Transcription

EPA’s Natural Gas STAR and Methane ChallengePrograms Technology Transfer Workshop:Pipeline Blowdowns inTransmission and Distributionwww.tdwilliamson.comTammy Wisenbaker – Technical Sales RepresentativeGulf Coast and Caribbean Region, Houston TXNovember 10, 2016 Registered trademark of T.D. Williamson, Inc. in the United States and in other countries. Copyright 2014

Images: Registered trademarks of T.D. Williamson, Inc. in the United States and in other countries. Copyright 2012

The SmartPlug SystemField proven, completely non-invasive, Remotely operated,piggable plugging tool that provides, true double blockisolation offully pressurized piping systems.Remotely Operated – Redundant systemFail-safe lock via differential pressureModular Design – 3D bendsBi-directionally piggableFull system DNV GL Type approvalDouble Block Isolation - Independent slips and seals

SmartPlug System OverviewTDW SmartPlug tool Design:DNV-RP-F113/3 Criteria: Each Barrier can retain fullpressure alone.Independent LockingSystemIndependently testedIntegrity can be monitoredIndependent from each otherHP Annulus50%100%LinePressureEach Plug Module can maintain100% of the line pressure aloneEach Plug module isindependently tested and hasindependent grips and sealsEach Plug module is operated andset independently from the othermoduleLP0%LinePressureLinePressure Failsafe via P Failsafe Unset Feature Annulus pressure is monitored to ensureisolation integrity of both seals

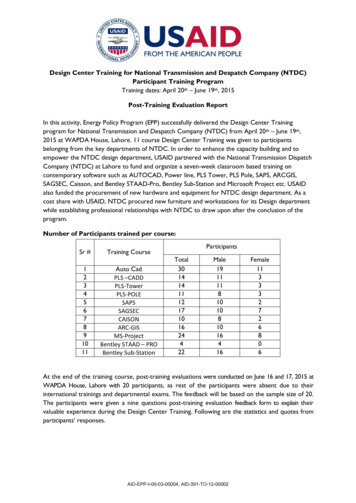

Safely and successfully performed 280 pipeline isolation jobs. Globally executed for various applications using SmartPlug tools ofdifferent configurations and sizes (8 to 48 inch). Pressures ranges from ambient to a maximum of 3,625psi (250 bar). Engineered applications significantly extended to 5,440 psi (375 bar).Since 2005, operators have “saved” an estimated 56.6 Billion standard cubic feet(Bscf) from being blown down using the SmartPlug tool for isolating their gas/gascondensate pipelines5

Case Study: Trap Station ReplacementIdentified isolation pointSmartPlug in-situ 100% Double Block IsolationHot-work carried out against SmartPlug ToolWork completed without full line shutdown

Case Study – 42” Valve ReplacementSituation: Leaking valve on pipeline in need of replacement in Gulf ofMexicoChallenge: Replace valve without shutting down productionSolution:– Use SmartPlug technology to isolate pipeline pressure on affectedline while valve replaced– Use SmartTrack system to track & position SmartPlug tool &monitor pipeline pressureOutcome:– Valve replaced while production maintained– Reduced downtime reduced costs– Pressure maintained at 83 bar (1200 psi)– Savings: USD 15 million

Pricing Pricing will be provided based on theproject application (Quote Request Form)The target price will typically be within15% above STOPPLE Train with fitting &welding

How can we work with you?Tammy Wisenbaker, Technical Sales RepresentativeE: tammy.wisenbaker@tdwilliamson.comC: 1-281-222-1107

15% above STOPPLE Train with fitting & welding. How can we work with you? Tammy Wisenbaker, Technical Sales Representative E: tammy.wisenbaker@tdwilliamson.com C: 1-281-222-1107. Title : Pipeline Blowdowns in Transmission and Distribution Author: Tammy Wisenbaker, TDW Subject: Presentation at the Pipeline Blowdowns in Transmission and Distribution workshop Created Date: