Transcription

Our technology. Your success.Pumps Valves Service Product Portfolio 2021Control Valves

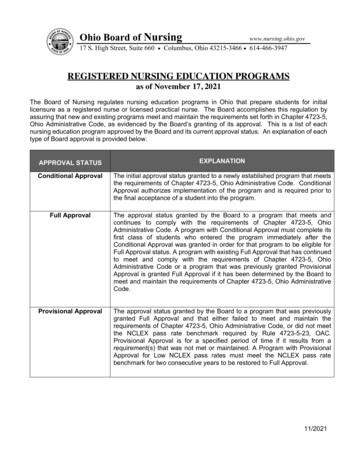

2Type Series IndexType Series IndexType Series IndexACTAIR NGACTELEC - AUMAACTELEC - BERNARD CONTROLSAMTROBOXAMTROBOX ATEX Zone 22AMTROBOX EEx iaAMTROBOX FAMTROBOX MAMTROBOX RAMTROBOX R EEx iaAMTROBOX R Ex dAMTRONIC222121242424242425252526BOA-CVE C/CS/W/IMS/EKB/IMS EKBBOA-CVE HBOA-CVP H151515DANAÏS 150DYNACTAIR NG2022HQ21ISORIA 10/16ISORIA 20/251920MIL 10000MIL 21000MIL 27000MIL 29000MIL 37-38MIL 400LMIL 41000MIL 496MIL 50000MIL 67-68MIL 70000MIL 71000MIL 7400MIL 76000MIL 77000MIL 78000MIL 8013MIL 81000MIL 9100017171717232518251823181826181919271919NORI 160NORI 40NORI -C LAPSISTO-LADSISTO-LAESISTO-LAPSMARTRONIC AS-iSMARTRONIC MASMARTRONIC PC1616161723222122262627TRIODIS 150TRIODIS 3002020

Introduction3IntroductionKSB TrademarksApart from the KSB umbrella brand, the following brand namesidentify quality products and services by the KSB Group:Butterfly valvesDiaphragm valvesControl valvesUnder the AMRI brand, KSB sells itsUnder the SISTO brand, KSB sells itsUnder the MIL brand, KSB sells controlbutterfly valves. They are used in buildingdiaphragm valves. They perform shut-offvalves for applications in the energyservices, industry, water engineering andduties in building services, industrial,sector and industry.power generation applications. AMRIwater management and power generationproducts include pneumatic, hydraulicapplications. Under this brand name,and electric valve actuators as well asKSB offers special valves for sterilecontrol systems.processes including biotech applications.

4IntroductionIntroductionA modern company – for 150KSB is celebrating its 150th anniversary in 2021 under the motto“People. Passion. Performance.” What began with an idea hasdeveloped into a leading global player for pumps, valves and service.It all began with an ideaIn 1871, mechanical engineer Johannes Klein received thepatent for his boiler feed apparatus. In that same year, togetherwith Friedrich Schanzlin and Jakob August Becker, he foundedFrankenthaler Maschinen- & Armatur - Fabrik Klein, Schanzlin& Becker, employing twelve staff.The company grew steadily, becoming an Aktiengesellschaft(public limited company) in 1887 and acquiring many companiesin Germany.The path to becoming a global groupIn 1925, KSB founded its first company abroad. New companiesin Argentina (1941), Pakistan (1953) and South Africa (1959)marked the beginning of the operations outside of Europe.During the 1980s KSB took over further companies andexpanded its range of products. In 1986, KSB acquired theleading French pump manufacturer Pompes Guinard, followedthree years later by Amri, the second largest valve manufacturerin the world. The acquisition of the US company GIW IndustriesSteam-driven pistonpump circa 1890 withtwo “Klein hearts”in 1988 signalled KSB’s entry to the slurry pump market. In1991, KSB integrated Hallesche Pumpenwerke GmbH into its

Introduction52IntroductionyearsInside the valves shop inFrankenthal (around 1930)operations, today a production site for water and waste wateroff, for example in building services and industrial applications,pumps.in the chemical/petrochemical industries, in water supply andTo strengthen activities in key markets such as China, India andBrazil, many new companies and joint ventures were foundedwaste water treatment as well as in power plant processes andmining.from the mid-1990s. In Europe additional companies such asAround the globe, over 190 service workshops and some 3500DP Industries B.V. in the Netherlands joined the Group, furtherservice specialists provide inspection, maintenance and repairexpanding KSB’s portfolio of products.services locally under the brand name KSB SupremeServ.Smart for the futureKSB helps customers to remain competitive with digitalInnovative technology that is the fruit of KSB’s research anddevelopment activities forms the basis for the company’s success.solutions geared towards the future. Smart products andservices ensure greater transparency in systems and increasetheir efficiency.Through its digital factory approach, KSB is increasinglyswitching its production processes to standardised andautomatic operations. Already today, additive manufacturingenables spare parts to be rapidly produced using 3D printingprocesses.150 years of experienceKSB is one of the world’s leading suppliers of pumps, valves andrelated systems. Over 15,000 employees work in production,sales and service locations on all continents. The Group isrepresented with subsidiaries in more than 40 countries.KSB’s highly efficient and reliable products are used inapplications where fluids need to be transported or reliably shutAdditive manufacturing enables KSB to produce complex components.

6IntroductionIntroductionSmart services for maximumavailability and efficiencyAs a leading supplier of pumps and valves, we attach great importance to providing you with a comprehensive service of the highest quality. In fact, we believeit’s so important that we even gave it a special name: KSB SupremeServ.KSB SupremeServ is on hand tosupport you with classic and digitalservice and spare parts solutions overthe entire product life cycle. Whetherit’s a KSB product, non-KSB productor other rotating equipment, you’llbenefit from the reliable and sustainable operation of your system.Applications: Water and Waste Water Industry Energy Building Services MiningWherever and whenever you need us,we’re there for you – worldwide.

Introduction7IntroductionOur mission:Certified quality assuranceFirst-class products and excellent service take top priority at KSB.Our five key goals:To maintain this level of excellence, we have developed a modern quality management system with globally applicable guidelines.It is based on the Business Excellence model of the EuropeanMaximum customer satisfaction: We do everything to fulfilour customers’ wishes on time and in full. Fostering quality awareness: We put our quality commitmentFoundation for Quality Management, which already ensuresinto daily practice – from executives to employees,improved quality management Europewide.whose qualifications and competence we foster throughcontinuing training.Our guidelines define uniform quality for all KSB locations and and prevent the causes.have helped us to optimise our manufacturing processes.The results are shorter delivery times and global availability Improvement in quality: We continually optimise ourprocesses in order to work more efficiently.of our products. These guidelines govern the way we act socomprehensively that even the competence of our consultingPrevention rather than cure: We systematically analyse errors Involvement of suppliers: We attach great importanceand the good value for money we offer are clearly stipulated.to working together fairly and openly to achieve ourLike the ‘Made in Germany’ quality seal, we introduced internalshared goals.certification as a sign of the highest quality: ‘Made by KSB’.As a signatory to the United Nations Global Compact, KSB is committed toendorsing the ten principles of the international community in the areasof human rights, labour standards, environmental protection and anticorruption.

8IntroductionIntroductionEverything under control:the KSB control valve portfolioKSB‘s portfolio of control valves covers a wide range of requirements from many different applications.Alongside our technical expertise and know-how, customer focus plays a key role in everything we do.This is reflected in our product portfolio. We are very familiar with our customers‘ needs and offerinnovative solutions for closed- and open-loop valve control in fluid processes.Our products cater to the requirements of light industrialVisit our online product catalogue at www.ksb.com/productsapplications through to building services and water transportfor an overview of our control valve range and additionalprojects just as efficiently as they cope with the harshestinformation.conditions in the oil and gas as well as power plant sectors.Our valves meet all relevant quality standards and directives.

Introduction9IntroductionKSB – your specialist for innovative valve solutionsOur intelligent positioners and controlunits such as AMTRONIC andSMARTRONIC perfectly complementour control valve portfolio, handlingyour process data, controlling yourFunctionProductSpecial featureApplicationsProcess controlSMARTRONIC PC4 programmable functionsIndustryWaterSMARTRONIC AS-iFirst digital positioner for AS-i fieldWasteSMARTRONIC MAbuses of the latest generation,waterSMARTRONIC MA Ex ia ATEX-compliant (ATEX II 1 G)EnergyPosition signalling and comMarineAMTRONICpressed air supply integrated inAMTRONIC Ex iaa single unit, ATEX-compliantOil and gas(ATEX II 1 G)Positioningvalves and enhancing performance.They offer a wide range of functionalitiesOn/off controland are highly rsFor allapplicationsMIL 91000Cl. 4500T: -10 – 725 CPNNORI 500PN 500T: -10 – 650 C500MIL 21000Cl. 2500T: -10 – 566 CNORI 160PN 160T: -10 – 550 CTRIODIS 600PN 100T: -196 – 260 CTRIODIS 300PN 50T: -196 – 260 CTRIODIS 150PN 25T: -196 – 260 C-196 CISORIA 20/25PN 25T: -10 – 80 CISORIA 10/16PN 16T: -10 – 200 CDANAIS 150PN 25T: -50 – 260 CBOA CVE/CVP HPN 40T: -10 – 450 C0KSB’s control valve portfolio – the right solution for all requirements. 700 C

10IntroductionIntroductionThe power. To win over challenges.With proven expertise across sectors including thermal, nuclear,fertilizer, oil & gas, petrochemicals and other core industries, KSB isequipped to cater to severe conditions prevalent in various processindustries and provide novel concepts and customized solutions fortough process control applications in all industry sectors.Energy SectorKSB’s credentials have proved thatits control valves can deliver highperformances at both captive powerplants and utility power plants includingsupercritical units from 660 MW to1000 MW. KSB can cater to the mostdemanding design challenges andapplications, including those in nuclearand combined cycle power plants,thereby powering the power generationindustry.Coal firedSupercritical(upto 1000 MW)Coal firedSubcritical(upto 600 MW)Combined Cycle(upto 1000 MW)Nuclear(upto 700 MW)Start-up Feed ControlnnnnBFP Min. Flow ControlnnnnSeperator Level Control ValvenN.AN.AN.ABoiler Circulation ControlnN.AN.AN.ASoot Blower Pressure ReductionnnN.AN.ASH/RH SpraynnnnAux. PRDS PackagennnnHP Turbine / Boiler DrainnnnnHeater Drain & Condensate SystemnnnnHP / LP Bypassn n n n Severe service applications catered Through alliance partnerStart-up Feedwater Control valveMIL 91000, 14”, 3000# ASME Alternatively uses Atmospheric Steam Discharge / Condenser Steam Dump valvesN.A: Not applicable for the sectorBFP Min.Recirculation Control valveMIL 91000, 12”, 3200# ASMESeperator Level Control valveMIL 71000, 12”, 2500# ASMESoot Blower Pressure Reduction Control valveMIL 91000, 4”, 3100# ASME

Introduction11IntroductionIndustry SectorControl valves have become keycomponents in offshore and onshoreoil & gas industry, both upstream anddownstream where applications aredemanding due to the high pressure andadverse corrosive conditions experiencedon production platforms and refineries.The indelible imprint of KSB quality hasmade its mark in the Indian fertilizerindustry as well, with Ammonia, Urealet down valves and Low noise valvesfor steam applications that are beingused at renowned facilities. We havethe distinction of being associated withthe supply of Cryogenic control valvesincluding Bellows sealed & Vacuumjacketed valves for LNG terminals andCryogenic test facilities.Oil / RefineryProducts(transportation)Oil & Gas(upstream)RefineryLNG/Petrochemical/Chemical/ FertilizerHydrocarbon servicennnnHydrogen servicennnN.AAntisurge ControlnnnN.AnnN.AN.ASevere service applications cateredHot / Cold HP Separator LetdownN.AnnN.AWater / Steam / Gas InjectionnN.AN.AN.AAmine / Carbamate LetdownN.AnnN.AHP Ammonia LetdownN.AN.AnN.AUrea ServiceN.AN.AnN.AHigh Pressure CO2Cryogenic serviceN.AN.AnN.AHP Pump RecirculationnnnnMicro FlownnnN.AHP Steam VentnnnN.AHot High Pressure Separator Level Control valveMIL 77000, 4”X6”, 1500# ASMEAmine Regeneration Control valveMIL 78000, 6”, 1500# ASMEMIL 41000 Series, 20”, 600# ASME valve withElectro-hydraulic actuator supplied to RefineryPipeline Augmentation ProjectCharge Gas Compressor Antisurge valveMIL 41000, 20”, 150# ASME

12General InformationGeneral InformationGeneral InformationRegional productsNot all depicted products are available for sale in every country. Products onlyavailable in individual regions are indicated accordingly. Please contact yoursales representative for details.Key to actuatorsIn the Products section from page the symbolin conjunction with therelevant letter indicates the actuator type(s) available.m manual (lever, handwheel, etc.)e electric actuatorp pneumatic actuatorh hydraulic actuatorTrademark rightsAll trademarks or company logos shown in the catalogue are protected bytrademark rights owned by KSB SE & Co. KGaA and/or a KSB Group company.The absence of the " " symbol should not be interpreted to mean that theterm is not a registered trademark.

Product Portfolio13Product PortfolioButterfly control valvesBOA-CVE C/CS/IMS/EKB/IMS EKB15BOA-CVE H15BOA-CVP H15NORI 4015NORI 16016NORI IL 1000017MIL 2100017MIL 2700017MIL 2900017MIL 4100018MIL 5000018MIL 7000018MIL 7100018MIL 7600018MIL 7700019MIL 7800019MIL 8100019MIL 9100019ISORIA 10/1619ISORIA 20/2520DANAÏS 15020TRIODIS 15020TRIODIS 30020Pharmaceuticals/FoodSolids transportBuilding ServicesEnergy ConversionIndustryWater Transport andWater TreatmentControl valves to ANSI/ASMEPageIndustryControl valves to DIN/ENType seriesAutomationDesign/ApplicationWater Transportand TreatmentValvesElectric actuatorsHydraulic actuatorsPneumatic actuatorsACTELEC (AUMA)21ACTELEC (BERNARD CONTROLS)21SISTOMAT-E21HQ21ACTAIR NG22DYNACTAIR NG22SISTO-LAD22SISTO-LAP22SISTO-C LAP23MIL 37-3823MIL 67-6823Pharmaceuticals/FoodPageSolids TransportType seriesBuilding s

Product PortfolioProduct PortfolioMonitoringON/OFF valve controllersPositionersIntelligent positioners24AMTROBOX EEx ia24AMTROBOX ATEX Zone 2224AMTROBOX F24AMTROBOX M24AMTROBOX R25AMTROBOX R EEx ia25AMTROBOX R Ex d25MIL 400L25MIL 49625AMTRONIC26SMARTRONIC MA26SMARTRONIC AS-I26MIL 740026MIL 801327SMARTRONIC PC27If requested by the customer, valves can also be fitted with other brands of actuators and equipment.Pharmaceuticals/FoodAMTROBOXSolids TransportPageBuilding ServicesType tomationWater Transportand Treatment14

Valves15ValvesControl valves to DIN/ENBOA-CVE C/CS/W/IMS/EKB/IMS EKBPNDNT [ C]e6/10/16 Description15 - 200 Control valve to DIN/EN based on standard type series BOA-Compact, BOA -10 - 120 SuperCompact, BOA-W, BOA-Compact EKB, BOA-Compact IMS EKB, BOAControl IMS and BOA-Control IMS EKB, bonnetless pressure-retaining body, softseated. Leakage rate selectable from 0.05 % to drop-tight, Kvs values between 6.3and 700 m³/h and closing pressures of up to 16 bar. With intelligentmicroprocessor-controlled and pre-set electric actuators providing actuating forcesfrom 1000 N to 14,000 N; electronic configuration of flow characteristic, Kvs value,actuating signal and actuating time using PC tool or manual parameterisation unit.Customised configuration can be implemented at the KSB factory on request.ApplicationsHot-water heating systems up to 120 C. Ventilation and air-conditioning systems.Water supply systems, drinking water. Not suitable for fluids containing mineraloils, steam or fluids liable to attack EPDM and uncoated cast iron. Other fluids t/ES000326BOA-CVE HPNDNT [ C]e16/25/40 Description15 - 200 Service-friendly control valve to DIN/EN with flanged ends, either with linear or -10 - 450 equal-percentage control characteristic at Kvs values of 0.1 to 630 m³/h and closingpressures of up to 40 bar; all internal parts are easy to replace without specialtools, including the reversible seat; noise level reduced by standard two-stagepressure reduction combining a parabolic plug and multi-hole cage; with electricactuator.ApplicationsGeneral industrial facilities, process engineering, plant engineering, coolingcircuits, heating ES000772BOA-CVP HPNDNT [ C]p16/25/40 Description15 - 200 Service-friendly control valve to DIN/EN with flanged ends, either with linear or -10 - 450 equal-percentage control characteristic at Kvs values of 0.1 to 630 m³/h and closingpressures of up to 40 bar; all internal parts are easy to replace without specialtools, including the reversible seat; noise level reduced by standard two-stagepressure reduction combining a parabolic plug and multi-hole cage; withpneumatic actuator.ApplicationsGeneral industrial facilities, process engineering, plant engineering, coolingcircuits, heating ES000662NORI 40PNDNT [ C]e, p25/40 Description10 - 200 Globe valve to DIN/EN with flanged, butt weld or socket weld ends, with electric or -10 to 450 pneumatic actuators to customer specification, with gland packing, with shut-offvalve disc or throttling plug, non-rotating stem, integrated position indicator, seat/disc interface made of wear and corrosion resistant chrome steel or chrome nickelsteel.ApplicationsIn industrial plants, power stations, process engineering and shipbuilding. Forwater and steam. Other non-aggressive fluids such as gas or oil on ES000341

16ValvesValvesNORI 160PNDNT [ C]63 - 160 Description10 - 200 Globe valve to DIN/EN with flanged, butt weld or socket weld ends, with electric or -10 to 550 pneumatic actuators to customer specification, with gland packing, with shut-offvalve disc or throttling plug, non-rotating stem, integrated position indicator, seat/disc interface made of wear and corrosion resistant 17 % chrome steel or Stellite.ApplicationsIn industrial plants, power stations, process engineering and shipbuilding. Forwater and steam. Other non-aggressive fluids such as gas or oil on request.e, 5NORI 500PNDNT [ C]250 - 500 Description10 - 65 Globe valve to DIN/EN with flanged, butt weld or socket weld ends, with electric or -10 to 650 pneumatic actuators to customer specification, with gland packing, with orwithout back seat, with throttling plug, non-rotating stem, integrated positionindicator, seat/disc interface made of Stellite.ApplicationsIn industrial plants, power stations, process engineering and shipbuilding. Forwater and steam. Other non-aggressive fluids such as gas or oil on request.e, 0SISTO-10PNDNT [ C]10 Description15 - 300 Diaphragm valve to DIN/EN with flanged ends, with pneumatic or electric actuator; -20 to 160 shut-off and sealing to atmosphere by diaphragm; body with or without lining,position indicator with integrated stem protection. All moving parts are separatedfrom the fluid by the diaphragm. Maintenance-free.ApplicationsShut-off or control duties in industrial and chemical plants and in processengineering. Suitable for service water, air, oil, abrasive and aggressive fluids.e, 5SISTO-16/-16SPNDNT [ C]16 Description15 - 300 Diaphragm valve to DIN/EN or with short face-to-face length (BS) with flanged -10 to 160 ends, with pneumatic or electric actuator; shut-off and sealing to atmosphere bycompletely enclosed spiral-supported diaphragm; body with or without lining,position indicator with integrated stem protection. All moving parts are separatedfrom the fluid by the diaphragm. Maintenance-free.ApplicationsShut-off or control duties in building services, industrial plants and power stations;suitable for drinking water, service water, air, oil, technical gases; from fluidshandled in the food and beverages industry to abrasive and aggressive products inchemical and process engineering.e, 6SISTO-20PNDNT [ C]16 Description15 - 300 Diaphragm valve to DIN/EN with flanged ends, with pneumatic or electric actuator; -20 to 160 shut-off and sealing to atmosphere by completely enclosed spiral-supporteddiaphragm; body with or without lining, position indicator with integrated stemprotection. All moving parts are separated from the fluid by the diaphragm.Maintenance-free.ApplicationsShut-off or control duties in building services, industrial plants and power stations;suitable for drinking water, service water, air, oil, technical gases; from fluidshandled in the food and beverages industry to abrasive and aggressive products inchemical and process engineering.e, pNot available for worldwide 0317Actuator/Automation

Valves17ValvesSISTO-CPNDNT [ C]p16 Description6 - 200 Diaphragm valve with butt weld ends or clamps; in straight-way, Y or T pattern, or -20 to 160 as a multi-port valve, with pneumatic piston actuator; shut-off and sealing toatmosphere by completely enclosed diaphragm. No dead volumes, suitable forsterilisation, SIP/CIP-compliant design, visual position indicator. All moving partsare separated from the fluid by the diaphragm. Maintenance-freeApplicationsShut-off and control duties in biotechnology, pharmaceutical industry, sterileprocesses, food and beverages /ES000320Control valves to ANSI/ASMEMIL 10000ClassNPS [inch]T [ C]150 - 1500 Description¾ - 16 The top- and bottom-guided double-ported control valve is characterised by a high -29 to 454 permissible pressure drop across the valve. The high flow capacity typical of thisdesign is attained with low pressure recovery. Bi-directional flow is permitted;wide flow passage, suitable for viscous fluids.ApplicationsIndustry, power stations, process ntrol-valves/mil-10000/e, h, pMIL 21000ClassNPS [inch]T [ C]150 - 2500 Description½ - 10 Top-guided single-ported heavy post-guided control valve for a wide temperature -100 - 566 range.ApplicationsIndustry, power stations, process ntrol-valves/mil-21000/e, h, pMIL 27000ClassNPS [inch]T [ C]150 - 300 Description½ - 2 Compact and light-weight construction, rugged stem guiding, field-reversible -27 to 427 actuator, tight shut-off.ApplicationsThe globe valve is used in industrial segments with moderate pressure drop forhandling fluids with a low solids content, viscous fluids in refineries, and fluids inthe petrochemical, pharmaceutical, chemical, and bio-medical industries whereaccurate monitoring and control of the valve position is critical as it affects /control-valves/mil-27000/pMIL 29000ClassNPS [inch]T [ C]p150 - 1500 Description½ - 1 Compact microflow globe valves with high rangeability (500:1), quick-change trim -100 to 343 for on-site adjustment of flow coefficient, rugged cage-style plug guide; anticavitation design available.ApplicationsIndustry, power stations, process engineering (e.g. fine control of spray water),chemical, petrochemical and pharmaceutical ntrol-valves/mil-29000/

18ValvesValvesMIL 41000ClassNPS [inch]T [ C]150 - 4500 Description½ - 36 Cage-guided single-ported heavy-duty control valves, high pressure drop -196 - 566 capability; noise reduction and anti-cavitation solution available by replacing thestandard cageApplicationsIndustry, power stations, process engineering, chemical and ccessories/control-valves/mil-41000/e, h, pMIL 50000ClassNPS [inch]T [ C]150 - 2500 Description½ - 4 Cryogenic control valves with extended body, rugged guided extended valve plug, -250 to -27 body-bonnet bolting outside the cold box.ApplicationsUsed in LNG terminals, storage tanks during transport and storage, bench testingof cryogenic engines for rockets and space shuttles, LPG production and processingplants, lves/mil-50000/e, h, pMIL 70000ClassNPS [inch]T [ C]150 - 2500 Description½ - 10 Top-guided single-ported heavy-duty control valves in angle pattern. -100 to 566 ApplicationsIndustry, power stations, process engineering, chemical and petrochemicalengineeringClassNPS [inch]T [ C]150 - 4500 Description½ - 36 Cage-guided single-ported high-performance angle valve. -196 to 566 ApplicationsIndustry, power stations, process engineering, chemical and petrochemicalengineering.e, h, pMIL 71000e, h, pMIL 76000ClassNPS [inch]T [ C]150 - 2500 Description1 - 2 The letdown control valves in angle pattern are designed for all applications -27 to 566 where flashing (flash evaporation) or two-phase (liquid and gaseous) flows mayoccur; no body/trim erosion, vibration or noise. Due to its angle pattern, the globevalve is self-draining.ApplicationsIndustry, power stations, process engineering, chemical and ccessories/control-valves/mil-76000/e, h, pNot available for worldwide saleActuator/Automation

Valves19ValvesMIL 77000ClassNPS [inch]T [ C]600 - 2500 Description2 - 8 Multi-stage low-noise control valve with labyrinth trim. -27 to 566 ApplicationsIndustry, power stations (e.g. start/bypass valve), process engineering, chemicaland petrochemical engineering (e.g. control valve at hot high-pressure ies/control-valves/mil-77000/e, h, pMIL 78000ClassNPS [inch]T [ C]150 - 2500 Description½ - 6 Multistage control valve in anti-cavitation design with wear-resistant multistage -29 to 260 trim and detachable flow bush / spacer.ApplicationsIndustry, power stations, process engineering, chemical and ccessories/control-valves/mil-78000/e, h, pMIL 81000ClassNPS [inch]T [ C]150 - 2500 Description¾ - 12 Three-way combining and diverting control valves. -30 to 454 ApplicationsBuilding services, industry, power ol-valves/mil-81000/e, h, pMIL 91000ClassNPS [inch]T [ C]150 - 4500 Description¾ - 20 Multistage multi-path control valve with Matrix trim; pressures of up to 420 bar -29 to 566 can be reduced by up to 50 pressure reduction stages, preventing cavitation andgreatly reducing fluid velocity.ApplicationsIndustry, power stations, process engineering, chemical and ccessories/control-valves/mil-91000/e, h, pButterfly control valvesISORIA 10/16PN [bar]DNT [ C]e, h, p Smartronic10/16 Description40 - 1000 Centred-disc butterfly valve, elastomer liner, with pneumatic, electric or hydraulic -10 to 200 actuator. Wafer-type body (T1), semi-lug body (T2), full-lug body (T4) or U-sectionbody with flat faces (T5). Body types T2 and T4 are suitable for downstreamdismantling and dead-end service with counterflange. Connections to EN, ASME,JIS.ApplicationsShut-off and control duties in all industrial and energy ES000377

20ValvesValvesISORIA 20/25PN [bar]DNT [ C]20/25 Description32 - 1000 Centred-disc butterfly valve, elastomer liner, with pneumatic, electric or hydraulic -10 to 200 actuator. Semi-lug body (T2), full-lug body (T4) or U-section body with flat faces(T5). Body types T2, T4 and T5 are suitable for downstream dismantling and deadend service with counterflange. Connections to EN, ASME, JISApplicationsShut-off and control duties in all industrial and energy sectors.e, h, p t/ES000379DANAÏS 150PN [bar]or ClassDNT [ C] 2515050 - 1200 -50 to 260e, h, p SmartronicDescriptionDouble-offset butterfly valve with plastomer seat ring (also in fire-safe design) ormetal seat ring, with pneumatic, electric or hydraulic actuator and SMARTRONICpositioner, body made of cast steel or stainless steel, wafer-type body (T1) or fulllug body (T4). The T4 body type is suitable for dead-end service and downstreamdismantling. EN, ASME, JIS connections.ApplicationsPetroleum, gas, chemical and petrochemical industry, nuclear power stations,sugar industry, paper industry, geothermal energy, shipbuilding, low-pressuresteam, vacuum service. All applications requiring offset-disc butterfly S000427TRIODIS 150PN [bar]or ClassDNT [ C] 2015080 - 1400 -196 to 260e, h, p SmartronicDescriptionTriple-offset butterfly valve, metal-seated (fire-safe), without gland packing,maintenance-free, with lever or manual gearbox, pneumatic, electric or hydraulicactuator. Body made of steel or stainless steel, full-lug body (T4), flanged body (T7)with flat or raised faces, body with butt weld ends (BWSE). Body types T4 and T7are suitable for dead-end service. Connections to EN, ASME or JIS. Connections toASME: Schedule 10S,

performances at both captive power plants and utility power plants including supercritical units from 660 MW to 1000 MW. KSB can cater to the most demanding design challenges and applications, including those in nuclear and combined cycle power plants, thereby powering the power generation industry.