Transcription

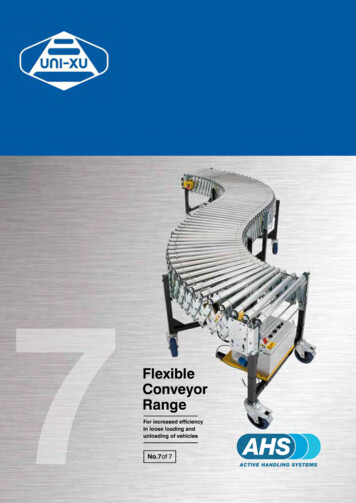

231Lineshaft Powered Roller Conveyor224V Motorised Roller ConveyorThe most versatile and economicalpowered conveyor available.‘O’ Ring & Poly VA low maintenance, low energy conveyordue to minimum moving parts.3Pallet Handling Conveyor4Belt Conveyor5Gravity Conveyor6Belt Under Roller Conveyor7Flexible ConveyorDesigned for flexibility and heavy dutyusage up to 1500kg per pallet.For careful and extremely lownoise conveying.The most cost-effective and simplestconveying solution available.Can achieve exceptionally high speedsand throughput rates.For increased efficiency in loose loadingand unloading of vehicles.8Post & Parcel ConveyorDesigned specifically for the high demandsof the Post & Parcel handling e uni-xu range of conveyors has been integral to thousands of turnkey solutions for some of the most demanding andsuccessful companies across Europe. It is renowned for the robustness of its design, with quality being reflected in a distinctdurability in the field. Furthermore, the modularity of the uni-xu design offers extreme flexibility and simplicity for totallyintegrated systems. It has been engineered and manufactured in Britain since 1963, resulting in five decades of engineeringdevelopment and excellence, which today, makes it one of the best known trademarks in conveyor manufacture.Facts UK’s largest conveyor manufacturer. 150,000 sq. ft. manufacturing plant on a 7 acre site. In excess of 1 million rollers manufactured every year. Over 20 km of conveyor produced each year. Over a third of conveyor orders shipped overseas.

47 Flexible ConveyorIndexUNI-XU Powered RollerUNI-XU Powered RollerExpandable Conveyor6TypeLoad150kgper linear metre*ConveyorWidthsRollerDiameter40mm8-9Master & Slave Conveyors10PoweredAncillaries11450, 600,750 or900mmGravity250kg450, 600,750 or900mm40mmGravitySkatewheelSkatewheel49mm450, 600,750 or900mm80kgLite 300, 400,500 or600mm48mm12-13UNI-XU Gravity Skatewheel 14Expandable ConveyorUNI-XU LITE Expandable Conveyor15UNI-XU Gravity SkatewheelSpecificationAccumulating ConveyorsUNI-XU Gravity RollerExpandable ConveyorUNI-XU Gravity Roller300kg*Based on level working height.1Increased Efficiency in LooseLoading and Unloading of Vehicles1 Large, Bright Zinc Plated Welded Steel HandlesPositive grip points for safe and easy manoeuvringof the conveyor.As one of the leading manufacturers of conveyor modules with proven build quality and reliability,we are proud to present a range of expandable, flexible and durable conveyors for loose loading andunloading applications. Loose loading eliminates ‘dead space’ created by pallets or roll-cages.Engineered to the highest standards to endure the rigorous demands of despatch areas, distributioncentres and parcel handling hubs around the world, UNI-XU flexible conveyors provide cost effectivehandling solutions – not only for the large distribution centres but also for smaller companiesrequiring only single units.Improved Performance – Patented PartsConveyor Units holds a European Patent for the following parts across its Flexible Conveyor range,making the UNI-XU range both unique and superior : Roller Tag Washers – for increased roller retention.Floating Leg Bolt – relieving stress and allowing easy manoeuvrability.Fixed Lower Axle – providing additional rigidity and strength to the conveyor structure.2 Reinforced, Ribbed Zinc Plated Steel Side PlatesFully bolted design without rivets. Roller retainingtag washers.3 Additional StrengthWe have also gained a reputation forsupplying high quality competitively pricedrollers and spares to all aspects of thematerial handling industry. Our productsare used by blue-chip companies in theUK and throughout Europe.Structural support across width with lower fixed axles.Heavy duty square tubing leg frames with bracing.Fully Adjustable Support LegsThese provide a ‘top of roller’ working height from:Powered Roller Expandable Conveyor790mm to 1080mm as standard.Gravity Expandable Conveyor750mm to 1035mm as standard.23Gravity Skatewheel Expandable Conveyor750mm to 1040mm as standard.UNI-XU LITE 580mm to 865mm as standard.Increases Materials Handling EfficienciesUp to 50% increased efficiencies in loose loading /unloading of vehicle trailers, offering rapid returnon investments.Conforms to Health and Safety StandardsAll steel electrical control cabinets. CE Compliant.Highly Mobile, Extremely Flexible and Easy to StoreQuickly manoeuvred, stretched and positioned onbraked swivel castors in seconds. Available up to 30m,and it compacts to a 1/3 of its size when not in use.5

467 Flexible ConveyorUNI-XU Powered Roller Expandable Conveyor4 Conforms to Health and Safety StandardsPowered ApplicationsPerfect for vehicle loading and unloading, parceldistribution centres, machine-to-machine linking andall cross docking applications. Can be easily movedin or out of trucks for faster, safer, easier loadingand unloading.All steel electrical control cabinets, housing a topspecification AC inverter with keypad, sealed toIP55 standard and mounted on a lockable slidingtray. Enables easy user access for any adjustmentsor maintenance. CE Compliant. Start/Stop switchat both ends for safety. Isolator switch included.1 Roller Connecting Bracket5 Conforms to Electromagnetic CompatibilityAllows you to quickly and easily connect two ormore conveyors together to expand your system.Directive 2014/30/EUSupplied with shielded, flat form cable whichmaintains correct cable routing.2 SEW Eurodrive AC MotorsFully adjustable conveyor speed from 10 to 40metres per minute; 0.09kw for 230V / 240V singlephase. Low maintenance – no brushes.3456Start/Stop switch at both ends and EmergencyStop fitted at mid-point for safety. Lengths over20.0 metres are fitted with two Emergency Stops.Smart optic sensors act as an electronic packagestop. When a package is detected by the sensor itautomatically stops the complete conveyor. Thestop has an adjustable time delay which can beset by the operator. When the package is removedthe conveyor will start automatically.To complete the model number replace the three dashes with thestandard conveyor width required; 450mm, 600mm, 750mm or 900mm.Flexible and Easily ManoeuvrableCombination of braked and non-braked, heavyduty swivel castors - 160mm diameter x 50mm.Powered Conveyor SpecificationModelNumberStandard LengthCompacted toExpandedSupportLegs perUnitModelNumberStandard LengthCompacted toExpandedSupportLegs perUnitUFP/ROS/0---/03.751.33 - 3.75 metres4UFP/ROS/0---/15.005.20 - 15.00 metres13UFP/ROS/0---/05.001.76 - 5.00 metres5UFP/ROS/0---/16.255.63 - 16.25 metres14UFP/ROS/0---/06.252.19 - 6.25 metres6UFP/ROS/0---/17.506.06 - 17.50 metres15UFP/ROS/0---/07.502.62 - 7.50 metres7UFP/ROS/0---/18.756.49 - 18.75 metres16UFP/ROS/0---/08.753.05 - 8.75 metres8UFP/ROS/0---/20.006.92 - 20.00 metres17UFP/ROS/0---/10.003.48 - 10.00 metres9UFP/ROS/0---/21.257.35 - 21.25 metres18UFP/ROS/0---/11.253.91 - 11.25 metres10UFP/ROS/0---/22.507.78 - 22.50 metres19UFP/ROS/0---/12.504.34 - 12.50 metres11UFP/ROS/0---/23.758.20 - 23.75 metres20UFP/ROS/0---/13.754.77 - 13.75 metres12UFP/ROS/0---/25.008.63 - 25.00 metres21Lengths up to 30.0 metres available on request.26 Start/Stop Buttons3 Smart Optics - PEC Package StopPowered Conveyor Specification1Optional Extras:Zero Line PressureProduct IndexingMaster & SlaveSmart OpticsRoller Impact CartsLED LightingGuard RailRoller Connecting BracketsLarger Diameter CastorsFor easier rolling over rough oruneven surfaces.Adds the following to conveyor height:45mm (200mm diameter castor).Roller Design40mm diameter, steel zinc plated tube withprecision bearings. Rollers are driven from heavyduty polyurethane drive belts.Fully Adjustable Support LegsThese provide a ‘top of roller’ workingheight from:790mm to 1080mm as standard.Other heights available on request.Roller Centres125mm as standard when the conveyor isfully extended. Optional 75mm and 100mm rollercentres can be supplied for the conveying ofsmaller packages or cartons. Please note thatoptional roller centres will affect the conveyorcompacted length.System Versatility with Variable Control OptionsIn addition to smart optics, the following are alsoavailable:Zero line pressure accumulation.Product indexing.Two independent conveyors can be connectedby use of harting plugs and castors to formone system.Self TrackingCartons follow twist of conveyor.No need for engineered mm600mm750mm900mmper linear metre**Based on level working height.RollerDiameterStandard Speed(metres per minute)10 - 40 variable7

487 Flexible ConveyorAccumulating ConveyorsOption 1 Zero Line Pressure ConveyorOption 2 Indexing ConveyorZero Line Pressure Accumulation is achieved by using Sensors to control the ON/OFF of the Geared MotorUnit within each Zone. Product travels along the conveyor to the final Zone where it is detected by a Sensor,whereupon the Motor driving this Zone will stop. The remaining conveyor rollers will, at this point, continueto run and accumulate products along the track using the same process. Each Zone is fitted with its ownSensor to detect product movement. When a product is removed from an Accumulation Zone, all precedingZones will automatically move product forward into the newly unoccupied Zone.Indexing Conveyors provide a simple and economic method for the accumulation ofproducts. Here the conveyor is equipped with a Sensor at the Infeed and Discharge ends.Each Zero Line Pressure Zone length is dependent on the roller pitch required.The conveyor is also fitted with a Clearing Switch, allowing the Operator at the Discharge end to‘call forward’ all products towards the Discharge Sensor.75mm pitch the Zone length is 0.75 metres.100mm pitch the Zone length is 1.00 metres.125mm pitch the Zone length is 1.25 metres.Upon the product reaching the first Infeed Sensor, the conveyor will start up and run, clearing productforward and away from the Sensor. This procedure is repeated until the products reach the DischargeSensor, thus creating a completely full conveyor. When the Operator removes a product at the Dischargeend, the products once again move forward allowing new products to be loaded at the Infeed end.9

4107 Flexible ConveyorMaster & Slave ConveyorsAncillaries12341 Rigid Impact CartsMaster and Slave Conveyors enable the user to quickly and easily connect twoconveyors together to form one long conveyor run. When not connected together,the conveyors can be used independently.Lengths up to 50 metres can be achieved when two conveyors are connected. Normally fitted at the load point of a conveyor,the Heavy Duty Impact Cart is supplied withstrengthened side plates, 50mm x 3mm wallrollers, additional support at mid-point andadditional bracings. Conveyors are joined together using cables fitted with 32A CEE CARA Plugs for Standard length of Cart is 1.25 metres (125mmMains power supply will only be required to the Master when the conveyors arejoined together. Can be supplied as a flexible Impact Section bypitch), 1.00 metre (100mm pitch) and 0.750metres (75mm pitch).power transfer and Harting Plug/Socket signals for control transfer. Once coupled, all Start/Stop and Emergency Stop Buttons will be linked. Ie., anyStart/Stop Button can be used to Start or Stop both conveyors and if an EmergencyStop is actuated, both conveyors will stop. Zero Line Pressure Zones and Smart Optic Package Stops can also beincorporated into this design of conveyor.3 Smart OpticsT he Smart Optic comprises a Sensor which isnormally fitted in the last conveyor Zone at theDischarge end. When the product covers the Sensor,all motors along the conveyor length automaticallystop, then restart upon product removal. Smart Optics can be positioned at both ends of theconveyor if required for reversible conveyors. Deactivation of the Smart Optic Sensor can beachieved by means of a Turn-Switch located on thePanel, thus making the conveyor a transportationconveyor only.removing the bracings.2LED Lighting LED lights can be fitted as an optional extra and areuseful when unloading products inside Lorries orunlit factory areas.4Guard Rail Further protection of the product can be providedvia a Sideguard Bracket Assembly. Here a singleSide Guard Bearing is mounted to the roller end viaa 60mm high bracket. This has the advantage ofmaintaining complete conveyor flexibility.11

4127 Flexible ConveyorUNI-XU Gravity Roller Expandable ConveyorGravity ApplicationsPerfect for conveying different sized boxes with irregular bases or bags etc. Very easyto quickly manoeuvre in or out of trucks for faster, safer, easier loading and unloading.1Drop Down Package StopPrevents product damage by stopping cartons and packages from falling off theconveyor at the discharge end. Simply drops down for storage when not requiredor when connecting to another flexible conveyor.2Roller Connecting BracketAllows you to quickly and easily connect two or more conveyors togetherto expand your system.3Heavy Duty Roller Impact Section OptionImproves impact loading by fitting of 50mm x 3mm wall rollers with 4mm rollermounting bracket. Additional support stand at mid point of 1.25m length.Rigid and flexible options available.124 G uard RailFurther protection of the product can be provided via a Sideguard Bracket Assembly.Here a single Side Guard Bearing is mounted to the roller end via a 60mm highbracket. This has the advantage of maintaining complete conveyor flexibility.34Powered Impact Cart ShownTo complete the model number replace the three dashes with thestandard conveyor width required; 450mm, 600mm, 750mm or 900mm.Gravity Roller Conveyor SpecificationGravity Roller Conveyor SpecificationModelNumberStandard LengthCompacted toExpandedSupportLegs perUnitModelNumberStandard LengthCompacted toExpandedSupportLegs perUnitUFG/ROS/0---/03.751.33 - 3.75 metres4UFG/ROS/0---/15.005.20 - 15.00 metres13UFG/ROS/0---/05.001.76 - 5.00 metres5UFG/ROS/0---/16.255.63 - 16.25 metres14UFG/ROS/0---/06.252.19 - 6.25 metres6UFG/ROS/0---/17.506.06 - 17.50 metres15UFG/ROS/0---/07.502.62 - 7.50 metres7UFG/ROS/0---/18.756.49 - 18.75 metres16UFG/ROS/0---/08.753.05 - 8.75 metres8UFG/ROS/0---/20.006.92 - 20.00 metres17UFG/ROS/0---/10.003.48 - 10.00 metres9UFG/ROS/0---/21.257.35 - 21.25 metres18UFG/ROS/0---/11.253.91 - 11.25 metres10UFG/ROS/0---/22.507.78 - 22.50 metres19UFG/ROS/0---/12.504.34 - 12.50 metres11UFG/ROS/0---/23.758.20 - 23.75 metres20UFG/ROS/0---/13.754.77 - 13.75 metres12UFG/ROS/0---/25.008.63 - 25.00 metres21Optional Extras:Roller Connecting BracketRoller Impact SectionGuard RailPackage StopLarger Diameter CastorsFor easier rolling over rough oruneven surfaces.Adds the following to the conveyor height:40mm (160mm diameter castor).85mm (200mm diameter castor).Roller Centres125mm as standard when the conveyor isfully extended. Optional 75mm and 100mm rollercentres can be supplied for the conveying ofsmaller packages or cartons. Please note thatoptional roller centres will affect the conveyorcompacted length.Roller Design40mm diameter, heavy duty, steel zinc platedtube with semi – precision bearings, offeringextended conveyor life. Also available with highimpact PVC Plastic Rollers for the conveying ofsensitive loads. (NB. At a reduced load rating).Fully Adjustable Support LegsThese provide ‘top of roller’ working height from:750mm - 1035mm as standard.Other heights available upon request.Self TrackingCartons follow twist of conveyor.No need for engineered curves.Flexible and Easily ManoeuvrableCombination of braked and non-braked, heavy dutyswivel castors - 125mm x 36mm. Larger diametercastors for easier rolling over rough or unevensurfaces. Please note this adds the following tothe conveyor height: 40mm (160mm diameter castor).85mm (200mm diameter 0mm600mm750mm900mmper linear metre*(Steel rollers only)*Based on level working height.Lengths up to 30.0 metres available on request.RollerDiameter13

147 Flexible ConveyorUNI-XU Gravity Skatewheel Expandable ConveyorGravity ApplicationsA rugged conveyor ideally suited for many roles frompackaging and flexible assembly lines to loading andunloading of trucks and containers. The conveyor iseasy to move around on heavy duty castors and simplycompacts to a quarter of its size when not in use.UNI-XU LITE Expandable ConveyorsSpecificationLoadper linear mm - steel80kg 48mm - plastic forlighter applications*Based on level working height.Flexible and Easily ManoeuvrableCombination of braked and non-braked, heavy dutyswivel castors, 125mm x 36mm.SkatewheelsThe UNI-XU flexible standard - 49mm diameter,heavy duty zinc plated and suitable for all flatbased loads. 48mm diameter plastic skatewheelalso available for lighter applications.Drop Down Package StopPrevents product damage by stopping cartons andpackages from falling off the conveyor at thedischarge end. Simply drops down for storagewhen not required or when connecting to anotherSkatewheel Centres125mm as standard when the conveyor is fullyextended. Optional 75mm and 100mm rollercentres can be supplied for the conveying ofsmaller packages or cartons. Please note thatoptional skatewheel centres will affect theconveyor compacted length.flexible conveyor.Fully Adjustable Support LegsThese provide a top of skatewheel working heightfrom 750mm to 1040mm as standard.Other heights available on request.For the ultimate in flexibility, specify the UNI-XU LITE range ofexpandable gravity conveyors. Perfect for ‘end of line’ packagingapplications or wherever flexibility and portability is demanded.Virtually any shape of conveyor design can be achieved with thissystem, from the very tight inside radius curves; to a full 360 complete circle.Withstands Rigorous DemandsReinforced, ribbed zinc plated steel side plates.Structural support across width with heavy duty squaretubing leg frame. Fully bolted design without rivets.All steel skatewheel axle support - ‘one-piece’ and ‘constantlyvertical’ - ensures maximum strength throughout.Jig welded and spanning the conveyor width.Fully Adjustable Support Legs580mm to 865mm as standard, with 100mm castors.Skatewheel Centres125mm as standard when conveyor is fully extended.To complete the model number replace the three dashes with thestandard conveyor width required; 450mm, 600mm, 750mm or 900mm.Gravity Skatewheel Conveyor SpecificationGravity Skatewheel Conveyor SpecificationModelNumberStandard LengthCompacted toExpandedSupportLegs perUnitModelNumberStandard LengthCompacted toExpandedSupportLegs perUnitUFG/SWS/0---/03.751.08 - 3.75 metres4UFG/SWS/0---/20.005.57 - 20.00 metres17UFG/SWS/0---/05.001.43 - 5.00 metres5UFG/SWS/0---/21.255.91 - 21.25 metres18UFG/SWS/0---/06.251.77 - 6.25 metres6UFG/SWS/0---/22.506.26 - 22.50 metres19UFG/SWS/0---/07.502.12 - 7.50 metres7UFG/SWS/0---/23.756.61 - 23.75 metres20UFG/SWS/0---/08.752.46 - 8.75 metres8UFG/SWS/0---/25.006.96 - 25.00 metres21UFG/SWS/0---/10.002.81 - 10.00 metres9UFG/SWS/0---/11.253.15 - 11.25 metres10UFG/SWS/0---/12.503.50 - 12.50 metresUFG/SWS/0---/13.753.84 - 13.75 metresUFG/SWS/0---/15.0011ConveyorWidthSkate Wheelsper Axle12450mm74.19 - 15.00 metres13600mm9UFG/SWS/0---/16.254.53 - 16.25 metres14750mm11UFG/SWS/0---/17.504.88 - 17.50 metres15900mm13UFG/SWS/0---/18.755.22 - 18.75 metres16Optional Extras:Roller Connecting BracketDrop Down Package StopRoller Impact SectionLarge Diameter CastorsFor easier rolling over rough oruneven surfaces.Adds the following to conveyor height:40mm (160mm diameter castor),85mm (200mm diameter castor).To complete the model number replace the three dashes with thestandard conveyor width required; 300mm, 400mm, 500mm or 600mm.UNI-XU LITE Conveyor 0---/02.002.0 metres0.63 metresUFGL/SWP/0---/03.003.0 metres0.94 metresUFGL/SWP/0---/04.004.0 metres1.25 metresUFGL/SWP/0---/05.005.0 metres1.57 metresUFGL/SWP/0---/06.006.0 metres1.88 metresLoadConveyorWidthsUFGL/SWP/0---/07.007.0 metres2.19 metres80kg300mm48mm / 125mm400mm500mm600mmUFGL/SWP/0---/08.008.0 metres2.50 metresUFGL/SWP/0---/09.009.0 metres2.82 metresSpecificationper linear metre**Based on level working height.SkatewheelDiameter / Pitch15

the conveyors can be used independently. Lengths up to 50 metres can be achieved when two conveyors are connected. Conveyors are joined together using cables fitted with 32A CEE CARA Plugs for power transfer and Harting Plug/Socket signals for control transfer. Mains power supply will only be required to the Master when the conveyors are