Transcription

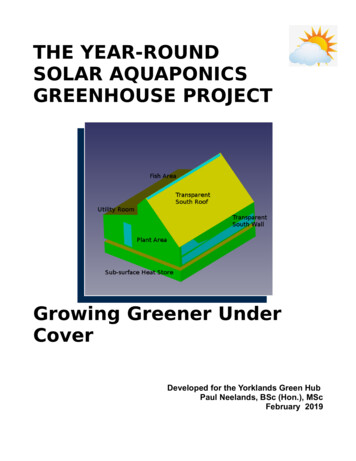

Aquaponics—Integration ofATTRA Hydroponics with AquacultureA Publication of ATTRA - National Sustainable Agriculture Information Service 1-800-346-9140 www.attra.ncat.orgBy Steve DiverNCAT AgricultureSpecialist 2006 NCATAquaponics is a bio-integrated system that links recirculating aquaculture with hydroponic vegetable,flower, and/or herb production. Recent advances by researchers and growers alike have turned aquaponics into a working model of sustainable food production. This publication provides an introductionto aquaponics with brief profiles of working units around the country. An extensive list of resourcespoint the reader to print and Web-based educational materials for further technical assistance.ContentsIntroduction . 1Aquaponics: KeyElements andConsiderations . 2Aquaponic Systems . 3The North Carolina StateUniversity System . 4The Speraneo System . 5The University of theVirgin Islands System . 7The Freshwater InstituteSystem . 8The Cabbage Hill FarmSystem . 9The New AlchemyInstitute. 9MiscellaneousSystems . 11Organic Aquaculture . 11Evaluating an AquaponicEnterprise . 12References . 13Resources . 13Appendix. 19Bibliography onAquaponics . 19Dissertations. 25ATTRA—National SustainableAgriculture Information Serviceis managed by the National Center for Appropriate Technology(NCAT) and is funded under agrant from the United StatesDepartment of Agriculture’sRural Business-Cooperative Service. Visit the NCAT Web site(www.ncat.org/agri.html) for more information on our sustainableagriculture projects. Aquaponic vegetable bed in Australia.Photo by Joel Malcolm, Backyard Aquaponics.www.backyardaquaponics.com(with permission)IntroductionAquaponics, also known as the integration of hydroponics with aquaculture,is gaining increased attention as abio-integrated food production system.Aquaponics serves as a model of sustainable food production by followingcertain principles: The waste products of one biologicalsystem serve as nutrients for a second biological system. The integration of fish and plantsresults in a polyculture thatincreases diversity and yieldsmultiple products. Water is re-used through biologicalfiltration and recirculation. Loca l food product ion pro vides access to healthy foods andenhances the local economy.In aquaponics, nutrient-rich effluent fromfish tanks is used to fertigate hydroponicproduction beds. This is good for thefish because plant roots and rhizobacteriaremove nutrients from the water. Thesenutrients—generated from fish manure,algae, and decomposing fish feed—are contaminants that would otherwise build upto toxic levels in the fish tanks, but insteadserve as liquid fertilizer to hydroponicallygrown plants. In turn, the hydroponic bedsfunction as a biofilter— stripping off ammonia, nitrates, nitrites, and phosphorus—so the freshly cleansed water can then berecirculated back into the fish tanks. Thenitrifying bacteria living in the gravel and inassociation with the plant roots play a critical role in nutrient cycling; without thesemicroorganisms the whole system wouldstop functioning.Greenhouse growers and farmers are takingnote of aquaponics for several reasons: Hydroponic growers view fishmanured irrigation water as asource of organic fertilizer thatenables plants to grow well. Fish farmers view hydroponics asa biofiltration method to facilitateintensive recirculating aquaculture. Greenhouse growers view aquaponics as a way to introduce organichydroponic produce into the marketplace, since the only fertility inputis fish feed and all of the nutrientspass through a biological process. Food-producing greenhouses—yielding two products from one

production unit—are naturallyappealing for niche marketing andgreen labeling. Aquaponics can enable the production of fresh vegetables and fish protein in arid regions and on waterlimited farms, since it is a waterre-use system. Aquaponics is a working model ofsustainable food production whereinplant and animal agriculture areintegrated and recycling of nutrientsand water filtration are linked.Related ATTRAPublicationsEvaluating anAquacultureEnterpriseAgricultural BusinessPlanning Templatesand Resources In addition to commercial application, aquaponics has become apopular training aid on integratedbio-systems with vocational agriculture programs and high schoolbiology classes.The technology associated with aquaponics is complex. It requires the ability tosimultaneously manage the productionand marketing of two different agriculturalproducts. Until the 1980s, most attemptsat integrated hydroponics and aquaculture had limited success. However, innovations since the 1980s have transformedaquaponics technology into a viable system of food production. Modern aquaponicsystems can be highly successful, but theyrequire intensive management and they havespecial considerations.Aquaponics: Key Elementsand ConsiderationsNutrients in Aquaculture Eff luent:Greenhouse growers normally control thedelivery of precise quantities of mineralelements to hydroponic plants. However,in aquaponics, nutrients are delivered viaaquacultural effluent. Fish effluent containssufficient levels of ammonia, nitrate, nitrite,phosphorus, potassium, and other secondary and micronutrients to produce hydroponic plants. Naturally, some plant speciesare better adapted to this system than others. The technical literature on aquaponicsprovides greater detail on hydroponic nutrient delivery; especially see papers cited inthe Bibliography by James Rakocy, PhD.A successful aquaponics enterprise requiresspecial training, skills, and management.The following items point to key elementsand considerations to help prospective growers evaluate the integration of hydroponicswith aquaculture.Plants Adapted to Aquaponics: Theselection of plant species adapted to hydroponic culture in aquaponic greenhousesis related to stocking density of fish tanksand subsequent nutrient concentration ofaquacultural effluent. Lettuce, herbs, andThis publication provides an introduction toaquaponics, it profiles successful aquaponicgreenhouses, and it provides extensiveresources. It does not attempt to describeproduction methods in comprehensive technical detail, but it does provide a summaryof key elements and considerations.Page 2ATTRAHydroponics: Hydroponics is the production of plants in a soilless medium wherebyall of the nutrients supplied to the crop aredissolved in water. Liquid hydroponic systems employ the nutrient film technique(NFT), floating rafts, and noncirculatingwater culture. Aggregate hydroponic systems employ inert, organic, and mixedmedia contained in bag, trough, trench,pipe, or bench setups. Aggregate mediaused in these systems include perlite, vermiculite, gravel, sand, expanded clay, peat,and sawdust. Normally, hydroponic plantsare fertigated (soluble fertilizers injectedinto irrigation water) on a periodical cycleto maintain moist roots and provide a constant supply of nutrients. These hydroponicnutrients are usually derived from syntheticcommercial fertilizers, such as calciumnitrate, that are highly soluble in water.However, hydro-organics—based on soluble organic fertilizers such as fish hydrosylate—is an emerging practice. Hydroponicrecipes are based on chemical formulations that deliver precise concentrations ofmineral elements. The controlled delivery of nutrients, water, and environmental modifications under greenhouse conditions is a major reason why hydroponics isso successful.Aquaponics—Integration of Hydroponics with Aquaculture

specialty greens (spinach, chives, basil, andwatercress) have low to medium nutritionalrequirements and are well adapted to aquaponic systems. Plants yielding fruit (tomatoes, bell peppers, and cucumbers) havea higher nutritional demand and performbetter in a heavily stocked, well establishedaquaponic system. Greenhouse varietiesof tomatoes are better adapted to low light,high humidity conditions in greenhousesthan field varieties.Fish Species: Several warm-water andcold-water fish species are adapted to recirculating aquaculture systems, includingtilapia, trout, perch, Arctic char, and bass.However, most commercial aquaponic systems in North America are based on tilapia. Tilapia is a warm-water species thatgrows well in a recirculating tank culture.Furthermore, tilapia is tolerant of fluctuating water conditions such as pH, temperature, oxygen, and dissolved solids. Tilapiaproduces a white-fleshed meat suitable tolocal and wholesale markets. The literatureon tilapia contains extensive technical documentation and cultural procedures. Barramundi and Murray cod fish species areraised in recirculating aquaponic systemsin Australia.Water Quality Characteristics: Fishraised in recirculating tank culture requiregood water quality conditions. Water quality testing kits from aquacultural supply companies are fundamental. Criticalwater quality parameters include dissolvedoxygen, carbon dioxide, ammonia, nitrate,nitrite, pH, chlorine, and other characteristics. The stocking density of fish, growthrate of fish, feeding rate and volume, andrelated environmental fluctuations can elicitrapid changes in water quality; constantand vigilant water quality monitoringis essential.Biofiltration and Suspended Solids:Aquaculture effluent contains nutrients, dissolved solids, and waste byproducts. Someaquaponic systems are designed with intermediate filters and cartridges to collect suspended solids in fish effluent, and to facilitate conversion of ammonia and other wastewww.attra.ncat.orgproducts to forms more available to plantsprior to delivery to hydroponic vegetablebeds. Other systems deliver fish effluentdirectly to gravel-cultured hydroponic vegetable beds. The gravel functions as a “fluidized bed bioreactor,” removing dissolvedsolids and providing habitat for nitrifyingbacteria involved in nutrient conversions.The design manuals and technical documentation available in the Resources section can help growers decide which systemis most appropriate.Component Ratio: Matching the volumeof fish tank water to volume of hydroponicmedia is known as component ratio. Earlyaquaponics systems were based on a ratioof 1:1, but 1:2 is now common and tank:bed ratios as high as 1:4 are employed.The variation in range depends on type ofhydroponic system (gravel vs. raft), fish species, fish density, feeding rate, plant species, etc. For example, the Speraneo systemdescribed below is designed for one cubicfoot of water to two cubic feet of grow bedmedia (pea gravel). Further, when shallowbed systems only three inches in depth areemployed for the production of specialtygreens such as lettuce and basil, the squarefootage of grow space will increase fourtimes. Depending on the system design, thecomponent ratio can favor greater outputs ofeither hydroponic produce or fish protein.A “node” is a configuration that links onefish tank to a certain number of hydroponicbeds. Thus, one greenhouse may containa multiple number of fish tanks and associated growing beds, each arranged in aseparate node.Tilapia is awarm-waterspecies thatgrows well in a recirculating tank culture.Male tilapia fish. AARM- Aquaculture & AquaticResources ManagementAsian Institute ofTechnology, c SystemsProfiles of several aquaponic greenhousesare highlighted below as models of commercially viable systems. Most of theseATTRAPage 3

operations are featured in magazine articlesand conference proceedings. Some operations offer technical assistance throughshort courses, design manuals, and on-sitetours. Please refer to articles in the Suggested Reading list, the Resources section, and the Bibliography for in-depthdescriptions and technical details.The North Carolina StateUniversity SystemWater consumption inan integrated aquavegeculture systemamounts to 1 percent of that requiredin pond culture toproduce equivalenttilapia yields.In the 1980’s Mark McMurtry (formergraduate student) and the late Doug Sanders (professor) at North Carolina State University developed an aqua-vegeculture system based on tilapia fish tanks sunk belowthe greenhouse floor. Effluent from the fishtanks was trickle-irrigated onto sand-cultured hydroponic vegetable beds located atground level. The nutrients in the irrigationwater fed tomato and cucumber crops, andthe sand beds and plant roots functioned asa biofilter. After draining from the beds,the water recirculated back into the fishtanks. The only fertility input to the systemwas fish feed (32 percent protein).S ome f i nd i ng s a nd h i gh l i ght s ofMcMurtry’s research: Benefits of integrating aquacultureand vegetable production are:1. conservation of water resourcesand plant nutrients2. intensive production of fishprotein3. reduced operating costs relativeto either system in isolation. Water consumption in an integratedaqua-vegeculture system amounts to1 percent of that required in pondculture to produce equivalent tilapiayields. Such low-water-use symbiotic systems are applicable to the needsof arid or semi-arid regions wherefish and fresh vegetables are in highdemand. Organic vine-ripened, pesticidefree produce and “fresh-daily”Page 4ATTRAfish can bring premium prices,particularly during winter monthsin urban areas. Biofilters (sand beds with vegetables) that are alternately floodedand drained with nutrient-laden fishtank water are called reciprocatingbiofilters. Reciprocating biofilters provideuniform distribution of nutrientladen water within the filtrationmedium during the flood cycle, andimproved aeration from atmosphericexchange during each dewateringwith benefits to both nitrifying bacteria and plant roots. Dissolved and suspended organicmateria ls accumulate rapidlyin aquaculture systems and mustbe removed for efficient fishproduction. Previous integrated fish-vegetablesystems removed suspended solidsfrom the water by sedimentation inclarifiers prior to plant application.Removal of the solid wastes resultedin insufficient residual nutrients forgood plant growth; acceptable fruityields had previously only beenachieved with substantial supplementation of plant nutrients. Aquaeous nitrate concentrations inrecirculating aquaculture can beadequately regulated when fish andvegetable production are linked viareciprocating biofilters. Tomatoes may have also assimilated nitrogen in organic aminoacid forms. In 1950 Gosh and Burris (Utilization of nitrogenous compounds by plants. Soil Science.Vol. 70: 187-203) found that tomatoes utilize alanine, glutamic acid,histidine, and leucine as effectivelyas inorganic nitrogen sources. Research to determine the optimumratio of fish tank to biofilter volumeon fish growth rate and water quality found that stocking density offish and plants can vary dependingAquaponics—Integration of Hydroponics with Aquaculture

on desired goal. The componentratios of the system may be manipulated to favour fish or vegetable production according to local markettrends or dietary needs. Fish stocking density and feeding rates areadjusted to optimize water qualityas influenced by plant growth rate.See the Bibliography on Aquaponicsin the appendix for a of list articles thatresulted from the North Carolina research.Aqua-vegeculture research at NCSU hasbeen discontinued because the technologyhad evolved to the point where it is readyfor grower application. The Department ofHorticulture and the Cooperative ExtensionService at NCSU provide technical assistance to aquaponic greenhouse growers inNorth Carolina.The Speraneo SystemIn the early 1990s, Tom and Paula Speraneo—owners of S & S Aqua Farm nearWest Plains, Missouri—modified the NorthCarolina State method by raising tilapia ina 500-gallon tank, with fish effluent linkedto gravel-cultured hydroponic vegetablebeds inside an attached solar greenhouse.Later, they expanded to a full-size commercial greenhouse. The Speraneo system waspractical, productive, and wildly successful.It became the model for dozens of commercial aquaponic greenhouses and high schoolbiology programs.tank-plus-hydroponic bed setup as a “node.”This way, each node can operate independently of one another.Some aspects of the Speraneo system weremodeled after the aquaponics research atNorth Carolina State University, while others are modified. The Speraneos employhydroponic vegetable beds as “fluidizedbed reactors,” but they use pea-grade rivergravel instead of sand. Tilapia are raisedin fish tanks, but the tanks are more conveniently located above ground and tilapiahybrids adapted to cooler water temperatures are grown. The reciprocating watercycle, PVC piping, and return-flow waterpumping methods were designed by Tomand Paula to match their system.For years, Purina fish chow at 40 percentprotein was the primary fertility input, supplemented with tank-cultured algae. Tilapia in the Speraneo system are raised for7 to 12 months, then harvested at one toone-and-a-half pounds in size. Later, Tomstarted adding small amounts of Planters2 rock dust on top of the gravel as a traceelement supplement.Sadly, Tom Speraneo died in February2004. Tom was a true pioneer in aquaponics, and he was unfailingly generousand helpful to others. Paula Speraneoand her family continue to run the greenhouse and actively participate in aquaponics technology transfer. The followingnotes describe the Speraneo system andavailable resources.S & S Aqua Farm has grown fresh basil,tomatoes, cucumbers, mixed salad greens,and an assortment of vegetable, herb, andornamental bedding plants in the aquaponic greenhouse. In the early 1990’s,Tom and Paula were raising and sellingbasil for 12 a pound to gourmet restaurants about four hours away in St. Louis,Missouri. Following passage of the NorthAmerican Free Trade Agreement (NAFTA),however, Mexican imports of basil resultedin a market crash to 4 per pound, so theydropped the St. Louis market. S & S AquaFarm now grows a diverse variety of vegetable and herbs, selling locally at a farmersmarket combined with direct sales out oftheir greenhouse.The commercia l-sca le solar g reenhouse at S & S Aqua Farm is 50 feet by80 feet, oriented East-West to create asouth-facing slope. It contains six 1,200gallon fish tanks. Each tank is linked tosix one-foot-deep hydroponic beds filledwith river gravel. Tom referred to eachTom once calculated the farm produces 45to 70 pounds of produce for every pound oftilapia, an impressive yield. However, Paulaexplained this figure takes into account thecummulative yields of multiple vegetablecrops raised during the 7 to 12 month timeperiod required to raise fish to harvest.www.attra.ncat.orgThe Speraneo systemwas practical, productive, andwildly successful.ATTRAPage 5

Aquaponic greenhouseat S&S Aqua Farms, WestPlains, Missouri. Photosby Steve Diver, NCAT.Page 6ATTRAAquaponics—Integration of Hydroponics with Aquaculture

The component ratio favors vegetables overfish yields in the Speraneo system.Interest in the Speraneo system resultedin more than 10,000 visitors to the smallfarm in Missouri, including school children,farmers, researchers, and government officials. To handle requests for assistance, theSperaneos compiled a resource packet anddesign manual with technical specificationsto establish an S & S Aqua Farm-style aquaponic system. The resource packet includesa 10-minute video and a list of supplies.Response from growers to a practical designmanual such as this was tremendous. TheSperaneo system is now in use worldwide.The resource packet, which sells for 250,is available through:S & S Aqua Farm[Contact: Paula Speraneo]8386 County Rd. 8820West Plains, MO .com/snsaqua/index.htmlEspecially see:Maturing Marvelby Vern ModelandThe Growing Edge, May-June 1998www.townsqr.com/snsaqua/0905ssaf.pdfThe Genius of Simplicityby John Wesely SmithThe Growing Edge, Winter cs—Revolution in Food Growing: Missouri Aquafarmer DiscoversHuge Benefits in Trace Elementsby David YarrowRemineralize the Earth, December 1997www.championtrees.org/topsoil/bioponics.htmThe University of the VirginIslands SystemJames Rakocy, PhD, and associates at theUniversity of the Virgin Islands (UVI) developed a commercial-scale aquaponic systemthat has run continuously for more than fiveyears. Nile and red tilapia are raised in fishwww.attra.ncat.orgrearing tanks, and the aquacultural effluent is linked to floating raft hydroponics.Basil, lettuce, okra, and other crops havebeen raised successfully, with outstandingquality and yields.The system components include: Four fishrearing tanks at 7,800 liters each, clarifiers, filter and degassing tanks, air diffusers, sump, base addition tank, pipes andpumps, and six 400-square foot hydroponictroughs totaling 2,400 sq. ft. The pH ismonitored daily and maintained at 7.0 to7.5 by alternately adding calcium hydroxideand potassium hydroxide to the base addition tank, which buffers the aquatic systemand supplements calcium and potassiumions at the same time. The only other supplemental nutrient required is iron, whichis added in a chelated form once everythree weeks.Tilapia are stocked at a rate of 77 fish percubic meter for Nile tilapia, or 154 fish percubic meter for red tilapia and cultured for24 weeks. The production schedule is staggered so that one tank is harvested everysix weeks. After harvest, the fish tank isimmediately restocked. The fish are fedthree times daily with a complete, floatingfish pellet at 32 percent protein. Projectedannual fish production is 4.16 metric tonsfor Nile tilapia and 4.78 metric tons forred tilapia.James Rakocy,PhD, and associates at theUniversity of theVirgin Islands (UVI)developed a commercial-scale aquaponic system thathas run continuously for more thanfive years.In one notable experiment the UVIresearchers compared the yields of a leafyherb (basil) and a fruiting vegetable (okra)grown in aquaponic vs field production systems. Basil and okra were raised in rafthydroponics. Yields of aquaponic basilwere three times greater than field-grown,while yields of aquaponic okra were 18times greater than field-grown. Based ona market price in the U.S. Virgin Islandsof 22 per kg for fresh basil with stems,researchers calculated gross income potential. The aquaponic method would result in 515 per cubic meter per year or 110,210per system per year. This compares to fieldproduced basil at 172 per cubic meterper year or 36,808 per year for the sameproduction area. When fish salesATTRAPage 7

are included, the aquaponic systemyields 134,245. (1)Like McMurtry, researcher Rakocy seesintegrated water reuse systems as a viablesolution to sustainable food production indeveloping countries and arid regions—such as the Caribbean Islands—where freshwater is scarce.LikeMcMurtry,researcherRakocy sees integrated water reusesystems as a viablesolution to sustainable food production in developing countries andarid regions—suchas the CaribbeanIslands—wherefresh water is scarce.To provide in-depth technical support, theUVI research team offers a week-long shortcourse on aquaponics each year at the UVIagricultural experiment station. The UVIshort course is the premier educationaltraining program available to farmers in theworld. In addition to aquaponics, UVI specializes in greenwater tank culture, a recirculating aquaculture system.Rakocy has published extensive researchreports and several Extension Service bulletins on recirculating aquaculture andaquaponics. See the Bibliography in theappendix for citations to articles and papersby Rackocy.Contact:James Rakocy, PhDUniversity of the Virgin IslandsAgriculture Experiment StationRR 1, Box 10,000Kingshill, St. CroixU.S. Virgin Islands AES/Aquaculture/aquaponics.htmlEspecially see:Update on Tilapia and Vegetable Production in the UVI Aquaponic SystemJames E. Rakocy, Donald S. Bailey, R.Charlie Shultz and Eric S. Thoman page676-690. In: New Dimensions on FarmedTilapia: Proceedings of the Sixth International Symposium on Tilapia in Aquaculture, Held September 12-16, 2004 inManila, Philippines.Proceedings paper: 15 pageshttp://ag.arizona.edu/azaqua/ista/ista6/Page 8ATTRAista6web/pdf/676.pdfPowerPoint presentation; 49 web/presentation/p676.pdfAquaponics: Integrated Technologyfor Fish and Vegetable Production inRecirculating SystemsJames Rakocy, University of the VirginIslandsUSDA Ministerial Conference and Expo onAgricultural Science and TechnologyPowerPoint presentation; 69 sion%202d/02-rakocy j-2D%202ndfiles/frame.htmThe Freshwater Institute SystemThe Freshwater Institute in Shepherdstown,West Virginia—a program of The Conservation Fund, an environmental non-profitorganization—specializes in aquacultureresearch and education. Fresh spring wateris an abundant resource in the Appalachian region. However, protection of springwater quality as it relates to aquacultureeffluent is viewed as a vital component ofthis technology.For years, the institute has specialized incold-water recirculating aquaculture systemsraising trout and arctic char. The institutehelps Appalachian farmers set up two typesof aquaculture systems: (a) an indoor, hightech recirculating tank method and (b) anoutdoor, low-tech recirculating tank method.Treatment of aquaculture effluent prior toits return to the natural stream flow ledto collaborative research with USDA-ARSscientists in Kearneysville, West Virginia,on integrated hydroponic-fish culturesystems. Trials at the institute’s greenhouses showed that nitrogen, phosphorus,and other nutrients in aquaculture effluent can be effectively removed by plantsgrown in NFT hydroponics or constructedwetland systems.In the mid-1990s, the institute implementedan aquaponic demonstration program basedon a Sperraneo-style gravel-cultured system. Tilapia is raised as a warm-water fishAquaponics—Integration of Hydroponics with Aquaculture

species. Hydroponic crops include basil,lettuce, and wetland plants.To provide technical assistance to farmersand high school biology teachers, the institute published a series of publications onrecirculating aquaculture and aquaponics.The Freshwater Institute Natural Gas Powered Aquaponic System—Design Manual is a37-page manual published by the institutein 1997. Included are diagrams and photos, details on greenhouse layout and aquaponic production, parts list with suppliersand cost, estimated operating expense, andfurther informational resources.Please note the institute no longer provides direct technical assistance to farmers on aquaponics. Instead, it has madethe aquaponics design manual and relatedpublications on recirculating aquacultureand aquaponics ava i lable a s freeWeb downloads.The Freshwater InstituteShepherdstown, WVwww.freshwaterinstitute.orgSelected Web Publications from TheFreshwater Institute Suggested Management Guidelinesfor An Integrated Recycle Aquaculture – Hydroponic System The Freshwater Institute NaturalGas Powered Aquaponic System Design Manual 880 Gallon Recycle AquacultureSystem Installation Guide Linking Hydroponics to a 880 Gallon Recycle Fish Rearing System Operators Manual for 880 - RecycleSystemThe Cabbage Hill Farm SystemCabbage Hill Farm is a non-profit organization located about 30 miles north of NewYork City. The foundation is dedicatedto the preservation of rare breeds of farmanimals, sustainable agriculture andlocal food systems, and aquaponicgreenhouse production.www.attra.ncat.orgCabbage Hill Farm designed and continuesto operate a simple recirculating aquaponicsystem. Cabbage Hill Farm promotes education on aquaponics and hosts greenhouseinterns. Tours are available.Tilapia fish and leaf lettuce are the mainproducts of the Cabbage Hill Farm system,though basil and watercress are also grownin smaller quantities. In addition to hydroponics, water passes through a constructedreed bed outside the greenhouse for additional nutrient removal.Aquaponics—Preserving the Future is a videofilm documenting the research and demonstration of aquaponics at Cabbage HillFarms. The cost is 18.Cabbage Hill Farm205 Crow Hill RoadMount Kisco, NY 10549914-241-2658914-241-8264 FAXwww.cabbagehillfarm.orgCabbage HillFarm promotes education on aquaponics and hostsgreenhouse interns.The New Alchemy InstituteThe New Alchemy Institute in East Falmouth, Massachusetts, conducted researchon integrated aquaculture systems duringthe 1970s and 1980s. Although the institute closed in 1991, New Alchemy publications on greenhouse production andaquaponics provide historical insight tothe emerging bioshelter (ecosystem greenhouses) concept and are still a valuableresource for technical information. TheGreen Center, formed by a group of former New Alchemists, is again making thesepublications available for sale. The Website has a section featuring for-sale articleson aquaculture and bioshelters (integratedsystems). A selection of past articles isavailable online.Contact:The Green Center237 Hatchville Rd.East Falmouth, MA 02536www.vsb.cape.com/ nature/greencenter/ATTRAPage 9

Backyard Aquaponicsin Western Australia.Photos by Joel Malcolm,Backyard Aquaponics.(with permission)www.backyardaquaponics.comPage 10ATTRAAquaponics—Integration of Hydroponics with Aquaculture

Especially see:An Integrated Fish Culture Hydroponic Vegetable Production Systemby Ronald D. ZweigAquaculture Magazine, May-June 1986.www.vsb.cape.com/ nature/greencenter/pdf/zweig.pdfSummary of Fish Culture Techniquesin Solar Aquatic Pondsby John Wolfe and Ron ZweigJournal of The New Alchemists, 1977www.vsb.cape.com/ nature/greencenter/pdf/j6ponds.pdfMiscellaneous SystemsInstead of loca

Aquaponic vegetable bed in Australia. Photo by Joel Malcolm, Backyard Aquaponics. www.backyardaquaponics.com (with permission) Introduction Aquaponics, also known as the integra-tion of hydroponics with aquaculture, is gaining increased attention as a bio-integrated food production system. Aquaponics serves as a model of sus-