Transcription

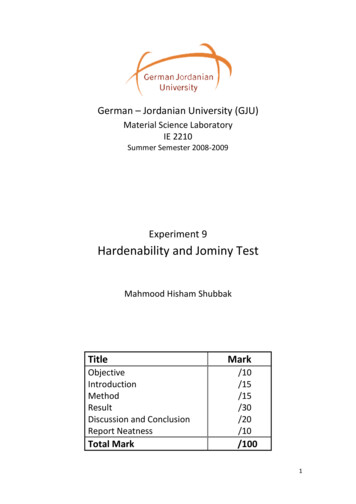

German – Jordanian University (GJU)Material Science LaboratoryIE 2210Summer Semester 2008‐2009iiExperiment 9Hardenability and Jominy TestMahmood Hisham iscussion and ConclusionReport Neatness/10/15/15/30/20/10Total Mark/1001

Objective:1. Distinguish between hardness and hardenability.2. Understand the concept of mass effect and ruling section.3. Perform Jominy test as a method to indicate hardenability.Introduction:One of the most important properties of materials is Hardness; which describes theresistance of a material to a permanent indentation.In steels, the value of hardness depends on many factors such as the carboncontent, alloying elements and the cooling rate during hardening process.The Maximum hardness in steels is obtained by producing a fully martensiticstructure. This can be done by austenitizing the steel and then quenching it. Duringthe austenitizing treatment all of the carbides dissolve and the ferrite transformsinto austenite.Quenching this structure causes the austenite to transform into Martensite.This transformation is so fast that there is no time tothe carbon to diffuse out of the Martensite grains orto form carbide phases. This Martensite is very hardand also very brittle.Another important property of materials isMartensiteHardenability which describes the ability of materialto be hardened in large depth, or the ability of a steelto partially or completely transform from austenite to some fraction of martensite ata given depth below the surface, when cooled under a given condition (themaximum depth of Martensite).When a thick steel component is quenched from its hardening temperature, it willtake longer time to the inner core of the component to cool than for the surfacelayers that are in contact with quenching medium. This leads to a variation inhardness across the section of the steel component, and this mass variation inhardness is referred to as “mass effect”. This mass effect in plain carbon steel maybe remedied to some extent by adding alloying elements to the steel, such as nickel,chromium, molybdenum, etc. these alloying elements make it possible to get amartensitic structure throughout the section of the steel component, even by oil‐quenching. This is one of the most important functions of alloying, but the lack ofuniformity of structure and hardness in steels, can seriously affect the othermechanical properties. For this reason it becomes necessary to specify the maximumdiameter of the bar of "ruling section".2

Thhe hardenabbility of matterials can beb studied byb a particuular test callled JominyTestt; in which a heated sppecimen of steels(austeenite) is dropped into pposition in aframme, and queenched by sprayingsa pre‐setpstandard jet of waterwagainnst its lowerrendd. The standdard specimen cools veery rapidly ata the quencched end anndproggressively leess rapidly towardstthee opposite end.eWhen cold, a flat is groundeddalonng the side of the specimen and itts hardness is measured every 3mmm form theequeenched end.Meethod:1. Specimmen Heatinng:a) Choose two typees of steel baars with propper dimensioons to be maachined to thhendard dimenssions of the Jominy test specimen. OneO of these steel bars isstanmadde from plainn carbon steeel and the otther is from alloyasteel (hhere we usedd d2Steeel).b) Heat each of theese two barss up to its ausstenite tempperature.2. Jominyy Test Macchine:c) Drop each bar innto its propeer position off the frame ofo the Jominyytest device.d) End quenches eaach bar withh tap water foor about 15mmins.3. Hardneess Measuring:e) Grinnd a flat alonng the side off each specimmen.f) Meaasure the hardness everyy 3 mm formm the quenched side of thhebar using Vickers1 hardness testingtmachhine (the oldest one in thheworrld).g) Plott the hardnesss measured (HV) of eachh bar with thhe relation toothe distance from quenchedd end (mm) ono the same graph paperr.h) Commpare the hardenability ofo the two obbtained curvves.Ressults:Appplying the experimentt method wew got the foollowing ressults:1In thet standard JominyJtest Roockwell C Harrdness must be used, but heere in this expperiment we havehusedd Vickers insteead.3

Specimen Type: Plain Carbon Steel 1045Load (kg)30Hardenability for Plain Carbon Steel [1045]800700HVHV)) . أأسي Vickers Hardness (HV))Distance d1d2avggHV30.30.30.361860.290.290.29 661.355590.30.30.3618120.30.30.3618150.310.310.31 578.7721180.310.28 0.295 639.1267210.290.3 0.295 639.1267240.310.290.3618270.30.29 0.295 639.1267300.280.280.28 709.4388330.310.32 0.315 560.5442360.310.3 0.305 597.9038390.320.33 0.325 526.5799420.340.30.32 543.1641450.340.35 0.345 467.2968480.330.34 0.335 495.6115510.380.37 0.375395.52540.360.37 0.365 417.4892570.390.370.38 385.1801600.40.39 0.395 356.4813630.390.38 0.385 375.2403660.380.39 0.385 375.2403690.370.4 0.385 375.2403720.390.4 0.395 356.4813750 370.370 390.390 38 385.18010.38385 1801780.370.38 0.375395.52810.380.40.39 365.6805840.380.40.39 365.6805870.370.390.38 385.180190040.40 420.420 41 330.87450.41330 874560050040030020010000204060Distance from quenched end (mm)80100

Specimen Type: d2 SteelHardenability for d2 Steel900800HVHV)) . أسي Vickers Hardnesss (HV)VDistance 59.472541.875504 1504.178478.981480.384423.187410.190628 5628.570060050040030020010000204060Distance from qquenched end (mm)()80100

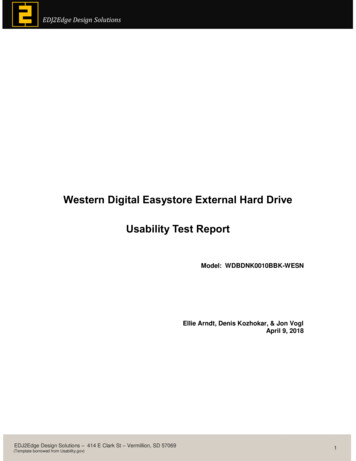

Hardenability for 1045 & d2 Steel900800700Pl i SteelPlainSt ld2 SteelPlain Steel)) . أسي d2 Steel)) . أسي Vicckers Hardness (HHV)Distance Plain Steel d2 Steel36187366 661.35553626.1961856112618662.115 578.77211598.518 639.12669579.121 639.12669561.124618598.127 639.12669561.130 709.43878579.133 560.54422579.136 597.90379662.439 526.57988765.442 543.16406736.145 467.29679708.548 495.61149712.151395.52700.454 417.48921666.857 385.1800666060 356.48133653.363 375.24034634.766 375.24034612.469 375.24034559.472 356.48133541.875 385.18006504.178395.52478.981 365.68047480.384 365.68047423.187 385.18006410.190 330.87448628.560050040030020010000204060Distance from quenched end (mm)80100

Discussion and Conclusion: In this experiment we learned about the Hardenability of Steels. Hardenability is an important property of material (especially steels) thatdescribes the capacity of the steel to harden in depth under a given set ofconditions. Jominy test is an effective method to measure Hardenability of steels; byquenching one end of a specimen to generate Martensite along its depth,then measuring the hardness at different distances from this end, anddetermine the ability of this steel specimen to generate Martensite withdepth. As we have studied (and also noticed in the lab) adding some alloys to steelmake it more hardenable. The following graph explains this: When we applied the Jominy test on the two specimens in this experimentwe found the following:1. The 1st specimen's (Plain Steel 1045) curve was approximately similar toour expectations except some out‐of‐range points –as you can see in theresults part of this report‐.2. The 2nd specimen's (D2 Steel) curve was almost strange; since the first 12points are less hard than the next part of the curve, and this doesn’t makesense (because these 1st points have more cooling rate i.e. moreopportunity to form Martensite).3. But in general we can notice from the third graph (the comparison one)the effect of alloying in increasing hardenability.This unexpected curve2 (of D2 steel) can be due to some factors such as:a. Some inhomogeneousity in the specimen.2Notice: this part of experiment for D2 steel has done by the other group of students, and I actuallydon’t know the way or conditions in which they made it. So all the reasons I mentioned are justexpectations.7

b. Mistakes in applying Jominy test (especially in the rate of coolingalong distance).c. Mistakes in measuring hardness.I think that the third reason is the most expected because they havechanged the hardness testing machine (from the manual one to theautomatic one) between the 12th and 13th points, and their mistakescould be either in measuring d1 & d2 of the impression, or incalculating the Vickers hardness. Alloying usually increases the hardenability of steels because it increases thetime needed to form martensite (decreases the critical cooling rate). From this experiment we can conclude that the plain carbon steel 1045 hasless hardenability than D2 steel. This property (hardenability) can help in choosing suitable metals for moreeffective heat treatment and performance in industrial applications.8

09.09.2018 · the austenitizing treatment all of the carbides dissolve and the ferrite transforms into austenite. . (and also noticed in the lab) adding some alloys to steel make it more hardenable. The following graph explains this: When we applied the Jominy test on the two specimens in this experiment we found the following: 1. The 1st specimen's (Plain Steel 1045) curve was approximately similar to .