Transcription

CURRICULUM FORTHE TRADE OFQUALITY CONTROL INSPECTOR(GOODS and GARMENTS)UNDERAPPRENTICESHIP TRAINING SCHEME (ATS)1

CONTENTSSl. No.1.2.3.4.5.6.7.8.TopicsAcknowledgementBackground Apprenticeship Training under the Apprentice Act, 1961 Changes in Industrial Scenario ReformationRationaleJob roles: DescriptionGeneral InformationCourse StructurePage No.34Block I - Basic Training – Cutter (G&G)56789Model Curriculum - Cutter (G&G)109.Assessment Criteria - Cutter (G&G)1410.Equipment List - Cutter (G&G)2111.Employability and Entrepreneurship Skills2312.Block II - Practical Training (on-job training)2613.Broad Skill Component2714.Model Curriculum – Quality Control Inspector (G&G)2815.Assessment Criteria4016.Equipment List – Quality Control Inspector (G&G)4317.Further Learning Pathways4618.Infrastructure for On-Job Training4719.Guidelines for Instructors and Paper Setters482

ACKNOWLEDGEMENTThe LSSC is grateful to all of those with whom it has had the pleasure to work during thisproject. Each of the members related to this project has provided extensive personal andprofessional guidance. LSSC sincerely expresses appreciation for the contribution of theIndustry, Trade Experts and all others who contributed in building the curriculum.Special acknowledgement by LSSC to the following expert members who have contributedimmensely in this curriculum.Sl.Name & ionExpert GroupDesignationCentral Leather ResearchInstituteNational institute of FashionTechnologyPrinciple scientist &HeadAssociate professor2.Dr. Aravendan3.Mr. MuraliCentral Footwear TrainingInstituteDirector4.Dr. Anitha ManoharNational Institute of FashionTechnologyDirector3

BACKGROUND Apprenticeship Training Scheme under Apprentice Act 1961The Apprentices Act enacted in 1961 with the objective of regulating the program of training ofapprentices in the industry by utilizing the facilities available therein for imparting on-the-jobtraining. The Act makes it obligatory for employers in specified industries to engage apprenticesin designated trades and in optional trades to impart Apprenticeship Training on the job inindustry to school leavers, graduates/ diploma and person having National Trade Certificate (ITIpass-outs) issued by National Council for Vocational Training (NCVT) to develop skilledmanpower for the industry. There are five categories of apprentices namely; trade apprentice,graduate, technician, technician (vocational) apprentices and optional trade apprentice.Qualifications and period of apprenticeship training of trade apprentices and optional tradeapprentices vary from trade to trade. The apprenticeship training for trade apprentices andoptional trade apprentices consists of basic training followed by practical training. At the end ofthe training, the apprentices are required to appear in a trade test conducted by NCVT andthose successful in the trade tests are awarded the National Apprenticeship Certificate . Changes in Industrial ScenarioRecently we have seen huge changes in the Indian industry. The Indian Industry registered animpressive growth during the last decade and half. The number of industries in India haveincreased manifold in the last fifteen years especially in services and manufacturing sectors. Ithas been realized that India would become a prosperous and a modern state by raising skilllevels, including by engaging a larger proportion of apprentices, will be critical to success; as willstronger collaboration between industry and the trainees to ensure the supply of skilledworkforce and drive development through employment. Various initiatives to build up anadequate infrastructure for rapid industrialization and improve the industrial scenario in Indiahave been taken. ReformationThe Apprentices Act, 1961 has been amended and brought into effect from 22 nd December 2014to make it more responsive to industry and youth. Key amendments are as given below: Prescription of number of apprentices to be engaged at establishment level instead oftrade-wise. Establishment can also engage apprentices in optional trades which are not designated,with the discretion of entry level qualification and syllabus. Scope has been extended also to non-engineering occupations. Establishments have been permitted to outsource basic training in an institute of theirchoice. The burden of compliance on industry has been reduced significantly.4

RATIONALENeed for Apprenticeship in trade for Cutting (G&G)Need for executives with sound knowledge to ensure quality at all stages of goods andgarments manufacturing, leading to overall quality of products, is not effectively met with any ofthe current training interventions. It is realized that any executive getting into quality role shouldhave direct exposure to at least one of the goods and garments manufacturing department, sothat he will be able to acquire the knowledge and skills required for this job role. Once thecandidates become proficient in one of the goods and garments manufacturing departments,they can acquire knowledge and skills pertaining to the role identified as part of careerprogression. Hence, the combination of Cutter – Goods and Garments (PMKVY role) andQuality Control Inspector – Goods and Garments is taken up to ensure supply of job readyquality control inspectors to the industry.5

JOB ROLE: DescriptionPMKVY RoleA Cutter (Goods and Garments) works, mainly, with machine and hand tools to cut the piecesfrom leather sheets as per the design specification and sample. A cutter lays out, marks, andcuts leather or non-leather material into parts for articles using cutting dies/ Hand knifes. Thecritical component of the role is to position leather/ non-leather for cutting to ensure goodnumber and quality of cut pieces.In addition to the above, Cutter (G&G) possess good hand-eye coordination and judgment inpositioning and cutting. Also, should have basic estimation and numerical skills along with abilityto choose the correct leather/ non-leather parts for different components.Role identified as per career progressionQuality Control inspector (Goods and Garments) inspects, monitors and ensures that all theproducts manufactured comply with the customer and organizational standards.In addition to the above, a Quality Control inspector (G&G) needs to be able to manage a teamand effectively utilize them for maintaining quality standards and targets. He needs to beobservant, alert and have an attention for detail. Good team management and effectivecommunication skills are helpful.6

GENERAL INFORMATION1.Name of the Trade:QUALITY CONTROL INSPECTOR (G&G)2.Duration of Apprenticeship Training:200Hrs 40Hrs 240 Hrs &(Basic Training & Practical Training)3.Duration of Basic Training1440 Hrs:Block–I: 200 Hrs 40 Hrs Employability &EntrepreneurshipTotal duration of Basic Training:240 Hrs (Additionally, 20 Hrs DigitalLiteracy inputs given in online mode)4.Duration of Practical Training:Block–II: 1440 HRS, i.e. 36 weeks or 9(On-job Training)months5.Entry Qualification:Passed 10th class6.Selection of Apprentices:The apprentices will be selected as perApprenticeship Act amended time to time7.Rebate for ITI passed trainees:N.A.Note: Industry may impart training as per above time schedule, however this is not fixed. Theindustry may adjust the duration of training considering the fact that all the components underthe syllabus must be covered. However, the flexibility should be given keeping in view that nosafety aspect is compromised and duration of industry training to be remain as 1 year7

COURSE STRUCTURETraining duration details: Time (in hours)Recommended DurationBasic Training240 hours1440 hoursBlock- I36 weeks (9 months)----------Block- IIPractical Training(On-job training)Components ofTrainingMonths123Basic Training Block- IPractical TrainingBlock- II845678910 1112

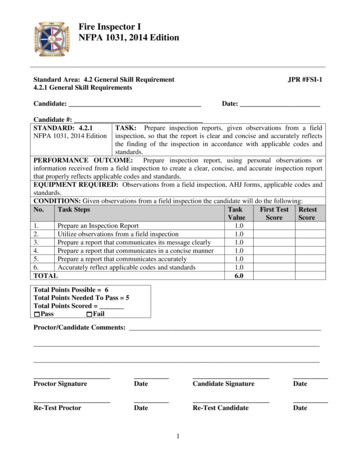

CURRICULUMBASIC TRAINING(BLOCK – I)DURATION: 200 hrs 40 hrs (Employability and Entrepreneurship Training) 240 hrs (Additionally,20 Hrs Digital Literacy inputs given in online mode)Total duration of Basic Training: 240 HrsGENERAL INFORMATION1.Name of Trade:Cutter (Goods and Garments)2.Hours of Instruction:200 Hrs 40 Hrs 240 Hrs.3.Batchsize:304.Power Norms:6 KW for Workshop4.Space Norms:10 (x20 200sq) feet5.Examination:The internal assessment will beheld on the completion of Block-I.6.InstructorQualification:Trainer pre-requisites for job role: Cutter (G&G)Sr.No.AreaDetails1DescriptionTo deliver accredited training service, mapping to the curriculum detailed above, inaccordance with the Qualification Pack “LSS/Q5301, Version 1.0”.2PersonalAttributesAptitude for conducting training, and pre/ post work to ensure competent, employablecandidates at the end of the training. Strong communication skills, interpersonal skills,ability to work as part of a team; a passion for quality and for developing others; wellorganised and focused, eager to learn and keep oneself updated with the latest in thementioned fication10th with 18 months certificate course in Goods and Garments (any) and above4a4bPlatformCertification5ExperienceCertified for Job Role: “Cutter (G&G)”, mapped to QP: “LSS/Q5301, Version 1.0”.Minimum accepted score as per SSC guidelines is 80% on the SSC prescribed onlinetheory assessment test based on an industry validated question bank.Recommended that the Trainer is certified for the Job Role: “Trainer”, mapped to theQualification Pack: “SSC/1402”. Minimum accepted score for the trainer is 80% as perSSC guidelines.Minimum 6 years site experience with Cutter (G&G) Level-4 qualified.9

Basic Training: Cutter (G&G) – LSS/Q5301MODEL CURRICULUMThis program is aimed at training candidates for the job of a “Cutter (Goods and Garments)”, in the “Leather”Sector/Industry and aims at building the following key competencies amongst the learner.Program NameCutterQualification Pack Name &Reference IDCutter (Goods and Garments)LSS/Q5301, Version 1.0Version No.1.0Pre-requisites to TrainingClass VTraining OutcomesAfter completing this programme, participants will be able to: Gain knowledge on overview of leather industry and generic skills:General instructions to importance of leather industry, general hazards inleather industry, basic health safety and hygiene precautions, genericskills to be followed in leather industry. Identify and use basic tools, equipment & materials: Effectivelyidentify, select & use the specified tools and equipment relevant to cuttingworks. Learn and perform cutting operation: Selection of tools and material,set up of machine effective utilization of leather piece and standardprocedure for leather cutting to produce leather goods and garments. Contribute to achieve quality product in cutting process: Ensurecutting parts produced according to specification sample, ensuremaximum usage of cut components with minimal wastages, carry outregular quality checks and fault identification in final product and maintainrecords and documents. Handle work area, tools and machines appropriately: Ensure correcthandling of material, tools and machines, maintain clean and hazard freework area, proper usage of cleaning equipment, maintain correct usage ofworkplace tools and equipment. Become well versed with environment, health, safety& security atwork: Well versed with health and safety measures in terms of personalsafety and equipment safety relevant to cutting occupation. Follow industrial regularity and organizational requirements: Carryout work in accordance with organizational guidelines and procedures,identify and report any possible deviation.Version Update Date1016–6 – 2016

Sr. No.ModuleKey Learning Outcomes1Introduction to Trade andOpportunities Explain the importance of leather industry anddescribe leather manufacturing process Explain general hazards or risk that can lead toaccidents Follow basic safety, health and hygienemeasures Wear and use PPE for safety Carry out communication effectively with coworkers in writing as well as orally Read the documents that are necessary forthem to read to carry out operator’s taskTheory Duration(hh:mm)12:00Practical Duration(hh:mm)10:002Corresponding NOS CodeCore skills/ Generic skillsand Professional skillscollated from all the NOS ofthe QPCarry-out CuttingOperations Using HandTheory Duration(hh:mm)02:00Practical Duration(hh:mm)40:00Corresponding NOS CodeLSS/N53013Carry-out CuttingOperations Using ClickingMachineTheory Duration(hh:mm)02:00Practical Duration(hh:mm)40:00Corresponding NOS CodeLSS/N53024Contribute to AchievingProduct Quality in CuttingProcesses Identify tools and quality of materials requiredfor hand cutting Calculate the number of components neededfor production Select the tools and materials for the work Make sure that tools are safe and clean to useon the material Check the quality and characteristics of thematerial match the required standards beforestarting to cut Use scissors or cutting knife to cut the leatherpiece as per the markings given on thecomponents Work in conformance to legal requirements,organizational policies and procedures Calculate the number of components neededfor production Select the tools and materials for the work Set up the clicking machine Check the quality and characteristics of thematerial match the required standard beforestarting to cut as per specification/sample. Make sure that tools are safe and clean to useon the material Utilize leather piece efficiently to get maximumcut pieces with minimum wastage Place cutting dies on the leather piece in anefficient manner to minimize waste Use the clicking machine to cut the material Ensure cut pieces match the numbermentioned in the job card Complete forms, records and otherdocumentation Carry out closedown procedures on completionof work Check the quality of the cut components meetsspecification during production Cut components to ensure maximum usage11EquipmentRequiredChairs, Trainersdesk and computer,Student table,Projector, Whiteprojector screen,White board, Flipchart display stand,Safety Hazard signs,Newspaper,Stationery, PPE setLeather, Scissors,Measuring tape,Steel rule, Handclicking knife,Hammer, Compass,White pencilClicking machine,Hydraulic clickingpress, Punches,Cutting mat,Measuring tape,Leather, Scissors,Stainless steel scale,Oil stone, Cuttingdies, White pencilSample leatherdefects material,Leather thickness

Sr. No.5ModuleTheory Duration(hh:mm)02:00 Practical Duration(hh:mm)30:00 Corresponding NOS CodeLSS/N5303 Maintain the Work Area,Tools and MachinesTheory Duration(hh:mm)04:00Practical Duration(hh:mm)20:006Corresponding NOS CodeLSS/N8501Maintain Health, Safetyand Security at WorkplaceTheory Duration(hh:mm)07:00Practical Duration(hh:mm)28:00Corresponding NOS CodeLSS/N86017Key Learning OutcomesComply with Industry,Regulatory andOrganizationalRequirementsTheory Duration(hh:mm)01:00Practical Duration(hh:mm)02:00Corresponding NOS CodeLSS/N8701 and minimum wastageCut different kind of problem faced with respectto quality and also solutions for the problemCarry out quality checks at agreed intervalsand in the approved wayIdentify process problems that effect productqualityMaintain the continuity of production withminimum interruptions and downtimeIdentify faults in finished products and tracetheir causesMaintain records and documentationHandle materials, machinery, equipment andtools safely and correctlyMaintain a clean and hazards free working areaUse cleaning equipment and methodsappropriate for the work to be carried outMaintain tools and equipmentMaintain proper lighting and ventilation Use and maintain personal protectiveequipment as per protocol Identify and correct malfunctions in machineryand equipment Minimize health and safety risks to self andothers due to own actions Monitor the workplace and work processes forpotential risks and threats Carry out periodic walk-throughs to keep workarea free from hazards and obstructions, ifassigned Undertake first aid, fire-fighting and emergencyresponse training, if asked to do so Take action based on instructions in the eventof fire, emergencies or accidents Follow organization procedures for shutdownand evacuation when required Carry out work functions in accordance withlegislation and regulations, organizationalguidelines and procedures Apply and follow policies and procedures withinyour work practices Provide support to the supervisor and teammembers in enforcing these considerations Identify and report any possible deviation toethical requirements12EquipmentRequiredmeasuring gauge,Gloves, Helmet,Safety shoe, Earplug, Apron,GogglesGloves, Helmet,Safety shoe, Earplug, Apron,Goggles, Cleaningcloth, Water bucket,Cleaning materials,Mop, Dust bin,BroomFirst aid kit, Fireextinguisher, PPESetSample legaldocuments

Sr. No.EquipmentRequiredModuleKey Learning OutcomesTotal DurationUnique Equipment Required:Leather, Scissors, Measuring tape, Steel rule, Hand clicking knife,Hammer, Compass, White pencil, Clicking machine, Hydraulic clickingpress, Punches, Cutting mat, Oil stone, Cutting dies, White pencil, Sampleleather defects material, Leather thickness measuring gauge, Gloves,Helmet, Safety shoe, Ear plug, Apron, Goggles, Cleaning cloth, Waterbucket, Cleaning materials, Mop, Dust bin, broom, First aid kit, FireExtinguisher, Sample legal documentsTheory Duration30:00Practical Duration170:00Grand Total Course Duration: 200 Hours, 0 Minutes(This syllabus/ curriculum has been approved by Leather sector skill council)13

Sr. No.Guidelines for Assessment1Criteria for assessment for each qualification pack will be created by the sector skill council. Eachperformance Criteria (PC) will be assigned marks proportional to its importance in NOS. SSC will alsolay down proportion of marks for Theory and Skills Practical for each PC2The assessment for the theory part will be based on knowledge bank of questions created by the SSC3Individual assessment agencies will create unique question papers for theory part for each candidate ateach examination/training centre (as per assessment criteria below)4Individual assessment agencies will create unique evaluations for skill practical for every student at eachexamination/training centre based on these criteria5To pass the Qualification Pack, every candidate should score a minimum 50% of aggregate marks tosuccessfully clear the assessment6In case of successfully passing only certain number of NOS's, the trainee is eligible to take subsequentassessment on the balance NOS's to pass the Qualification Pack14

AssessableOutcome1. LSS/N5301:Carry outcuttingoperationsusing handTotalMarkAssessment CriteriaPC1. Make sure the work area is freefrom hazardsPC2. Obtain and check the data on thework ticket or job card and carry outfunctions in line with the responsibilitiesof the job rolePC3. Ask questions to obtain moreinformation on tasks when theinstructions are unclearPC4. Calculate the number ofcomponents needed for productionPC5. Select the tools and materials forthe workPC6. Set up the equipmentPC7. Make sure that tools are safe andclean to use on the materialPC8. Check the quality andcharacteristics of the material match therequired standards before starting to cutas per specification/samplePC9. Utilise leather piece efficiently toget maximum cut pieces with minimumwastagePC10. Ensure no defects on the materialPC11. Check the stretch-ability andtightness of leather as per end productPC12. Use scissors or cutting knife to cutthe leather piece as per the markingsgiven on the componentsPC13. Count the number of cut piecesPC14. Ensure cut pieces match thenumber mentioned in the job cardPC15. Bundle the cut components andtransfer material for quality checkPC16. Make sure that when cutting thematerial avoid damaging self and others avoid damage to the knife andother equipmentPC17. Avoid any imperfections in thematerial when cuttingPC18. Agree and review the agreedupon work targets with the supervisorPC19. Minimise wastage while cuttingmaterialPC20. Meet company usage tolerancesfor efficient pattern interlockingPC21. Check with others when unsure ofnew product detailsPC22. Produce the required batch ofcomponents to match the job card 1101202202101853

AssessableOutcome2. LSS/N5302:Carry outcuttingoperationsusing clickingmachineAssessment Criteriathe company’s production targetsPC23. Dispose of waste materials safelyand return re-useable materialsPC24. Work in conformance to legalrequirements, organizational policies andproceduresPC25. Identify and respond toimperfections, defects and damage dueto mishandlingPC26. Report defects in the tools andequipment one does not have theauthority to repairPC27. Report risks/ problems likely toaffect services to the relevant personpromptly and accuratelyPC28. Complete forms, records andother documentationPC29. Make sure that the cut material iscorrectly sorted to assist the next stageof productionPC30. carefully placed to minimise therisk of damagePC31. Carry out closedown procedureson completion of workTotalPC1. Make sure the work area is freefrom hazardsPC2. Obtain and check the data on thework ticket or job card and carry outfunctions in line with the responsibilitiesof the job rolePC3. Ask questions to obtain moreinformation on tasks when the NationalOccupational instructions are unclearPC4. Calculate the number ofcomponents needed for productionPC5. Select the tools and materials forthe workPC6. Set up the equipment and clickingmachinePC7. Make sure that tools are safe andclean to use on the materialPC8. Check the quality andcharacteristics of the material match therequired standards before starting to cutPC9. Utilize leather piece efficiently toget maximum cut pieces with minimumwastagePC10. Ensure no defects on the materialPC11. Check the stretch-ability andtightness of leather as per end productPC12. Place cutting dies on the 03853202303752101101101101303752

AssessableOutcomeTotalMarkAssessment Criteriapiece in an efficient manner to minimizewastePC13. Use the clicking machine to cutthe materialPC14. Count the number of cut piecesPC15. Ensure cut pieces match thenumber mentioned in the job cardPC16. Bundle the cut components andtransfer material for quality checkPC17. Make sure that when cutting thematerial avoid damaging self and others avoid damage to the knife and otherequipmentPC18. Avoid any imperfections in thematerial when cuttingPC19. Agree and review the agreedupon work targets with the supervisorPC20. Update and develop knowledge ofthe productsPC21. Minimise wastage while cuttingmaterialPC22. Meet company usage tolerancesfor efficient pattern interlockingPC23. Check with others when unsure ofnew product detailsPC24. Produce the required batch ofcomponents to match the job card andthe company’s production targetsPC25. Dispose of waste materials safelyand return re-useable materialsPC26. Work in conformance to legalrequirements, organizational policies andproceduresPC27. Identify and respond toimperfections, defects and damage dueto mishandlingPC28. Report defects in the tools andequipment one does not have theauthority to repairPC29. Report risks/ problems likely toaffect services to the relevant personpromptly and accuratelyPC30. Complete forms, records andother documentationPC31. Make sure that the cut material iscorrectly sorted to assist the next stageof productionPC32. Make sure that the cut material iscarefully placed to minimise the risk 53202

AssessableOutcome3. LSS/N5303:Contribute toachievingproductquality incuttingprocess4. LSS/N8501:Maintain thework area,tools andmachinesTotalMarkAssessment CriteriadamagePC33. Carry out closedown procedureson completion of workTotalPC1. Set up and test equipment to meetquality standardPC2. Ensure materials and componentparts meet specificationsPC3. Ensure the quality of the cutcomponents meets specification duringproductionPC4. Cut components to ensuremaximum usage and minimum wastagePC5. Maintain the required productivityand quality levelsPC6. Carry out quality checks at agreedintervals and in the approved wayPC7. Apply the allowed tolerancesPC8. Identify process problems thateffect product quality and report thempromptly to appropriate peoplePC9. Maintain the continuity ofproduction with minimum interruptionsand downtimePC10. Identify faults in finished productsand trace their causesPC11. Identify causes of faults and takeaction to rectify the same to maintainproduct qualityPC12. Identify faults and irregularities inequipment and machinery and takeaction within the limits of responsibilityPC13. Report and replace faultymaterials and component parts which donot meet specificationPC14. Follow reporting procedureswhere the cause of faults cannot beidentifiedPC15. Maintain records anddocumentationTotalPC1. Handle materials, machinery,equipment and tools safely and correctlyPC2. Use correct lifting and handlingproceduresPC3. Use materials to minimize wastePC4. Prepare and organise workPC5. Maintain a clean and hazard freeworking areaPC6. Deal with work interruptionsPC7. Move about the workplace 01101101503515101303170512651310031

AssessableOutcome5. LSS/N8601:Maintainhealth, safetyand securityat workplaceTotalMarkAssessment CriteriacarePC8. Maintain tools and equipmentPC9. Carry out running maintenancewithin agreed schedulesPC10. Carry out maintenance and/orcleaning outside responsibilityPC11. Report unsafe equipment andother dangerous occurrencesPC12. Ensure that the correct machineguards are in placePC13. Work in a comfortable positionwith the correct posturePC14. Use cleaning equipment andmethods appropriate for the work to becarried outPC15. Dispose of waste safely in thedesignated locationPC16. Store cleaning equipment safelyafter usePC17.Complete and store accuraterecords and documentationPC18.Maintain proper lighting, ventilationto make sure general comfort is therewhile workingPC19.Give inputs and assist incompleting documentationPC20.Report the need for maintenanceand/or cleaning outside your area ofresponsibilityPC21.Ensure safe and correct handlingof materials, equipment and toolsPC22.Maintain appropriate environmentto protect stock from pilfering, theft,damage and deteriorationTotalPC1.Comply with health and safetyrelated instructions applicable to theworkplacePC2.Use and maintain personalprotective equipment as per protocolPC3.Carry out own activities in line withapproved guidelines and proceduresPC4.Maintain a healthy lifestyle andguard against dependency on intoxicantsPC5.Follow environment managementsystem related proceduresPC6.Identify and correct (if possible)malfunctions in machinery andequipmentPC7.Report any service malfunctionsthat cannot be 015351011010.500.51010.500.5651101

AssessableOutcome6. LSS/N8701:Comply withindustry,regulatory andorganizationalrequirementsTotalMarkAssessment CriteriaPC8.Store materials and equipment inline with manufacturer’s andorganizational requirementsPC9.Safely handle and move waste anddebrisPC10.Minimize health and safety risks toself and others due to own actionsPC11.Seek clarifications, fromsupervisors or other authorizedpersonnel in case of perceived risksPC12.Monitor the workplace and workprocesses for potential risks and threatsPC13.Carry out periodic walk-through tokeep work area free from hazards andobstructions, if assignedPC14.Report hazards and potential risks/threats to supervisors or other authorizedpersonnelPC15.Participate in mock drills/evacuation procedures organized at theworkplacePC16.Undertake first aid, fire-fightingand emergency response training, ifasked to do soPC17.Take action based on instructionsin the event of fire, emergencies oraccidentsPC18.Follow organization procedures forshutdown and evacuation when requiredTotalPC1.Carry out work functions inaccordance with legislation andregulations, organizational guidelinesand proceduresPC2.Seek and obtain clarifications onpolicies and procedures, from thesupervisor or other authorized personnelPC3.Apply and follow these policies andprocedures within the work practicesPC4.Provide support to the supervisorand team members in enforcing theseconsiderationsPC5.Identify and report any possibledeviation to these requirementsTotalGrand TotalPercentage weightage:Minimum pass % to 7%1522063%2535050%20

EQUIPMENT LISTCUTTER (G&G) – LSS/Q5301Sr.NoSSCQP CodeName ofthe QPNSQFLevelEquipmentNameMinimumnumber ofEquipmentrequired(per batchof 30trainees)10UnitTypeNosIs this amandatoryEquipment to beavailable at 01Cutter(G&G)4Dimension/Specification/Description oftheEquipment/ANY OTHERREMARK150mm and300mmMeasuring tape2NosYesStandardSteel rule2NosYesStainless Steel6" - 15 NOS &12 "4LSSCLSS/Q5301Cutter(G&G)4Hand clickingknife5NosYesStainless Steel5LSSCLSS/Q5301Cutter(G&G)4Hammer2NosYes100 gms, 200gms, 300 gmsand 500 7LSSCLSS/Q5301Cutter(G&G)4White pencil30NosYesDrawing pencil8LSSCLSS/Q5301Cutter(G&G)4Cutting knife5NosYesStainless steel9LSSCLSS/Q5301Cutter(G&G)4Punches3SetYesSize - 00,0,1,2,3 and 410LSSCLSS/Q5301Cutter(G&G)4Clicking Awl5NosYesTemperedsharp steelneedle withwooden handle11LSSCLSS/Q5301Cutter(G&G)4Hydraulicclicking press1NosYesCutt

Quality Control inspector (Goods and Garments) inspects, monitors and ensures that all the products manufactured comply with the customer and organizational standards. In addition to the above, a Quality Control inspector (G&G) needs to be able to manage a team and effectively utilize them for maintaining quality standards and targets.