Transcription

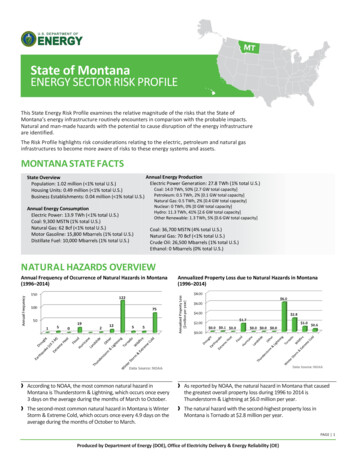

Directive 060Release date: April 6, 2022Effective date: April 6, 2022Replaces previous edition issued April 21, 2021Upstream Petroleum Industry Flaring, Incinerating, and VentingContents12Introduction . 61.1Purpose of This Directive . 61.2What’s New in This Edition . 61.3Flaring, Incineration, and Venting Management Hierarchy and Framework . 61.4Access to Production Flaring, Incineration, and Venting Data . 81.5AER Requirements . 81.6Frequency . 91.7Notification Through the Designated Information Submission System . 91.8Review and Revision . 9Solution Gas Management (Crude Oil / Bitumen Battery Flaring, Incineration, and Venting) . 102.1Solution Gas Flaring Reduction Targets . 102.2Solution Gas Venting Reduction . 102.3Solution Gas Flaring and Venting Decision Tree . 112.4Conservation at Crude Bitumen Batteries . 112.5Conservation at Conventional Crude Oil Batteries . 122.6General Conservation Requirements at all Condensate Producing Sites and Crude Oil andCrude Bitumen Batteries. 132.7Clustering . 142.8Power Generation Using Otherwise-Flared/Vented Gas . 152.9Economic Evaluation of Gas Conservation . 152.9.1Economic Evaluation Criteria . 152.9.2AER Economic Evaluation Audit Requirements . 172.10 Public Involvement . 182.10.1 Public Information Package . 182.11 Nonroutine Flaring, Incineration, and Venting at Solution Gas Conserving Facilities . 19Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)1

Alberta Energy Regulator2.11.1 Limitations on Nonroutine Flaring, Incineration, and Venting During Outages at SolutionGas Conserving Facilities . 192.11.2 Planned Shutdown (Turnaround) Considerations . 212.11.3 Alternatives to Solution Gas Shut-in Requirements . 212.12 Royalty Treatment of Flared and Vented Gas . 212.13 Solution Gas Reporting Requirements and Data Access . 222.13.1 Solution Gas Reporting Requirements . 222.13.2 Cooperating with Third Parties . 223Temporary and Well Test Flaring and Incinerating . 233.1Temporary Flaring and Incinerating Decision Tree . 233.2Oil and Gas Well Test Flaring, Incinerating, and Venting Duration Limits. 243.3Temporary Flaring/Incineration Permits. 263.3.1Conditions That Require a Temporary Flaring/Incineration Permit . 263.3.2Conditions That Do Not Require a Temporary Flaring/Incineration Permit. 283.4Flaring and Incineration Permits for Underbalanced Drilling . 293.5Permit Requirements for Temporary Flares and Incinerators . 293.5.1General Permit Requirements . 303.5.2Requests to Exceed the Volume Allowance Threshold . 303.5.3Blanket Flaring/Incineration Permits. 313.5.4AER Review of Permit Requests . 323.6Site-Specific Requirements Related to Well Flaring and Incineration . 323.7Temporary Facilities for In-Line Tests . 333.8Notification Requirements . 343.93.8.1Addressing Resident Concerns . 373.8.2AER Flaring/Incinerating/Venting Notice Form . 37Reporting Gas Well Test Data . 373.10 Zero Flaring Agreements . 384Gas Battery, Dehydrator, and Compressor Station Flaring, Incinerating, and Venting . 394.1Gas Battery, Dehydrator, and Compressor Station Flaring, Incinerating, and Venting DecisionTree. 395624.2Notification . 404.3Reporting . 40Gas Plant Flaring, Incinerating, and Venting . 415.1Gas Plant Flaring, Incinerating, and Venting Decision Tree . 415.2Gas Plant Flaring/Incineration/Venting Volume Limits . 425.3Frequent Nonroutine Flaring/Incineration/Venting Events . 435.4Notification . 445.5Measurement and Reporting . 44Pipeline Flaring, Incinerating, and Venting . 46Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)

Alberta Energy Regulator76.1Pipeline Systems Flaring, Incineration, and Venting Decision Tree . 466.2Additional Requirements for Gas Gathering Systems . 476.3Natural Gas Transmission Systems . 486.4Notification . 48Performance Requirements . 497.1Conversion Efficiency . 507.1.1Heating Value and Exit Velocity for Flares . 507.1.2Minimum Residence Time and Exit Temperature for Incinerators . 517.1.3Design and Operating Parameters for Enclosed Combustors . 537.2Smoke Emissions . 547.3Ignition . 547.3.1Requests to Extinguish Sour Flare Pilots at All Batteries. 557.4Stack Design . 567.5Sour and Acid Gas Flaring/Incineration Procedures . 577.6Liquid Separation . 577.6.1Exceptions to Separator Requirements. 597.7Backflash Control . 597.8Flare and Incinerator Spacing Requirements . 607.9Compliance with Fire Bans . 617.10 Noise . 617.11 Flare Pits . 617.12 Dispersion Modelling Requirements for Sour and Acid Gas Combustion . 627.12.1 Modelling Approach . 637.12.2 Individual Source . 637.12.3 SO2 Cumulative Emissions Assessment . 647.12.4 Temporary and Well Test Flaring Dispersion Modelling . 647.12.5 Nonroutine Flaring and Dispersion Modelling . 668Vent Gas Limits and Fugitive Emissions Management . 718.1Methane Reduction Retrofit Compliance Plan . 728.2Measurement and Reporting of Methane Emissions. 728.3Overall Vent Gas Limit . 738.3.18.4Exceptions . 73Defined Vent Gas Limit . 738.4.1Reporting . 738.4.2Exceptions . 748.5Vent Gas Limits for Crude Bitumen Batteries . 748.6Equipment-Specific Vent Gas Limits . 748.6.1Vent Gas Limits for Pneumatic Devices . 748.6.2Vent Gas Limits for Compressor Seals . 75Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)3

Alberta Energy Regulator8.6.3Vent Gas Limits for Glycol Dehydrators . 788.7Additional Requirements . 798.8Requirements for Venting Gas Containing H2S or Other Odorous Compounds . 808.9Noncombustible Vent Gas Requirements . 818.10 Fugitive Emissions Management . 818.10.1 Fugitive Emissions Management Program . 818.10.2 Fugitive Emissions Surveys . 828.10.3 Fugitive Emissions Screenings . 848.10.4 Repairs . 858.10.5 Reporting . 858.10.6 Alternative Fugitive Emissions Management Program . 868.11 Methane Emissions Record Keeping. 869Sulphur Recovery Requirements and Sour Gas Combustion . 899.1Sulphur Recovery Exemption at Solution Gas Conservation Facilities . 8910 Measurement and Reporting . 9110.1 Flaring, Incineration, and Venting Records (Logs) . 91Appendix 1References and Contacts Cited . 92Appendix 2Definitions of Terms as Used in Directive 060 . 94Appendix 3Abbreviations . 101Appendix 4Background to Directive 060 . 102Appendix 5Permit Request for Flare or Incinerate Exceedance . 105Appendix 6Sour Gas Flaring/Incineration Data Summary Report. 107Appendix 7Air Quality Management Plans for Temporary SO2 Emissions . 108Appendix 8Screening Dispersion Modelling Using AER Spreadsheet. 110Appendix 9Resident Flaring/Venting/Incinerating Notification Sample Form . 113Appendix 10Agreement on Zero Flaring and Venting Agreement . 114Appendix 11Request to Extinguish Sour Gas Flare Pilots . 115Appendix 12Mandatory Elements of a Fugitive Emissions Management Program . 117Appendix 13Fugitive Emissions Record Keeping. 118FiguresFigure 1.Solution gas flaring/venting management framework (adapted from CASA) . 8Figure 2.Solution gas flaring/venting decision tree (adapted from CASA) . 11Figure 3.Temporary flaring and incineration decision tree (adapted from CASA). 24Figure 4.Temporary flaring/incineration permit process . 28Figure 5.Facility flaring, incinerating, and venting decision tree (adapted from CASA) . 39Figure 6.Facility flaring, incinerating, and venting decision tree (adapted from CASA) . 42Figure 7.Pipeline flaring, incinerating, and venting decision tree (adapted from CASA) . 47Figure 8.Comprehensive management of the nonroutine flaring of sour gas . 67Figure 9.Flare management strategy flowchart . 704Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)

Alberta Energy RegulatorFigure 10.Methane emission sources covered under section 8 . 71Figure 11.Process for developing and implementing a methane reduction retrofit compliance plan 72TablesTable 1.Requirements during outage of a solution gas conserving facility . 20Table 2.Temporary flaring, venting, and incineration notification requirements1 . 35Table 3.Major flaring event definition . 43Table 4.Frequency of fugitive emissions surveys by equipment or facility type . 83Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)5

Alberta Energy Regulator1Introduction1.1Purpose of This DirectiveThe Alberta Energy Regulator (AER) Directive 060: Upstream Petroleum Industry Flaring,Incinerating, and Venting contains the requirements for flaring, incinerating, and venting in Albertaat all upstream petroleum industry wells and facilities. Directive 060 requirements also apply topipeline installations that convey gas (e.g., compressor stations, line heaters) licensed by the AERin accordance with the Pipeline Act. With the exception of oil sands mining schemes andoperations, Directive 060 applies to all schemes and operations approved under section 10 of theOil Sands Conservation Act (OSCA). Directive 060 does not apply to any processing plantsapproved under section 11 of the OSCA.Most of these requirements have been developed in consultation with the Clean Air StrategicAlliance (CASA) to eliminate or reduce the potential and observed impacts of these activities andto ensure that public safety concerns and environmental impacts are addressed before beginning toflare, incinerate, or vent. Directive 060 requirements are also aligned to ensure compliance withAlberta Environment and Parks (AEP) Alberta Ambient Air Quality Objectives and Guidelines(AAAQO).Note: Appendices have been included to further the understanding of Directive 060 requirements.See appendix 1 for a list of references and contacts, appendix 2 for definitions of terms, andappendix 3 for abbreviations.1.2What’s New in This EditionInterim Directive 2003-01 was replaced by Directive 087. References have been updated.References to IL 98-01 have been removed as the information letter has been rescinded. Explicitconditions have been added to table 1 to indicate when the AER field centre must be notified of anevent.1.3Flaring, Incineration, and Venting Management Hierarchy and FrameworkFlaring, incinerating, and venting are associated with a wide range of energy development activitiesand operations, including disposal of gas associated with6 oil, bitumen, and gas well drilling; oil, bitumen, and gas well completion or well servicing (well “cleanup”); gas well testing to estimate reserves and determine productivity; routine oil or bitumen production (solution gas); planned nonroutine depressurizing of processing equipment and gas pipelines for maintenance;Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)

Alberta Energy Regulator unplanned nonroutine depressurizing of process equipment and gas pipelines due to processupsets or emergency; and oilfield waste management facilities.Two multistakeholder teams from CASA have made recommendations for flaring, incineration, andventing for the upstream petroleum industry, and the AER has based this directive on thoserecommendations (see appendix 4 for background on Directive 060).In particular, the AER has adopted CASA’s objective hierarchy and its framework for managingroutine solution gas flares (see figure 1; www.casahome.org) and has extended its application of thehierarchy to include flaring, incineration, and venting of gas in general. 1In accordance with the objective hierarchy, licensees, operators, and approval holders must evaluatethe following three options:1 Can flaring, incineration, and venting be eliminated? Can flaring, incineration, and venting be reduced? Will flaring, incineration, and venting meet performance standards?See CASA’s website www.casahome.org.Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)7

Alberta Energy RegulatorFigure 1. Solution gas flaring/venting management framework (adapted from CASA)1.4Access to Production Flaring, Incineration, and Venting DataThe AER reports flaring, incineration, and venting volumes annually in the ST60B: UpstreamPetroleum Industry flaring report on the AER website www.aer.ca.The AER also makes flaring, incineration, and venting information available to licensees, operators,and approval holders in order to facilitate solution gas conservation and clustering opportunities, asdescribed in section 2.13.1.5AER RequirementsFollowing AER requirements is mandatory for the responsible duty holder, as specified inlegislation (e.g., licensee, operator, company, applicant, approval holder, or permit holder). Theterm “must” indicates a requirement, while terms such as “recommends” and “expects” indicate arecommended practice.Each AER requirement is numbered.8Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)

Alberta Energy RegulatorInformation on compliance and enforcement can be found on the AER website.1.6FrequencyFor the purposes of this directive, terms like annually or quarterly are defined as follows: Monthly is at least once per calendar month. Bimonthly is at least once every two consecutive calendar months. Quarterly means at least once per calendar quarter. Calendar quarters are January to March,April to June, July to September, and October to December. Triannually means at least once per four calendar months. Annually means at least once every four calendar quarters.Example: If a survey needs to be done annually and the last survey occurred in May 2019 (secondquarter), the operator has to perform another survey by the end of the second quarter of 2020(June 30).1.7Notification Through the Designated Information Submission SystemThe licensee, operator, or approval holder must notify the appropriate AER field centre beforeplanned flaring, venting, or incineration operations by completing and submitting an AERflaring/incineration/venting notice form within the designated information submission system. TheAER strongly encourages all licensees, operators, and approval holders to follow the FIS Web UserGuide when completing and submitting this form. Any operations that may result in a publiccomplaint must be called in to the appropriate AER field centre’s 24-hour emergency phonenumber (see appendix 1).For questions on using FIS, contact the FIS administrator by email at FIS.Administrator@aer.ca orby telephone at 403-297-4845.1.8Review and RevisionThe AER will review the methane emission requirements in this directive no later thanDecember 31, 2022, taking into account the efficiency and effectiveness of the requirements in reducing methane emissions to meet theoutcome of a 45 per cent decrease by 2025 relative to 2014 levels; and developments in practices, processes, and technologies to control methane emissions.Based on the outcome of the review, requirements may be revised.Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)9

Alberta Energy Regulator2Solution Gas Management (Crude Oil / Bitumen Battery Flaring, Incineration, andVenting)The AER’s goal is to have the upstream petroleum industry continue to reduce the volume ofsolution gas routinely flared, incinerated, and vented. The AER expects that the upstream petroleumindustry will pursue continuous improvement in reducing solution gas flaring, incineration, andventing in Alberta, and, in consultation with stakeholders, will monitor progress to determine theneed for additional requirements to facilitate increased solution gas conservation.Combustion of solution gas in incinerators is not considered an alternative to conservation.For solution gas management and disposition reporting, incinerated gas must be reported as flared.Conservation is defined as the recovery of solution gas for use as fuel for production facilities, forother useful purposes (e.g., power generation), for sale, or for beneficial injection into an oil or gaspool (e.g., pressure maintenance, enhanced oil recovery). Conservation opportunities are evaluatedas economic or uneconomic based on the criteria listed in section 2.9.In this section, for the “combined flared and vented volumes” the vented volumes must not exceedthe vent gas limits in section 8.2.1Solution Gas Flaring Reduction TargetsDirective 060 incorporates recommendations made by CASA in 2002, 2004, and 2005 to reduceflaring.1) The Alberta solution gas flaring limit is 670 million cubic metres (106 m3) per year (50 per centof the revised 1996 baseline of 1340 106 m3/year).2) If solution gas flaring exceeds the 670 106 m3 limit in any year, the AER will impose reductionsthat will stipulate maximum solution gas flaring limits for individual operating sites based onanalysis of the most current annual data so as to reduce flaring to less than 670 106 m3/year. Forexample, solution gas flaring could be limited to a maximum of 500 thousand (103) m3/year atany one site.2.2Solution Gas Venting ReductionThe AER does not consider venting an acceptable alternative to flaring. If venting is the onlyfeasible alternative, the requirements in section 8 must be met.In 2005, 59 per cent less solution gas was vented than in 2000. The CASA Flaring and VentingProject Team considered solution gas venting in the report, Gas Flaring and Venting in Alberta:Report and Recommendations for the Upstream Petroleum Industry by the Flaring/Venting Project10Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)

Alberta Energy RegulatorTeam, which it released in 2004. 2 The AER accepts these recommendations and has incorporatedthem into Directive 060.2.3Solution Gas Flaring and Venting Decision TreeThe AER adopted the solution gas flaring/venting management framework (figure 1) and endorsesthe solution gas flaring and venting decision tree process (figure 2) as recommended by CASA. Thelicensee or operator must apply this decision tree to combined flaring and venting of more than900 m3/day and be able to demonstrate how each element of the decision tree was considered and,where appropriate, implemented.Figure 2. Solution gas flaring/venting decision tree (adapted from CASA)2.4Conservation at Crude Bitumen BatteriesFor the purpose of Directive 060, crude bitumen battery is defined in appendix 2.1) The licensee or operator of a multiwell bitumen site must build solution gas conservation linesto one common point on the lease as part of initial construction.2) For new bitumen wells, the test period (excluding completion and cleanup operations) limit iseither six months or until combined flared and vented volumes at the site exceed a rollingaverage of 900 m3/day for any consecutive three-month period, whichever is less.2This and other reports from this team are available on CASA’s website, www.casahome.org.Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting (April 2022)11

Alberta Energy Regulatora) As soon as testing shows that combined flaring and venting volumes at the site exceed900 m3/day, conservation must be evaluated as described in section 2.9. Volumes arecalculated based on a three-month rolling average.b) If conservation is required, it must occur as quickly as po

Directive 060 Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting April ( 2022) 1 . Release date: April 6, 2022 Effective date: April 6, 2022