Transcription

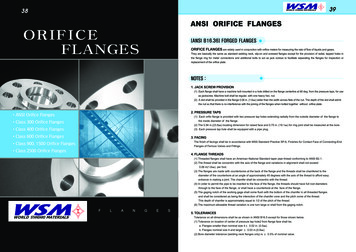

ANSI FLANGESClass 150 FlangesClass 300 FlangesClass 400 FlangesClass 600 FlangesClass 900 FlangesClass 1500 FlangesClass 2500 Flanges

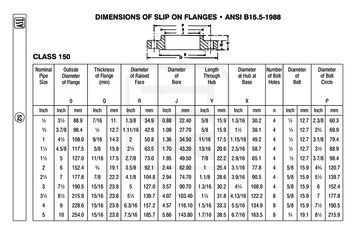

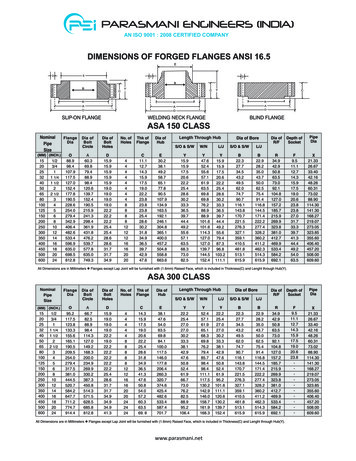

8CLASS 150 FLANGESANSI B16.5 FORGED FLANGESUnit : mmBORENominal OutsidePipeDiam.Size1/23/411 1/41 1/222 1/233 1/2456810121416182024Diam.at Baseof HubO. D. onSocketWeldingLENGTH THRU LapJointDiam. ofHub :(1) For the‘Bore’(B1) other than Standard Wall Thickness, refer to page 52.(2) Class 150 flanges except Lap Joint will be furnished with 0.06″(1.6mm) raised face, which is included in‘Thickness’(t) and‘Length through Hub’(T1),(T2).(3) For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to topor tapered within the limits of 7 degrees.

9Unit : mmDRILLINGNominal DepthPipeofSizeSocketBOLTINGBoltNumber DiamCircle ofofDiam HolesHolesY1/23/411 1/41 1/222 1/233 .1APPROXIMATE WEIGHTMachineStud BoltDiam BoltLengthofLengthBolts(inch) Raised Raised RingFace 4.90 10.808.905.90 13.0011.007.41 16.3013.008.76 19.3014.0016.70 11.31 24.9027.90 19.92 43.9037.00 29.39 64.8062.40 43.70 96.3091.50 59.42 140.00116.80 77.11 170.00130.00 94.80 209.00159.00 123.38 272.00218.30 188.24 2.335.003.557.804.028.904.99 11.005.99 13.206.68 14.707.99 17.6013.29 29.3019.50 43.0029.03 64.0038.56 85.0044.49 98.0054.43 120.0070.31 155.0095.25 210.00(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree.To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (t).(6) Depth of Socket (Y) is covered by ANSI B16.5 only sizes through 3 inch, over 3 inch is at the manufacturer’s option.

10CLASS 300 FLANGESANSI B16.5 FORGED FLANGESUnit : mmBORENominal OutsidePipeDiam.Size1/23/411 1/41 1/222 1/233 1/2456810121416182024Diam.at Baseof HubO. D. onSocketWeldingLENGTH THRU HUBLapJointCounterBore Min.ThreadedMin.Welding 7152.4Diam. ofHub 855.660.563.568.369.973.282.6Notes:(1) For the‘Bore’(B1) other than Standard Wall Thickness, refer to page 52.(2) Class 300 flanges except Lap Joint will be furnished with 0.06″(1.6mm) raised face, which is included in‘Thickness’(t) and‘Length through Hub’(T1),(T2).(3) For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to ortapered within the limits of 7 degrees.

11Unit : mmDRILLINGNominal DepthPipeofSizeSocketBOLTINGBoltNumber DiamCircle ofofDiam HolesHolesY1/23/411 1/41 1/222 1/233 141.1APPROXIMATE WEIGHTMachineStud BoltDiam BoltLengthofLengthBolts(inch) Raised Raised RingFace 107.7218.0024.90 10.1333.30 12.5843.40 16.0467.20 24.5096.40 34.16142.00 51.26194.70 72.12249.00 90.40305.00 109.00369.00 136.00519.00 0(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree.To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (t).(6) Depth of Socket (Y) is covered by ANSI B16.5 only is sizes through 3 inch, over 3 inch is at the manufacturer’s option.

12CLASS 400 FLANGESANSI B16.5 FORGED FLANGESUnit : mmBORED1/23/411 1/41 1/222 1/233 279318381445521584648711775914Diam.at Baseof HubO. D. nAndThreadedLapJointDiam. ofHub atBevelB1B2B3BT1T2T3ASee Note(1)To be specified by purchaser.Nominal OutsidePipeDiam.SizeLENGTH THRU 323.9355.6406.4457.2508.0609.6Notes:(1) For the inside diameter of pipes (corresponding to‘Bore’(B1) of Welding Neck Flanges), refer to page 52.(2) Class 400 flanges except Lap Joint will be furnished with 0.25″(6.35mm) raised face, which is not included in‘Thickness’(t)and‘Length through Hub’(T1),(T2).(3) For Slip-on, Threaded and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered withinthe limits of 7 degrees.

13Unit : mmNominal Radius ThreadPipeofLengthSizeFillet1/23/411 1/41 1/222 1/233 28.431.835.135.138.138.441.147.8Stud Bolt LengthDiam0.25″ Male- RingofRaised Female 1.5190.5203.2209.6222.3228.6247.7279.4APPROXIMATE 0(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree.To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (t).(6) Dimensions of sizes 1/2″through 3-1/2″are the same as for Class 600 Flanges

14CLASS 600 FLANGESANSI B16.5 FORGED FLANGESUnit : mmNominal OutsidePipeDiam.Size1/23/411 1/41 1/222 1/233 1/2456810121416182024Diam.at Baseof HubO. D. .4584.2692.2LENGTH THRU HUBThicknessWeldingNeckSocketWeldingtB1B2B3BT1See Note(1)To be specified by eMin.Welding 152.4165.1184.2Diam. ofHub 265.069.973.277.779.282.691.9Notes:(1) For the insi

ANSI B16.5 FORGED FLANGES 8 Unit : mm Notes: (1) For the ‘Bore’(B1) other than Standard Wall Thickness, refer to page 52. (2) Class 150 flanges except Lap Joint will be furnished with 0.06″(1.6mm)raised face, which is included in ‘Thickness’(t) and ‘Length through Hub’(T1),(T2). (3)For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical .