Transcription

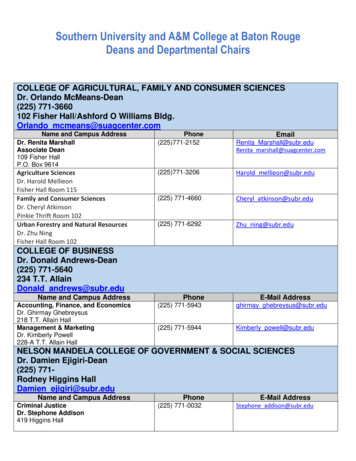

HIGGINSSTEEL ROOFINGSERIES 2000 STANDING SEAMDETAIL MANUALFor Metal Roofing SystemsFascia, Mansards,& SoffitsWall Panels/SidingHIGGINS CONSTRUCTION & SUPPLY CO.3801 U. S. 50 HILLSBORO, OHIO 451331-800-782-4239 937-364-2331 FAX 937-364-2333www.higginsroofing.com

HIGGINS CONSTRUCTION & SUPPLY CO.The details contained in the following pages are merely suggestions/guidelines asto how our product can be installed. While we believe all information presented isaccurate, it is not intended to cover all instances, building requirements, designs orcodes. The details may require adaptations, changes, or revisions for each projectsince conditions may vary from one project to another and may be unique for eachapplication.The details shown are widely used methods of construction; however, it must benoted that weather tightness through the use of these details, good materials andworkmanship, the use of the right type of sealant, and sealing and caulking all jointsadequately.It is the responsibility of the designer/roofing contractor /installer to ensure that theenclosed details are adapted to meet particular building requirements and to assureadequate weather tightness. Higgins shall be held harmless from any and all claimsarising from a lack of weather tightness as a result of using these suggesteddrawings. The designer/installer must be aware of and allow for expansion/contraction of roof panels when designing and/or installing panels and flashing.In like manner, ensuring adequacy of anchoring framing materials to walls,structures, sub girts, and cees/zees, shall be determined by the designer/installer andHiggins shall be held harmless against all claims resulting from any inadequacy. Theinstaller should familiarize themselves with all erection instructions before startingwork.Before beginning erection of panels, the installer shall examine the substrate toensure that all supporting members are straight, level, plumb, and true in accordancewith minimum tolerances. Report any variations and potential problems to thearchitect. Do not start work until unsatisfactory conditions have been corrected.Special precautions must be taken when storing and handling Galvalume, copper,etc. panels. Please contact Higgins for proper instructions and recommendations toprevent unnecessary and serious damage to panels.The roofing/fascia system shall be installed plumb, straight, and true to adjacentwork. Seams shall be equal distance from corners, hips, mullions, columns, etc., inaccordance with design concept as shown on the drawings. Horizontal panel endlaps are not acceptable. Closed cell rubber closures and metal top closures shall beembedded in sealant. Roof clips, when required, shall allow for thermal movementand shall be installed at each panel joint. Longitudinal spacing of roof clips shall beas specified for design loads. No perforations shall be made in roofing/fascia byfasteners, except as shown of the drawings. To control thermal expansion in onedirection the panel must be through/face fastened to the substrate below, either at thetop of the panel or at the bottom of the panel.

Installation procedures, which are not indicated, shall be inaccordance with the SMACNA details. Flashing and trim shall be installed true and inproper alignment, with any exposed fasteners equally spaced for best appearance.Sealants for joints and flashing end caps shall be non-drying, non-toxic, non-shrinking,and shall have a serviceable temperature of 50 to 212 degrees F. Sealant shall be fieldapplied on dry, clean surfaces. To ensure weather tightness, the sealant shall be installedwhere indicated without skips or voids. Sealants shall be furnished by others.The installer may utilize details provided and procedures recommended for installation ofmaterials. Some field cutting and fitting of panels and flashing is expected of the installerand field corrections of materials are a part of normal erection work, Workmanship shall bethe best industry standards and installation shall be performed by experienced craftsmen.Oil canning in the flat areas of the pans is common to the industry and shall not be causefor product refusal.SMACNA(Sheet Metal and Air Conditioning Contractors National Association)architectural sheet metal manual specifications shall govern for material and workmanshipnot shown.

ROOF LAYOUTBFAGEDCCONSTRUCTION DETAILS LOCATIONA. EAVE DETAILPG. 2D. SIDEWALL DETAILPG. 6B. RIDGE DETAILPG. 3E. ENDWALL DETAILPG. 7B. VENTED RIDGE DETAILPG. 4F. RAKE DETAILPG. 8C. VALLEY DETAILPG. 5G. TRANSITION DETAILPG. 9

APPLCATION DETAILSIDE VIEWFIELD NOTCHPANEL AT ONEEND1"RETURNUNDERNEATHFOLD ANDBEND IN THEFIELDPANEL BOTTOM RETURN (FIELD FORM)TYPICAL FOR ALL PANELS

InterlockPROFILE18"Sealant1 ¾”Snap Lock7456321562311POST TRIM2CLEAT3EAVE TRIM4CLIP5ROOF PANEL6PANALASTIC7PANCAKE SCREW

EAVE DETAILPG.2ROOF CLIP 6"FROM PANELENDSSEALANT TAPEROOF PANELCUT AND BENDRETURN ONBOTTOMFILL END WITHSEALANTSolid DeckSS EAVE TRIM(2 PIECE)30# felt or VaporBarrierSS CLEAT1"4"1 ½”3 ½”SS CLEATSS EAVE TRIM(LOWER)( SPECIFY PITCH)SS EAVE TRIM(UPPER)

RIDGE DETAILPG.3SS RIDGECAPSS Z TRIMSEALANT TAPEPOP RIVET ONESIDE ONLY @24" CENTERSROOF PANEL3 FASTENERSPER Z TRIM@ RIDGESolid Deck30# feltROOF CLIP 6"FROM PANELENDS1"1 ¾”5 ½”1"SS Z TRIMSS RIDGECAP(SPECIFY PITCH)

VENTED RIDGE DETAILPG.4SS RIDGECAPCOR-A-VENTSS Z TRIMMETALFASTFASTENERSTHROUGHZ TRIMSEALANT TAPEROOF PANEL3 FASTENERSPER Z TRIM@ RIDGESolid Deck30# felt or VaporBarrierROOF CLIP 6"FROM PANELENDS1"1 ¾”5 ½”1"SS Z TRIMSS RIDGECAP(SPECIFY PITCH)

VALLEY DETAILPG.5ROOF PANELCUT AND BENDRETURN ONBOTTOMFILL END WITHSEALANTSS W VALLEYSEALANT TAPESS CLEAT30# felt or VaporBarrierSolid Deck1 ½”18 ½”SS CLEATSS W VALLEY(SPECIFY PITCH)

SIDEWALL DETAILPG.6WallSS SIDEWALLCLIPSEALANT TAPEROOF PANELPOP RIVETSolid Deck30# felt or VaporBarrierSS SIDEWALL3 ½”1 ¼”1 ¾”

ENDWALL DETAILPG.7SS ENDWALLSS Z TRIMPOP RIVET @24" CENTERSROOF PANELSEALANT TAPE3 FASTENERSPER Z TRIM@ ENDWALLSolid Deck30# feltROOF CLIP 6"FROM PANELENDSSS ENDWALL5”1"(SPECIFY PITCH)1 ¾”1"4”SS Z TRIM

RAKE DETAILPG.8SS CORNERCLIPSEALANT TAPEROOF PANELPOP RIVETSolid Deck30# felt or VaporBarrierSS CLEAT1½”1 ¾”SS CORNERCLEATSS CORNER5 ½”2”½”½”

TRANSITION DETAILPG.9ROOF CLIP6" FROMPANEL ENDSROOF PANELSS ENDWALLSS Z TRIMPOP RIVET@ 24"CENTERSROOF PANELSEALANTTAPE3 Fasteners Per Z Trim @Endwall30# feltSolid DeckROOF CLIP6" FROMPANEL ENDSSS ENDWALL1"5”(SPECIFY PITCH andDIMENSIONS)1 ¾”1 ½”1"SS Z TRIMSS CLEAT4”

HIGGINS STEEL ROOFING SERIES 2000 STANDING SEAM DETAIL MANUAL HIGGINS CONSTRUCTION & SUPPLY CO. 3801 U. S. 50 HILLSBORO, OHIO 45133 1-800-782-4239 937-364-2331 FAX 937-364-2333 www.higginsroofing.com For Metal Roofing Systems Fascia, Mansards,& Soffits Wall Panels/Siding.