Transcription

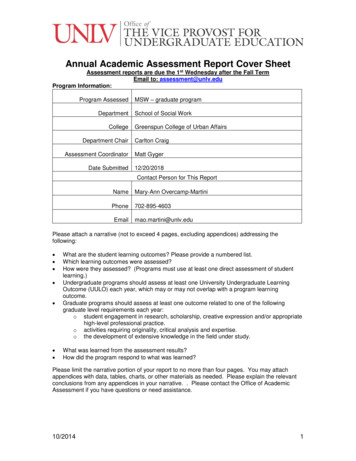

/ICover Sheet for a HanfordHistorical DocumentReleased for Public AvailabilityReleased 1995Prepared for the U.S. Department of Energyunder Contract DE-AC06-76RLO 1830Pacific Northwest LaboratoryOperated for the U.S. Department of Energyby Battelle Memorial Institute

DISCLAIMERThis report w a s prepared as an account of work sponsoredby an agency of t h e United States Government. Neither t h eUnited States Government nor any agency' thereof, nor anyof their employees, make any warranty, express or implied,or assumes any legal liability or responsibility for t h eaccuracy, completeness, or usefulness of any information,apparatus, product, or process disclosed, or represents thatits use would not infringe privately owned rights. Referenceherein to any specific commercial product, process, orservice by trade name, trademark, manufacturer, orotherwise does not necessarily constitute or imply itsendorsement, recommendation, or favoring by t h e UnitedStates Government or any agency thereof. The views andopinions of authors expressed herein do not necessarilystate or reflect those of t h e United States Government orany agency thereof.

DISCLAIMERPortions of this document may be illegiblein electronic image products. Images areproduced from the best available originaldocument.I

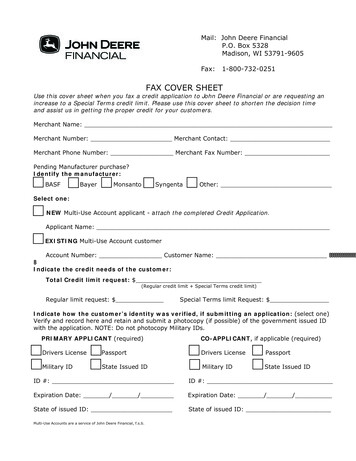

Cf e p i c s , SerieseHcnf ord %rkslknufacturiny: DepartmentScpzr4&na .?ectionD. .!elMayStarkE, 19524 MSTe3180710N OF THIS DOCUMENT IS UNLIMITED.

p. .-2- ;zTABLE-W CONTENTSPAGE'moaI. SUMMARYProblem Under InvestigationImportant ResultsRecommendations And Conclusions11.44-S5 - 6DISCUSSIONOrigin Of Investigation71 - 88Present ConditionsEquipment Used ElsewhereCourse Pursued In Investigation--8-99 1G10 llResultsSafety And Special HazardsNuclear Safetyll-I21110 APPENDIXFimes1.2,Task I ModificationTask I Modification(se-795)3. Task I Modification4. Task I Modification5.-- FlowDiagram (SKZ-781)Equipent Arrangement-- Process1314a p i n g (SE-794) 15Greenhouse Tspe Hood,16And Equipment Arrangement (SQ-796)Task I Modification Alteration To PIX%17fication Vessel (Sa-782)Tables--I, Alternative Methods Of'Actikting Task I-18-19 .11, Cost Estimate Surmary For Modification OfPresent Task I EquipmentIII 0ost.Estimate S m a q For Greenhouss Facility20Iv. Design Basis U s e d For Task I Astivation S t p d y21v. Task I Haintenance Costs And Maintenaaae22ProbluasV I . Estimated Annual Cost For Providing PFo-bctive 23Clothing For One Additional Opcjrator h3 4 - 5BuildingVII. Source O f Personnel Contamination 2%-5 ,.24Building.LI-.-43,i

2khitit sA 3CDBibliographyAdjusted Cost % s t h a t e s for Task IRevisions%sic Cost Estimates f c r Tack IRevisionsTask I Flow Sheet (Prcliminnry)r-- . .PACE Nd.252627-3334

-4-I .- SUMMARY.;.- .*1'.7I.

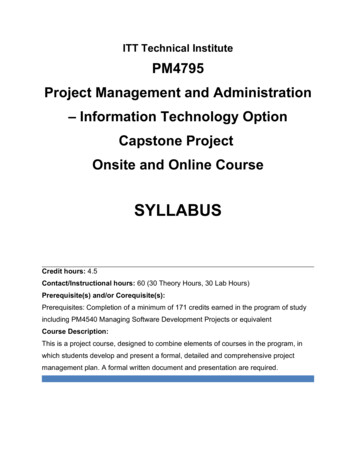

I.I .-5'iiie c o s t of providing a new greenhouse type operation was estimated ont3o saxe bnois t o be &O,OOO.It is anticipated ttiat the'maintenanc@cos5s k i l l bc a p p r o - h t e l y 5,ooo/str. higher i n t h e remotely operatedinsl-:Slation because of increased electridal maintenance.Jrcrcnt rcactor vessels a r e of sufficient size t o process materialnccording t o the flow ,sheet i n reference Uocument Hl?-23633 ( bit . D);.'or &OW the present reactor head assemblies can be revised t o; ccaiOdr?tea l a r g e r vessel i n which materisl of lesser concentrationc:x I.Ctbe processed, (Figure 5 )0'Ilie saran valves performed satisfactorily in t e s t s conducted by t h eGeneral Xngineering Labratory a t Schenectady and in subsequent shaked c w it e s t s a t Hanford Works. The present saran valves will requirerc:iorking, a t a t o t a l cost of 1,200, t o eliminate leakzge a t the sarantubing connections t t h e valve body. The estimated minimum cost f o rr e v i s i n g the existing Task I equipnent i s based on the assumption t h a tsaran valves w i l l give sakisfactow service and replacement a t thistime with valres made of other materials i s not justifikd. Shouldlater information prove the saran valve to be unsatisfactory, ana d d i t i o n a l estimated replacemonk cost of 18,500 would be incurred.Records of personnel contadnation.incidents in the 234-5 B u i l d k g showt h a t operation and ma ktenar.ce of e i t h e r a manual or remote Task Ii n s t d l a t i o r c can be perforhed with equal safety.-.-IRISC@3ENDATIONS AND CONCLUSIONS: - It i s recmended that i f T a s k 1 5sactivated, t h e e x i s t i n g equipment be revised.'i

1.*.emi-2.4046-6Ifacility can be obtained by revising existing remotely operated equipment. If, however, there were no existing equfpment, a .satisfactorymanually operated i n s t a l l a t i o n could be designed, procured, and 3.ns t a l l e d much more cheaply,'W, A. BrownContact EngineeringWhB :RJA: ga.-.3t

,3'i,.:-7-I.II- DXSCUSSION@ORIGIEJ OF INVESTIGATION: This investigation was initiat.ed a t t h e requestof the lhnager of the Separations Section. Th13 two alternative methodsof activeting Task I were first brought t o attention by a l e t t e r from O,F,Deauliea t o V. R. Chapman, "Recommendations f o r Reactivation of Task 1'1,dated January 7, 1952.Activation of Task I came under consideration when t e s t s indicated t h a ts u f f i c i e n t purification of the Redox plutonium . n i t r a t e solution could beobtained by a single 4 oxalate precipitation. 2he Recuplcx study wasbased on the assumption t h a t Task I would be operating t o process anyn i t r a t e solutions produced by Recuplex and t h a t the Task I process wouldbe a 4 oxalate precipitation.At present, t h i s process has not bet3 firmlytherefore, necessarily covers only proaesses.Task I was originally designed. InformationUnit indicates adoption of such a process isestablished, This study,s M l a r t o those f o r w h i c hreceived from the Frocessprobable.PRBENT CONDITIONS: The existing Task I equipent.was designed t o re ceive a sample can containing product'from'the 231 Building and todeliver a 3 oxalate slurry to Taskby means of an overhead alarrytransfer line. The o r i g i n a l boat loading s t a t i o n i n Task 11 has beenreplaced t o permit introduction of f i l t e r boats containing a plutoniumoxalate cake which are loaded i n the 231 Building. With the sxcaption ofintroducing and removing sample cans and taking process samples, sll.oper;.a t i o n s were t o be performed from behind a -steel and l u c i t e barrier. - - -a.-The Task I equipment i s contained i n several staiXLess s t e e l process hoods.Product U n e s between hoods a r e enclosed i n stainless s t e e l ducts. Hood .1B ccntains a remotely operated balance for weiRhing the samle cans andt h e i r contents. Hoods 2 and 3 contain the sample can handling equipnentwith provisions f o r diluting, agitating, and samplbg t h e sample cancontents.The main process hood, Hood 6 , contains six pgrex-reactor vessels eqyipped with agitators, d i p tubes, etc. The upper portion of the hood containsa slurry head tank which was used in the operation of transferring slurryt o Task 11, Solution transfers a r e accomplished by ev%cuating.the receivingvessel and venting the vessel from which the liquid is being transferred,

IQ-8-Special caran valves a r e used which a r e solenoid controlled, air operated.The major portion o f t h e valves which handle contaminated f l u i d s arelocated i n Hoods 5 and 7. These a r e special valve hoods located adjacentt o Hood 6. 'Hood 8 contains two pyrex ves3els of the sane size as the Hood6 reactors and i s used as a measuring and sampling station f o r t h e supernatant solution which is decanted from t h e reactors i n the 3 oxalateprocess bThe &sting equipment was operated on a shakedown and t r a i n i n g b a d e fara period of approxhately 4 months following acceptance of t h o f a c i l i t yfrom construotion forces. During this period over 300 runs were prbcessedurine cerous nitrate and ceric nitrate 8 s staiid-in materials. A t the endof the shakedown period the equipment w a s flushed out and has not s b c ebcen gperatcd. Nith t h e exception of removal of the wet transfer s t k t i o nIa t Hood 9, the equipment d s t s essentially as it w a s h s t a l l e d .!All of the equipment associated with Hood 6 operated s a t i s f a c t o r i l y &ringt h e shakedown period. There were a great number of Maks a t the tubingconnections t o the saran valves, however, and f o r this reasoh t h e ebst 6frevising these connections has been included in the estimate.ECUIEPMENT USED EISEWHWE: The type of w e t chemistry opePation that iscontemplated for Task Iis currently being perfombd i n t h e 231 Buildingand i n the RG &e of the 2344 Building.-.In the 231,l3uilding t h e proeess esuipment i s located h i d e of "grei@&ou &tmade of glass. Piping, va1ves;andprocess vtssels'are stainlese stgel.Valve bandies a r e ektended through t h e hood panels'fvr manual opra &th.Access for maintenapce is obtained bs removing the neeessay glass p&&s.In the 234-5 Building, RG Line, pm4;ess equipment is located i n hoods -deof stainless s t e e l and lucite. The reactor vessels a r e glass. VaLvee gadpiping are s t a h l e s s s t e e l and valves a r e operated manually e i t h e r tW ughrubber gloves ox' by valve handles extended through the hood wall, Mabhenance work is performed through rubber gloves.COURSE PUFtSZIED I N IBVESTIGATION: &e Superintendent of t h e Process U n i t ,Separations Section, was requested t o furnish a description of the ppocessto be used in Task I upon its activation. Based on t h i s infomatim wMohwas issued as HW-23633 (see Exhibit D), design sketches were prepared toshow what revisions would be required i f t h e existing equipment were used

'and c . 3 : y u i r n w t would be rcqiiired 2f a new manually operated f a c i l i t yw ; r * ir:: ts13.ed (Figure'l-5).Based on these design sketches, cost e s t - h t e sfor ti:c v'irious alternatives were made by the Project Services U n i t of theXti;;i ?r: rin;;Department. (Tables I1 and 111, ExhibitsB and C)S u p p l s e n t a l information w a s obtained from personnel of the General Znghxn?i n g Lriboratory, Power and b t e n a n c e U n i t , Radiation Monitoring Unit, Separations ';echr,ology Unit Pile Technolorn Unit, and Operations Unit.R!;CULT3:A11 r e s u l t s herein reported are specifically limited to theIf process selectionconditions disclosed i n Vroblem Under Investigation"necessitates major changes t o Task I, a re-study of t h e problem w i l l berequired. Cost estimates of the alternatives proposed indicate that t-evisionof the existing hoods and equipment w i l l be less costly than providing a newgreenhouse type hood. It was estimated t h a t revision of existing equipentwould cost approximately 25,000 w h i l e providing a new greenhouse tspeoperation would cost a p p r o d t e l y 9O,OCO. (Fkhibit B)'30One of t h e larger cost items i n the proposal w a s t h e removal of the existinghoods and equipnent. The e s t h t e d cost i s based on equipment removal inlarge units. It w i l l be necessary t o package t h e sample can balance. Caref u l hahdling of glass vessels w i l l be required. Hoods are t o be removed witht h e saran valves intact. The only dismantlirig contemplated is t h a t necessaryf o r simplification of handlhg and p a r t s reserved for.reuse. A more detailedbreakdown of the elemental' cost estimates comprising- the basic cost es*temay be found in Exhibit C.-,Maintenance costs w i l l be. roughly.the same for a l l cases whether stainlesss t e e l or saran -ralves a r e used. (Table V) It is estimated t h a t E l e c t r i dmaintenance costs fl ba 5,Goo/yr. Mgher f o r remote type operation.Shakedown experience ih icated t h a t t h e saran valves a r e satisfactory. -era1Engineering Laboratory h g i n e e r s stated t h a t saran valves Were used a t Zas Alamqwith relatively f e w failures. They stressed, however, that-the problea of H Icorrosion was t h e only'basis f o r use of saran valves i n t h e i r design.The existing Task I reactors a r e Large enough, t o process an incoming solutionvolume of 2.7 l i t e r s . A t a r e s t h a t e d cost of l,OOO %he six reactor assembliec2n be modified as shown on Figure 5, t o increase .he reactor volume stdficientt o handle a product volume of 7 l i t e r s . Information obtained from the Pile:,Technology Unit disclosed that u t i l i z a t i o n of larger reactors present: no critFc,

.,0HW-24046-10-mass ,problem i n Ilodd 6 i f a t least a 24 inch reactor spacing wereprovided.The purificatAon process which will be performed i n Task I can beperformed with equal'aafety i n e i t h e r a remotely operated o r manua l l y opnrated f a c i l i t y . A t l e a s t one operator w i l l be required i nZone 3 for all cases. The annual cost of providing SWP clothingf o r an additionalcoperator i n t h e 234-5 Building i s not significant.(Table V I )Three r e a d - o r s a r e adequate t o handle t h e maximum anticipated planfproduction.The present reactor spacing of 18" on centers trill notbe adequate from a c r i t i c a l mass standpoint t o permit simultaneoususe of all six reactors, For t h i s reason t h e production capacity oft h e present - i n s t a l l a t i o n was based on using a l t e r n a t e reactors or 3of t h e 6 reactors at any one time, Critical mass protection will beprovided with locked sequence switches, locked valves o r interrhediatetanks. (Table I ) I n a new greenhouse i n s t a l l a t i o n the reactorsspacing cul be increased so t h a t inter-action between vessels i s nolonger a problem.SAFETY AND SPECIAL H WLRDS:. The type of operation that w i l l be performed i n Task I of the WA Line i s not a particularly hazardous one.Considering o w t h e normal mindustrial hazards, t h e operation couldbe performed manually or by t h e use of remotely operated equipmentwith equal safety.-,.Records of personnel contamination incidents 3q the- 234-5 Buildingshcw t h a t operation a

Cover Sheet for a Hanford Historical Document Released for Public Availability Released 1995 Prepared for the U.S. Department of Energy under Contract DE-AC06-76RLO 1830 Pacific Northwest Laboratory Operated for the U.S. Department of Energy by Battelle Memorial Institute . DISCLAIMER This report was prepared as an account of work sponsored by an agency of the United States Government. Neither .

![[Page 1 – front cover] [Show cover CLEAN GET- AWAY 978-1 .](/img/13/9781984892973-6648.jpg)