Transcription

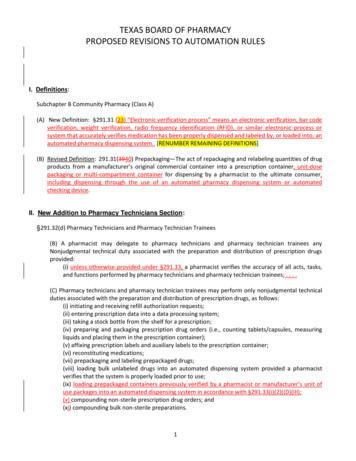

TEXAS BOARD OF PHARMACYPROPOSED REVISIONS TO AUTOMATION RULESI. Definitions:Subchapter B Community Pharmacy (Class A)(A) New Definition: §291.31 (23) “Electronic verification process” means an electronic verification, bar codeverification, weight verification, radio frequency identification (RFID), or similar electronic process orsystem that accurately verifies medication has been properly dispensed and labeled by, or loaded into, anautomated pharmacy dispensing system. [RENUMBER REMAINING DEFINITIONS](B) Revised Definition: 291.31(3940) Prepackaging—The act of repackaging and relabeling quantities of drugproducts from a manufacturer’s original commercial container into a prescription container, unit-dosepackaging or multi-compartment container for dispensing by a pharmacist to the ultimate consumer,including dispensing through the use of an automated pharmacy dispensing system or automatedchecking device.II. New Addition to Pharmacy Technicians Section:§291.32(d) Pharmacy Technicians and Pharmacy Technician Trainees(B) A pharmacist may delegate to pharmacy technicians and pharmacy technician trainees anyNonjudgmental technical duty associated with the preparation and distribution of prescription drugsprovided:(i) unless otherwise provided under §291.33, a pharmacist verifies the accuracy of all acts, tasks,and functions performed by pharmacy technicians and pharmacy technician trainees; . . . .(C) Pharmacy technicians and pharmacy technician trainees may perform only nonjudgmental technicalduties associated with the preparation and distribution of prescription drugs, as follows:(i) initiating and receiving refill authorization requests;(ii) entering prescription data into a data processing system;(iii) taking a stock bottle from the shelf for a prescription;(iv) preparing and packaging prescription drug orders (i.e., counting tablets/capsules, measuringliquids and placing them in the prescription container);(v) affixing prescription labels and auxiliary labels to the prescription container;(vi) reconstituting medications;(vii) prepackaging and labeling prepackaged drugs;(viii) loading bulk unlabeled drugs into an automated dispensing system provided a pharmacistverifies that the system is properly loaded prior to use;(ix) loading prepackaged containers previously verified by a pharmacist or manufacturer’s unit ofuse packages into an automated dispensing system in accordance with §291.33(i)(2)((D)(III);(x) compounding non-sterile prescription drug orders; and(xi) compounding bulk non-sterile preparations.1

TEXAS BOARD OF PHARMACYPROPOSED REVISIONS TO AUTOMATION RULESIII. Revisions to Automated Pharmacy Dispensing System Section:§291.33(i) Automated devices and systems.(1) Automated compounding or counting devices. [NO CHANGE](2) Automated pharmacy dispensing systems.(A) Authority to use automated pharmacy dispensing systems. A pharmacy may use an automatedpharmacy dispensing system to fill prescription drug orders provided that:(i) the pharmacist-in-charge is responsible for the supervision of the operation of the system;(ii) the automated pharmacy dispensing system has been tested by the pharmacy and found todispense accurately. The pharmacy shall make the results of such testing available to the boardupon request; and(iii) the pharmacy will make the automated pharmacy dispensing system available for inspectionby the board for the purpose of validating the accuracy of the system.(B) Automated pharmacy dispensing systems may be stocked or loaded by a pharmacist, or a pharmacytechnician or pharmacy technician trainee under the supervision of a pharmacist.(C) Quality assurance program. A pharmacy which uses an automated pharmacy dispensing system to fillprescription drug orders shall operate according to a written program for quality assurance of theautomated pharmacy dispensing system which:(i) requires continuous monitoring of the automated pharmacy dispensing system; and(ii) establishes mechanisms and procedures to test the accuracy of the automated pharmacydispensing system at least every six months and whenever any upgrade or change is made to thesystem and documents each such activity.(CD) Policies and procedures of operation.(i)) When an automated pharmacy dispensing system is used to fill prescription drug orders, itshall be operated according to written policies and procedures of operation. The policies andprocedures of operation shall:(I) provide for a pharmacist's review, approval, and accountability for the transmission ofeach original or new prescription drug order to the automated pharmacy dispensingsystem before the transmission is made;(II) provide for access to the automated pharmacy dispensing system for stocking andretrieval of medications which is limited to licensed healthcare professionals orpharmacy technicians acting under the supervision of a pharmacist;(III) require prior to use, that a pharmacist checks, verifies, and documents that thecorrect medication and strength of bulk drugs, prepackaged containers, ormanufacturer’s unit of use packages was properly stocked, filled, and loaded in theautomated pharmacy dispensing system prior to initiating the fill process; alternatively,an electronic verification system may be used for verification of manufacturer’s unit ofuse packages or prepackaged medication previously verified by a pharmacistautomated pharmacy dispensing system has been accurately filled each time thesystem is stocked;2

TEXAS BOARD OF PHARMACYPROPOSED REVISIONS TO AUTOMATION RULES(IV) provide for an accountability record to be maintained which documents alltransactions relative to stocking and removing medications from the automatedpharmacy dispensing system;(V) require a prospective drug regimen review is conducted as specified in subsection(c)(2) of this section; and(VI) establish and make provisions for documentation of a preventative maintenanceprogram for the automated pharmacy dispensing system.(ii) A pharmacy which uses an automated pharmacy dispensing system to fill prescription drugorders shall, at least annually, review its written policies and procedures, revise them ifnecessary, and document the review.(DE) Recovery Plan. A pharmacy which uses an automated pharmacy dispensing system to fillprescription drug orders shall maintain a written plan for recovery from a disaster or any other situationwhich interrupts the ability of the automated pharmacy dispensing system to provide services necessaryfor the operation of the pharmacy. The written plan for recovery shall include:(i) planning and preparation for maintaining pharmacy services when an automated pharmacydispensing system is experiencing downtime;(ii) procedures for response when an automated pharmacy dispensing system isexperiencing downtime; and(iii) procedures for the maintenance and testing of the written plan for recovery.(EF) Final check of prescriptions dispensed using an automated pharmacy dispensing system. For thepurpose of §291.32(c)(2)(D) of this title (relating to Personnel), a pharmacist must perform the finalcheck of all prescriptions prior to delivery to the patient to ensure that the prescription is dispensedaccurately as prescribed.(i) This final check shall be considered accomplished if:(I) a check of the final product is conducted by a pharmacist after the automatedpharmacy dispensing system has completed the prescription and prior to delivery to thepatient; or(II) the following checks are conducted by a pharmacist:(-a-) if the automated pharmacy dispensing system contains bulk stock drugs, apharmacist verifies that those drugs have been accurately stocked as specified insubparagraph (C)(i)(III) of this paragraph;and(-b-) if the automated pharmacy dispensing system contains manufacturer’sunit of use packages or prepackaged medication previously verified by apharmacist, an electronic verification system has confirmed that that themedications have been accurately stocked as specified in subparagraph (D)(i)(III)of this paragraph;(-c-) a pharmacist checks the accuracy of the data entry of each original or newprescription drug order entered into the automated pharmacy dispensingsystem;. and(-d-) an electronic verification process is used to verify the proper prescriptionlabel has been affixed to the correct medication, prepackaged medication ormanufacturer unit of use package for the correct patient.3

TEXAS BOARD OF PHARMACYPROPOSED REVISIONS TO AUTOMATION RULES(ii) If the final check is accomplished as specified in clause (i)(II) of this subparagraph, thefollowing additional requirements must be met.(I) The dispensing process must be fully automated from the time the pharmacistreleases the prescription to the automated pharmacy dispensing system until acompleted, labeled prescription ready for delivery to the patient is produced.(II) The pharmacy has conducted initial testing and has a continuous quality assuranceprogram which documents that the automated pharmacy dispensing system dispensesaccurately as specified in subparagraphs(A) and (B) of this paragraph.(III) The automated pharmacy dispensing system documents and maintains:(-a-) the name(s), initials, or identification code(s) of each pharmacistresponsible for the checks outlined in clause (i)(II) of this subparagraph; and(-b-) the name(s), initials, or identification code(s) and specific activity(ies) ofeach pharmacist, pharmacy technician, or pharmacy technician trainee whoperforms any other portion of the dispensing process.(IV) The pharmacy establishes mechanisms and procedures to test the accuracy of theautomated pharmacy dispensing system at least every month rather than every sixmonths as specified in subparagraph (B) of this paragraph.4

NEW MEXICOTITLE 16OCCUPATIONAL AND PROFESSIONALLICENSING CHAPTER 19PHARMACISTSPART 6PHARMACIES16.19.6.28AUTOMATED FILLING SYSTEMS:A.Definitions. The following definitions shall apply to this section:“Electronic verification system” means an electronic verification, bar code verification, weightverification, radio frequency identification (RFID), or similar electronic process or system that accuratelyverifies medication has been properly dispensed and labeled by, or loaded into, an automated fillingsystem.“Prepacked” means any drug that has been removed from the original packaging of the manufacturer oran FDA repackager and is placed in a properly labeled dispensing container by a pharmacy for use in anautomated filling system for the purpose of dispensing to the ultimate user from the establishment inwhich the prepacking occurred.Medication Stocking. Automated filling systems (hereinafter “system”) may be stocked or loaded by apharmacist or by an intern pharmacist or pharmacy technician under the direct supervision of apharmacist.Verification Criteria. The pharmacist verification requirements of Subsection C of 16.19.6.28 NMAC shallbe deemed satisfied if all the following are met: . . .(2) the filling process is fully automated from the time the filling process is initiated until acompleted, labeled, and sealed prescription is produced by the system that is ready fordispensing to the patient; no manual intervention with the medication or prescription mayoccur after the medication is loaded into the system; for purposes of this section, manualintervention shall not include preparing a finished prescription for mailing, delivery, or storage;(3) a pharmacist performs a prospective DUR and verifies the accuracy of the prescriptioninformation used by or entered into the system for a specific patient prior to initiation of theautomated fill process; the identity of the verifying pharmacist shall be recorded in thepharmacy’s records;(4) a pharmacist verifies the correct medication and strength, prepacked container, ormanufacturer unit of use package was properly stocked, filled, and loaded in the system prior toinitiating the fill process; alternatively, an electronic verification system may be used forverification of manufacturer unit of use packages or prepacked medication previously verified bya pharmacist; . . .(6) an electronic verification system is used to verify the proper prescription label has beenaffixed to the correct medication and strength, prepacked container, or manufacturer unit ofuse package for the correct patient; . . .

MISSOURITitle 20—DEPARTMENT OF INSURANCE, FINANCIALINSTITUTIONS AND PROFESSIONAL REGISTRATIONDivision 2220—State Board of Pharmacy20 CSR 2220‐2.950 Automated Filling Systems(1) Definitions. The following definitions shall be applicable for purposes of this rule:(B) “Electronic verification system”—An electronic verification, bar code verification, weightverification, radio frequency identification (RFID), or similar electronic process or system thataccurately verifies medication has been properly dispensed and labeled by, or loaded into, anautomated filling system;(E) “Repacked”—Any drug that has been removed from the original packaging of themanufacturer or a repackager’s packaging and is placed in a container for use in an automatedfilling system.(2) Medication Stocking. Automated filling systems (hereinafter “system”) may be stocked or loadedby a pharmacist or by an intern pharmacist or pharmacy technician under the direct supervision of apharmacist. Pharmacy repacked medication, cartridges, or containers shall comply with 20 CSR 2220‐2.130.(4) The pharmacist verification requirements of section (3) shall be deemed satisfied if—(B) The filling process is fully automated from the time the filling process is initiated until acompleted, labeled, and sealed prescription is produced by the automated filling system that isready for dispensing to the patient. No manual intervention with the medication or prescriptionmay occur after the medication is loaded into the automated filling system. For purposes of thissection, manual intervention shall not include preparing a finished prescription for mailing,delivery, or storage;(C) A pharmacist verifies the accuracy of the prescription information used by or entered intothe automatic filling system for a specific patient prior to initiation of the automatic fill process.The name, initials, or identification code(s) of the verifying pharmacist shall be recorded in thepharmacy’s records and maintained for five (5) years after dispensing;(D) A pharmacist verifies the correct medication, repacked container, or manufacturer unit ofuse package was properly stocked, filled, and loaded in the automated filling system prior toinitiating the fill process. Alternatively, an electronic verification system may be used forverification of manufacturer unit of use packages or repacked medication previously verified bya pharmacist;(F) An electronic verification system is used to verify the proper prescription label has beenaffixed to the correct medication, repackaged container, or manufacturer unit of use package forthe correct patient;

FLORIDAFlorida Administrative Code64. Department of Health64B16-28 General Requirements – Permits64B16-28.608 Automated Filling Systems within a Pharmacy.(1) Definitions. The following definitions shall be applicable for purposes of this rule:(b) “Electronic verification process” means an electronic verification, bar code verification, weightverification, radio frequency identification (RFID), or similar electronic process or system that accuratelyverifies medication has been properly prepared for dispensing by an automated filling system. (3) MedicationStocking. Automated filling systems (hereinafter “system”) may be stocked or restocked by a pharmacist,pharmacy intern, or registered pharmacy technician under the supervision of a pharmacist, as each aredefined by subsection 64B16-27.1001(7), F.A.C.(e) “Prepacked” means any drug that has been removed from the original packaging of the manufactureror an FDA Repackager and is placed in a container for use in an automated filling system, as referenced bySection 499.003(42), F.S.(3) Medication Stocking. Automated filling systems (hereinafter “system”) may be stocked or restocked by apharmacist, pharmacy intern, or registered pharmacy technician under the supervision of a pharmacist, as each aredefined by subsection 64B16-27.1001(7), F.A.C.(5) The pharmacist verification requirements of subsection (4), shall be deemed satisfied if:(b) The system is fully automated from the time the medication is stocked into the machine until acompleted, labeled and sealed prescription is produced by the system that is ready for dispensing to thepatient. No manual intervention with the medication may occur after the medication is stocked into thesystem. For purposes of this section, manual intervention shall not include preparing a finished prescriptionfor mailing, delivery, or storage;(c) A pharmacist must perform a prospective drug review and verify the accuracy of the prescriptioninformation used by or entered into the system for a specific patient prior to initiation of the automatic fillprocess. The name, initials or identification codes(s) of the verifying pharmacist shall be recorded in thepharmacy’s records and maintained for four (4) years after dispensing, or longer if required by applicable law;(d) All medication Prepacked by the pharmacy must be verified by a pharmacist pursuant to subsection64B16-27.1001(3), F.A.C.(e) A pharmacist verifies the correct medication, either the Manufacturer Unit of Use Package, Repacked,or Prepacked container, was properly filled and stocked in the system. Alternatively, an electronic verificationprocess may be used to verify a Manufacturer Unit of Use Package, repackaged, or prepacked containers;(g) An electronic verification process is used to verify the proper prescription label has been affixed to thecorrect medication, prepackaged medication or Manufacturer Unit of Use Package for the correct patient;

64B16-28.608 Automated Filling Systems within a Pharmacy.(1) Definitions. The following definitions shall be applicable for purposes of this rule:(a) “Automated filling system” means an automated system used within a pharmacy to assist in filling a prescription drug orderby selecting, labeling, filling, or sealing medication for dispensing. An “automated filling system” shall not include automateddevices used solely to count medication, vacuum tube drug delivery systems, or systems governed by Rule 64B16-28.606 or 64B1628.607, F.A.C.(b) “Electronic verification process” means an electronic verification, bar code verification, weight verification, radio frequencyidentification (RFID), or similar electronic process or system that accurately verifies medication has been properly prepared fordispensing by an automated filling system.(c) “Manufacturer Unit of Use Package” means a drug dispensed in the manufacturer’s original and sealed packaging, or in theoriginal and sealed packaging of a repackager.(d) “Repackager” means a repackager registered with the United States Food and Drug Administration (FDA), as defined bySection 499.003(50), F.S.(e) “Prepacked” means any drug that has been removed from the original packaging of the manufacturer or an FDA Repackagerand is placed in a container for use in an automated filling system, as referenced by Section 499.003(42), F.S.(f) “System drug identifier database” means the database or other system which positively identifies the drug to be dispensed bythe automated filling system.(2) The system drug identifier database shall be maintained by a pharmacist and shall not be delegated.(3) Medication Stocking. Automated filling systems (hereinafter “system”) may be stocked or restocked by a pharmacist,pharmacy intern, or registered pharmacy technician under the supervision of a pharmacist, as each are defined by subsection 64B1627.1001(7), F.A.C.(4) Verification. Except as provided herein, a licensed pharmacist must verify the accuracy of the final contents of anymedication filled or packaged by a system, and any label affixed thereto, prior to dispensing, as defined by subsection 64B1627.1001(3), F.A.C.(5) The pharmacist verification requirements of subsection (4), shall be deemed satisfied if:(a) The pharmacy establishes and follows a policy and procedure manual that complies with subsection (6), of this rule;(b) The system is fully automated from the time the medication is stocked into the machine until a completed, labeled andsealed prescription is produced by the system that is ready for dispensing to the patient. No manual intervention with the medicationmay occur after the medication is stocked into the system. For purposes of this section, manual intervention shall not includepreparing a finished prescription for mailing, delivery, or storage;(c) A pharmacist must perform a prospective drug review and verify the accuracy of the prescription information used by orentered into the system for a specific patient prior to initiation of the automatic fill process. The name, initials or identificationcodes(s) of the verifying pharmacist shall be recorded in the pharmacy ’s records and maintained for four (4) years after dispensing,or longer if required by applicable law;(d) All medication Prepacked by the pharmacy must be verified by a pharmacist pursuant to subsection 64B16-27.1001(3),F.A.C.(e) A pharmacist verifies the correct medication, either the Manufacturer Unit of Use Package, Repacked, or Prepackedcontainer, was properly filled and stocked in the system. Alternatively, an electronic verification process may be used to verify aManufacturer Unit of Use Package, repackaged, or prepacked containers;(f) The medication to be dispensed is selected, filled, labeled, or sealed in the prescription container by the system or dispensedby the system in a Manufacturer’s Unit of Use Package, repacked, or prepacked container;(g) An electronic verification process is used to verify the proper prescription label has been affixed to the correct medication,prepackaged medication or Manufacturer Unit of Use Package for the correct patient; and,(h) An audit trail is maintained for the prescription from the beginning of the system to the dispensing from the system, andmaintain for four (4) years.(6) The pharmacist verification requirements of subsection (4), shall be deemed satisfied for a system that is not fully automatedwhen all or part of the system is used for Manufacturer Unit of Use Packages if:(a) The system utilizes an Electronic Verification Process to verify that the correct drug matches the correct prescription label;

(b) The Electronic Verification Process activities are undertaken by a pharmacist, pharmacy intern, or registered pharmacytechnician under the supervision of a pharmacist, as each are defined by subsection 64B16-27.1001(7), F.A.C., and consistent withSection 64B16-27.4001, F.A.C.; and,(c) An audit trail is maintained for the prescription from the beginning of the system to the dispensing from the system, andmaintained for four (4) years.(7) Policies and Procedures. Pharmacies verifying prescriptions pursuant to subsection (5) or (6), of this rule, shall establish andfollow written policies and procedures to ensure the proper, safe, and secure functioning of the system. Policies and procedures shallbe reviewed annually by the prescription department manager or consultant pharmacist of record and shall be maintained in thepharmacy’s records for a minimum of four (4) years. The required annual review shall be documented in the pharmacy’s recordsand made available upon request. At a minimum, the pharmacy shall establish and follow policies and procedures for:(a) Maintaining the system and any accompanying electronic verification process in good working order;(b) Ensuring the integrity of the system drug identifier database and identification of persons responsible for database entries;(c) Ensuring accurate filling, stocking, and verification of the system, as applicable;(d) Ensuring sanitary operations of the system and preventing cross-contamination of cells, cartridges, containers, cassettes, orpackages;(e) Testing the accuracy of the system and any accompanying electronic verification process. At a minimum, the system andelectronic verification process shall be tested before the first use of the system or restarting the system and upon any modification tothe system or electronic verification process that changes or alters the filling or electronic verification process;(f) Training persons authorized to access, stock, restock, or utilize the system in equipment use and operations, as applicable;(g) Conducting routine and preventive maintenance and, if applicable, calibration;(h) Removing expired, adulterated, misbranded or recalled drugs;(i) Preventing unauthorized access to the system, including assigning, discontinuing or changing security access;(j) Identifying and recording persons responsible for stocking, and filling the system;(k) Ensuring compliance with state and federal law, including, all applicable labeling, storage, and security requirements;(l) Maintaining an ongoing quality assurance program that monitors performance of the system and any electronic verificationprocess to ensure proper and accurate functioning, including tracking and documenting of automated filling system errors that arenot corrected prior to dispensing to the patient. Such documentation shall be maintained for four (4) years and produced to the Boardupon request.(8) Recordkeeping. Except as otherwise provided herein, records required by this rule shall be maintained in the pharmacy’srecords electronically or in writing for a minimum of four (4) years, or longer if required under applicable law. If the verificationrequirements of paragraph (5)(d), of this rule, are completed by a pharmacist, the name, initials or identification code(s) of theverifying pharmacist shall be recorded in the pharmacy’s records and maintained for four (4) years after dispensing. Records shall bemade available for inspection and produced to the Board or the Board’s authorized designee upon request.Rulemaking Authority 465.005, 465.0155, 465.022(1) FS. Law Implemented 465.003(17), 465.0155, 465.022(1) FS. History‒New 3-24-14,Amended 11-5-17.

(2) Automated pharmacy dispensing systems. (A) Authority to use automated pharmacy dispensing systems. A pharmacy may use an automated pharmacy dispensing system to fill prescription drug orders provided that: (i) the pharmacist-in-charge is responsible for the supervision of the operation of the system;