Transcription

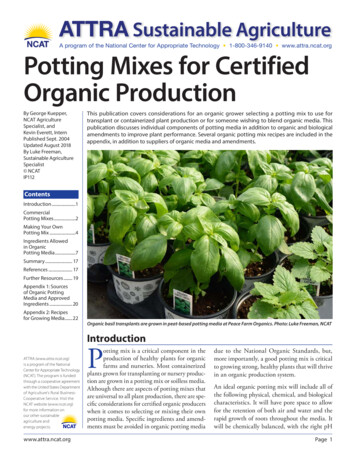

A program of the National Center for Appropriate Technology 1-800-346-9140 www.attra.ncat.orgPotting Mixes for CertifiedOrganic ProductionBy George Kuepper,NCAT AgricultureSpecialist, andKevin Everett, InternPublished Sept. 2004Updated August 2018By Luke Freeman,Sustainable AgricultureSpecialist NCATIP112This publication covers considerations for an organic grower selecting a potting mix to use fortransplant or containerized plant production or for someone wishing to blend organic media. Thispublication discusses individual components of potting media in addition to organic and biologicalamendments to improve plant performance. Several organic potting mix recipes are included in theappendix, in addition to suppliers of organic media and amendments.ContentsIntroduction .1CommercialPotting Mixes .2Making Your OwnPotting Mix .4Ingredients Allowedin OrganicPotting Media .7Summary . 17References . 17Further Resources . 19Appendix 1: Sourcesof Organic PottingMedia and ApprovedIngredients . 20Appendix 2: Recipesfor Growing Media. 22Organic basil transplants are grown in peat-based potting media at Peace Farm Organics. Photo: Luke Freeman, NCATIntroductionATTRA (www.attra.ncat.org)is a program of the NationalCenter for Appropriate Technology(NCAT). The program is fundedthrough a cooperative agreementwith the United States Departmentof Agriculture’s Rural BusinessCooperative Service. Visit theNCAT website (www.ncat.org)for more information onour other sustainableagriculture andenergy projects.www.attra.ncat.orgPotting mix is a critical component in theproduction of healthy plants for organicfarms and nurseries. Most containerizedplants grown for transplanting or nursery production are grown in a potting mix or soilless media.Although there are aspects of potting mixes thatare universal to all plant production, there are specific considerations for certified organic producerswhen it comes to selecting or mixing their ownpotting media. Specific ingredients and amendments must be avoided in organic potting mediadue to the National Organic Standards, but,more importantly, a good potting mix is criticalto growing strong, healthy plants that will thrivein an organic production system.An ideal organic potting mix will include all ofthe following physical, chemical, and biologicalcharacteristics. It will have pore space to allowfor the retention of both air and water and therapid growth of roots throughout the media. Itwill be chemically balanced, with the right pHPage 1

and nutrients for plant growth – or the ability toretain nutrients that may be added later in a liquidfertilizer. And it will be biologically active, withthe microorganisms needed to mineralize organicfertilizers, suppress plant pathogens, and supportthe health of the plant.Related ATTRAPublicationswww.attra.ncat.orgPlug andTransplant Productionfor Organic SystemsOrganic GreenhouseVegetable ProductionSustainableSmall-scale NurseryProductionTipsheet: CompostOrganic System Plans:Market Farms andGreenhousesCommercial Potting MixesMany organic farmers choose to purchase a commercial potting mix instead of making their own.A commercial mix is usually slightly more expensive than the sum of the raw ingredients, but thetrade-off in terms of time spent procuring andmixing the ingredients makes it worthwhile formany farmers to buy a pre-mixed blend.Over the past decade, the number of commercially available organic potting mixes has drastically increased, with most large potting-mediacompanies offering at least one organic mixin their product line. A list of organic pottingmixes and manufactures is included in Appendix 1 for your reference. If you are curious aboutthe organic status of a potting mix not found inour list, a good place to start is the OMRI List.OMRI, or the Organic Materials Review Institute, is a third-party organization that evaluatesproducts and processes for the organic industry.If a potting mix bears the “OMRI Listed” labelor is listed on the OMRI website (www.omri.org),you can be assured that it is allowed in organicproduction. The Washington State Departmentof Agriculture’s organic program also maintainsA commercial organic potting media is used by PeaceFarm Organics for their transplant production.Photo: Luke Freeman, NCATPage 2a list of allowed products, which can be viewedon its website (www.agr.wa.gov/FoodAnimal/Organic). However, it is still best to check withyour certifier if you have any question aboutallowed substances for organic production.If you are considering using a commercial pottingmix that is not listed by OMRI or the WSDA,read through the ingredient list carefully andmake sure that none of the ingredients are prohibited by the USDA National Organic Program(NOP). Common non-organic ingredients incommercial potting mixes are synthetic wettingagents and synthetic fertilizers. Sometimes theseingredients are not listed on the bag, and youmay need to contact the manufacturer or referto the product page on the manufacturer’s website to obtain a complete list of ingredients. Youwill find an in-depth discussion of potting mixingredients at the end of this publication.An important consideration of organic commercial potting mixes is that they do not have a longshelf life. Because of the nature of organic wetting agents and biologically alive amendmentslike compost and microbial inoculants, organicmixes are best used fresh. Plan to use all of thepotting mix you purchase within one year to getthe best performance.Selecting the Right Potting MixWhen selecting a commercial potting mix, it isimportant that you choose a mix that is appropriateCell packs are filled with organic media using a mechanized filler at Peace FarmOrganics. Photo: Luke Freeman, NCATPotting Mixes for Certif ied Organic Production

for your intended use. You will be able to findcommercial blends formulated for seed starting,growing transplants, and maintaining larger containerized plants, with each blend differing insignificant ways.Mixes designed specifically for seed startingare usually made from screened peat moss sothat they are fine in texture and have a very lowfertilizer concentration, if any. A seed-startingmix is ideal for germinating seeds in flats or plugtrays, but seedlings will need to be potted upinto a growing mix soon after true leaves develop.A germination mix can also be used for propagating cuttings.Growing mixes or “all-purpose mixes” usuallycontain peat moss, perlite, and/or vermiculite, anorganic wetting agent, a liming agent, an organicfertilizer, and an array of organic amendmentsincluding compost, worm castings, organic fertilizers, and microbial inoculants. Many growerschoose to use a standard growing mix to germinate seeds. This helps reduce the need to pot upyoung seedlings, but it is important to note thata high fertilizer concentration in the potting mixcan inhibit seed germination. If you are selecting agrowing mix for germination, choose a blend witha lower fertilizer concentration and plan to addsupplemental fertilizer as needed during transplant production.Potting mixes designed for larger containerizedplants are usually coarser in texture and includecomposted pine bark or other woody material,in addition to the standard components of aThe type of potting mix you select will depend on the types of plants you aregrowing and the size of containers you are using. Photo: Luke Freeman, NCATTable 1. Commercial Organic Potting MixesNote: These product listings are provided for informational purposes only. NCAT does not recommend one product over another or endorseany specific product or company.CompanyNameBergerOM 2LambertLM-18 OrganicGermination MixUseG, PPIngredientsPeat moss, perlite, vermiculite, calcitic and dolomitic limestone, wetting agent*,pelletized organic fertilizerGPeat moss (80-90%), perlite, calcitic and dolomitic limestone, wetting agent*,organic nutrient chargeLM-111 Organic AllPurpose MixG, PPPeat moss (80-90%), perlite, calcitic and dolomitic limestone, wetting agent*,organic fertilizerPremier TechHorticulturePro-Mix PG OrganikGPeat moss (60-70%), coconut coir, vermiculite, limestone, wetting agent*Pro-Mix MPOrganik**PPPeat moss (55-65%), coconut coir, perlite, limestone, and wetting agent*Sun GroHorticultureSunshine #3Natural & OrganicGPeat moss, vermiculite, dolomitic limestone, silicon, organic nutrientsSunshine #5Natural & OrganicG, PPPeat moss, perlite, dolomitic limestone, silicon, organic nutrientsFort-Lite PottingMixG, PPPeat moss, compost, perlite, vermiculite, coconut coir, blood meal, kelp meal, bonemeal, gypsum, crushed granite and basalt, and biodynamic preparationsPerennial BlendContainer MixWP, LCCompost, composted maple and birch bark, vermiculite, coconut coir, blood meal,kelp meal, bone meal, gypsum, and biodynamic preparationsVermontCompostCompanyG germination/propagation, PP plant production, WP woody perennials, LC large containers*organic wetting agent**formulations available with mycorrhizae and other microbial inoculantswww.attra.ncat.orgPage 3

but you may choose to add additional organicfertilizers to reduce the amount of supplementalliquid fertilizer that needs to be applied. Also,high-quality compost and vermicompost can beadded to a commercial mix to increase moistureretention, add nutrient value, and provide beneficial microbes to support plant health and speedthe mineralization of organic fertilizers. Otherbiological amendments, such as mycorrhizal fungiand rhizobacteria, can also be added to improvethe performance of a commercial blend. You willfind a more detailed discussion of these amendments in the section on biological amendments.Some potting media companies, such as Vermont Compost Company, will offerdiscounts if commercial media is purchased in bulk. Photo: Andy Pressman, NCATpotting mix, to provide better drainage andincrease porosity. These mixes can also have ahigher nutrient concentration, to feed the potted plant for a longer duration than a standardgrowing mix for transplants.You will find a list of popular commercial organicpotting mixes in Table 1, along with their intendeduse and list of ingredients. More information onpotting-mix suppliers can be found in Appendix 1.Bulk discounts are available from some suppliers,which can help you save money if you purchasea large quantity of mix in cooperation with othergrowers in your area. In addition, if you are buying in large quantities, you may be able to workwith the manufacturer to have them create a custom blend. You may want to check with your localfarming organizations, conservation district, andfarming neighbors to see if any groups are alreadyparticipating in a bulk-buying program.Making Your OwnPotting MixMaking your own potting mix is fairly straightforward and can save you money, but it doesinvolve an investment of time and some planning ahead. Also, you will need to have a location on your farm where you can store and mixbulk ingredients. Many organic growers chooseto purchase a commercial mix because they havedecided that they would rather pay someone elseto make a quality product, but if you would liketo explore making your own potting mix, hereare some things to consider.Boosting a CommercialPotting MixInstead of creating a custom potting mix fromscratch, you may choose to purchase a basic commercial mix and boost it with additional organicamendments. This allows you to save time mixingbulk ingredients, but still end up with a premiumpotting mix. A basic “peat-lite” mix, composedprimarily of peat moss and perlite and/or vermiculite, makes a good foundation for a custom mix.These commercial mixes already have a balancedpH and contain an organic wetting agent to helpthe peat moss absorb water. A starter fertilizer isusually included in commercial peat-lite mixes,Page 4A tub such as this can be used to mix small batches ofpotting mix. Photo: Luke Freeman, NCATThe Basic RecipeYou will find a list of recipes in Appendix 2, andit is recommended to start from a proven recipeand make adjustments from there. The best recipefor you depends on the ingredients you can accessand the intended purpose of the potting mix. AsPotting Mixes for Certif ied Organic Production

discussed in the context of commercial mixes,whether the mix is intended for seed-starting,growing out transplants, or growing out largerpotted plants will determine the ingredients andthe proportions.Traditional potting mixes usually included garden soil and sharp sand, in addition to compostand other ingredients. These ingredients are rarelyused in modern organic potting mixes because ofthe possibility that they could introduce plant diseases into the mix. Once peat moss became widelyavailable as a potting mix ingredient, it mostlyeliminated the need to use soil because it wasa sterile, effective, and affordable substitute. Inaddition, modern potting mixes tend to use perliteor vermiculite instead of sharp sand, for similarreasons. If you would like to use soil in your potting mix, it is recommended that you sterilize thesoil by heating it to a temperature of 180 F for30 minutes (Maynard and Hochmuth, 2007).This can be accomplished by using a home ovenpreheated to 275 F and baking 1-gallon batchesof moist soil for 30 to 40 minutes (Bubel, 1988).For commercial production, there are large-scaleovens and steam sterilizers available. Sand canalso carry pathogens and other contaminates, soensure that it is from a clean source and considerheat-treating it as well.The Cornell peat-lite mix was one of the first soilless potting mix recipes and relies on peat mossas the main substrate. The basic recipe for a peatlite mix is 50% peat moss with 50% perlite orvermiculite to add porosity and lighten the mix.For every cubic yard of peat moss, 20 pounds ofground dolomitic limestone should be used to balance the pH (Boodley and Sheldrake, 1982). Thisrecipe is well-suited to conventional production,where soluble fertilizers are used to provide forplant nutrition, but it lacks the biological component to assist in the mineralization of organic fertilizers that would be used in organic production.Many modern organic potting mix recipes are anadaptation of the peat-lite mix that use compostto supplement a portion of the peat-moss component. Compost will add water-holding capacity and structure like peat moss, but it also addsa living biological component that will assist inthe mineralization of organic nutrients for plantuptake. Many of these recipes include peat moss,compost, and perlite/vermiculite at a proportionof roughly 1:1:1 or 2:1:1. Coconut coir is sometimes substituted for peat moss, and perlite andwww.attra.ncat.orgWorkers at Peace Farm Organics pot up tomato seedlings from plug trays into1204-cell packs. Photo: Luke Freeman, NCATvermiculite can be used interchangeably or mixed.Though compost does assist in balancing theacidic pH of peat moss, lime is usually requiredto bring the pH up to an ideal range. You willfind a discussion of the individual componentsof a potting mix recipe in the following pages.Fertilizer BlendsMany organic growers focus on providing for allof the plants’ nutrient needs within the mediaitself. To accomplish this, a blend of organicfertilizers must be added. Compost can provide a significant amount of phosphorus, potassium, sulfur, and trace elements, as well asminor amounts of nitrogen, depending on itsquality and age. However, additional fertilizers are needed to ensure adequate supply of allthe plant-essential nutrients. An ideal pottingmix contains nitrate-nitrogen (N) at 10 to 200ppm, phosphorus (P2O5) above 3 ppm, potassium (K2O) above 25 ppm, calcium (Ca) above30 ppm, magnesium (Mg) above 10 ppm, andsodium and chloride below 130 and 200 ppm,respectively (Wander, 2015). By using a recipethat contains a complete fertilizer blend and testing the performance in small batches, you canassess the supply of nutrients without necessarilyhaving to measure nutrient concentration.Two example fertilizer blends are included inthe text box on page 6, and you can find a listof common organic fertilizers in Table 2.Page 5

Organic Fertilizer Blends forPotting MixEliot Coleman Base Fertilizer Mix (publishedin The New Organic Grower, 1995)Add 3 cups of fertilizer mix for every20 gallons of potting mix 1 part blood meal 1 part colloidal (rock) phosphate 1 part greensandJohn Greenler Fertility Mix (published inJanuary 1996 issue of Growing for Market)Add 1 ½ cups of fertility mix for every15 gallons of potting mixA sifting screen such as this one can help remove largeparticles from compost used in a potting mix.Photo: Luke Freeman, NCAT 2 cups colloidal (rock) phosphateTheavailabilityof organicfertilizers dependson the rate ofbiologicalmineralization,which is driven bytemperature and theactivity of microbes. 2 cups greensand 2 cups blood meal ½ cup bone meal ¼ cup kelp mealMixing the IngredientsYou may also find it beneficial to mix your fertilizer blend into the potting mix beforehand andallow several weeks for “incubation.” Research onincubation time for an alfalfa-based organic fertilizer found that one to three weeks was an optimalincubation period at application rates of 0.6% to1.2% of 3-3-3 fertilizer in a peat-based pottingmix weight-by-weight (Nair et al., 2011). Thisincubation period allows time for the biology inyour potting mix to begin to break down organicnutrients into forms that are plant-available.Even if your potting mix contains a complete fertilizer blend, it may be necessary to provide readily available nutrients in the form of liquid organicfertilizers. The availability of organic fertilizersdepends on the rate of biological mineralization,which is driven by temperature and the activityof microbes. For example, phosphorus deficiencies can appear in greenhouse transplants in earlyspring because cold temperatures limit the mineralization of P (Wander, 2015). A Canadian studyon pepper transplants found that optimal plantgrowth resulted from a mix of granular organicfertilizers (shrimp meal and kelp meal) mixed inthe media in addition to a liquid organic fertilizer (3-0.4-0.8) applied at watering three timesper week (Gravel et al., 2012). A common liquidfertilizer for organic farms is fish emulsion or fishhydrolysate, which usually contains around 5%Page 6N, 1% P2O5, and 1% K20. Other brand-nameorganic liquid fertilizers include Nature’s SourceOrganic Plant Food (3-1-1) and Phytamin AllPurpose Fertilizer (3.7-2.7-3.7).When mixing the ingredients for a potting mix,follow the steps below to end up with a consistentand high-quality product. Also, wear a mask toavoid breathing in dust from dry peat or perlite.A concrete mixing tub or large plastic bin can beused to mix the ingredients by hand on a smallscale. For larger scales, an electric concrete mixercan be used. It is important to start with premoistened peat moss because peat can be verydusty and difficult to wet if it is handled whencompletely dry. If you are using a dry bale of peat,you can pre-moisten it with one gallon of warmwater for every two bushels of peat (Boodley andSheldrake, 1982). An organic wetting agent suchas yucca extract can be added to the water toassist in the wetting of peat. After the peat ismoistened and added to the mixer, the lime andfertilizer blend should be spread over the peat andmixed thoroughly to distribute evenly. Next, thecompost, vermiculite, and/or perlite can be addedand mixed until combined. Be sure to avoid overmixing once the vermiculite or perlite has beenadded because these materials can break downif over-handled. As mentioned earlier, lettingthe mix incubate for one to three weeks at roomtemperature can be beneficial, but avoid storing the mix for more than one season, as qualitywill decline. Also avoid letting the mix dry out,because re-wetting dry peat moss can be difficult.Potting Mixes for Certif ied Organic Production

Testing Your MixIf you are trying new potting mix recipes, it isimportant to have a consistent process to test theperformance and characteristics of the recipes. Alow-tech way to test your mix is to conduct a germination test and a pot trial. Seeds such as cress,oats, beans, and lettuce will germinate quicklyand are fairly fast-growing, which makes themideal for testing a potting mix (Wander, 2015.)Comparing the germination and growth of a testcrop in your home-made mix compared to a commercial blend will give you a good idea of thequality, assuming all factors are equal.For a more scientific approach, you can purchasea pH and electrical conductivity (EC) meter tomeasure the chemical properties of your mix.Research has shown that nutrients are mostavailable in a peat-based media when the pH isbetween 5.5 and 6.0 (Warncke and Krauskopf,1983). EC is the measure of soluble salts, or fertilizer concentration, in the media. A Cornellstudy found that organic lettuce, spinach, andbeet transplants grew best in a mix with an ECof 850 µS/cm, while mixes with EC of 1400 µS/cm had poor plant performance (Shaw et al., nodate). In general, an EC of 260 to 750 µS/cm isgood for germination and an EC of 760 to 1250µS/cm is desirable for plant growth, as measuredby 1:2 extraction method (one part soil to twoparts water) (Shaw et al., no date). Some stateCooperative Extension Services offer potting mixanalysis, which would be able to give you the pH,EC, and nutrient analysis of a mix. You can finda list of soil testing labs on the ATTRA websiteat https://attra.ncat.org/attra-pub/soil testing/index.php. Just make sure that the lab is able torun a test specifically for potting mix, as a standard soil test will return inaccurate results. Seethe publication Greenhouse Growth Media: Testing& Nutrition Guidelines by Warncke and Krauskopf for a more detailed discussion of pH, EC,and nutrient levels in potting mixes.Ingredients Allowed inOrganic Potting MediaEven if you are making your own media, it isimportant to ensure that the individual ingredients are approved for organic production. Purchased components such as peat moss, perlite,and fertilizers may bear the OMRI or WSDAlabel, which would give you assurance that theyare allowed. If you are unsure about a specificwww.attra.ncat.orgGerminating seeds in a small batch of potting mix can serve as a quality test.Photo: Luke Freeman, University of Arkansasmaterial, you can check the OMRI website ortalk to your certifier.SoilThe trend in containerized plant production hasbeen towards soilless media to reduce the risk ofplant disease and produce a consistent, uniformproduct. However, you will still find some organicgrowers who like to use soil in their potting mix.Soil will provide water and nutrient retention, willhelp the mix hold together for soil blocks, andwill introduce beneficial microbes. The downsideto using soil is that it can introduce soil-bornepathogens, weed seeds, and chemical contaminates into your mix, which can wreak havoc onyour plant production. In addition, soil is relatively heavy and dense and can contribute to pooraeration and drainage in a mix, especially if smallcontainers or plugs are used. Sterilization of soilin an oven or steamer can effectively eliminatepathogens, though it will also kill many of thebeneficial microbes in the soil. More informationon sterilizing soil can be found in the publicationHow to Pasteurize Medium and Sterilize Containers and Tools by Lamont, Kelley, and Sellmer,listed in the Further Resources section.Regarding organic certification, clean commercialtopsoil is an acceptable natural ingredient, butyou have to be certain that it has not been treatedwith prohibited ingredients to kill microbes andweed seeds. Check the label or ask the supplier tobe sure. If you are using soil from a farm or garden, use only the best and ensure that the soil isnot from an area that has been treated with pesticides or has been subject to contamination. Somecertifiers might even require that soil used mustcome from land in certified organic production.Page 7

SandLike soil, sand is a potting mix ingredient foundin traditional recipes but used less commonlytoday. Traditionally, coarse builder’s sand wasused to add porosity to a mix, but perlite or vermiculite have replaced sand in modern mixesbecause of their sterile nature. If using sand in apotting mix, make sure that it is clean and freeof contaminants. It is possible for sand to contain synthetic contaminants like herbicide residuethat are prohibited in organic production. Twoinstances where sand may be necessary are in ablocking mix that benefits from the added weightand stability of coarse sand or in a mix for largepotted plants where the added weight would keepthe pots from tipping over.CompostCompost is a foundational ingredient in manyorganic potting mixes. High-quality compostwill inoculate your potting mix with a diversityof beneficial microbes with a much lower riskof introducing pathogens and weed seeds thanun-sterilized field soil. In fact, high-quality compost can actually suppress seedling diseases suchas damping off and root rot by overwhelmingthe rhizosphere with beneficial microorganisms(Klein and Hammer, 2006; Wallace, 2012). Compost often contains enough nitrogen, phosphorus,and potassium to meet a seedling’s nutritionalneeds for the first two to three weeks of growth(Rynk, 1992). Additionally, the presence of beneficial bacterial and fungi in the potting mix willassist in the mineralization (or break-down) oforganic fertilizers into plant-available forms.High-quality compost will improve the performance of an organic potting mix.Photo: NCATPage 8Joey Klein and Karl Hammer of Vermont Compost Company advise that careful watering andsoil-temperature management are crucial to success with compost-based potting media (2006).Compared to peat-based growing mixes, compost-based mixes require less-frequent watering,which may be an adjustment if you are used topeat-based media. You should wait until the surface of compost-based media is dry before plantsare watered again. Additionally, nutrient releasefrom a compost-based mix is driven by temperature, so keeping the medium warm is critical toensuring that plants are able to access the nutrients they need. Some growers will place transplants directly on a heated concrete slab or provideforced-air heating under the growing benches tokeep the root zone above 60 F. Heating the irrigation water so that it is above 60 F will also helpto keep soil temperature warm.Some organic growers raise seedlings in 100%compost, but generally it is recommended to addcompost to a potting mix at a concentration of20 to 33% by volume (Rynk, 1992). Research onmelon seedlings has indicated that a concentration of as much as 50% is beneficial (Tittarelli etal., 2009). Compost used in a potting mix shouldbe high-quality, mature, and—ideally—screenedto remove large particles. Unfinished compost ortoo much compost in a potting mix can actuallyinhibit seed germination and be detrimental toplant growth. Immature compost will produceammonia gas, which damages seedlings (Grubinger, 2012). In addition, it is important to ensurethat the compost used meets the NOP requirements for finished compost if manure was used asa feedstock. See the sidebar for more informationon the NOP compost rule.High-quality compost can be made at home or onthe farm, though consistency in the final product can be difficult to maintain, due to the manyvariables involved. Many organic growers chooseto purchase compost from a professional supplierto ensure that they have access to a consistent andhigh-quality product. If you are producing yourown compost to use in a potting mix, test yourcompost by sending samples to a lab or conducting a germination test to ensure that it is fullymature before using it in a batch of potting mix.John Biernbaum from Michigan State University has developed a plant-based compost recipethat is used on the MSU student organic farm toPotting Mixes for Certif ied Organic Production

produce a consistent and high-quality compostfor use in their potting mix and in their vegetable beds. Plant-based composts such as this onegenerally have a lower EC, or salt content, thancomposts made with animal manures.NOP Compost and Manure RulesThe National Organic Standards include rules formaking compost and recordkeeping requirements for growers using compost in their production system (§205.2 of the NOP Final Rule).Compost-production records should includea list of feedstock materials, temperature logs,and records of management practices such asturning. In a static or enclosed-vessel composting system, compost piles must maintaina temperature between 131 and 170 F for atleast three days; in a windrow system, the pilemust reach these temperatures for at least 15days and be turned at least five times. For vermicompost, production records must also bekept, but the temperature requirement doesnot apply (NOP 5021). More information can befound in ATTRA’s Tipsheet: Compost.Manure that has not been composted according to NOP guidelines has a restricted application window on edible crops due to food-safetyconcerns (§205.203(1) of the NOP Final Rule).For crops that have an edible portion that hasdirect contact with the soil, manure must beapplied at least 120 days before harvest of thatcrop. For crops that have an edible portion thatdoes not come in contact with the soil, manuremust be applied at least 90 days before harvest of that crop. This restriction eliminates theoption of using uncomposted manure in thegrowing media of greenhouse crops such assalad greens and baby vegetables that haveless than 90 days to maturity. See ATTRA’sTipsheet: Manure in Organic Production Systemsfor more information.Vermicompost will impart disease-suppressive qualities to a potting mix inaddition to improving moisture retention and providing nutrients.P

NCAT website (www.ncat.org) for more information on our other sustainable agriculture and energy projects. A program of the National Center for Appropriate Technology 1-800-346-9140 www.attra.ncat.org By George Kuepper, NCAT Agriculture Specialist, and Kevin Everett, Intern Published Sept. 2004 Updated August 2018 By Luke Freeman,