Transcription

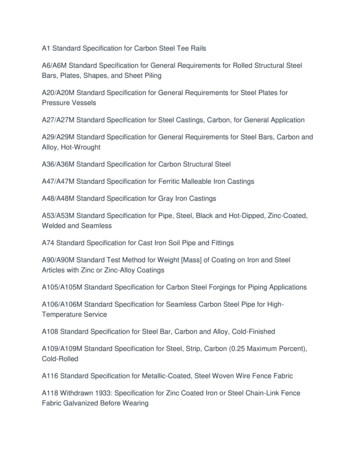

Distribution TransformersFunctional Specification GuideThree-Phase Pad-mounted Compartmental TypePS202003ENFunctional Specification for Critical Application, Envirotran HDC Transformers45 – 10,000 kVANote: Any item below labeled as {Optional} should be used or removed to ensure spec clarity.1.0Scope1.1.2.0This specification covers the electrical and mechanical characteristics of Eaton’sCooper Power series 45-10,000 kVA Three-Phase Step-Down Pad-MountedDistribution Transformers. KVA ratings for transformers with secondary voltages notexceeding 700V are 45-3,750 kVA, while kVA ratings for transformers with secondaryvoltages greater than 700 V are 1,000-10,000 kVA. Product is per Catalog DataCA202003EN. The transformers will be applied to critical load, so the design,manufacture, and test of the transformers must yield unwavering quality.Applicable Standards2.1.All characteristics, definitions, and terminology, except as specifically covered in thisspecification, shall be in accordance with the latest revision of the following ANSI ,IEEE , NEMA , and Department of Energy standards.IEEE Std C57.12.00 -2010 standard – General Requirements for Liquid-ImmersedDistribution, Power, and Regulating Transformers.IEEE Std C57.12.28 -2014 standard – Pad-Mounted Equipment - Enclosure Integrity.IEEE Std C57.12.34 -2009 standard – Requirements for Pad-Mounted,Compartmental-Type, Self-Cooled, Three-Phase DistributionTransformers (2500 kVA and Smaller) - High Voltage: 34500GrdY/19920Volts and Below; Low-Voltage: 480 Volt 2500 kVA and Smaller (issued inMarch 2005 - combines IEEE Std C57.12.22 and IEEE Std C57.12.26standards).IEEE Std C57.12.90 -2010-standard – Test Code for Liquid-Immersed Distribution,Power, and Regulating Transformers and IEEE Guide for Short-CircuitTesting of Distribution and Power Transformers.IEEE Std C57.12.91 -2011 standard – Guide for Loading Mineral-Oil-ImmersedTransformers.NEMA TR 1-1993 (R2000) – Transformers, Regulators and Reactors, Table 0-2 AudibleSound Levels for Liquid-Immersed Power Transformers.1 of 14 September 2015 G210-12-2 August 2012 2015 Eaton. All Rights Reserved.

Three-Phase Pad-mounted Compartmental TypePS202003ENNEMA 260-1996 (2004) – Safety Labels for Pad-Mounted Switchgear and TransformersSited in Public Areas.10 CFR Part 431 – Department of Energy – Energy Conservation Program: EnergyConservation Standards for Distribution Transformers; Final Rule.3.0Ratings3.1.The transformer shall be designed in accordance with this specification and the kVArating shall be listed in the data sheet (end of specification). The acceptable range willbe 45 thru 10,000 kVA.3.2.The primary voltage and the basic lightning impulse insulation level (BIL) shall bespecified on the data sheet (reference Table 1 for common examples). {Optional} Thebasic impulse level (BIL) shall be upgraded to the “Power Transformer” column listed inTable 1. The upgraded insulation is intended to add additional protection againstvoltage transients and switching surges.OR{Optional} The basic impulse level (BIL) shall be higher than that listed in Table 1, andwill be stated on the data sheet.3.3.The secondary voltage and the basic impulse insulation level (BIL) shall be inaccordance with the secondary voltages listed in Table 1 and shall be specified on thedata sheet. {Optional} The basic impulse level (BIL) shall be upgraded to the “PowerTransformer” column listed in Table 1. The upgraded insulation is intended to addadditional protection against voltage transients and switching surges.OR{Optional} The basic impulse level (BIL) shall be higher than that listed in Table 1, andwill be stated on the data sheet.2 of 14 September 2015 G210-12-2 August 2012 2015 Eaton. All Rights Reserved.

Three-Phase Pad-mounted Compartmental TypePS202003ENTable 1Transformer Ratings and ElectricalCharacteristicsTransformerBasic Impulse Insulation Level – BIL(kV)Voltage Ratings (volts)Secondary 0 Delta480 Delta240 Delta with 120 Mid-Tap480 Delta with 240 Mid-TapPrimary Voltages2400 Delta4160 Delta4800 Delta7200 Delta12000 Delta12470 Delta13200 Delta13800 Delta14400 Delta16340 Delta34500 Delta43800 * Note to Specifier – The above table is not meant to list every voltage available. For complete connector rating, see IEEE Std 386 -2006 standard.Transformers are suitable for connectors with phase-to-ground or phase-to-ground/phase-tophase high-voltage ratings as listed.Arrester coordination may require higher BIL on multiple connections than indicated to achieve aminimum protection level of 20%.3 of 14 September 2015 G210-12-2 August 2012 2015 Eaton. All Rights Reserved.

Three-Phase Pad-mounted Compartmental TypePS202003EN3.4.{Optional} The transformer shall have a dual voltage primary to be reconnected with anexternally operable, de-energized switch. Voltage provided per data sheet. The voltageprovided and the basic lightning impulse insulation level (BIL) shall be in accordancewith Table 1.3.5.{Optional} The transformer shall be furnished with full capacity high-voltage taps. Thetap-changer shall be clearly labeled to reflect that the transformer must be de-energizedbefore operating the tap-changer as required in Section 4.3 of IEEE Std C57.12.34 2009 standard. The tap configuration shall be listed in the data sheet provided. Thetap-changer shall be operable on the higher voltage only for transformers with dualvoltage primaries.3.6.The transformer, filled with Envirotemp FR3 , shall have a 65 oC average windingtemperature rise rating. The above winding temperature rise shall not exceed 65 oCwhen loaded at base kVA rating.ORThe transformer, filled with Envirotemp FR3 , shall have a 75 oC average windingtemperature rise rating. The average winding temperature rise shall not exceed 75 oCwhen loaded at base kVA rating. Note: [delete after selection] The higher winding riseutilizes the benefits of Envirotemp FR3 fluid, making for a more cost effectivesolution.3.7.The percent impedance voltage, as measured on the rated voltage connection, shall beper Table 2. For target impedances, the tolerance on the impedance shall be /- 7.5%of nominal value for impedance values greater than 2.5%. The tolerance on theimpedance shall be /- 10.0% for impedance values less than or equal to 2.5%.Table 2Percent Impedance VoltageKVA Rating (Low voltage 700 V)75112.5-300500750-3750KVA Rating1000 - 50007500 - 100004.0Impedance1.10 - 5.751.40 - 5.751.70 - 5.755.75 nominalLow voltage 700 V (all nominal values)200 kV BIL250 kV BIL 150 kV BIL5.757.007.506.507.007.50Construction4 of 14 September 2015 G210-12-2 August 2012 2015 Eaton. All Rights Reserved.

Three-Phase Pad-mounted Compartmental TypePS202003EN4.1.The core and coil shall be vacuum processed to ensure maximum penetration ofinsulating fluid into the coil insulation system. While under vacuum, the windings will beenergized to heat the coils and drive out moisture, and the transformer will be filled withpreheated filtered degassed insulating fluid. The core shall be manufactured from burrfree, grain-oriented silicon steel and shall be precisely stacked to eliminate gaps in thecorner joints. The coil shall be insulated with B-stage, epoxy coated, diamond pattern,insulating paper, which shall be thermally cured under pressure to ensure properbonding of conductor and paper. Coils shall be either aluminum or copper {eliminate ametal if one is required over the other}.4.2.The dielectric coolant shall be listed less-flammable fluid meeting the requirements ofNational Electrical Code Section 450-23 and the requirements of the National ElectricalSafety Code (IEEE Std C2 -2002 standard), Section 15. The dielectric coolant shallbe non-toxic*, non-bioaccumulating and be readily and completely biodegradable perEPA OPPTS 835.3100. The base fluid shall be 100% derived from edible seed oils andfood grade performance enhancing additives. The fluid shall not require geneticallyaltered seeds for its base oil. The fluid shall result in zero mortality when tested on troutfry *. The fluid shall be certified to comply with the US EPA Environmental TechnologyVerification (ETV) requirements, and tested for compatibility with transformercomponents. The fluid shall be Factory Mutual Approved , UL Classified DielectricMedium (UL-EOUV) and UL Classified Transformer Fluid (UL-EOVK), Envirotemp FR3 fluid.*(Per OECD G.L. 203)4.3.Tank and Cabinet Enclosure4.3.1. The high-voltage and low-voltage compartments, separated by a metal barrier, shallbe located side-by-side on one side of the transformer tank. When viewed from thefront, the low-voltage compartment shall be on the right. Each compartment shallhave a door that is constructed so as to provide access to the high-voltagecompartment only after the door to the low-voltage compartment has been opened.There shall be one or more additional fastening devices that must be removedbefore the high-voltage door can be opened. Where the low-voltage compartmentdoor is of a flat panel design, the compartment door shall have three-point latchingwith a handle provided for a locking device. Hinge pins and associated barrels shallbe constructed of corrosion-resistant material, passivated ANSI Type 304 or theequivalent.4.3.2. A recessed, captive, penta-head {or hex-head} bolt that meets the dimensions perIEEE Std C57.12.28 -2014 standard shall secure all access doors.4.3.3. The compartment depth shall be in accordance with IEEE Std C57.12.34 -2009standard, unless additional depth is specified.4.3.4. The tank base must be designed to allow skidding or rolling in any direction. Liftingprovisions shall consist of four lifting lugs welded to the tank.5 of 14 September 2015 G210-12-2 August 2012 2015 Eaton. All Rights Reserved.

Three-Phase Pad-mounted Compartmental TypePS202003EN4.3.5. The tank shall be constructed to withstand 7 psi without permanent deformation, and15 psi without rupture. The tank shall include a 15 psig pressure relief valve with aflow rate of minimum 35 SCFM.4.3.6. The exterior of the unit shall be painted Munsell 7GY3.29/1.5 green (STD), {ANSI 70 gray}, or {ANSI 61 gray} in color. If a special paint color is specified on the datasheet, a federal spec number or paint chip will be provided at the time of order. Thecabinet interior and front plate shall be painted gray for ease of viewing the insidecompartment.4.3.7. The tank shall be complete with an anodized aluminum laser engraved nameplate.This nameplate shall meet Nameplate B per IEEE Std C57.12.00 -2010 standard.4.4.High Voltage Bushings and Terminals4.4.1. High voltage bushings will be installed in the high voltage termination compartmentlocated on the front left of the transformer and requiring access via the low voltagetermination compartment on the front right.4.4.2. The transformer shall be provided with three (3) {six (6)} sidewall mounted highvoltage bushings, either 200 amp wells {or 600 amp dead-break} for deadfrontapplication and arranged for radial {loop} feed configuration.ORThe transformer shall be provided with three (3) sidewall mounted electrical gradewet process porcelain high voltage bushings rated for full three-phase duty with atwo-hole spade {or an eyebolt} connector.4.5.Low Voltage Bushings and Terminals4.5.1. Bushing Style4.5.1.1.Voltages less than 700 Volts: The transformer shall be provided with tinplated spade-type bushings for vertical takeoff.The spacing of theconnection holes shall be 1.75” on center, per IEEE Std C57.12.34 -2009standard Figure 13a.4.5.1.2.Transformers 300 kVA and below, and 500 kVA with 480Y/277 secondary willhave two piece low voltage bushings with studs and screw on spades.Transformers 500 kVA with 208Y/120 secondary and all transformers above500 kVA will have one-piece bushings.4.5.1.3.Bushing hole quantities shall be provided per Table 3 unless specificallyrequested on the data sheet.6 of 14 September 2015 G210-12-2 August 2012 2015 Eaton. All Rights Reserved.

Three-Phase Pad-mounted Compartmental TypePS202003ENTable 3Standard / Maximum Bushing Hole QuantitieskVA Rating208Y Secondary480Y Secondary 300Four {Up to 16}Four {Up to 16}500Six {Up to 12}Four {Up to 16}750 – 1500Twelve {Up to 20}Six {Up to 12}2000 – 3750N/ATwelve {Up to 20}(Re: Catalog Data CA800017EN, CA800023EN, and CA800018EN)4.5.1.4.Bushing supports shall be provided for transformers requiring 10 or moreconnection holes. Bushing supports shall be affixed to the cabinet sidewalls;tank-mounted supports mountings are not acceptable.4.5.1.5.The transformer shall be provided with bushings in a staggered arrangementin accordance with Figure 11a dimensions (Figure 12a dimensions may bespecified when a larger termination compartment for greater working space isdesired) of IEEE Std C57.12.34 -2009 standard.4.5.2. Voltages greater than 700 Volts: The transformer shall be provided with three (3) {six(6)} sidewall mounted high voltage bushings, either 200 amp wells {or 600 ampdead-break} for deadfront application and arranged for radial {loop} feedconfiguration.ORThe transformer shall be provided with three (3) sidewall mounted electrical gradewet process porcelain high voltage bushings rated for full three-phase duty with atwo-hole spade {or an eyebolt} connector. Provide additional front barrier for highvoltage live front secondary, creating an additional barrier after the low voltage doorhas been opened.4.6.The primary switching scheme provided with the transformer shall be one (note: onlyavailable option for radial feed), two, or three on-off under-oil load-break switch(s), orone four-position V or T-blade load-break sectionalizing switch. Refer to Appendi

This nameplate shall meet Nameplate B per IEEE Std C57.12.00 -2010 standard. 4.4. High Voltage Bushings and Terminals 4.4.1. High voltage bushings will be installed in the high voltage termination compartment located on the front left of the transformer and requiring access via the low voltage termination compartment on the front right. 4.4.2. The transformer shall be provided with three (3) {six