Transcription

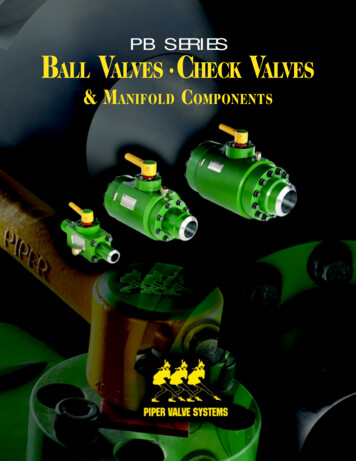

PB SERIESBALL VALVES CHECK VALVES& M ANIFOLD C OMPONENTS

P BS E R I E SBALLVALVESDesigned ForPerformanceEngineered For PerformancePB Series Ball Valves are engineered to perform well underdiverse pressure and flow situations, and offer the economy ofrepairability.Removable Seat Carriers serve two important functions:1) They allow equalization of pressure around the seat seal thuseliminating the possibility of pulling a seat seal out of the seatpocket under high differential pressure while opening the valve; and2) They allow valve repair even if minor erosion of the seat pocketoccurs.L-Seal assures low pressure sealing by energizing contact betweenthe ball and seat seal.Extra-Large Ball-To-Seat Contact Area reduces operating torque,assures positive sealing over the full range of pressures, anddistributes the force between the ball and seat seal for reduced wearand extended service life.Valve Bonnet easily accommodates hydraulic or pneumaticactuators.PB Series Ball Valves by Piper ValveSystems are designed to performefficiently and dependably every time.Compact Design occupies up to 40% less space than conventionalflanged-end ball valves for skids or manifolds where space is critical.Easy Removal From Service by unbolting from end connections, withminimal line spread required.Modular 3-Piece Design provides unlimited options for end connections.Maximum Flow Bore Sizes are offered which correspond to the insidediameters of conventional ASTM A106 Grade B pipe, reducing oreliminating transition areas and thereby minimizing system frictionalpressure losses.PB BALL VALVES & THROTTLE VALVESBODY GROUP TRIM CODEBODY/BONNET MATERIAL:1234Standard Material17-4PH SS316 SSLow Temp Alloy SteelBALL MATERIAL1234ENP Carbon Steel17-4PH SSChrome Plated 316 SSNitronic 60STEM MATERIAL12317-4PH SSNitronic 60K500 MonelSEAT CARRIER MATERIAL:123Carbon Steel17-4PH SS316 SSSEAT SEAL MATERIAL:12CelconPEEKSTEM SEAL MATERIAL / O-RING MATERIAL:123456PolyMyte-Nitrile / Peroxide-Cured NitrilePolyMyte-Nitrile / Sulfur-Cured NitrilePolyMyte-Nitrile / Low Temperature NitrilePolyMyte-Viton / VitonViton-Viton / VitonEPDM-EPDM / EPDMFASTENERS:123MODEL NUMBERA193-B7A320-L7A320-L7MACTUATION:012Bare StemHandle-OperatedGear OperatorSERVICE:1 Standard2 NACE (MR01-75)XX XXX – X XXXX X X XX2

P BS E R I E SBALLVALVESBuilt For PerformancePB Series Ball Valves are manufactured with specifiedmaterials, coatings and processes to ensure durability andprecision.Xylan Coating of body group external surface provides a thin,tough corrosion protection much better than conventional valvepaints. Internal Xylan coating of body groups is also provided asa standard to minimize internal corrosion. Fasteners are alsoXylan coated for maximum corrosion protection.Seat Seals Available In Celcon and PEEK provide a variety oftemperature ranges at high operating pressures.Stem Material Is 17-4PH Stainless Steel for maximum strengthand corrosion resistance.Fire Tested in compliance with API Specification 6FA, 2ndEdition.PB BALL VALVE SELECTION nal Sizepsi (bar)–––––ANSI 1500inBall ValveBody Group WeightAssembly Weightw/Weld End Conns.CompanionCheck 1081 1/ 23825114320CC1082 1/ 23CA200380BB2092 9/1665753412255CC206CC3023,705 psi CWPAPI 3000Port Diameter/2-11(250)Ball ValveModelkg4100BA30535/168410849170776,000 psi Test4100BA3123 3/ 21125209CC013250BC1081 1/ 23825114320CC1085,000 psi CWP2 1/ 7269041CC206380BB2092 9/1665753412055CC206–––––API 500010,000 psi Test4100BC3043 1/ 48318082260118CC302(700)6150BC4024 1/ 8 1/ CC013CC1081250BC1081 1/ 238251143206,170 psi CWP2 1/ 265BC113113/164640187534CC113(420)380BC2042 1/ 457843813059CC206–––––ANSI 250010,000 psi Test(700)110,000 psi CWP(700)API 100004100BC3043 1/ 48318082260118CC3026150BC4024 1/ 8105340155540245CC4016150BC4124 3/ 86CC61310250BC8088 1/ CD013CD108250BD1081 1/ 238522489402 1/ 265BD113113/1646602710045CD113380BD2022 1/ 8541004516073CD201CD21215,000 psi Test380BD2102 5/ 86715068230105(1,050)4100BD3023 1/ 87920091300136CD3016150BD4024 1/ 9CD60110250BD7127 3/ 4174160072723001045CD7123

P BS E R I E 17211422162525151723PB BALL VALVE PARTS LISTIndexQtyDescriptionStandard MaterialsNACE MaterialsOptional Materials(1)11BodyCarbon Steel(2); Alloy Steel(3)Carbon Steel(2 ; Alloy Steel(3)316 SS; 17-4PH SS21BonnetCarbon SteelCarbon Steel316 SS; 17-4PH SS32Cap Screw, StopA193-B7 (Xylan)A193-B7 (Xylan)A320-L7 (Xylan); A320-L7M (Xylan)44Cap Screw, BonnetA193-B7 (Xylan)A193-B7 (Xylan)A320-L7 (Xylan); A320-L7M (Xylan)51Bonnet SealNitrile, P/CViton; Nitrile, P/CLow Temp Nitrile; Aflas; EPDM61Stem BearingGarlock DUGarlock DU71Stem17-4PH SS17-4PH SSNitronic 6081Stem SealPolyMyte/Buna-NPolyMyte/VitonViton/Viton91Stem Backup RingGlass-Filled TeflonGlass-Filled Teflon101Thrust BearingAlloy Steel (Xylan)Alloy Steel (Xylan)Nitronic 60111BallENP Carbon SteelENP Carbon Steel; 17-4PH SS316 SS; Nitronic 60122SeatCelconCelconPEEK132Seat CarrierCarbon Steel; (SBN-QPQ)Carbon Steel; (SBN-QPQ)316 SS; 17-4PH SS142L-SealNitrile, P/CViton; Nitrile, P/CLow Temp Nitrile; Aflas; EPDM151RetainerCarbon SteelCarbon Steel316 SS; 17-4PH-SS161Retainer SealNitrile, P/CViton; Nitrile, P/CLow Temp Nitrile; Aflas; EPDMCarbon Steel, Plated172Bolt, Retainer(5)Carbon Steel, Plated181HandleCarbon SteelCarbon Steel191Cap, HandlePlasticPlastic201Stop PlateCarbon SteelCarbon Steel212Swivel FlangeCarbon SteelCarbon Steel316 SS222Bevel-for-Weld NippleCarbon Steel; Alloy SteelCarbon Steel; Alloy Steel316-L23224VariesHalf Ring SetAlloy SteelAlloy SteelCap Screw, End ConnectionA193-B7 (Xylan)25A193-B7 (Xylan)A320-L7 (Xylan); A320-L7M (Xylan)2End Connection SealNitrile, P/CViton; Nitrile, P/CLow Temp Nitrile; Aflas; EPDM261Body Grease FittingCarbon SteelAlloy Steel316 SS271Bolt, HandleStainless SteelStainless Steel(1)Consult factory for other material(2)Employed up to and including 6,170 psi CWP valves(3)Employed on 10,000 psi CWP valves4

P BS E R I E SBALL3-Way Ball ValvesPB Series 3-Way Ball Valves offer the same design,engineering and manufacturing advantages of standard PBSeries Ball Valves, plus.Cross-Ported Ball prevents complete shut-off duringball rotation.90 Angle-Ported Ball allows flow to be divertedfrom either of two outlets, 180 apart, with fullshut-off of downstream port.Valve Bonnet enables easy mounting forremote actuation.Minimal Line Spread facilitates easyremoval from service for repair.Bore Sizes of the PB Series 3-Way BallValve are available in 13/16",1-1/2", 1-13/16" and 2-1/4", in workingpressures from 3,705 psi to 10,000 psi.VALVESThrottle Ball ValvesPB Series Throttle Ball Valves are designed and manufactured to the exacting specifications of all PB Series Valves, andalso offer.Throttle Handle/Indicator Dial for precise flow control.Throttle Ball Venturi Port Design permits throttling under highdifferential pressures. Greater flow rates can be obtained withthe PB Throttle Ball Valve in full open position than withconventional stem and seat chokes.Throttle Ball Material is Nitronic 60 as standard for prolongedresistance to erosion. Standard seat carrier and retainer materialis 17-4PH SS and are positioned as replaceable wear members.Enlarged Diameter of Downstream Nipple and tapered retainerreduce the effects of erosion due to cavitation. A replaceableblast tube nipple, placed between two swivel flanges, is availableas an option for extreme flow conditions.Applications for the Throttle Ball Valve include waterfloodinjection, gas injection, blow-down applications, hydraulic pumpsurface manifolds (artificial lift), and as back-pressure controlfor electric submersible pump installations (artificial lift).Bore Sizes of the PB Series Throttle Ball Valve are available in13/16", 1-1/2" and 2-1/16", in working pressures from 3,705 psito 10,000 psi.STANDARD BALLTHROTTLE BALL5

P BS E R I E SCHECKVALVESDesigned For PerformanceEngineered For PerformancePB Series Check Valves by Piper Valve Systems are designedunder the same stringent specifications as PB Series Ball Valves.Compact Design occupies up to 40% less space than conventional flanged-end check valves for skids or manifolds wherespace is critical.Easy Removal From Service by unbolting from end connections,with minimal line spread required.Modular 3-Piece Design provides unlimited options for endconnections.Maximum Flow Bore Sizes are offered which correspond to theinside diameters of conventional ASTM A106 Grade B pipe,reducing or eliminating transition areas and thereby minimizingsystem frictional pressure losses.PB Series Check Valves are engineered to perform well underdiverse pressure and flow situations, and offer the economy ofrepairability.Wafer Body Style provides short end-to-end dimension and iseasily removed from service for repair.Fire-Safe Design is the result of metal-to-metal secondarysealing in critical areas.Ball Valve/Check Valve Combination Assemblies offer theshortest overall length available. For even greater space savings,smaller size check valves can be direct-bolted to the ball valve.PB CHECK VALVE BODY GROUP TRIM CODEBODY MATERIAL:1234Standard Material17-4PH SS316 SSLow Temp. Alloy SteelFLAPPER MATERIAL:12317-4PH SSNitronic 60316 SSRETAINER - SEAT CARRIER MATERIAL:123417-4PH SS316 SSCarbon SteelAlloy SteelO-RING SEALS:123456MODEL NUMBERPeroxide-Cured NitrileSulphur-Cured NitrileLow Temperature NitrileVitonEPDMAflasCHECK VALVE ORIENTATION:12XXXXX–XXXXX6Other Than Vertical DownflowVertical Downflow

P BS E R I E SCHECKVALVESBUILT For PerformancePB Series Check Valves are manufactured with specifiedmaterials, coatings and processes to ensure durability andprecision.Xylan Coating of body group external surface provides a thin,tough corrosion protection much better than conventionalvalve paints. Internal Xylan coating of body groups is alsoprovided as a standard to minimize internal corrosion. Fastenersare also Xylan coated for maximum corrosion protection.Flapper Material is 17-4PH Stainless Steel for corrosion anderosion resistance.Spring Material Is Inconel X-750 for additional corrosionresistance.Teflon Flapper Seal promotes positive sealing and extendedservice life.Fire Tested in compliance with API Specification 6FA, 2ndEdition.PB CHECK VALVE SELECTION rablepaPressurePressurerableClassCheck ValveNominal Sizepsi (bar)–––––ANSI 1500inmmCheck ValveAssembly WeightCompanionBody Group Weightw/Weld End ConnsBall Valvemm/2-112-25CCO1313/162184167BC013250CC1081 1/ 2381572913BC1082 1/ 01380CC2062 3/ 86029136530BB2093,705 psi CWPAPI 3000Port Diameterin1(250)Modellbkglbkg4100CC3023 1/ 879663012657BA3056,000 psi Test4100CA3103 5/ 8 1/ CC1081 1/ 2381572913BC1085,000 psi CWP2 1/ 265CC113113/164635166931BC113(350)380CC2062 3/ 86029136530BC2044100CC3023 1/ 879653012657BC30210,000 psi BB701BC8081–––––API 500010250CC8088 1/ CC1081 1/ 2381572913BC1086,170 psi CWP2 1/ 265CC113113/164635166931BC113(420)380CC2062 3/ 86029136530BC2044100CC3023 1/ 879653012657BC302BC4011–––––ANSI 250010,000 psi Test6150CC40141/1610320091400182(700)6150CC4104 5/ BC613110,000 psi CWP(700)API 1000010250CC8088 1/ 13BD108250CD1081 1/ 238401872332 1/ 40BD202BD21015,000 psi Test380CD2122 3/ 4340155660300BD60110250CD7127 3/ 41745802641050477BD7127

121110P B1413S E R I E SCHECK8VALVES19941382357610111412PB CHECK VALVE PARTS LISTIndexQty1121DescriptionStandard MaterialsNACE MaterialsOptional Materials(1)BodyCarbon Steel(2)Carbon Steel(2)316 SSAlloy Steel(3)Alloy Steel(3)17-4PH SS17-4PH SS17-4PH SSFlapper316 SSNitronic 6031Pivot Pin17-4PH SS41SpringInconel X-75017-4PH SSInconel X-75051Seat SealTeflon, Glass-FilledTeflon, Glass-Filled61Carrier / RetainerCarbon SteelCarbon Steel316 SS17-4PH SS71Seal, Carrier / RetainerNitrile, P/CVitonLow Temp Nitrile;Nitrile, P/CAflas; EPDM82Pin Support PlugStainless SteelStainless Steel92Support Plug SealNitrile, P/CViton102Swivel Flange112Bevel-for-Weld Nipple12213VariesCarbon SteelLow Temp Nitrile;Nitrile, P/CAflas; EPDMCarbon Steel316 SS316-LCarbon SteelCarbon SteelAlloy SteelAlloy SteelHalf Ring SetAlloy SteelAlloy SteelCap Screw, End ConnectionA193-B7 (Xylan)A193-B7 (Xylan)A320-L7 (Xylan)A320-L7M (Xylan)142End Connection Seal(1)Consult factory for other materials.(2)Employed up to and including 6,170 psi CWP valves(3)Employed on 10,000 psi CWP valvesNitrile, P/C8VitonLow Temp Nitrile;Nitrile, P/CAflas; EPDM

MANIFOLDSYSTEMSWater Flood InjectionHead AssemblyReverse Circulating Manifold2” 6,170 psi CWPManifold SystemSManifold System Fitting FeaturesPB Series Ball & Check Valves can be easily combined to fabricate anentire manifold system. Piper Valve Systems also manufactures acomplete line of fittings to assemble a manifold system. Te

Extra-Large Ball-To-Seat Contact Area reduces operating torque, assures positive sealing over the full range of pressures, and distributes the force between the ball and seat seal for reduced wear and extended service life. Valve Bonnet easily accommodates hydraulic or pneumatic actuators. Designed For Performance PB Series Ball Valves by Piper ValveFile Size: 1MBPage Count: 14