Transcription

PRODUCT SUPPORT CATALOG2020 FALLFEATURED INSIDEThe John Deere Powertrain ReLife Plus MachineRebuild Program and new Certified RebuildCenters can pump new life into your iron.See pages 20–2117 Half-Arrow Blades19 Big Parts Promise22–23 Reman Solutions32–33 BatteriesContact your dealer to order parts, anytime,through their Customer Portal.

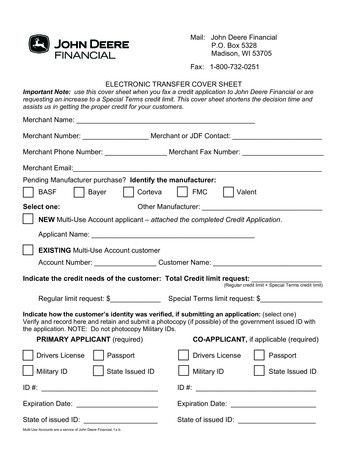

PowerPlan is a flexible line of commercialcredit that gives you the power to manageequipment expenses and your cash flow.Get instant, interest-free1 purchasingpower for these John Deere andnon-John Deere purchases:RENTALSPARTSSERVICEMORE THAN 100 ATTACHMENTSGROUND ENGAGING TOOLSPREVENTATIVE MAINTENANCETECHNOLOGY SOLUTIONSOpen your PowerPlan account today!See your dealer, or go toJohnDeereFinancial.com/PowerPlan to apply.¹Subject to John Deere Financial approval. Available for preferred customers only.PowerPlan is a service of John Deere Financial, f.s.b.CR2211577 Litho in U.S.A. (19-08)JohnDeereFinancial.com

WHAT’S NEW?John Deere SecuRing SealTable of ContentsJohn Deere SecuRing seal is a new, patentedsealant family that provides a modular grip formaximized security.SecuRing improves seal retention in the groove, greatly reducingpinched and missing seals. Coated with a light blue PTFE coatingthat acts as a lubricant, SecuRing secures the seal so it can properlyseat itself under pressure — the first usage and every usage after.Unlike other seals, SecuRing remains firmly in place while the joint isassembled, making sturdy connections even sturdier.Round O-ringSecuRing eliminates the margin of error in a proper seal byeliminating the gap between different shapes in the sealing area.Available in eight different sizes.Also available as a kit containing 12 of each SecuRing size.SecuRing SealJohn Deere Orange V-PlugsJohn Deere Orange V-Plugs are an exciting new additionto our Hydraulic Multiplier, Caps, and Plugs lineup.Orange V-Plugs are the perfect solution for quickly and reliably plugging hose and tube ends,ports, and other openings to prevent the leakage of messy fluids. With each plug covering arange of Inside Diameters (IDs), challenges encountered while performing maintenance orrepair on fluid-conveyance systems are met swiftly and easily, and with your uptime in mind.For use:– Around the farm– On the jobsite– I n various industrial and commercial venuesUse Orange V-Plugs to:–H elp prevent environmental contamination andunsafe work environments– S top the infiltration of dust and other ambientcontaminants into sensitive systems–M aintain a well-equipped shop tool chest and/or service vehicle toolboxJohn Deere Financial. 2What’s New. 3John Deere Connected Support . 4–5Undercarriage.6–7TK-Series Tooth System. 8–9All-Makes RVJ Bucket Teeth.10All-Makes Bucket Teeth.11Cutting Edges. 12–14Forestry Saw Teeth.14Rubber Tracks.15JAGZ .16Half-Arrow Blades. 17Hydraulic Hoses.18Big Parts Promise.19Powertrain ReLife Plus.20Certified Rebuild Centers. 21Reman. 22–23Oil, Lubricants, and Filters.24–25Coolants.26Diesel Exhaust Fluid andEquipment. 27Fuel Additives.28Grease.29Towels and Chemicals.30Paint. 31Batteries and BatteryAccessories. 32–33Commercial Job and WorkshopProducts. 34–35Temperature range:–40 F (–40 C) to 194 F (90 C)See your local John Deere dealer for more details on these new products.3

John DeereConnected Support When you buy John Deereequipment you expectreliability.You should, because NothingRuns like a Deere.That’s why John Deereequipment comesprepared from the factorywith technology built in.It senses potential issues andcan alert you promptly — in thecab or anywhere you are.You also know that whenyou’re on the jobsite, theunexpected can happen.When it does, you need aquick resolution.Better yet, your dealercan receive alertsand connect to yourequipment.You know your dealer is alwaysready to keep you running —and running better.WHEN YOU CONNECT YOUR MACHINE:You Can–M onitor alerts from the machine remotely–M onitor engine hours and utilization–V iew machine location and get driving directions to the jobsite– Monitor fuel level and idle timeYour Dealer Can–M onitor alerts coming from your machine– Remotely connect to your machine for real-time diagnosis– Leverage Expert Alerts from John Deere to address potentialfuture downtime– Perform software updates from the dealershipMost new John Deere machines come ready with five years of machine connectivity to enable these tools that you keep running.Ask your dealer about John Deere Connected Support to learn more.4

One of the most powerfulreasons to choose John Deere.Our remote machine-monitoringcapability for tracking the health ofmachines in the field enables your dealerto respond more efficiently to criticalissues that can result in costly downtime.Our Machine Monitoring Center specialists use advanced telematicsand alert-management tools to stay on top of potential issues. Whennecessary, they engage John Deere factory-trained technicians, whohave the ability to read and clear diagnostic codes, record machineperformance data, and even update software — without ever visitingthe machine in the field.Typical response time is quick, and many times problems can beaddressed before they cause downtime. When technicians do needto visit the jobsite, they often arrive with the correct repair partsalready in hand.Looking at the big picture now can help us improve ourservice to you in the futureJohn Deere Machine Health Monitoring Center specialists developsolutions that enrich our monitoring services. They do this byanalyzing accumulated machine data, identifying trends thatwarrant a closer look, and then developing new and improvedpreventative maintenance and repair protocols that we canleverage in the future.So while we focus on addressing issues that may immediately impactyou and your fleet, the Machine Health Monitoring Center keeps aneye on the big picture so we can repair machines faster and even helpyou avoid unexpected downtime altogether.John Deere Connected SupportALERT MONITORING PROCESSgDianostrouic icateerE xpRemote Diagnostics/ProgrammingRepJohn DeereMachine HealthMonitoring CenterDTCTC)ler ttAler tJohn Deere DealerMachine Monitoring CenterDealer Technician5

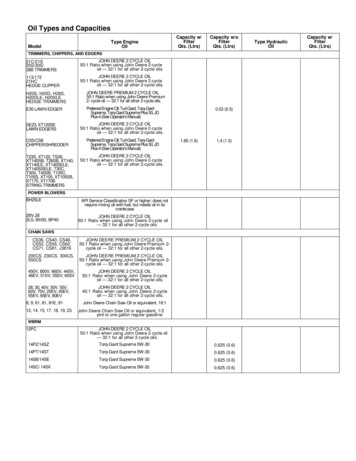

John DeereUndercarriageTough undercarriages with longerand more even wear.With rapid and unbalanced undercarriagewear eating up some 50 percent of theaverage contractor’s maintenance budget,John Deere undercarriages are strongallies in the battle to keep uptime up andoperating costs down.The steel that goes into our undercarriages provides the kind ofdeep-hardened resiliency that goes directly to your bottom line.And that’s why we say the value that we build into John Deereundercarriages is truly hardened to the core.We offer three choices to cover your needs:Standard UndercarriageAll components are carefully matched in tolerance, strength,hardness, and wear limits, for optimum wear life.Extended Life UndercarriageThis wear resistant system features the addition of the popularand exclusive SC-2 -coated bushings.Maximum Life UndercarriageThe Maximum Life Undercarriage incorporates SC-2 coatedbushings along with stronger seals and larger componentscompared to the Standard and Extended Life Undercarriagesystems that already deliver longer and more balanced wearin most soil conditions.6Undercarriage selectionThe chart below compares the three John Deere undercarriagechoices relative to seven different attributes. Your John Deere dealerhas the expertise to help you understand the characteristics of eachundercarriage and choose the one that is right for your operatingconditions and business needs.StandardGOODExtended Life Maximum LifeBETTERBESTPurchase PriceOperating CostRide ComfortWear LifeAbrasion Resistance – SC-2Impact Resistance – LargerComponentsVarying GroundConditionsNote: All factors are dependent on soil conditions and specific application. Consultyour local John Deere dealer to choose the right undercarriage for your operation.

WARRANTYBacked by a 3-year/ 4,000-hour warranty.Standard bushingSC-2 wear comparisonSC-2-coated bushings minimize service requirements becausethey deliver up to twice the life before you need to make a “turndecision.” In some cases, bushing turns may even be ushing with SC-21.821.00Stands up to punishing testsTrack-chain assemblies were field-tested in sand. The photosabove show that the standard bushing wore 32 percent, whilethe bushing with SC-2 coating had minimal wear.7

John DeereTK-Series Tooth SystemWhy it’s better.SLIP THE TKTOOTH OVERTHE ADAPTERNOSE1The TK-Series System is engineered todeliver maximum performance, quickand safe replacement, and superiortooth retention.3–R ubber locks are held captive when the tooth is retained forsecurity and protection from direct impact– Nearly a 70-percent consumption ratio1 means you aregetting more for your money– Over 50-percent-more usage with heavy-duty TK-Seriesloader teeth2– Includes a lifetime warranty against breakage2SLIDE THETURN KAMDETENT PININTO THE NOSEROTATETHE PIN ½TURN TOLOCK INTOPLACENO HAMMERS OR PRY BARSSYMMETRICAL DESIGNALLOWS THE TEETH TO BE FLIPPED ANDPINS TO BE RETAINED FROM EITHER SIDEFanggs ToothRock Chisel ToothTiger ToothA NEARLY 70-PERCENTCONSUMPTION RATIOMEANS YOU ARE GETTINGMORE FOR YOUR MONEYTwin Tiger ToothLoader ToothMETALLURGICAL COMPARISON GRAPH2.001.80Flare ToothSevere-Duty (SD) ToothNote: TK-Series teeth installed on new John Deere equipment arepainted yellow as shown. Aftermarket TK-Series teeth are black.See your dealer for specific part numbers.1 Richmond, Virginia, field-test data from August 2012. A set of eight TK550LD teeth and eight TK550LDH teethon a 90-metric-ton loader loading blasted granite was monitored and weighed at end of life. Data showed anaverage consumption ratio across all teeth for the LD set to be 67.18 percent, and 69.29 percent for the LDH set.2 Field-test data from October 2012 showed the TK550LDH (heavy-duty) teeth at end of life yielded 550 hours ofproduction compared to an average of 254 hours for two sets of TK550LD (standard-duty) teeth tested on thesame 90-metric-ton production loader in a blasted granite loading application.8Percent of ElementHeavy-Duty (HD) Loader K23ESCO 45MTG 67HENSLEY TK-SERIES TEETH ARE VERY SIMILAR TO THOSE OFOTHER MAJOR COMPETITORS IN THE INDUSTRY8

PUT DOWNTHE HAMMERTK-Series adapter stylesWeld-onadapterBolt-on adapter(center)FREEADAPTERTK Conversion ProgramBolt-on adapter(one-hole end)Bolt-on adapter(two-hole end)Offer ends October 31, 2020.Dealers: Refer to Program Number TS-T4.9

John DeereAll-Makes RVJ Bucket TeethA new twist on old technology.The RVJ Bucket Tooth System is engineered to deliver hammerlesstechnology to existing Caterpillar J-Series adapters through a converterand helical pin design. The converter is secured between the existingcompetitive J-Series adapter and the RVJ tooth. The helical pin is placedin the tooth’s nose, where it is rotated 180 deg. with a common socketwrench and tightly secured. Convert to a fully hammerless systemwithout changing adapters!Convert to a fully hammerlesssystem without changing adapters.1 Insert converter into adapter.2 Fit tooth over nose and converter.3 Insert helical pin and rotate 180 deg.with socket wrench to engage lock.Standard1FlarePenetration Plus2TigerTwin Tiger3LoaderHD AbrasionSee your dealer forspecific part numbers.FREEConverter with purchase ofRVJ teeth and pin set throughOctober 31, 2020.Dealers: Refer to Program Number TS-V2.10

John DeereAll-Makes Bucket TeethJohn Deere “Original Line” TeethJohn Deere builds rugged replacement teeth and adapters for most brandsof backhoes, excavators, loaders, scrapers, and graders. John Deere teethare available in either split-washer or two-piece-pin configurations to makereplacement of these critical wear parts as quick and cost efficient as possible.Caterpillar Replacement TeethThe oversized pocket characteristics of these teeth with the extended adapternosepiece provide a nose fit between the tooth and adapter that results instrong impact resistance with a loose fit in the ramps. Cat style teeth use ahorizontal pin and retainer.John Deere “OriginalLine” TeethCaterpillarReplacement TeethH&L Replacement TeethH&L style teeth are designed for backhoes and excavators. They are availablein a multitude of shapes offering superb performance and reliability in alldigging conditions. H&L style teeth use a horizontal flex pin.H&L Replacement TeethHensley Replacement TeethThe parabolic (dished-out) design creates a wedging and self-tighteningfit. Most Hensley style teeth use a vertical roll pin, flex pin, or steel keeper,depending on size.Hensley Replacement TeethESCO Helilok /Vertalok SystemTeeth mount on both the Vertalok and Helilok adapters with a quarter turnand “butts ups” against the adapter nose to take thrust loads head-on.The helical threads and large stabilizing flats at the end of the nose delivermaximum resistance to severe breakout forces.ESCO Conical TeethThe “conical” design mating system between tooth and adapter createsself-tightening action. The design reduces tooth movement both verticallyand horizontally. Conical teeth use a vertical pin and rubber lock.ESCO Helilok/Vertalok SystemESCO Super V The Super V tooth twists a quarter turn onto the adapter and “butts up”against the adapter nose to match breakout forces more closely. The onepiece pin provides easier changeover and is reusable for 29 Series sizesand larger.John Deere meets your all-makes bucket teeth needs.See your local John Deere dealer for a full listing ofavailable parts.ESCO Conical TeethESCO Super V11

John DeereCutting EdgesProtect your investment!John Deere is your one-stop solutionfor all your cutting-edge needs.Our full line of cutting edges covers everything from a standard, economical carbon edgeto specialty edges like our John Deere Jagz Interlocking Edge System. Talk with your dealerto review your specific application and find out which John Deere system is best for you.Carbon EdgesDual Carbide EdgeThe standard for cutting edges, these edges are formed from a highcarbon rolled steel, made harder by the addition of carbon.The dual carbide edge features two tungsten carbide insertsspecifically designed for high-abrasion and low-impact applications.First insert is formulated with our proprietary macrocrystallinecarbide grade for toughness and impact resistance, and mounts onthe front of the blade. Second insert is made from a wear-resistantcarbide grade and mounts directly behind the first insert to resistwear caused by blade down pressure and abrasion.Dura-Max EdgesManufactured with thru-hardened 15B30 boron steel, which issignificantly harder than the standard carbon edge. Dura-Maxedges are made harder via a heat-treatment process in which theblades are heated to extreme temperatures and then quenched toreach maximum hardness levels.John DeereLattice EdgeAggressively cut into ice and snow with the John Deere Lattice Edge.This edge is designed to create a rough surface for salt or sand tocollect onto the ice and snow. This cutting edge features a Latticestyle design across the entire moldboard width and length to allowfor full rotatability.12Features, advantages, and benefits:– Provides maximum wear resistance.– Offers the longest-lasting blade life span in the industry.– Exclusive, innovative blade design that outlasts imbeddedcarbide granule-style blades.– Features a universal bolt-hole and a variety ofavailable lengths for maximum compatibility.– Reduces costs associated with replacementpart inventory, downtime, labor, andoverall operations.– Resists “crowning” and maintainsa straighter cutting edgethroughout the life ofthe blade.

John Deere Stinger Scarifier-Style Grader EdgesJohn Deere Stinger grader edges deliverconsistent, reliable performance in a widerange of applications.Stingers eliminate washboarding and potholes, with fewer passesthan standard grader blades, as well as decrease the numberof passes necessary to properly maintain a road surface. Thesetungsten-carbide-tipped cutting tools are stronger than steel andpenetrate hard-packed, gravel, and frozen surfaces easily. Stingerreplaceable, rotating, self-sharpening tools wear uniformly andmaintain an even cutting height by enabling them to be rotatedfrom position to position.Stingers come in over a dozen tool styles and fit universallyinto three blade strengths for a variety of applications:– S tandard duty – ideal for light-use grading in average conditions– Heavy duty – useful in most grading environments– S evere duty – best for working in extreme elementsCover bladesWear-resistant steel cover blades areavailable for operating your scarifiersystem in extremely abrasive conditionsor carrying heavy debris loads on themoldboard. These cover blades providebetter protection for the blocks andwelds, and easily attach throughexisting bolt-holes on the blade.End protectorsEnd protectors are alsoavailable for working inrough conditions. Thetough steel, heavy-dutydesigned end protectionbits feature an exclusivecombination of ductilityand air-hardening steel.30-DAYDEMONSTR ATION OFFEROn Stinger system base edgesthrough October 31, 2020.Dealers: Refer to Program Number TS-9U.30-Day Demonstration Offer for Stingersis not available for Canada.13

John DeereCutting EdgesIsolated Carbide Edges (I.C.E. )with Carbide OverlaySevere road applications call forabrasion-resistant solutions.I.C.E. blades with carbide overlay offer the latest applicationtechnology in one advanced blade for motor graders.Traditional blades wear prematurely, while I.C.E. bladeswithstand blade-edge breakage and damage in harsh snowyand icy conditions.Features, advantages, and benefits:–C ombines durable, individually mounted bullet-shapedinserts protected with a layer of wear-resistant carbidegranules imbedded in a tough, abrasion-resistant,steel-weld material in one blade–O ffers maximum blade strength and longevity even in theharshest of road applications– F eatures the highest levels of combined blade wear, impact,and fracture resistance–P erforms effectively to remove snow on roads withembedded lane markers and rumble strips by effectivelyresisting carbide fractures– I mproves penetration versus traditionalstraight-edged designsSee your dealer for specificpart numbers.Forestry Saw TeethTough jobs require toughersaw teeth.These exclusive long-life teeth areavailable for wheeled and tracked fellerbunchers, and for both new- and oldermodel cutting heads.See your dealer for specific part numbers.Extended Life– Additonal hours of cuttingefficiency in rocky applications– Heat-treated to withstand moreimpact over longer periods of timeOne-Piece Hardened Concave– Rocky soil application– Stays sharp longer in rockysoils and stays functionalafter rock denturesOne-Piece Carbide Beaver– Abrasive material application– Stays sharp longer in sandy soils– Carbide steel and efficientcutting design10OFF%Through October 31, 2020.See your dealer for program details.Dealers: Refer to Program Number TS-E7.14

John DeereRubber TracksNow is the perfect time to addressyour rubber-track needs.Ensure maximum productivity and longevityfrom your John Deere rubber tracks .Proper track tensioning is particularly important, as excessivetightness can accelerate component wear. The ideal time toinspect the track system is during periodic cleaning. Tracks shouldbe thoroughly inspected for cuts, punctures, or tears.Key benefits of John Deere rubber tracks:Basic structure of a typical rubber track:–R einforced edge designReinforced structure of track edge makes it more durableand can improve track life–A nti-detracking metal coreEquipped with a continuous steel-cord design to reducedetracking–R einforced track baseMore material in the base of the track to increase surfacecoverage and prevent against cracks, chips, and cutsA Rubber casingBB Sprocket holeC Steel cordAD Intermediate cordE Embedded metalFE Tread lugsCDF15

Production-ClassEquipment SolutionsJAGZ Cutting EdgesJAGZ interlocking cutting edge systemsprovide an alternative to conventional,non-interchangeable cutting edges.JAGZ utilize bolt-on edges common to many buckets and canbe mounted in a staggered or straight pattern depending onyour application. When mounted in a staggered pattern, you getincreased penetration and better bucket fill. The straight patternleaves a smoother working surface, making it perfect for loading.JAGZ also balance wear by swapping the more quickly worn outsideedge with the less worn centers.In addition, JAGZ maximize usable steel by allowing for up to90-percent wear before replacement, compared to 50-percentusable steel on conventional bolt-on edges. This flexibility iswhat makes the JAGZ system stand out from the crowd.JAGZ highlights:–G uaranteed for life against breakage–E asy to install and adjust, saving you time and money– S elf-sharpening edges wear from the bottom up, forincreased wear–R eversible, interchangeable pieces deliver more versatility–U nique cutting angle gives better bucket fill–D esigned for fleet flexibility, including most competitive loaders– L eaves a smoother work surface, reducing tire wear andincreasing comfortEasy-to-install JAGZ areguaranteed againstbreakage and fit anymodel or make of loader.16

John DeereHalf-Arrow BladesMeet your everyday job solution.Cover PlatesHalf-arrow designs offer the benefitsof more material in high-wear areas,increased bucket capacity, and enhancedbucket penetration.Maximum depth countersinking allows for optimum wearbefore the bolt head’s failure. The sharpened nose designenables excellent penetration capability and enhanced materialflow into the bucket. The combination of half-arrow bladesand base-edge covers protects the base edge while optimizingthe flow of material into and out of the bucket. This uniquedesign puts more wear material where it is needed most, onthe underside of the bucket where abrasion is highest, makingit an excellent solution for production-class applications.Half-arrow edges and segments are built to perform usingHighSpec Alloy X14 steel for excellent wear characteristics andsuperior impact resistance. Half-arrow edges are used to replacethe standard double-bevel design commonly used on loaders whenno tooth and adapter options are installed. Segments are placedbetween loader teeth to protect the base edge of the bucket. Thehalf-arrow design offers enhanced protection for the edge andbevel. Combining half-arrow-shaped segments or blades with baseedge covers completely protects the base edge from abrasion.BladesHalf-arrow blades are now available for the new L-Series Loaders:644L, 644L Hybrid, 724L, 744L, 824L, and 844L Loaders, and844L Aggregate Handler.17

Hydraulic HosesJohn Deere hose assembliesbuilt to OEM specifications.Ask your dealer about hoses forany brand of equipment.HOSES IN MINUTESDelivering on the extra mile.Stay up and running, and eliminate the worryabout contaminants entering your hydraulicsystem. Trust your John Deere dealer to delivercomplete solutions, like Ultra Clean, that ensurecontaminants are completely removed fromnew hose assemblies.Ask your dealer how Ultra Clean can help yougo above and beyond.18

JohnDeere.com/BigHAVING BIG PARTS WHENYOU NEED THEM IS A BIG DEAL.With John Deere’s Big Parts Promise, we guarantee that parts availability won’t be the cause of extended machinedowntime. Because if your dealer doesn’t have a quickly installed production-class part in stock, it’s free.* And if alarge production-class part isn’t available by the next day, John Deere pays the freight.** You can even get the BigParts Promise on our new L-Series Loaders.† See your participating dealer or our website for details. It’s all part ofour promise to help you Run Your World.*At participating dealers. If a critical, quickly installed production-class part is not in participating dealer stock, the part is free.**At participating dealers. If large production-class parts are not delivered to your dealer the next day, you do not pay the freight charges.†Eligible models are 744L, 824L, 844L Loaders, and 844L Aggregate Handler.19

John DeerePowertrain ReLife PlusREBUILTRUNNING.NOW THAT’S A PLUS.John Deere Powertrain ReLife PlusMACHINE-REBUILD PROGRAMExtend the life of your machine with John Deere Powertrain ReLife Plus.Design a comprehensive and flexible machine- rebuild solution thatprotects your bottom line — and keeps y ou moving forward.The John Deere Powertrain ReLife Plus program extends the lifeof your machine with:– A thorough machine inspectionby a certified technician.– A complete set of John DeereReman powertrain components.–A John Deere Powertrain ReLifePlus warranty.20Plus, your John Deere dealer willhelp you understand the inspectionresults so you can tailor theprogram precisely to your needsand optimize your total owningand operating costs. QUALITY PRODUCTS SUPERIOR SUPPORT THE POWER OF CHOICEVisit JohnDeere.com/ReLife to learnhow your dealer can maximize yourmachine’s uptime.

IntroducingJohn Deere Certified Rebuild CentersMACHINE SOLUTIONS NEAR YOURebuilding a piece of construction equipmentis a major undertaking and requires a specialset of skills, tooling, and processes to makesure the job gets done right. The John DeereCertified Rebuild Center program sets thebar high to ensure that your machine rebuildis done efficiently and professionally, anddelivers on your expectations by designatingspecific dealership locations as CertifiedRebuild Centers.Here’s what a John Deere Certified RebuildCenter can do for you:– T horoughly assess the condition of themachine and provide expert advice on theareas of highest concern– Provide you with multiple rebuild optionsto ensure the work being done meets theneeds of your business– Execute your customized machine rebuildplan on schedule, and on budget, tominimize disruption to your operationWhether you are looking to make yourmachine look, feel, and function like brandnew, or if you just need a plan to extend themachine’s life by a few thousand hours, yourlocal Certified Rebuild Center can help youdesign a customized rebuild plan that meetsyour needs and fits your budget. The result isa rebuilt machine you can count on, at a lowerhourly cost than buying a new machine —it’s the John Deere way.Contact your local John Deeredealer to learn how to keep yourdowntime way down.21

Introducing.Extended Warrantyfor Reman EnginesWhether you have dirt to push, trucks to load, or mountainsto move, your engine is the heart of your machine. Having thepeace of mind that you can depend on, your engine allows youto focus on running your operation.The Extended Warranty program for John Deere Reman engines gives youthat peace of mind at an affordable price. When you select a John DeereReman replacement engine, you can now select from the following extendedwarranty options:— 2yr/2,000hr— 3yr/2,000hr— 2yr/3,000hr— 3yr/3,000hr— 2yr/4,000hr*— 3yr/4,000hr*— 2yr/5,000hr*— 3yr/5,000hr*— 2yr/6,000hr*— 3yr/6,000hr**Not available for Scraper Tractor applications.22See your John Deeredealer today for detailson this program.

Reman solutions.When time is money and reliability is critical, you needa repair solution you can count on. John Deere Remanprovides a full line of remanufactured componentswhich minimize downtime and deliver the same levelsof performance and durability as a new component at60 to 75 percent of the price of new.ArticulatedDump TrucksEnginesFuel InjectionTransmissionsAxles / Final DrivesHydraulic PumpsHydrostatic PumpsHydrostatic MotorsRotary ManifoldsStarters and AlternatorsElectronic ControllersA/C CompressorsTurbochargersInternal Engine WD orsXXXXXSkid SteersXXXXXXXXXXXXXXXXXXXXXXXNEW! More Remanufactured Engine options recently added!Reman Complete EnginesReman Part M100122RM100123RM100124Engine Designation 0796068HT0866068HT0896068HTJ906068HTJ91Machine Models444K444K450J550K and 650K130G160G LC and 180 G LC310SK TC, 410K, and 410K TC210K, 310K, 310SK, 310SK TC, 410K, and 410K TC310K EP, 310L EP, 210K EP, and 210L EP644K Hybrid710K210G and 210GLC655K1070E and 1170E1110E, 1210E, and 1510EMachine TypeLoaderLoaderCrawler DozerCrawler DozerExcavatorExcavatorBackhoe LoaderBackhoe LoaderBackhoe LoaderLoaderBackhoe LoaderExcavatorCrawler LoaderWheeled HarvesterForwarderNew Part 0DD22388Reman Complete Block AssembliesReman Part No.RM100171SE502829RM100176RM100172Engine Designation Code4045HT069, 4045HDW56, 4045HDW58, and 4045HT0684045HT066, 4045HT070, and 4045HFL924045HT063 and 4045HT0734045HT072Model605K, 444K, 160G LC, and 180G LC130G, 550K, 6

- Leverage Expert Alerts from John Deere to address potential future downtime - Perform software updates from the dealership WHEN YOU CONNECT YOUR MACHINE: Most new John Deere machines come ready with five years of machine connectivity to enable these tools that you keep running. Ask your dealer about John Deere Connected Support to learn more.