Transcription

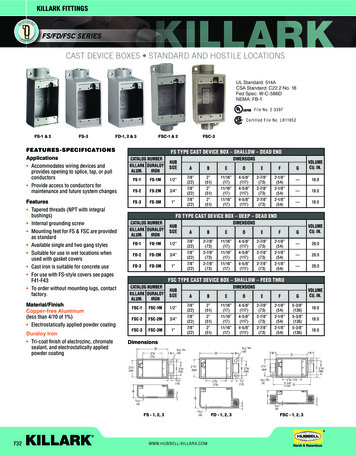

Cast Iron Junction BoxesNEC/CEC:Rated for Ordinary (Unclassified) LocationsI. Purpose of EnclosureII. Design of EnclosuresEnclosures are offered in different designs and construction to permittheir use in various locations and areas. These are as follows:Non-hazardous Locations:1. Weatherproof boxes are so constructed as to be suitable for useoutdoors under normal conditions. If it is necessary to prevent theentry of water under extreme conditions of weather, boxes listedas watertight or raintight are recommended.2. Raintight boxes are so constructed as to exclude a beating rain.All boxes in this catalog which are designated as raintight havebeen so listed by Underwriters Laboratories, Inc. and CSA group.3. Watertight boxes (NEMA Type 4) are constructed to meet therequirements listed under “NEMA DATA.”4. Submersible boxes are so constructed that they will excludewater when submerged under specified conditions of pressureand time.IV. Cast MetalsCAST IRON BOXES will provide long life, are inherentlycorrosion resistant and have the lowest initial cost.V. Finishes on Cast EnclosuresCAST IRON - The hot-dip galvanized finish which is appliedto all our cast iron boxes will conform to ASTM DesignationA153-73, Class A and NEMA requirements for rustresistance.VI. Hardware Used on Cast EnclosuresCAST IRON BOXES are furnished with stainless steel screws.VII. Specification of Extras on Cast EnclosuresThe type of holes to be provided for the entrance of conduitinto the enclosure are defined under “Instructions forOrdering Boxes.”VIII. Specification of Extras on Cast EnclosuresThe “Standard Construction” of each type of enclosure isshown on each listing. The extras which are available andmust be specified are shown under “Additional Cost Items.”5. Dust-tight boxes are so constructed to meet the requirementslisted under “NEMA DATA”.Hazardous Locations:Consult the Enclosures and Junction Boxes section for ourcomplete offering.III. Advantages of Cast EnclosuresCast metal enclosures have the advantage over formed(fabricated) sheet metal enclosures for the following reasons:A. They are of one piece construction and do not have thedisadvantages of spot welded seams usually found in formedsheet metal boxes.B. They have greater mechanical strength,have thicker walls andare suitable for drilling and tapping at the factory or in the field.C. They are corrosion resistant and can withstand moremechanical abuse.Visit our website at www.emerson.com or contact us at (800) 621-1506. May 201785ENCLOSURES AND JUNCTION BOXES: NEC/CEC WEATHERPROOF/DUSTPROOF JUNCTION AND OUTLET BOXESEnclosures are used to protect personnel against accidentalcontact with enclosed electrical devices or connections and toprotect the enclosed devices or connections against specifiedexternal conditions. They also serve as intermediate pulling andsplicing points in a conduit system.

Cast Iron Junction Boxes — NEMA DataENCLOSURES AND JUNCTION BOXES: NEC/CEC WEATHERPROOF/DUSTPROOF JUNCTION AND OUTLET BOXESNEC/CEC:Rated for Ordinary (Unclassified) LocationsOur cast junction boxes are designed, constructed and tested tocomply with NEMA standards. The following chart has been preparedto provide a quick reference for selecting enclosures to meet specificNEMA requirements. Type 5 enclosures are intended for indoor use primarily toprovide a degree of protection against dust and falling dirt. Type 6 enclosures are intended for indoor or outdoor useprimarily to provide a degree of protection against the entryof water during occasional temporary submersion at a limiteddepth. (30 min. @ 6 ft.)A brief description of the more common types of enclosures usedby the electrical industry relating to their environmental capabilitiesfollows. Please refer to the appropriate sections of NEMA StandardsPublication No. 250-2014. Enclosures for Electrical Equipment (1000Volts Maximum) for complete information regarding applications,features and design tests. Type 6P enclosures are intended for indoor or outdoor useprimarily to provide a degree of protection against the entry ofwater during prolonged submersion at a limited depth. (24 hrs.@ 6 ft.)Definitions Pertaining to Non-hazardous Locations Type 12 enclosures are intended for indoor use primarily toprovide a degree of protection against dust, falling dirt, anddripping non-corrosive liquids. Type 1 enclosures are intended for use primarily to provide adegree of protection against contact with the enclosed equipment. Type 12K enclosures with knockouts are intended for indooruse primarily to provide a degree of protection against dust,falling dirt, and dripping non-corrosive liquids other than atknockouts. Type 2 enclosures are intended for indoor use primarily to providea degree of protection against limited amounts of falling water. Type 3 enclosures constructed for either indoor or outdoor useto provide a degree of protection to personnel against incidentalcontact with the enclosed equipment; to provide a degree ofprotection against falling dirt, rain, sleet, snow and windblowndust; and that will be undamaged by the external formation of iceon the enclosure. Type 13 enclosures are intended for indoor use primarily toprovide a degree of protection against dust, spraying of water,oil, and non-corrosive coolant.Definitions Pertaining to Hazardous (Classified) Locations Type 3R enclosures are intended for outdoor use primarily toprovide a degree of protection against falling rain, sleet, andexternal ice formation. Type 7 enclosures are for use indoors in locations classifiedas Class I, Groups A, B, C, or D, as defined in the NationalElectrical Code. See Enclosures and Junction Boxes section. Type 3S enclosures are intended for outdoor use primarily toprovide a degree of protection against windblown dust, rain, sleet,and provide for operation of external mechanisms when ice laden. Type 9 enclosures are for use in indoor locations classified inClass II, Groups E, F, or G, as defined in the National ElectricalCode. Enclosures and Junction Boxes section. Type 4 enclosures are intended for indoor or outdoor use primarilyto provide a degree of protection against windblown dust and rain,splashing water, and hose-directed water.Type 2Type 3Type 3RType 3SType 4 WYF/YF WYW/YW WYR/YR WYU/YU WYT/YT WY58E/Y58E Type of EnclosureType 1Type 5WYS/YSWYL/YL86Type 6 Type 12Type 12KType 13 Visit our website at www.emerson.com or contact us at (800) 621-1506. May 2017

Cast Junction Box Ordering InformationBoxes Available for Raintight, Watertight, or Submersible ApplicationsNEC/CEC:Rated for Ordinary (Unclassified) LocationsThe following information should be given onall box orders:Conduit Entrances:Sketch showing size and location of conduit entrances shouldbe furnished similar to Drilling Templete, Fig. 2. Tables giverecommended spacing between conduits and minimum distancefrom corner and back of box. When spacings are not specified, theywill be located at our discretion.1 Enclosures for use in Non-hazardous Locations must have awall thickness of not less than 1/4” at the tapped holes for theconduit and there shall be not less than 3-1/2 threads in themetal. Compare the wall thickness shown in the catalog page forthese enclosures with the chart below to determine the numberof threads which the box wall will provide for the various conduitsizes. If more threads are required, please specify a Bossed,Drilled and Tapped hole, type ABDT.Type of Conduit Entrances (see Fig. 1, below) should be specifiedas follows:1. Slip-Hole (ASH) - conduit clearance hole.2. Drilled and Tapped hole (ADT).3. Bossed, Drilled and Tapped hole to provide greater threadengagement (ABDT).4. Boss only (ABWH) - for Drilling and Tapping in field. Specifyconduit size.Bossed, Drilled and Tapped Holes are holes threaded thru the boxwall and a boss (or pad) which has been added at the location ofthe conduit entrance to provide added wall thickness for 5 threadsof engagement.Mounting Lugs (See Fig. 1 below) are provided on all surfacemounted boxes. Boxes up to 12” x 6” have 2 mounting lugs. Largerboxes have 4 mounting lugs. All mounting lugs will be locatedon the long sides of the box, unless otherwise specified. Refer toW-Series Cast Box Mounting Lug data for dimensional information.Wall Inches Required in Millimeters (Inches)Conduit SizeNo. of Threads Per Inch3-1/2 Threads5 Threads1/2 – 3/4146.35 (0.25)0.17 (0.38)1–211-1/20.14 (0.31)0.2 (0.44)2-1/2 – 680.2 (0.44)0.29 (0.63)SLIP HOLE (SH)BOSSED, DRILLED ANDTAPPED HOLE (BDT)DRILLED AND TAPPED HOLE (DT)MOUNTING LUGS (ML)Fig. 1Visit our website at www.emerson.com or contact us at (800) 621-1506. May 201787ENCLOSURES AND JUNCTION BOXES: NEC/CEC WEATHERPROOF/DUSTPROOF JUNCTION AND OUTLET BOXESSlip Holes: These are clearance holes for conduit. No threads areprovided. Conduits are usually fastened in slip holes by means oflocknuts and bushings. STANDARD LOCKNUT SPACINGS MUSTBE ALLOWED BETWEEN THE CONDUITS.Drilled and Tapped Holes are threaded holes provided in theenclosure wall into which the conduit is screwed. To meet ULrequirements, they must conform to the following:Catalog Number and Inside Dimensions(L x W x D) should be specified

Cast Iron Junction Box Ordering InformationBoxes Available for Raintight, Watertight, or Submersible ApplicationsNEC/CEC:Rated for Ordinary (Unclassified) LocationsWidth “W”12”(2) 2” D & Twith Boss View looking into box – sides laid down. Dimensions are always understood to be InsideMeasurements unless otherwise specified. See Drilling Templete for Junction Boxes, for copierreproduction or computer scanning.(1) 11/2” D & Twith th “L”All boxes of the Type WYS/YS, WYL/YL, WYW/YW, and WYT/YT have a post in each corner and allowance must be madefor them, when conduit entrances are to be located close toa corner. Dimension “A” in the table below is the minimumdistance allowable from the sidewall of these boxes to thecenterline of the conduit entrance, which provides the properclearance between a locknut and the post. The “B” dimensionwill provide the proper clearance between a locknut or bushingand the sidewall of all other types of boxes and between alocknut or bushing and the backs of all boxes, including TypesWYS/YS, WYL/YL, WYW/YW, and WYT/YT.LeftSideRight15/8”CLSide13/4” CLCL6”Depth “D”ENCLOSURES AND JUNCTION BOXES: NEC/CEC WEATHERPROOF/DUSTPROOF JUNCTION AND OUTLET BOXESDrilling Templete(2) 2” SlipHoles31/4”BottomCLFigure 2Minimum Allowable Spacing from Back and SidesAllowance made for clearance over locknuts and bushings.Types WYS/YS, WYL/YL, WYW/YW, and WYT/YTTypes WYF/YF, WYR/YR, ”2-1/2”3”3-1/2”4”5”6”Dimension Amm .63)107.9(4.25)123.9(4.88)Dimension Bmm .13)95.3(3.75)111.3(4.38)88Visit our website at www.emerson.com or contact us at (800) 621-1506. May 2017

Cast Iron Junction Box Ordering InformationBoxes Available for Raintight, Watertight, or Submersible ApplicationsNEC/CEC:Rated for Ordinary (Unclassified) LocationsMinimum Recommended Spacing Between Conduit OpeningsAllowance made for clearance over locknuts and bushings.Space Between Centers of Conduit Millimeters (Inches)Size ofConduitMinimum Space Between Centers of Conduits 40(1.63)38.10(1.50)3 8)5203.20(8.00)184.15(7.25)6219.20(8.63) If Conduit Fittings are used additional spacing between conduits will be required. Determine spacings based on fittings being used.Visit our website at www.emerson.com or contact us at (800) 621-1506. May 201789ENCLOSURES AND JUNCTION BOXES: NEC/CEC WEATHERPROOF/DUSTPROOF JUNCTION AND OUTLET BOXESWhen unions are used, additional space must be allowed. Table shows minimum distances between conduit opening centerlines in varioussize combinations. For example, if 1-1/2” and 3/4” openings are to be drilled and tapped into one side of box, the minimum spacingbetween centerlines would be 54.1 mm (2.13”).

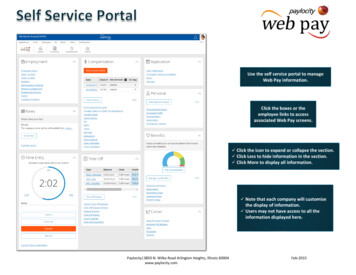

Cast Iron Junction Box Drilling TempleteBoxes Available for Raintight, Watertight, or Submersible ApplicationsNEC/CEC:Rated for Ordinary (Unclassified) LocationsDRILLING TEMPLETE for JUNCTION BOXESENCLOSURES AND JUNCTION BOXES: NEC/CEC WEATHERPROOF/DUSTPROOF JUNCTION AND OUTLET BOXESFor copier reproduction or computer scanning. Please send to your local representative for quotation or order confirmation.DistributorP.O. No.End UserDateReq. No.Mark BoxLooking Into Box - Sides Laid DownWidthAll dimensions are from inside of box.DepthTopLengthCLCLLeft SideRight SideBackCLCLCLBottomCLDrilling DataNOTE: If location of openings are not definitelydimensioned, they will be located at our discretion.Slip-hole Only Drilled and TappedDrilled and Tapped with Boss Boss OnlyCatalog No.QuantityMounting LugsNOTE: Mounting Lugs are provided on all surfacemount boxes.Additional Specifications:Dwg. No.Company/Location90SignaturePrint NameVisit

1. Weatherproof boxes are so constructed as to be suitable for use outdoors under normal conditions. If it is necessary to prevent the entry of water under extreme conditions of weather, boxes listed as watertight or raintight are recommended. 2. Raintight boxes are so constructed as to exclude a beating rain. All boxes in this catalog which are designated as raintight have been so listed by .File Size: 921KBPage Count: 18