Transcription

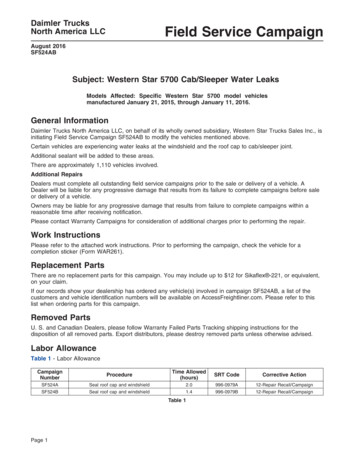

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524ABSubject: Western Star 5700 Cab/Sleeper Water LeaksModels Affected: Specific Western Star 5700 model vehiclesmanufactured January 21, 2015, through January 11, 2016.General InformationDaimler Trucks North America LLC, on behalf of its wholly owned subsidiary, Western Star Trucks Sales Inc., isinitiating Field Service Campaign SF524AB to modify the vehicles mentioned above.Certain vehicles are experiencing water leaks at the windshield and the roof cap to cab/sleeper joint.Additional sealant will be added to these areas.There are approximately 1,110 vehicles involved.Additional RepairsDealers must complete all outstanding field service campaigns prior to the sale or delivery of a vehicle. ADealer will be liable for any progressive damage that results from its failure to complete campaigns before saleor delivery of a vehicle.Owners may be liable for any progressive damage that results from failure to complete campaigns within areasonable time after receiving notification.Please contact Warranty Campaigns for consideration of additional charges prior to performing the repair.Work InstructionsPlease refer to the attached work instructions. Prior to performing the campaign, check the vehicle for acompletion sticker (Form WAR261).Replacement PartsThere are no replacement parts for this campaign. You may include up to 12 for Sikaflex -221, or equivalent,on your claim.If our records show your dealership has ordered any vehicle(s) involved in campaign SF524AB, a list of thecustomers and vehicle identification numbers will be available on AccessFreightliner.com. Please refer to thislist when ordering parts for this campaign.Removed PartsU. S. and Canadian Dealers, please follow Warranty Failed Parts Tracking shipping instructions for thedisposition of all removed parts. Export distributors, please destroy removed parts unless otherwise advised.Labor AllowanceTable 1 - Labor AllowanceCampaignNumberProcedureTime Allowed(hours)SRT CodeCorrective ActionSF524ASF524BSeal roof cap and windshieldSeal roof cap and windshield2.01.4996-0979A996-0979B12-Repair Recall/Campaign12-Repair Recall/CampaignTable 1Page 1

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524ABIMPORTANT: When the campaign has been completed, locate the base completion label in the appropriate location on the vehicle, and attach the gray completion sticker provided in the field service kit (Form WAR261). Ifthe vehicle does not have a base completion label, clean a spot on the appropriate location of the vehicle andfirst attach the base completion label (Form WAR259). If a field service kit is not required or there is no completion sticker in the kit, write the campaign number on a blank sticker and attach it to the base completion label.Claims for CreditYou will be reimbursed for your parts, labor, and handling (landed cost for Export Distributors) by submittingyour claim through the Warranty system within 30 days of completing this campaign. Please reference thefollowing information in OWL: Claim type is Field Service Campaign. In the Campaign field, enter the campaign number and appropriate group (SF524-A or SF524-B). In the Primary Failed Part field, enter 25-SF524-000. In the Parts section, you may include up to 12.00 for Sikaflex -221 silicone, or equivalent, on your claim. In the Labor section, enter the appropriate SRT from the Labor Allowance Table. Administrative time willbe included automatically as SRT 939-6010A for 0.3 hours. The VMRS Component Code is 002-006-001 and the Cause Code is A1 - Campaign.This Field Service Campaign will terminate on August 31, 2017. Dealers will be notified of any changes to thetermination date via Important Campaign Information Letter posted on AccessFreightliner.com.IMPORTANT: OWL must be viewed prior to beginning work to ensure the vehicle is involved and the campaignhas not previously been completed. Also, check for a completion sticker before beginning work.All claims must be submitted within 30 days of the repair and within 30 days of the termination date of thecampaign. U.S. and Canadian Dealers: All excess inventory to be returned to the PDC following the conclusionof the campaign must be returned in resaleable condition to the Memphis PDC within 90 days from thetermination date. Please submit a PAR to request return to the Memphis PDC. (Canadian dealers should returnthe kits to their facing PDC.) Export Distributors: Excess inventory is not returnable.For questions, U.S. and Canadian dealers, contact the Warranty Campaigns Department from 7:00 a.m. to 4:00p.m. Pacific Time, Monday through Friday, via Web inquiry at AccessFreightliner.com / Support / My Ticketsand Submit an Inquiry, or the Customer Assistance Center at (800) 385-4357, after normal business hours, ifyou have any questions or need additional information. Export distributors submit a Web inquiry or contact yourInternational Service Manager.Page 2

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524ABCopy of Notice to OwnersSubject: Western Star Cab/Sleeper Water LeaksDaimler Trucks North America LLC, on behalf of its wholly owned subsidiary, Western Star Trucks Sales Inc., isinitiating Field Service Campaign SF524AB to modify specific Western Star 5700 model vehicles manufacturedJanuary 21, 2015, through January 11, 2016.Certain vehicles are experiencing water leaks at the windshield and the roof cap to cab/sleeper joint.Additional sealant will be added to these areas.Please contact an authorized Daimler Trucks North America dealer to arrange to have the campaign performedand to ensure that parts are available at the dealership. To locate an authorized dealer, search online atwww.Daimler-TrucksNorthAmerica.com / Contact Us / Find a Dealer. The campaign will take approximately 2hours and will be performed at no charge to you.This Field Service Campaign will terminate on August 31, 2017. Please make sure the campaign is completedprior to this date. Work completed after this date will be done at the customer’s expense.As stated in the terms of your express limited warranty, Daimler Trucks North America LLC will not pay for anydamage caused by failure to properly maintain your vehicle. Daimler Trucks North America LLC considers thework necessary under this campaign to be proper maintenance and will, therefore, not pay for any damage toyour vehicle caused by your failure to have the repairs that are the subject of this campaign performed in areasonable time.Contact the Warranty Campaigns Department at (800) 547-0712, from 7:00 a.m. to 4:00 p.m. Pacific Time,Monday through Friday, e-mail address DTNA.Warranty.Campaigns@Daimler.com, or the Customer AssistanceCenter at (800) 385-4357, after normal business hours, if you have any questions or need additionalinformation.WARRANTY CAMPAIGNS DEPARTMENTEnclosurePage 3

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524ABWork InstructionsSubject: Western Star 5700 Cab/Sleeper Water LeaksModels Affected: Specific Western Star 5700 model vehiclesmanufactured January 21, 2015, through January 11, 2016.Perform the appropriate procedure below: SF524-A: Follow Sleeper Cab Sealant procedure below. SF524-B: Follow the Day Cab Sealant procedure on page 11.SF524A Sleeper Cab Sealant Procedure1. Check the base label (Form WAR259) for a completion sticker for SF524 indicating this work has beendone. The base label is usually located on the passenger-side door about 12 inches (30 cm) below the doorlatch. If a sticker is present, no work is needed. If there is no sticker, proceed with step 2 below.2. Park the vehicle on a level surface, shut down the engine and set the parking brake. Chock the tires.3. Remove the forward fairing panels as follows:3.1Remove the eight fasteners that attach the upper and lower aluminum treads to the forward fairingpanel and rails, then remove the treads. See Fig. 1.NOTICEDo not hold the panel by the slots on the steps, as they are not designed to bear the weight of thepanel, and may crack.3.2Hold the panel by the outer edges and remove it.03/18/2015f602545Fig. 1, Fastener Locations on Fairing TreadsPage 4

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524AB4. If the rear edges of the cab-to-sleeper transition panels are not attached with fasteners to the sleeper skin,install rivnuts using the procedure in "Adding Fasteners to a Transition Panel" on page 7.If the rear edges of the cab-to-sleeper transition panels are attached with fasteners to the sleeper skin, proceed to the next step.5. Remove the transition panel fasteners.If the rear edges of the transition panels are not attached with adhesive to the sleeper skin, remove thepanel and the proceed to the next step.If the transition panels are attached with adhesive to the sleeper skin, detach the panels using the procedure in "Removing a Transition Panel Attached with Adhesive" on page 10.6. Clean the surfaces to be sealed at: the roof cap seam in the rain tray, from the cab/sleeper/roof joint to the upper mirror mount; the gap under the rain tray at the cab/sleeper/roof joint (see Fig. 2 ).7. Apply masking tape above the seam in the rain tray and on the lip of the of the rain tray. See Fig. 3.8. Apply a bead of Sikaflex -221, or equivalent, to the seam in rain tray. See Fig. 4.9. Seal the gap at the joint below the rain tray. See Fig. 5.21304/29/2016f602581Fig. 3, Masking the Areas to Be Sealed05/02/2016f6025851. Cab Rain Tray2. Sleeper Rain Tray3. GapFig. 2, Cab/Sleeper/Roof Joint04/29/2016f602582Fig. 4, Applying SealantPage 504/29/2016f602583Fig. 5, Sealing the Gap

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524AB10. Smooth the sealant by running a wetted finger over the bead. See Fig. 6.04/29/2016f602584Fig. 6, Smoothing the Sealant Bead11. Allow the sealant to cure as specified by the sealant instructions, then remove the masking tape.12. Prepare a wash solution of at least one-quarter cup of soap to one gallon of water in a spray bottle.13. Close all doors, windows, and vents.14. With the HVAC system in "Fresh Air" mode, turn the fan blower motor on high.NOTE: Perform the leak detection test with the HVAC system in the "Fresh Air" mode only. Do not set the system in the "Recirculation" mode.15. Spray the rain tray and the windshield seal with the solution.NOTE: This method of leak detection may also identify areas that will not leak water, even though those areasproduce bubbles. If small bubbles are found in an area that is not suspected to leak, a repair may not be necessary.16. Mark areas of suspected leaks.17. If no leak is found, go to step 19.If a leak is found in the rain tray, seal an 8 to 10-inch (20 to 25-cm) length of the rain tray centered at thelocation of the suspected leak.If a leak is found at the windshield seal, spot seal at the location of the leak.NOTE: The external sun visor may need to be removed before spot sealing the windshield.18. Allow the sealant to cure as specified by the sealant instructions, then perform the leak test at the repairedlocations.19. Rinse the wash solution off the vehicle with water.20. Turn off the fan blower motor.IMPORTANT: Carefully hand-tighten the machine screws, making sure no dents are made in the transition panels.21. Install the cab-to-sleeper transition panels, using the washers and machine screws. Carefully hand-tightenthe machine screws.Page 6

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524AB22. Install the forward fairing panels as follows:22.1Position the forward fairing panel on the step-support rails.22.2Position the upper and lower aluminum treads on the panel, then install the eight fasteners. See Fig.1 on page 4. Tighten the capscrews 14 to 18 lbf·ft (19 to 25 N·m).23. Clean a spot on the base label (Form WAR259). Write the campaign number, SF524, on a blank greycompletion sticker (Form WAR261) to indicate the work has been completed and attach it to the base label.Adding Fasteners to a Transition Panel1. Measure and mark three drilling locations on the transition panel, as shown in Fig. 7. Use masking tape formarking and to protect the finish.2. Using a 25/64-inch drill bit, drill through BOTH the transition panel and the sleeper skin at the marked rement:Measurement:Measurement:f6025662-3/16 in (56 mm)54-13/16 in (1393 mm)36 in (915 mm)16-7/8 in (428 mm)1. Existing FastenerFig. 7, Drilling Locations (LH panel shown)Page 7

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524AB3. Drill 9/16-inch holes through the transition panel ONLY, as follows.3.1Install a stop collar 1/8 inch (3 mm) from the end of the cutting edge of a 9/16-inch drill bit. If a stopcollar is not available, make a stop using tape wrapped around the bit, 1/8 inch (3 mm) from the endof the cutting edge. Use enough layers of tape to create an effective stop. See Fig. 8IMPORTANT: Do not drill the 9/16-inch hole through the sleeper skin. Drilling through the sleeper skin willmake it impossible to install the rivnuts.3.2At the drilling locations, drill ONLY through the transition panel, using the 9/16-inch drill bit equippedwith the stop collar or tape stop. See Fig. 9.3.3Smooth the edges of the 9/16-inch hole and clean off any debris. See Fig. 10.A08/14/201508/14/2015f602560f602558Fig. 9, Drilling the 9/16-inch HolesA. Measurement: 1/8 in (3 mm)Fig. 8, Making a Stop for the Drill Bit08/14/2015f602561Fig. 10, Cleaning the 9/16-Inch HolePage 8

Daimler TrucksNorth America LLCField Service CampaignAugust 2016SF524AB4. Install the rivnuts (WWS 4013-3435), as follows:4.1Thread a provided machine screw (23-12011-100) a couple of turns into the rivnut.4.2Insert the rivnut in the drilled hole.4.3Lightly tap in the screw and rivnut. See Fig. 11.4.4.Remove the screw from the rivnut. Make sure the flange of the rivnut is seated against the sle

Daimler Trucks North America LLC, on behalf of its wholly owned subsidiary, Western Star Trucks Sales Inc., is initiating Field Service Campaign SF524AB to modify the vehicles mentioned above. Certain vehicles are experiencing water leaks at the windshield and the roof cap to cab/sleeper joint. Additional sealant will be added to these areas. There are approximately 1,110 vehicles involved .

![OHN1-I EMP, LLC, dba Sa]em North Healthcare Center 07/13 .](/img/9/osha20201392.jpg)