Transcription

I M PAC TR E P O R T2 0 17-18GUARANTEEMOMENTUMP E N N S Y LVA N I AC O L L EGEO FT EC H N O L OGY

PRESIDENT’S MESSAGE‘People make the difference’– then and nowIt has been two decades since I firstspoke to an all-college audience aboutthe foundation of a leadership philosophythat has always guided me in my roleas president of Pennsylvania College ofTechnology. “People make the difference”was as appropriate in 1998 as it is today,and it helps to explain the success storythat is Penn College.The college community knows howmuch I like to end my remarks with aninspiring quotation. As I was preparing my20th spring all-college address, nothingI found seemed sufficiently inspirational– or aspirational. Then I recalled myfirst address as a new president, and Iremembered the origin of “people makethe difference,” which has served as atouchstone for me ever since.As I reiterated for the faculty and staffwho gathered at the end of the 2017-18Academic Year: “You matter – you matterto your family, to our students and to yourcolleagues. Never doubt that you matter,and that what you do makes a difference.Please keep caring, sharing and believingin Penn College. I do.”Penn College has, in many ways,realized its aspiration to become a nationalleader in applied technology education.We have long known that our mission andmodel attract students who seek stable,lifelong employment in never-out-of-vogue1Penn College Impact Reportcareer fields. Increasingly, those beyondour immediate sphere are learning aboutthis former “best-kept secret,” nestledas we are in the mountains of northernPennsylvania, yet within a few hours’ driveof bustling metropolitan hubs. We are thecollege that produces the graduates whofill the jobs that the workforce needs – the“tomorrow makers,” as I like to call them.This progress would not be possiblewithout the steadfast support of thefaculty, staff, retirees, students and alumni– not to mention the donors, friends ofthe college and elected officials – whoserve as vocal ambassadors in our localcommunities, the region, the nation andthe world.To help us tell the compelling stories ofthe tomorrow makers who exemplify ourunique approach to higher education, weenlisted the support of an accomplishedbranding agency from one of theaforementioned metropolitan centers:Philadelphia-based 160over90. Theambitious campaign began with an inwardlook to identify the language and graphicelements that best convey our mission andvalues to the outside world. You may havealready seen evidence of this campaign ina wave of new printed marketing materials,ads, billboards and TV commercials – andin the refreshed design of this ImpactReport. Video and website refinements arealso on tap. I think you will be impressedwith the results – how they help define usand distinguish us from our peers.One of the highlights of an eventful2017-18 was the dedication of the Maj.Gen. Fred F. Marty Veterans and MilitaryResource Center, which serves as acomprehensive resource for the hundredsof veteran and military students we enrollat Penn College. The past year also markedthe launch of our Army ROTC program’snew affiliation with Bald Eagle Battalion,and our Penn College cadets are alreadytaking on key leadership roles.Construction took place throughoutSpring and Summer 2018 on the Dr.Welch Workshop: A Makerspace at PennCollege, which officially opened in Augustin the Carl Building Technologies Center.Many thanks to the Welch Family: MaryL. Welch and sons Scott, Graham andMarshall III, who dedicated a special giftto memorialize Dr. Marshall Welch Jr.Kudos also to the students who conceivedthe design for the space, which will fosterstudent, faculty and staff innovation:Thomas P. Abernatha, of Williamsport,and Christopher D. Fox, of York, who haveearned associate degrees in architecturaltechnology, and John A. Gondy, ofGlenmoore, a senior in residentialconstruction technology and management:architectural technology concentration.

PRESIDENT’S MESSAGEThe college was also fortunate tobe gifted with a facility by UPMCSusquehanna that, once renovations arecompleted, will serve as the new homefor practical nursing and other trainingprograms offered through Penn Collegeat Wellsboro.With the help of a U.S. EconomicDevelopment Administration Grant, wehave begun construction on a weldingChemical Appalachia’s multi-billiondollar petrochemical (ethane cracker)complex under construction less than 250miles away in Beaver County. The facilitywill employ 600 workers to produce theethylene that is used in products rangingfrom food packaging to automotive parts.The year saw an expansion of ourrelationship with SEKISUI SPI, whichhas been a valued partner of the collegeWe are the college that produces the graduateswho fill the jobs that the workforce needs –the “tomorrow makers.”expansion that will allow us to enroll upto 60 more welding students annuallyin a popular program that helps satisfythat industry’s demand for highlyskilled workers. The lab expansion,being constructed in the LycomingEngines Metal Trades Center (namedfor a company that employs many of ourgraduates and provides vital equipmentand advisory support) is expected to openfor the Fall 2019 semester.A generous gift from Shell Polymershas enhanced our efforts to provide highlyskilled graduates for another industry –plastics. The funding enables the collegeand our Plastics Innovation & ResourceCenter to enhance and upgrade theacademic and research lab now known asthe Shell Polymers Rotational MoldingCenter of Excellence. We envision someof our graduates playing a role in Shellfor years. It hires our graduates, providesinternships, sends employees to workforcetraining and works on projects with thePIRC. The company also supports studentscholarships and provides funding to bringthe SPE Foundation PlastiVan programhere to educate students in grade five andolder about the importance of plastics andcareers in the industry.I’m proud to say 2017-18 saw thebest participation ever in study abroadopportunities for our students, some ofwhom may have never before traveled outof the country or even flown in an aircraft.Global experiences can enrich the life ofany college student, but at Penn College,students often practice skills and provideservices related to their chosen careerfields, making a difference in people’slives in the bargain. A prime examplewas the nursing students’ participationin a volunteer-led medical clinic in ruralGuatemala, where chief among the lessonslearned were gratitude and patience.The students saw up to 300 patientsdaily, administering services related tooral health, pediatrics, obstetrics andgynecology, and general medicine. Checkout Penn College’s Instagram site for moreexamples of our wonderful study abroadinitiatives.To close the book on 2017-18 – andto offer inspiration for 2018-19 – allowme to finish with another quotation,this one from a tomorrow maker who isalready making his mark in the workforce:December 2017 welding and fabricationengineering technology graduate – andcommencement speaker – Garrett D.Corneliussen, employed by Tesla.“Penn College definitely made mypassion and dream a reality. I came inknowing what I wanted to do, but had noidea where it would take me, the peoplethat I would meet because of it, andthe experiences that I would have. Andcoming here just changed my whole lifecompletely, made me super excited aboutwhat I was learning, and just reinforcedeverything that I thought it would be, andis now sending me out into the real worldwith skills that I don’t think I could getanywhere else.”Our people mattered – and made thedifference – for Garrett and for manyothers like him. It is why, after 20 yearsas president, I continue to believe inPenn College.Garrett D. Corneliussen, now employed byTesla, captures an on-stage moment withPresident Davie Jane Gilmour while servingas the student speaker at the Winter 2017commencement ceremony. He earned abachelor’s degree in welding and fabricationengineering technology.2017-182

EMPOWERING INDUSTRYShell gift enhances college’sservice to plastics industryROTATIONAL MOLDINGappreciate Shell’s investment in ourstudents’ success.”Skilled manufacturing professionals arein high demand, and the plastics industryis no exception.Penn College addresses those needsthrough its academic offerings – abachelor’s degree in plastics and polymerengineering technology and an associatedegree in plastics and polymer technology– and through the training it offers toincumbent workers through the PIRC.“Shell believes in hands-on technologyeducation like that offered at PennCollege,” said Todd Whittemore, Shell’sgeneral manager for polyethylenetechnology. “As a key provider to theplastics industry, we see this as aninvestment in not only education, but theviability of our industry.”Penn College has the capacity togrow its plastics program and intendsto do so with a continued focus onproviding the finest education andtraining opportunities. In the next threeyears, the college anticipates that 150students will receive hands-on trainingon the new rotational molder, and at least100 incumbent workers are expected toparticipate in hands-on seminars at thePIRC, where 45 research-and-developmentprojects will be completed for plasticsfirms over the same period.CENTER OF EXCELLENCEIn Pennsylvania College ofTechnology’s plastics and polymerprogram, academic laboratories doubleas research labs for the college’s PlasticsInnovation & Resource Center.Faculty help to close the growing skillsgap in plastics manufacturing by makingstudents real-world ready, while the PIRChelps those already in industry throughresearch and development and workforcetraining.Often, students serve as researchassistants as the PIRC tests and developsnew materials and new processes forindustry partners. The undergrads areactively immersed in their future careers,seeing the impact their work will have onthe industries of tomorrow.A 250,000 gift from Shell Polymerswill enhance those efforts in the area ofrotational molding. The crucial sectorproduces items that are too thick forinjection or blow molding processes. Thefunding will enable the college to upgradean academic and research lab that has beenrenamed the Shell Polymers RotationalMolding Center of Excellence.“This support is important not only toPenn College, but to a niche industry thatdoes not have many places in the worldwith the capabilities offered here,” saidElizabeth A. Biddle, director of corporaterelations at Penn College. “We greatlyIn 2017-18, the Penn College Plastics Innovation & Resource Center completed 53 research- conducted 12 hosted nine open workshopsand-development andcustomized coursesfor 194 trainees in such topicscompounding projectsfor 193 trainees atas Lean Six Sigma Blackbelt,for 31 companiestheir workplacesInjection Molding, andTroubleshooting.3Penn College Impact Report

EMPOWERING INDUSTRYPlastics and polymer engineeringtechnology student Anthony P. Wagner,of Williamsport, shows a completedplastic test piece in the college’s ShellPolymers Rotational Molding Center ofExcellence. The center is set to receiveupgrades thanks to a donation fromShell. Wagner received his inspiration topursue a degree in plastics while hunting:He hopes to develop a new process forproducing waterfowl decoys.Apprenticeship programs beginIn May, the college formed theApprenticeship Center at Penn College.The center, inside the Center for Business& Workforce Development, provides aone-stop shop to coordinate programs forapprentices, companies, schools and otherorganizations.The college’s first apprenticeship consortiawere approved by the state, and in spring,participants from 14 companies begantraining in a mechatronics apprenticeshipand a CNC apprenticeship. The pilotprograms are delivered using in-personinstruction combined with remote learning.2017-184

EMPOWERING INDUSTRYKeeping workers ahead of the gameBoosting the health care workforceWorkforce Development & Continuing Education atPenn College provided training to 5,228 participantsin 2017-18.The college continues to help reduce shortages inthe health care workforce through its continuingeducation offerings. Emergency medicaltechnician training courses in Lycoming, Unionand Clinton counties graduated 46 participantsin 2017-18. The Practical Nursing Program inWellsboro produced 27 graduates. Almost 100percent of the licensed practical nurse graduateswere offered at least one position, and in somecases, several, prior to graduation.Among them, 35 Industrial courses – in topicssuch as programmable logic control, welding andblueprint reading – were delivered to 403 people.Thirty Business & Leadership courses weredelivered to 62 people in such areas as supervisortraining, project management and developingteam skills.Nearly 350 people received computer trainingat client-customized sessions or in openenrollment courses.The college’s National Sustainable StructuresCenter delivered 56 weatherization courses toprovide critical support for the state’s successfulpilot program in weatherizing multifamily dwellings.5Penn College Impact ReportIn its academic degree programs, the collegegraduated 19 emergency medical technician andparamedic students, and 143 nursing students.As a whole, 452 students graduated from theSchool of Nursing & Health Sciences, earningdegrees in nine health care fields.

EMPOWERING INDUSTRYSTUDENT PROFILELogan A. Tatemajor:plastics and polymer engineering technologyTate received five scholarships from the Society of Plastics Engineers in 2017-18. “Plastics hadn’tcrossed my mind until my cousin, who is in the industry, said, ‘Plastics is everything.’”“If physics is everywhere and plastics is everything, it only made sense to combine the two,”he told Plastics News, which named him one of the industry’s “Rising Stars” in August 2017.Tate graduated in May with a bachelor’s degree in plastics and polymer engineering technologyand accepted a position as a process engineer for medical technology company BD, confirmingthe wisdom of his choice.Tate is surprised by the lack of young professionals entering the plastics industry. “I have beento six conferences thus far, and the message is always the same: ‘Where are the graduates?’”he told Plastics News. “The industry is full of experienced professionals who are getting readyto pass the torch but who will they pass it to?”2017-186

INSPIRING INNOVATIONMakerspace launchesEvery project starts with an idea.Industrial design Professor ThomasE. Ask’s idea was to provide a place forstudents from every major to collaborate,create and bring their own ideas to life.The faculty member’s idea became areality when The Dr. Welch Workshop:A Makerspace at Penn College, openedin the Carl Building Technologies Centerin August. Designed by students in thearchitectural technology major, it housesa “clean space” (named The GilmourTinkertorium) and a “dirty space” (namedThe Logue Fabritorium).The clean space contains suchequipment as computers, a projectiondisplay system, 3D printers, electroniccomponents and instruments, vinyl cutters,sewing machines, and small hand andpower tools.Dirty space operations generally involvecutting wood, metal and plastics, as well aswelding and joining processes. Equipmentincludes drill presses, lathes, millingmachines, sanders, table and miter saws,routers, and grinders.“The equipment was the most importantpart,” said John A. Gondy, a student inresidential construction technology andmanagement: architectural technologyconcentration. “We designed the space forenough equipment to work any material,program or project. It can lend to any ofour various degrees.”Gondy was one of 10 students in theSpring 2017 session of ArchitecturalDesign Studio III who developed designsfor the space. The course was taught byRob A. Wozniak, associate professor ofarchitectural technology. A committeeselected three students’ designs and askedthem to combine them into one.“My vision was to bring studentsfrom different majors together and helpthem learn,” said Christopher D. Fox,who was chosen along with Gondy andThomas P. Abernatha. Fox and Abernatha7Penn College Impact Reportearned associate degrees in architecturaltechnology in 2017.“With the many students from variousmajors who will use this makerspace, itis hoped that they take the opportunityto collaborate with others. To create. Toexplore. To learn about the tools thatthey may otherwise never have been ableto have access to. To try another way ofdoing something. To invent – and maybeeven patent – something new,” Wozniaksaid. “And as a result, Penn College, thecommunity and the world will benefit.”The Dr. Welch Workshop: A Makerspaceat Penn College memorializes Dr. MarshallWelch Jr., a local orthodontist and longtimephilanthropist who died in 2012. TheWelch family, including son Marshall III, isthe principal donor for the facility.Marshall III said his father knew hewanted to be a dentist by the time he was ineighth grade.“The students of Penn College alsoappear to have amazing clarity at a veryyoung age,” he said. “They come to honetheir skills in dozens of majors across adizzying amount of fields. We hope themakerspace will add tremendous value totheir futures.”George E. “Herman” Logue Jr.supported The Logue Fabritorium, andFrederick T. Gilmour, faculty emeritus,made a commitment for The GilmourTinkertorium.Other individuals and companieswho have made leadership gifts to theproject are: William F. Geyer and DorothyJ. Gerring; Williams’ Atlantic SunriseProject; Young Industries Inc.; the AlbertsFamily; Al and Jane Clapps; AuroraGilmour, representing the Scott C. GilmourMemorial Fund; Bill and Veronica Muzic;and PPL Electric Utilities.STUDENT PROFILENina M. Haddenmajor:industrial designHadden’s list of dream jobs includesdesigning Nerf Blasters or Legos. Ordesigning equipment to help train themilitary’s working dogs. Maybe gettinginvolved in automotive or defensedesign. And working for the likes ofBoeing or Lockheed Martin.“As a designer it seems important tofind a niche, but to do that you haveto explore all the possibilities so youknow which one is right for you,”she said. “Our new makerspace isa valuable tool to nurture all of themakers at our school.”In high school, Hadden spent a greatdeal of time in the art room and washeavily involved with her school’srobotics team.“Industrial design is a nice mix of bothart and technical design,” she said,noting that she chose Penn College’sindustrial design program becauseof the college’s strength in teachingboth. “The opportunity to take coursesin plastics and automotive subjectsappealed to me, too.”“My hope for tomorrow is that themaker culture continues to grow,”she said. “Makers like to create newthings, as well as tinker with oldthings, which makes it unique.”Watch a time-lapse video of the Dr. Welch Workshop’sconstruction at magazine.pct.edu/ii

INSPIRING INNOVATIONInnovation majors commenceThe future needs innovators. Innovation isa process that can be taught, learned andapplied to any endeavor. New bachelor’sdegree offerings in applied innovation andentrepreneurial innovation teach studentsto develop meaningfully unique ideas, writebusiness plans, submit provisional patentapplications and use sales-forecasting tools.Students explore the makerspace’s equipment during an earlysemester open house at the new facility.An innovation lab opened in the BreuderAdvanced Technology & Health Sciences Centerin Fall 2017. The space has small- and largegroup work spaces equipped for collaborationand idea generation. Courses in innovation,marketing and information technology use thespace daily.2017-188

HELPING STUDENTS SUCCEEDVeterans and Military Resource Centerserves as ‘base of operations’Penn College opened the Maj. Gen.Fred F. Marty, USA Retired, Veterans andMilitary Resource Center to provide a sitefor veteran and active-duty students togather, collaborate, study and discuss theirmilitary benefits with campus mentors.“The transition is the hardest frommilitary to civilian,” said JenniferNicholson, a radiography student andemployee of the center, who says sheexperienced that struggle when shefinished her 10 years of service in theNavy. “(Veterans) have a place that theycan go that’s solely for them where theycan confide in us if they’re having issueswith adjustments and transitions.”The center is named for a 30-yearArmy veteran who commanded majormilitary units and installations in theUnited States and overseas. Marty earnedthe Distinguished Service Medal, theArmy’s highest peacetime award, andserved two tours in Vietnam. After retiringas the Army’s chief of field artillery, hereturned to his alma mater, MissouriState University, as vice president foradministrative services, and he laterserved as Lycoming County’s directorof administration. The center was madepossible through a gift from his family.The center includes a common officefor Army ROTC personnel and one forthe college’s coordinator of veteran andmilitary services, Chet Beaver, a 25-yearArmy veteran who earned two degreesand a certificate from the college.“We call it a base of operations forthem,” Beaver said. “We have computerstations here where they can do someof their military requirements, do theirhomework, meet and collaborate withother veterans.”Support for all studentsThe Tutoring Center provides free assistance to all students.The Academic Success Center provides study skillsworkshops, mentoring and many other services.The biannual Career Fair hosts nearly 240 employers seeking torecruit Penn College students and graduates for more than 2,700jobs and internships.Writing Center tutors help students develop writingassignments, including papers, lab reports, resumés, coverletters and capstone projects.The Dunham Children’s Learning Center provides accessto child care.Career Services provides mock interviews and resumé andbusiness card services.Research librarians are ready to help in the Madigan Library.9Penn College Impact ReportIn Fall 2017, 363 Penn College studentswere veterans, making up about 6 percentof the student body. Another 71 studentswere actively serving, and 20 were ArmyROTC participants.“We have things in common thingsto talk about,” said Pennsylvania AirNational Guard Staff Sgt. Gina M. Peluzzo,a civil engineering technology student.“You just like being around other peoplewho are similar to yourself, honestly.”“It is rare now that a school would havea person, and even better yet, a whole staff,that is totally dedicated to doing whatveterans need to keep them in school,”Beaver said.

HELPING STUDENTS SUCCEEDSTUDENT PROFILEGina M. Peluzzomajor:civil engineering technologyPeluzzo is a staff sergeant in the PennsylvaniaAir National Guard. She was deployed toQatar and Jordan, where she gained valuableengineering experience by helping to install andmaintain external communication infrastructure.She genuinely enjoys working with herhands. “There are so many labs and thingsyou do hands-on. I love that about thiscollege. What you do with your hands,you remember a lot more.”Peluzzo selected Penn College not onlybecause of its hands-on learningopportunities, but because of itsreputation as a veteran-friendly college.“I was really surprised that they had afull-time person employed just to helpmilitary members use their benefits thebest way they can,” she said. “And that’sa big deal because there’s a lot ofpaperwork involved.”2017-1810

PREPARING TOMORROW MAKERSPartnership yieldsworld-ready workforceFor nearly a century, Lycoming Engineshas helped to provide hands-on educationto students of Pennsylvania College ofTechnology and its predecessors.In October, the college’s AvcoLycoming Metal Trades Center became theLycoming Engines Metal Trades Center.Lycoming’s piston aircraft enginespower more than half the world’s generalaviation fleet. The manufacturer competesglobally from a single base of operations inWilliamsport, with a skilled workforce thatincludes many Penn College graduates.In fact, more than a quarter of thecompany’s 400-plus employees aregraduates of Penn College or one of itspredecessors.“Penn College is a strategic resource forcompanies like ours to remain competitivein the global marketplace,” said MichaelKraft, senior vice president and generalmanager of Lycoming Engines.Support from industry partners likeLycoming Engines has been equallyimportant to the college in preparingreal-world-ready graduates. The companyfunds three scholarships. It donatesequipment to academic programs –including a donation of 15 piston enginesvalued at 317,500 in June – and tools tothe college’s SAE Baja off-road race team.It frequently hosts student tours, andits employees serve on several programadvisory committees, helping to ensurethat the college’s curriculum meetstomorrow’s workforce needs.“Lycoming Engines is a much-valuedpartner of Penn College,” college PresidentDavie Jane Gilmour said.Since 1996, the college has beendesignated the authorized training centerfor the hands-on Lycoming Piston EngineService School.In 2017-18, the college conducted 18training events and four Road ServiceSchools in Switzerland, Ecuador, Spainand the United Kingdom.“That relationship has afforded usthe ability to bring people from all overthe world to campus,” said Shannon M.Munro, the college’s vice president forworkforce development. “In addition, ourinstructor has been able to travel to othercountries representing both LycomingEngines and Penn College.”Inside the Lycoming Engines Metal Trades Centeris a state-of-the-art welding laboratory wherebachelor- and associate-degree and certificategraduates are educated to fill in-demand positions.11Penn College Impact ReportA history that changed livesThe company’s relationship withthe college dates to when the industrialeducation coursework that would becomePenn College was part of a WilliamsportHigh School vocational educationprogram. Students gained hands-onexperience in local industry, including atthe company then known as the LycomingDivision of Aviation Corp., or AvcoLycoming.In the 1930s, high school studentKenneth E. Carl participated in a workstudy experience at Lycoming. Carl wouldlater become the director of Penn Collegepredecessor Williamsport TechnicalInstitute and the first president ofWilliamsport Area Community College.Later in the decade, war preparationhelped put Americans back to work afterthe Great Depression. By 1940, to meetthe training needs of local companieslike Lycoming, classes were in session 24hours a day. More than 5,000 studentswere enrolled in the high school’s trainingprograms.

PREPARING TOMORROW MAKERSRelationship continuesWhen the college offered its firstcomputer courses to the business sectorin 1984 in the Hager Lifelong EducationCenter, 20 Lycoming employees werethe first to enroll. The company hadcontributed funds to help build the center.The institution’s historic connectionexpanded in 1996, when Penn Collegewas named the worldwide LycomingAuthorized Training Center.The Williamsport-born institutionshave been partners in preparinggenerations to take on the world’schallenges. In the 1930s and ’40s,tomorrow makers did their part to fight aworld war. For current students, tomorrowis waiting.STUDENT PROFILELauren S. Herrmajor:construction managementHerr and fellow constructionmanagement student Julianna M.Reazor organized the Penn CollegeWomen in Construction Club’s second“Framing Your Future” event for highschool girls.“Witnessing a high school girl’s facelight up when her nail finally made itstraight into a 2 4 and pronouncing,‘I did it!’ was amazing,” Herr said.“‘Framing Your Future’ is such a specialevent to me because it encouragesand enlightens young girls on theopportunities in construction. Moreimportantly, not to be intimidated butactually intrigued by the industry.”Herr plans to graduate in May andalready has several job offers.2017-1812

PREPARING TOMORROW MAKERSFilling the jobs of tomorrowEncouraging teensContractors charged with repairing andupgrading the nation’s aging bridge andhighway infrastructure are begging forspecialists who understand the scienceof concrete.They are not the only ones. Concreteis one of the most widely usedconstruction materials.To fill that need, Pennsylvania College ofTechnology’s School of Construction &Design Technologies, working with inputfrom industry representatives, initiated aconcrete science technology associatedegree.Offering a mixture of science, technologyand construction education, the programoffers the only associate degree on theEast Coast.Industry-valued credentials, such asthe American Concrete Institute andInsulated Concrete Forms certifications,are embedded in the curriculum.Penn College offered 12 summercamps to help high-schoolersexplore careers in its state-of-theart facilities. From “ArchitecturalOdyssey” to “Health CareersCamp,” campers immersed inhands-on activities to help themchart their futures.13Penn College Impact Report

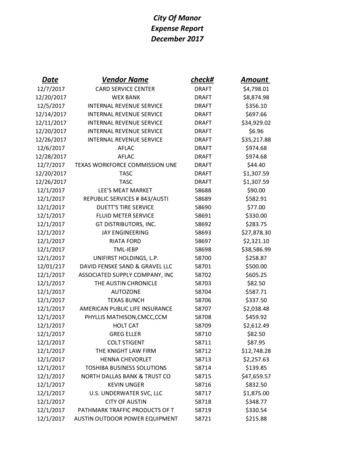

Operating Budget . . . . . . . . . . . . . . . . . . . . . . . 114,157,5752017-18 FUNDINGState Appropriation . . . . . . . . . . . . . . . . . . . . . . 22,470,000Restricted FundsGrants, contracts and restricted donations . . . . . . . . . . . 13,287,000Auxiliary Funds . . . . . . . . . . . . . . . . . . . . . . . . . . 28,009,324TUITION & FEESPENNSYLVANIA RESIDENTSTuition per credit hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 462Tuition and fees per credit hour . . . . . . . . . . . . . . . . . . . . . . . 545Annual tuition and fees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16,350based on 15 credits per semesterIncrease over prior year (tuition-only): 1.99 percentIncrease over prior year (tuition and fees): 1.68 percentOUT- OF-STATE RESIDENTSTuition per credit hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6931Tuition and fees per credit hour . . . . . . . . . . . . . . . . . . . . . . . . 776Annual tuition and fees .

apprentices, companies, schools and other organizations. The college's fi rst apprenticeship consortia were approved by the state, and in spring, participants from 14 companies began training in a mechatronics apprenticeship and a CNC apprenticeship. The pilot programs are delivered using in-person instruction combined with remote learning.