Transcription

216 Upton Drive St. Joseph, MI 49085Phone: [269] 983-5543 Fax: [269] 983-0902www.abmrack.com

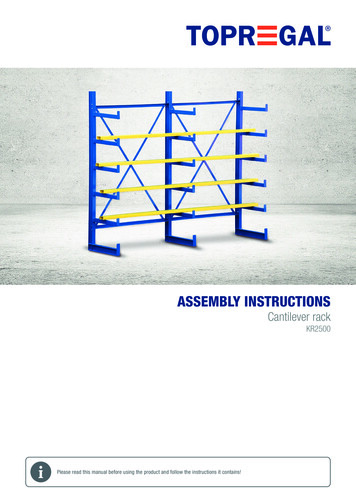

C A N T I L E V E RR AC KS Y S T E MS trong and durable structuralsteel constructionN o front posts – unrestrictedaccess to your productA rms adjustable on4” centers to accommodatevarious loadsE fficient use of vertical spaceE asily store materials ofvarying dimensionsU prights punched on bothsides for single or double sidedstorageA lso available with steel gratingor wire deckingI nside or outside storageC overed cantilever “L” and“T” shed designs availableB olted base, arm and braceconnectionsA variety of upright and armsizes for different loads2Phone: [269] 983-5543Fax: [269] 983-0902www.abmrack.com

C A N T I L E V E RR AC KS Y S T E MMULTI-LEVEL RACK SYSTEMM U LT I - L E V E L R A C K S Y S T E MStructural Steel Cantilever Storage Systems are multilevel, high density storage racks designed to handlehundreds of different types and sizes of products withfreedom from Upright interference. This allows for easierproduct removal and replacement. Cantilever StorageSystems are ideally suited to the storage of lumber,furniture, bar or plate stock; virtually any material which isinventoried in varying dimensions and requires long andunobstructed space.Accessories available:Single-Sided Cantilever Safety end caps Pole sockets and end poles Sign holders Sign platesDouble-Sided Cantileverwww.abmrack.comPhone: [269] 983-5543Fax: [269] 983-09023

ARMS & BRACINGC A N T I L E V E RR AC KS Y S T E MARMSBRACINGDetermine how many arms are required to supportyour load. Base this on the maximum lateralspacing of arms (due to load rigidity or weight)and in conjunction with the Arm Capacity Chartshown below. Individual arm capacity is determinedby dividing the total load weight by the number ofsupporting arms. Arm length equals the depth ofyour load. Arm capacities are based upon uniformloads.Lateral stability and spacing of the Uprights isaccomplished with Vertical Brace Panels andHorizontal Brace Angles.Determine the number of load levelsper upright considering:Vertical Brace Panels as shown, are required ineach end bay of any row, and in alternate interiorbays, i.e. bays 1, 3, 5, etc. in rows with an evennumber of bays, two adjacent bays will needvertical brace panels. Bracing shown is for interiorapplications. For exterior application, contactAnderson Building Materials. Factory positionedbracing clips will properly position the braces. Maximum lift capabilities of your fork lift truck. Unobstructed vertical space available. Subtract the base height from the maximumBRACING POSITIONlift height. Divide this height by the sum of: (oneload height 5” clearance the heightof one arm). This will equal the number of loadsbelow the top arm that can be stored withinthe lifting capabilities of your truck. Check forunobstructed vertical space, if adding one moreload height exceeds vertical space available,reduce arm levels by one.8’10’20’364824’ 4848483660603048*Upright heights showing position of required bracing in inches. To ascertain bracingrequired for in between sizes, select next larger size.ARM CAPACITY CHARTARMHEIGHTARM CAPACITIES ”32002500 2100 1800 1550 1425 13001050A44”52254200 3500 3000 2625 2425 23502100A55”66005300 4400 3750 3300 3050 29252650*Arm capacities are based upon uniform load.4Phone: [269] 983-5543Fax: [269] 983-090226’606012614’ 2412’16’18’ 1222’ 12www.abmrack.com

C A N T I L E V E RR AC KUPRIGHTSS Y S T E MUPRIGHTSDetermine the Upright capacity bymultiplying the desired number ofarm levels by the capacity of theselected arms. A load can be storedon the base, however, this load is notincluded in the Upright capacity.The minimum total Upright heightis equal to:UPRIGHT CAPACITY CHARTCol.TypeCol.DepthTopArm To*Pound Capacities for Each Sidefor Arm Lengths * Upright capacities shown are for single side only, not including the base. Double these for double sided uprights.For additional sizes and seismic ratings, contact Anderson Building Materials Company. The total number of arms per sidemultiplied by the individual armheight, plus. The space between the arms(load height plus 4” - 6” clearance)multiplied by the number of spaces,plus. The base height, plus. 4 ” minimum above the top arm.If you want the upright to be a backsupport for the top load, add in thedesired height.1/4L1/2L1/4L1/6L1/3L1/3L1/6LThe distance between uprights determines the bracing width. If you have two arms underyour load the Brace Panel would be one-half the load length, three arms under the loadwould be one-third the load length.www.abmrack.comPhone: [269] 983-5543Fax: [269] 983-09025

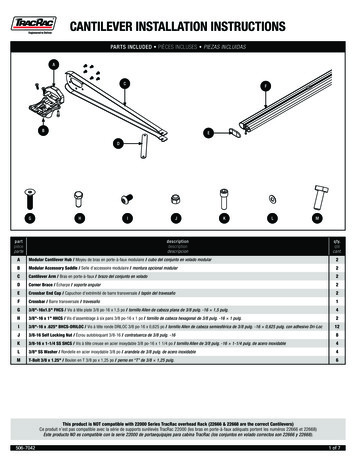

RACKSC A N T I L E V E RA Cantilever Rack has the load carrying armprojecting from a single column, and is supportedon one end only. Cantilever Racks have no front postor columns along the aisle, therefore, optimizingspace utilization and allowing immediate access toyour inventory.R AC KS Y S T E MECEnd CapA. Arm - Adjustable 4” on center in multiples of 4”from floor: Arm pitch approximately 3/4” per foot.B. Base - Base length equals arm length or longer.Base height equals column depth.C. Column - Single sided has base and arms onone side only. Double sided has base and arms bothsides. Holes 4” on center on both sides. Columntype equals column depth in inches.APArm Pole & SocketBPBase PoleVB. Vertical Brace - Rigid, pre-punched andfactory welded, for bolting to bracing clips.HB. Horizontal Brace (not shown) Pre-punched for bolting to brace clip.VBAP. Arm Pole - Retains load on armPS. Pole Socket - Retains load on baseBP. Base Pole - Bolts to armand accepts poleEC. End Cap - Optional softplastic protective cap softensimpact and minimizes injuries.ACB6Phone: [269] 983-5543Fax: [269] 983-0902www.abmrack.com

C A N T I L E V E RR AC KS Y S T E MAnderson Building Materials CompanyProviding quality products, without compromiseat a competitive price and delivered on time.For nearly 80 years.Anderson Building Materials Co. has been dedicated to providing quality products, efficient service, andintegrity in our relationships with our customers. This has been the basis of our business and, we believe, thereason Anderson Building Materials has grown and prospered. With three generations in management we arecommitted to preserving this legacy.Knowledge.As with any successful business, people are our greatest asset. Well trained, quality employees arethe backbone of Anderson Building Materials Company. Through guidance and membership in tradeorganizations such as the Material Handling Industry (MHI), American Institute Of Steel Construction(A.I.S.C.), American Welding Society (A.W.S.) and Central Fabricators Association (CFA),we have kept abreast of the technical changes that have allowed us to remain competitive in today’s world.Investment.Through capital investments in facilities, training, process improvements and automated equipment, Andersonis continually striving to improve and enhance our products. The addition of robotic welding systems, beamand anglelines have increased production efficiency as well as capacity.Achievement.As a Cantilever Rack producer since 1984, Anderson has been instrumental in the current rack design andfabrication standards adopted by numerous industries. Innovation, efficient manufacturing processes, andknowledge of fabrication have allowed Anderson to become one of the top producers of Cantilever Rack.Service.Anderson’s customer base ranges from small businesses to Fortune 500 companies, yet each receives thesame attention to detail and outstanding customer care. This customer service, along with quality products,innovation, commitment to excellence and delivery schedules are the qualities that set Anderson BuildingMaterials Company apart from the competition.www.abmrack.comPhone: [269] 983-5543Fax: [269] 983-09027

216 Upton Drive St. Joseph, MI 49085Phone: [269] 983-5543 Fax: [269] 983-0902www.abmrack.com

CANTILEVER RACK SYSTEM. 2. Phone: [269] 983-5543. Fax: [269] 983-0902 www.abmrack.com. Strong and durable structural steel construction . No front posts - unrestricted access to your product . ms adjustable on Ar . 4" centers to accommodate various loads Efficient use of vertical space Easily store materials of varying dimensions ights .