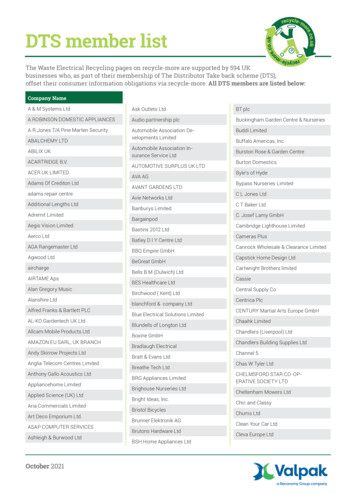

Transcription

LTL Galvanizers (Pvt) Ltd.

VISIONTo be the preferred supplier of high quality Hot DipGalvanized steel products, having a major market share inthe country as well as globally.MISSIONSupply products and services that are of distinct quality tocreate value and satisfaction to customers, throughinnovation, creativity and professionalism while effectivelyincorporating sustainability.

LTL Galvanizers (Pvt) LimitedLTL Galvanizers (Pvt) Limited, the foremost galvanizerand manufacturer of Steel Towers and Structures in SriLanka, was started in the year 1991 by Sri Lanka'srenowned Engineering organization, LTL HoldingsThe facility with two galvanizing baths is capable ofgalvanizing full length members of transmission linetowers in single dip operation.(Pvt) Limited to complement their constructionThe Steel fabrication facility of the Company withinactivities.the same premises, equipped with ComputerToday this subsidiary of LTL Holdings, owns andoperates ultra modern facilities for galvanizing,designing and fabrication of steel towers andControlled precision equipment, is supplyingfabricated items for towers and structures to be usedon major transmission line projects.structures and serves all major industries in Sri Lanka,The factory also produces steel structures forincluding the power and telecommunication sectorscommunication towers, substation structures, pre-and for ship repairing industry. The Company virtuallyfabricated buildings, bridges, pre-engineered steel,has served every infrastructure project implementedrailings etc. The Company's internationally trainedin the country and since of late has attracted severalengineers, utilizing the latest state of the art softwareoverseas clients as well.packages efficiently handle the designing andThe Hot Dip Galvanizing Plant is equipped withGerman machinery and technology and has aproduction capacity of 150 Metric Tons per day.fabrication, to the maximum satisfaction of theclients.

2 4Products and ServicesWe provide design, fabrication, galvanizing and testing for following products and variousstructures on customer requirements according to relevant technical standards, BS, ISO, DIN, JIS.Transmission TowersCable bridgesTelecommunication & radio TowersBailey bridgesCellular communication towersLadders, Stairways, Handrails, GratingsTelevision MastsNuts & BoltsSubstation structuresCross arms & Line HardwareTransformer tanksSteel buildings & other steel structuresPipes / pipe racks / ducts

Steel Fabrication FacilityModern factory with CNC machinery supports the fast and accurate production. Manufacturingfacility of LTL Galvanizers is fully equipped with modern machinery with computer numericallycontrolled systems. Very high accuracy, repeatability and high rate of production of thesemachines put the plant in the high end of similar type of production lines and becomes theonly facility of this type in Sri Lanka.All welding conforms to the requirements of the American Welding Society D1.1 Standard.All material is hot-dip galvanized after fabrication to BS EN ISO 1461:2009 or ASTM StandardA123 Standard .All structural bolts conform to ISO 698: and are galvanized to BS EN ISO 1461:2009.

6Hot Dip Galvanizing FacilityThe Galvanizing Facility is equipped with state-of-the artSpecifications :plant and machinery from LOI-Thermprocess of Germany,and updated regularly with the latest technologies as atBath 1 Steel bathtoday. We have a strong technical collaborationDimensionsagreement with American galvanizers Association (AGA),Length 7.0 mand we are also a member of AGA.Width1.3 mDepth2.1 mAll pre galvanizing processes; such as de-greasing,pickling, rinsing, fluxing, drying, dipping , quenching andde-oxidizing are in accordance with company standardsand BS EN ISO 1461: 2009.Capacity5.0 Tons/hourFacilitate up to 13.5 m length by double end dippingBath 2 Ceramic bath (For centrifuge items)The total production capacity of the plant is 6.2 MT/hourDimensionsand operates for 24 hours per day.Length 3.0 mWidth0.8 mDepth1.2 mCapacity1.2 Tons/hour

Towers & StructuresPower Transmission TowersLTL Galvanizers is the only company in Sri Lanka, which manufacture power transmission towersranging 33 kV, 132kV and 220 kV.Telecommunication towersWe manufacture microwave towers and GSM antenna structures and mobile telecommunicationstructures for leading telecommunication companies.Grid Substation StructuresSubstation gantry and equipment support structures are designed, fabricated and galvanized for33kV, 132kV and 220kV.

8Galle Expressway Sign board StructuresFences in JapanEngineering Planning & DesigningEngineering, Planning & Designing precedes of the commencement of fabrication. Based on thedesigns of towers, bridges, structures etc. furnished fabrication drawing are developedutilizing state of the art computer software facilities. By this process, while 100% accuratefabrication drawings are developed, bill of quantities, bolt and nut requirement, and shopfloor drawings etc are also simultaneously generated. These are further verified by theengineering staff of the facility before the production process commence.All functions starting from the ordering of raw material up to the transferring of the end productsto the customers are planned and monitored by the use of a computer software designed torecord every aspect of the production process with dates for fabrication, galvanizing, shopassembly of sample, packing, final inspection and delivery. This ensure timeliness and resultantlymaximizing of customer satisfaction. Our dedicated staff from engineers to workmen is fullyfocused to serve our customers to their satisfaction at all times.Railway workshop Colombo

Packing & TanzaniaMaldivesMauritiusGlobal Presence

Quality AssuranceLTL Galvanizers has been synonymous with highestOur steel Fabrication and hot dip galvanizing is in strictquality steel fabrication and hot dip galvanizing.compliance with the relevant technical standards (BS,We have always delivered the highest quality product toour customers. Our continuous efforts in improving ourperformance through strict process controls, in processISO, DIN) required by the customers. Regular internaland external audits ensure the full and continuousconformity with these international standards.inspections and system implementation have given usAll incoming materials are tested at independentthe extra edge in the business today.Laboratories for chemical and mechanical properties.Integrated Management System of LTL Galvanizers iscertificated to ISO 9001:2008, ISO 14001:2004 & OHSASAll our structures are also Prototype tested for all designloads at an independent laboratory.18001:2007 by internationally acclaimed certifyingThoroughly trained and highly skilled quality controlagency, Det Norske Veritas (DNV) Netherlands.staff provides an excellent back up to the establishedquality management system.

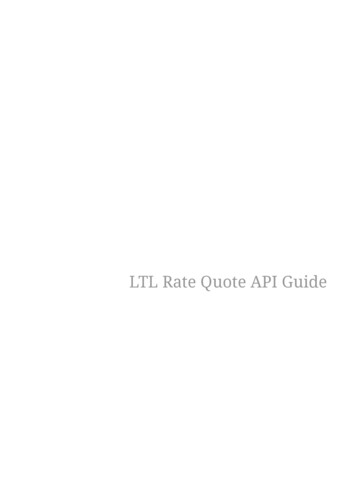

Time to First Maintenance Chartfor Hot-Dip Galvanized CoatingsTime to First Maintenance* (years)1009080Key70Rural60SuburbanTemperate Marine50Tropical Marine40Industrial30201001. 01.52.02.53.03.54.0Average Thickness of Zinc (mils)*Time to first maintenance is defined as the time to 5% rusting of the steel surface.4.55.01 mil 25.4μm 0.56oz/ft2

LTL Galvanizers (Pvt) Ltd.A Subsidiary of LTL Holdings (Pvt) LtdHead Office No.67, Park Street, Colombo 02, Sri Lanka.Tel : 94 112 695 007 Fax : 94 112 684 900Factory -Blocks 3&4, LINDEL, Sapugaskanda, Makola, Sri Lanka.Tel : 94 112 401 305-7 Fax : 94 112 401 309Website : www.ltl.lkE- mail : info@ltl.lkOHSAS 18001Certified Company

LTL Galvanizers is the only company in Sri Lanka, which manufacture power transmission towers ranging 33 kV, 132kV and 220 kV. Telecommunication towers We manufacture microwave towers and GSM antenna structures and mobile telecommunication structures for leading telecommunication companies. Grid Substation Structures