGHLIGHTSPot LifeViscositySpray ApplicatorsWipe-On ApplicationApplication TempOperating (Service) Temp1 Component (1K)200 cpsHVLP, Conventional or AirlessShurLine Deck Pad40 F to 90 F-40 F to 250 FRelative HumidityDry Time: Dust Free @ 68-72 FDry-To-Handle @ 68-72 FRecommended for small areas20% to 80%30 minutes4 hoursYesNanovere Technologies, LLC4023 S. Old US 23, Suite 101Brighton, MI 48114 USA810-227-0077INFO NANOcoatings.comȩsȩHTTP WWW NANOCOATINGS COM 2016 Nanovere Technologies, LLC. All rights reserved. Nano-Clear is a registered trademark of Nanovere Technologies, LLC. OO RWKHU WUDGHPDUNV DUH SURSHUW\ RI WKHLU UHVSHFWLYH RZQHUV 6SHFLƓFDWLRQV VXEMHFW WR FKDQJH V 8 Industrial

ASTM D3363 ASTM D4366 ASTM D2794 ASTM D2794 SASO ISO 3248 ASTM D2794 ASTM D3170 ASTM D3170 ASTM D968 ASTM D5178 SAE J1960 ASTM G155 ASTM D4587 ISO 2812-2 SASO ISO 11997 ASTM D 1735-02 JIS H8502-7 GM9525P ASTM D 1308 ASTM D 1308 ASTM D 1308 ASTM D 1308 ASTM D 1308 ASTM D 1308 ASTM D6943-A ASTM 4752 ASTM D4541 SASO ISO 2409 SASO