Transcription

EHT-1362/20AQUAPONICS?What isJoseph Masabni1 and Todd Sink2The term “aquaponics” is the combinationof two words: aquaculture and hydroponics.Aquaculture is the science of raising fish, whilehydroponics is the science of growing plants ina soilless media or nutrient solution. Therefore,aquaponics is a combination of these two foodproduction systems.Most of the world’s aquaculture productiontakes place in earthen ponds or raceways;these systems are either static or flow-through.Fish in these systems produce nitrogenousand mineral wastes that require extensivefiltration. In hydroponics, inorganic fertilizersare used as the source of nutrients for plants,which requires flushing the system regularlyto replenish the fertilizer solution or to removeany excess salt accumulation. In an aquaponicsystem, ammonia (NH3) excreted by fish asa waste product from protein metabolismis converted to nitrate (NO3-) by nitrifyingbacteria. Plants act as a water filtration systemby absorbing nitrogenous and mineral products,which improves water quality for the fish. Thenitrifying bacteria convert fish waste productsinto usable nutrients for the plants, and theplants filter the nutrients from the water tobenefit the fish (Figs. 1 and 2). Therefore, fish,nitrifying bacteria, and plants benefit from eachother.Aquaponics is a unique ecosystem withina food production system where fish, bacteria,and plants are mutually benefiting from each1Extension Small-Acreage Vegetable Specialist, Department ofHorticultural Sciences, and 2 Extension Fisheries Specialist–Departmentof Wildlife and Fisheries Sciences, The Texas A&M University Systemother. In other words, aquaponics is the combination ofboth intensive aquaculture and hydroponic productionsystems in a recirculating water system.The immediate benefits of aquaponics are reducedcosts of fish waste filtration by conventional methods,and, more importantly, inorganic fertilizers andassociated costs of fertilization management are nolonger required. An aquaponic system requires water, fishfeed, and electricity for the water and air pumps. ThereFish Produce WastePlants Uptake Nutrient Rich WaterFish TankClean Water Returns to Fish TankFigure 1. Schematic representation of an aquaponic system.Figure 2. Backyard aquaponics model with room for 12 plants.Plant Grow Bed

bacteria are Nitrosomonas and Nitrobacter.Nitrosomonas convert ammonia to nitrite. Nitrobacterthen converts the nitrite to nitrate. Ammoniais a natural product of fish protein metabolism.Freshwater fish excrete ammonia from their gills andin their feces. Excessive concentrations of un-ionizedammonia in water are toxic to fish. The amount ofun-ionized ammonia in the water depends upon thetotal ammonia nitrogen (TAN) present and the waterpH and temperature. Un-ionized ammonia (NH3)is toxic to most fish species at concentrations of 1part per million (ppm) or less. The conversion ofammonia to nitrite by Nitrosomonas slightly reducesthe risk of fish toxicity. However, nitrite is not readilyusable for plant growth. Therefore, Nitrobacter isalso crucial as it converts nitrite to nitrate, which isrelatively non-toxic to fish, easily absorbed by plantroots, and necessary for plant growth.The biotic, or living, components of an aquaponicsystem are fish, plants, and two genera of bacteria,all working in unison (Fig. 4).The abiotic, or non-living, components of anaquaponic system consists of a fish tank(s), clarifieror solid waste filtration tank, biofilter, plant growingbeds, a water pump, and an air pump (Fig. 5).Many designs combine one or more of those basiccomponents in production. Some systems using“low-density” methods may consist of only a fishtank and trough(s). Systems using “high-density”Figure 3. Live lettuce plant ready for storage or sale.are many benefits to implementing an aquaponicsystem. For example, aquaponic systems are 100percent natural, since no synthetic fertilizers areused. Other system advantages include low waterconsumption, fast and efficient food production, andless filtration equipment and costs are required asplants act as filters. Additionally, harvested plantsremain alive since the roots are not cut at harvest.Live plants store longer in a refrigerated cooler,staying crisp and still tasting fresh 2 weeks later(Fig. 3). Live plants stored in this manner have beensuccessfully replanted in a garden, demonstratingthe plant freshness when harvested in this manner.It can be an easy step for an existing hydroponicsproducer to convert a hydroponic system into anaquaponic system. Conversion of a hydroponicsystem means the addition of one or more tanks forfiltration, a fish tank, some extra PVC plumbing,and then the old system becomes a new aquaponicsystem.The crucial component of aquaponics is thenitrifying bacteria. The conversion, or nitrification,of ammonia excreted by fish does not occurautomatically. While fish produce ammonia—thefuel that runs the system—bacteria are consideredthe engine running the aquaponic system. Dailymaintenance activities revolve around maintainingan optimal environment for the bacteria, while dailywater quality measurements indirectly measure thehealth of the bacteria.Two types of bacteria act in stages to convertammonia, or fish waste, into usable nitrates andminerals for plant nutrition. The two types ofFi smoAmPl asp.*r iaasc tePlants uptake nutrientsfrom the water, filteringit for the fish.N itrosomonBaniaFish excreteammonia throughwaste and gills.hNitriteNitrobacter sp.NitrateBacteria convert wasteinto usable nutrientsfor plant growth.Figure 4. The aquaponic nitrogen cycle.*bacteria colonizing a root system2nt s

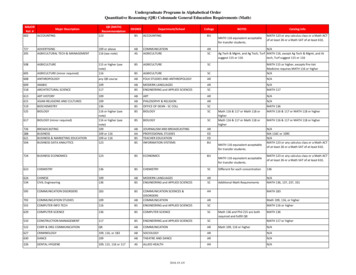

methods may consist of all the parts mentionedabove, plus a media bed. Additional componentssometimes used on a commercial scale include a“base supplementation” tank to adjust or amendwater so that fish and plants are not immediatelyexposed to rapid pH or other water-quality changes.Fish tanks, of course, are where the fish arehoused. A properly constructed aquaponic systemshould include at least two fish tanks. Some largecommercial operations have four or more fish tanks.Two fish tanks are strongly encouraged, even forbackyard or hobby systems. Two tanks are beneficialfor many reasons. Separating fish of various sizesreduces the risk of cannibalism. With a single fishtank, you cannot harvest the entire tank at oncewithout the risk of running out of nutrients forthe plants. With two fish tanks, all the fish in onetank may be harvested quickly, efficiently, andeconomically, while continuing to supply nutrientsfor the plants from the other fish tank. Partial fishharvest and replacement with fingerlings increasesthe risk of loss due to cannibalism for many species,so it may not be feasible to have a single tank forsome species. A minimum of two fish tanks is theideal solution.Imagine you have two fish tanks, with fingerlingsin one and medium-sized fish, about ½ pound, inthe other. When the larger fish mature and are readyfor sale or consumption, usually at about 1 pound,Plant Growthen the fingerlings are now at ½ pound. Addingfingerlings in the tank that was just harvested willbring you back to where you started: one tank withfingerlings, the other with mid-size fish. Dependingon your greenhouse size or the size of the troughs,fish tanks can range from a 100-gallon tank to a1500-gallon tank.Most commercial aquaponic startups do notconsider fish as part of the business plan. Acommon myth exists that aquaponics is cheaperthan hydroponics; this is not the case. One ton of32 percent fish feed costs about 485 and supplies305 pounds of nitrate. A similar amount of nitratesupplied from urea in a hydroponic system costsonly 107. If you plan to run a commercial aquaponicoperation, fish must be sold to cover operationalcosts. Finally, some fish species are poor choices inaquaponics. Examples of poor choices are catfish,bluegill, goldfish, or any other non-food fish withlimited sales outlets. The best choices are tilapia,hybrid striped bass, and rainbow trout in northernclimates. As a rotational winter crop, the mostsuitable options would be tilapia in summer, and koi,but only where there is a significant retail outlet forlarge koi.The clarifier comes in many shapes and underdifferent names, such as the solid waste filter, radialfilter, swirl filter, or solids settling tank. The primaryfunction of the clarifier is to separate the solid wasteBeds56’ 2”Filtration11’ 11”Fish Rearing Tank s18’ 4”Projected ProductionFish:Annual Harvests: 6.12Pounds/Harvest: 150 lbsAnnual Fish Production: 918 lbsAnnual Feed Input: 1,560.6 lbsVegetables:Time to Harvest: 4 weeksAnnual Lettuce Production:26,280–46,720 headsTotal Water Volume: 4,100 gallonsDug into GroundFlow Rate: 10 GPM3’ 6”Tanks:Fish Tanks: 4Clarifier (settleable solid removal): 2Flow-Through Filters (suspended solid removal): 2Degassing Tank (Volatilizes CO2/Methane Gas): 1Hydroponic Raceways (vegetable production): 2Sump (houses water pump): 1Water Pump:Quantity: 1Danner Supreme Mag Drive pump(2,400 gph, 265 W, 1/3hp)Figure 5. Schematic representation of an aquaponic system.3Airblowers:Quantity: 1Sweetwater Series 2 RegenerativeBlower, 2hp, 105 cfm, 230/460V,3-Phase

from the nutrientrich water (Fig. 6).Most clarifiers relyon reduced water andgravity to settle solidwaste at the bottomof tanks to be drainedout regularly.Some systemsemploy two clarifiertanks in a series (Fig.7) to remove most, ifnot all, the solid waste.This solid waste is notFigure 6. Schematic diagram of atruly a waste. It is stillclarifier tank for solid waste separation.rich in nutrients andshould be used efficiently instead of being discarded.The solid waste can be placed in a separate tank andaerated for a few days, filtered, and the resultingproduct, or “compost tea,” can be put back in theaquaponic system. The filtered compost tea can alsobe used as fertilizer in the garden. Alternatively, thesolid waste can be added to a vermicompost bin as asource of food for the worms (Fig. 8).The biofilter is where large numbers of nitrifyingbacteria are housed on inert media with a highsurface area. The biofilter is the primary site forthe conversion of ammonia to nitrites and nitrates.There are many approaches to building a biofilter,Figure 8. Earthworms in a media bed made of crushed granite, acting asanother step for solid waste filtration.just as long as you use an inert media with a verylarge surface area in contact with the water. Thereare also numerous biofilters available commercially.Ammonia conversion becomes more efficient withincreases in the surface area provided by the media.Commonly used materials are nylon or PVC birdnetting, lava rock, polyethylene filter pads, biomatrixpads, polyester filter fiber, floating or sinking plasticbeads, and fine-pore porcelain. Various other plasticmedia, including bio-balls, bio-barrels, bio-stars, andbio-tubes, are also commonly used. Once the systemis operational or has “matured,” nitrifying bacteriacan be found on every inert surface exposed tosufficient oxygen and little organic debris, includingthe growing troughs, plant roots, in the pipes, andon all other tanks. Still, the majority of biofiltration,or ammonia conversion, will take place in thebiofilter. Commercial units that combine the clarifierand biofilter in a single unit are available, althoughit is preferable to keep solid wastes separate fromareas containing nitrifying bacteria. Some operationsuse a media bed as biosolid digestion (Fig. 9). Mediabeds can also be planted so as not to waste valuablespace.The base tank serves the purpose of an additionalpoint to add water amendment products whenadjusting the pH of the aquaponic system. Thealkalinity and pH of water in an aquaponic systemtend to decrease over time due to the consumptionFigure 7. Two clarifier tanks connected in a series. The first one (top tank)relies on gravity to separate solids, the second (bottom left tank) relies onnetting.4

mesh bag submerged in the tank will act as a bufferby slowly and continuously adjusting the water pH.However, oyster shells may not be sufficient alone.The growing troughs or tanks are where plantproduction occurs. There are currently three typesof troughs used in aquaponics. Media beds are filledwith materials such as expanded clay pellets or pHneutral rock and are usually operated using theflood and drain method (Fig. 10). The media bedis set to fill with water during 20-minute intervals,then a float-valve, inverted siphon, or other drainmechanism is activated, and the water is drainedover a 10-minute period. This continuous flood anddrain cycle guarantees that the plant roots neverbecome dry or wet for too long. Expanded clay isexpensive, and many growers use other materialslike pea gravel or crushed granite. In this case, itis important to use pH neutral rock alternatives. Totest if the rock is pH neutral, add vinegar to a smallamount of rock. If it starts bubbling, the rock is notsuitable for an aquaponic system, no matter howwell it is washed before use. The advantage of amedia bed is that larger fruiting vegetable plants canbe grown in this media. The expanded clay providesphysical support for the roots of those large plants.The disadvantage of media beds is that large areasFigure 9. Media bed for solid waste filtration.and utilization of carbonates during bacterialprocesses and plant growth. Decreases in pH can berapid, especially if a rain event adds a large volumeof water to an open-air system. The water pH shouldbe checked regularly and adjusted by adding a base,bringing it as close to a neutral pH of 7 as possible.Chemical bases such as calcium carbonate (CaCO3),calcium hydroxide (Ca(OH)2), calcium oxide (CaO),or potassium bicarbonate (KHCO3) are availableproducts for raising pH. Crushed oyster shells, a formof calcium carbonate, are also popular among smallscale operations and homeowners. Oyster shells in aFigure 10. Flood and drain trough filled with expanded clay (left) or crushed granite (right).5

can become clogged, creating areas lacking oxygen,which requires frequent cleaning of the media.The second type of growing trough uses thenutrient film technique (NFT), commonly used inhydroponic operations. PVC pipes, gutters, or similarmaterials can be used for system construction(Fig. 11). In this system, a thin layer of water iscontinuously running through the pipes, and theplants’ roots are constantly exposed to nutrientrich water. No additional aeration is needed. Thissystem is suitable for small-sized plants such as leafygreens. Larger plants will have larger roots, whichwill clog the pipes or gutters. One disadvantage ofthe NFT is that water temperature can warm up veryquickly due to smaller volumes and thin sheets ofwater. However, with the addition of water chillers,lettuce production using the NFT can be done yearround.Figure 12. Deep water raft culture with lettuce at various stages of growth.Figure 11. Various lettuce cultivars are grown in an NFT system.water weight can be substantial. The DWRC systemis very popular among commercial operationsspecializing in leafy greens such as lettuce and kale.In a typical aquaponic system, the fish tanksare the highest point in terms of water level.Water cascades from the fish tank (black), to theclarifier(s), to the biofilter, to the supplementalaeration tank (blue barrels), and then to the growingtrough (not shown) (Fig. 13).The base tank is usually located at or near thereturn pump at the end of the production troughs,which is the lowest water level in the system. Hence,a water pump is necessary to push the water backup to the fish tank. This is normally the only waterpump that is needed in an aquaponic system. Airliftsystems use the blower supplying air to the fish andplants to return water to the fish tanks.The third and most popular type of growingtrough is the deep water raft culture system (DWRCor DWC) (Fig. 12). In this system, a rigid foam boardfloats on the surface of a relatively deep water troughthat is continually filled with water, and transplantsare placed in holes in the foam board so that rootsare submerged in water. Supplemental aerationfrom air stones or an air pump is absolutely vital forplants in a DWRC system. Troughs can be as shallowas 6 inches and as deep as 24 inches, although 18inches is the typical standard. Troughs do not haveto be on the ground. The troughs can be built on abench or table, but caution should be observed as theFigure 13. Cascading flow of water from fish tanks to the trough (not shown).6

When purchasing a water pump, keep in mindthat the flow rating of a pump is for a pump pushingwater horizontally. If the pump must push water upor vertically, the flow rating drops significantly. Forexample, a water pump rated at 500 gallons per hour(gph) can push water an elevation of 3 feet (headheight) at 300 gph only. Therefore, most pumpscarry a graph of flow rate in gallons per hour versushead height. When choosing a water pump, selectone that can circulate the entire volume of water inthe whole system a minimum of three times per day.For example, in a system with 1,000 gallons of watertotal, and a 500-gph pump pushing 300 gph of waterup 3 feet of head, you achieve a complete turnoverevery 3.3 hours, or 7.3 times per day.An air pump or blower is the only othercomponent using electricity. The air pump shouldbe connected via pressure tubing to airstones placedin the bottom of the fish tank(s) and growingtrough(s).One final component, not commonly consideredwhen building an aquaponic system but is of utmostimportance, is a backup generator. In the case of apower outage, plant roots can survive in low-oxygenlevels for about 12 to 24 hours without significantdamage. On the other hand, fish can suffocate in aslittle as 30 minutes to 4 hours depending on stockingdensity and time of the year after a power outage.In summary, aquaponics offers many advantagesto the homeowner or commercial producer.Aquaponics serves a dual purpose of producingboth fish and plants as food. Plants in an aquaponicsystem tend to grow faster than in an open fieldand use about 10 percent of the water needed. Mostimportantly, aquaponics produces fresh, healthyvegetables that were not treated with any chemicalpesticide or inorganic fertilizer. Aquaponics isnot restricted to commercial operations. Manyhomeowners install home-scaled systems for theirenjoyment and consumption (Fig. 14).Figure 14. Backyard system using barrels as growing beds (left) and home system with an aquarium (right).Texas A&M AgriLife Extension ServiceAgriLifeExtension.tamu.eduTexas A&M AgriLife Extension provides equal opportunities in its programs and employment to all persons, regardless of race,color, sex, religion, national origin, disability, age, genetic information, veteran status, sexual orientation, or gender identity.The Texas A&M University System, U.S. Department of Agriculture, and the County Commissioners Courts of Texas Cooperating.

The biotic, or living, components of an aquaponic system are fish, plants, and two genera of bacteria, all working in unison (Fig. 4). The abiotic, or non-living, components of an aquaponic system consists of a fish tank(s), clarifier or solid waste filtration tank, biofilter, plant growing beds, a water pump, and an air pump (Fig. 5).