Transcription

Landscape Irrigation Design Manual

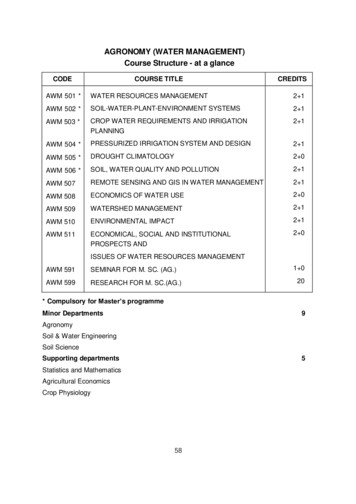

cContentsForward .vIntroduction .viiStep one: Understanding basic hydraulics .3Static water pressure .4Dynamic water pressure .6Exercises on basic hydraulics .9Step two: Obtaining site information .13Step three: Determining irrigation requirements .19Soil type .19Exercises on site information and irrigation requirements .23Step four: Determining water and power supply .27Calculating water meter capacity and working pressure .27Rule number one .27Rule number two .28Rule number three .28Exercises on water capacity and pressure .30Step five: Selecting sprinklers and spacing ranges .35Selecting sprinklers .35Spray sprinklers .35Rotating sprinklers .35Bubblers and drip irrigation devices .35Exercises on selecting sprinklers .40Spacing sprinklers and calculating precipitation rates .41Exercises on spacing sprinklers and calculating precipitation rates .47Locating sprinklers on the plan .48Exercises on locating sprinklers .52Step six: Lateral layout, circuiting sprinklers into valve groups .55Locating valves, main lines and lateral piping .57Calculating lateral operating time .58Sample lateral number 1 .59Sample lateral number 2 .59Step seven: Sizing pipe and valves and calculating system pressure requirements .65Exercises on calculating system pressure requirements .71Step eight: Locating the controller and sizing the valve and power wires .75Locating the controller .75Sizing valve wires .75Sizing power wires .78Step nine: Preparing the final irrigation plan .83Exercises on system electrics and preparing the final irrigation plan .85Irrigation references .86Landscape Irrigation Design Manual iii

ContentsSolutions .89Solutions to exercises on basic hydraulics .89Solutions to exercises on site information and irrigation requirements .89Solutions to exercises on water capacity and pressure .89Solutions to exercises on selecting sprinklers .90Solutions to exercises on spacing sprinklers and calculating precipitation rates .90Solutions to exercises on locating sprinklers .90Solutions to exercises on circuit configuration and operating time .91Solutions to exercises on calculating system pressure requirements .91Solutions to exercises on system electrics and preparing the final irrigation plan .91Technical Data .94U.S. Standard Units .94Friction loss characteristics PVC schedule 80 IPS plastic pipe .94Friction loss characteristics PVC schedule 40 IPS plastic pipe .95Friction loss characteristics PVC class 315 IPS plastic pipe.96Friction loss characteristics PVC class 200 IPS plastic pipe.97Friction loss characteristics PVC class 160 IPS plastic pipe.98Friction loss characteristics PVC class 125 IPS plastic pipe.99Friction loss characteristics polyethylene (PE) SDR-pressure-rated tube .100Friction loss characteristics schedule 40 standard steel pipe.101Friction loss characteristics type K copper water tube .102Pressure loss in valves and fittings .103Pressure loss through copper and bronze fittings .103Climate PET .103Estimated service line sizes .103Pressure loss through swing check valves .104Soil characteristics .104Maximum precipitation rates .105Friction loss characteristics of bronze gate valves .105Slope reference .105Pressure loss through water meters AWWA standard pressure loss .106International System Units.107Friction loss characteristics PVC schedule 80 IPS plastic pipe .107Friction loss characteristics PVC schedule 40 IPS plastic pipe .108Friction loss characteristics PVC class 315 IPS plastic pipe .109Friction loss characteristics PVC class 200 IPS plastic pipe .110Friction loss characteristics PVC class 160 IPS plastic pipe .111Friction loss characteristics PVC class 125 IPS plastic pipe .112Friction loss characteristics polyethylene (PE) SDR-pressure-rated tube .113Friction loss characteristics schedule 40 standard steel pipe.114Friction loss characteristics type K copper water tube .115Pressure loss in valves and fittings .116Climate PET .116Estimated service line sizes .116Pressure loss through copper and bronze fittings .116Pressure loss through swing check valves .117Soil characteristics .117Maximum precipitation rates .118Friction loss characteristics of bronze gate valves .118Slope reference .118Pressure loss through water meters AWWA standard pressure loss .119Appendix.121Table of formulas .123Table of figures .124Index .129iv Landscape Irrigation Design Manual

ForwardThis manual was prepared at the request of numerousindividuals who either wished to learn the basic techniquesof landscape irrigation design or who are teachers of thesubject. Intended as a very basic text for irrigation design,this manual proceeds as if the reader has no priorknowledge in the subject.As you use this manual, be sure to review the practicalexercises at the end of each section. In some cases, newinformation and tips, not covered in the previous section,are found in the exercises.The main omission from a design manual such as this isthe real, hands-on experience of designing and theninstalling a landscape irrigation system. The editors of theLandscape Irrigation Design Manual hope such anopportunity is available to you and that the informationpresented here is of benefit.Landscape Irrigation Design Manual v

IntroductionProperly designed, installed, maintained and managedlandscape irrigation systems greatly reduce the volume ofirrigation water that is wasted every year. In some watershort areas, we have seen the beginnings of planned waterconservation efforts. In time, these could become the basisfor a coordinated national policy toward waterconservation. Today many municipalities require home orbusiness owners to submit irrigation designs for approvalprior to construction.This manual is part of the effort to promote properlydesigned landscape irrigation systems. It is our goal topresent the material as simply as possible while explainingsome theory behind the process. Understanding the basichydraulics material in the first section of the manual is veryimportant, especially to new students of irrigation design.Even intermediate level design students may find it helpfulto “brush up” on hydraulics before going on to furtherstudies. With that said, please turn the page to discoversome facts about the nature of water.Note: Information contained in this manual is based upongenerally accepted formulas, computations and tradepractices. If any problems, difficulties, or injuries shouldarise from or in connection with the use or application ofthis information, or if there is any error herein,typographical or otherwise, Rain Bird Sprinkler Mfg. Corp.,and its subsidiaries and affiliates, or any agent or employeethereof, shall not be responsible or liable.Note: Metric data (International System Units) containedin this manual is not always a one-to-one conversion fromU.S. measurements (U.S. Standard Units). Some metricdata has been altered to simplify examples. 2000 Rain Bird Sprinkler Manufacturing Corporation.All rights reserved.Landscape Irrigation Design Manual vii

UnderstandingBasic Hydraulics1

1Step one: Understanding basichydraulicsHydraulics is defined as the study of fluid behavior, at restand in motion. Properly designed piping, with soundhydraulics, can greatly reduce maintenance problems overthe life of an irrigation system. Controlling the water flowvelocity, holding velocity within proper limits, reduces wearon the system components and lengthens service life. Poorhydraulic design results in poor performance of theirrigation system, leading to stressed landscaping material,or even broken pipes and flood damage. Lack of designknow-how can also cost the system owner more moneybecause the designer may over-design the system to avoidunknown factors. In addition to wasting money, a poorhydraulic design will often waste water. Hydraulic analysisis important to minimize financial risks, produce efficientdesigns and eliminate waste.To accomplish all these things we need to understand thenature of water. Water takes the shape of the container.Water is relatively incompressible. Water is also quite heavy— one gallon (one liter) of water weighs 8.3 lbs (1 kg) andwater has a specific weight per cubic foot of 62.4 lbs (oneton per cubic meter). Water responds to gravity and seeksits own lowest level (responding to gravity). Water exertspressure — defined as the force of water exerted over agiven area. The formula for water pressure looks like this:P force Farea AP pressure in pounds per square inch (kilograms per squarecentimeter)F force in pounds (kilograms)A area in square inches (square centimeters)The force is created by the weight of the water above thepoint where it is being measured. When the area is constant,such as 1 in2 (1 cm2), then the force in pounds (kilograms) isdependent on, simply, the height of the water. The moreheight to a column of water, the more weight, force, andpressure. Pressure is expressed as pounds per square inch(kilograms per square centimeter) and abbreviated as psi(kg/cm2 or bar).A container 1 in2 (1 cm2) and filled with water to a height of1 ft (50 cm) — the pressure (psi/bar) would equal:Understanding Basic HydraulicsP W .036 lb in3 x 12 in3 0.433 lbA1 in x 1 in1 in2P W 1gm/cm3 x 50 cm3 50 gm 0,05 kg/cm2A1 cm x 1 cmcm2P 0.433 psi (0,05 bar)P W .036 lb in3 x 24 in3 0.866 lbA1 in x 1 in1 in2P W 1 gm/cm3 x 100 cm3 100 gm 0,10 kg/cm2A1 cm x 1 cmcm2P 0.866 psi (0,1 bar)Consider a 1 in2 (1 cm2) container filled with water to adepth of 1 ft (50 cm). One foot (50 cm) of water creates apressure of .433 psi (0,05 bar) at the base of the container. Itmakes no difference if the 1 ft (50 cm) of water is held inthis narrow container or at the bottom of a 1 ft (50 cm)deep lake. The area we are concerned with is only 1 in2 (1cm2) at the bottom of either container.24 in(100 cm)12 in(50 cm)1 in 1 in(1 cm) (1 cm)1 in 1 in(1 cm) (1 cm)Figure 1: Water towers filled at 12 in and 24 in (50 cm and 100 cm)If you double the height of the water, the pressure is doubled.433 x 2 ft of height .866 psi0,05 bar x 2 0,1 barThis relationship between pressure and elevation is knownas “feet of head” (meters of head). By using this conversionfactor, we can easily determine the static (no flow) waterpressure within any pipe.The factors for converting pressure to feet of head (metersof head) and feet of head (meters of head) back to pressureare both multipliers. To convert feet of head to pressure inLandscape Irrigation Design Manual 3

Understanding Basic Hydraulicspsi, multiply the feet by .433 One foot of water .433 psi.For example, 200 ft of water height x .433 produces 86.6 psiat its base. (To convert meters of head to pressure inkg/cm2, divide the meters by 10. One meter of water 0,1kg/cm2. For example, 100 meters of water x 0,1 kg/cm2 10kg/.cm2 or 10 bar of pressure at its base.) Further, usingthis factor we can determine that a water tower with awater surface 200 ft (100 m) above the point where we needit would create a pressure of 86.6 psi (10 bar).To convert pressure in psi to feet of head, multiply thepressure by 2.31. One psi 2.31 ft of water. For example,100 psi x 2.31 231 feet of head. (To convert pressure in baror kg/cm2 to meters of head, multiply the pressure by 10. 1kg/cm2 10 meters of water 1 bar. For example, 10kg/cm2 100 meters of head.)Calculating with this factor in advance, we would knowthat we can’t pump water up into a lake that is 300 ft(200 m) above our water source if we had a pumping waterpressure available of 100 psi (10 bar). Pressure of 100 psi(10 bar) would only lift the water 231 ft (100 m).200 ft(100 m)86.6 psi(10 bar)Figure 2: Water tower – 200 ft (100 m)Figure 3: Water supply to a house4 Landscape Irrigation Design ManualThe word hydrostatic refers to the properties of water atrest. We will be discussing static water pressure as a startingpoint for hydraulic design of an irrigation system.Hydrodynamic refers to the properties of water in motion.Moving water, at the correct flow and pressure, to where it’sneeded is the hydraulic basis of irrigation design. Staticwater pressure refers to the pressure of a closed systemwith no water moving. A water-filled main line, with allvalves closed, would experience full static pressure withonly pressure variation due to elevation. Static waterpressure is an indication of the potential pressure availableto operate a system.Static water pressureThere are two ways to create static water pressure. As wehave seen in our discussion regarding the relationshipbetween pounds per square inch (bar) and elevation, waterheight can create pressure. By elevating water in tanks,towers and reservoirs, above where the water is needed,static pressure is created. Water systems may also bepressurized by a pump or a pump can be used to increase,or boost, pressure. Whether from elevation differences orby mechanical means, understanding the static pressure atthe water source for an irrigation system is where hydrauliccalculations begin.Here is an example of a simple system for supplying waterto a house from a city main line. We will be following thecomplete irrigation design process for this projectthroughout the manual.The supply system to this home looks like this (see Figure3): at point “A,” under the street at a depth of 4 ft (1,2 m), isthe city water main with a fairly high static pressure of 111psi (7,7 bar). From the main line there is a supply pipemade of 1-1/2 in (40 mm) copper that rises 3 ft (1 m) to

1connect to the meter and is 12 ft (4 m) in length. At thecurb side is an existing 3/4 in (20 mm) size water meter.Connected to the meter is a 3/4 in (20 mm) copper serviceline that runs 35 ft (11 m) to where it enters the housethrough the garage. There is a small rise in elevation of 2 ft(0,5 m) from the meter location to the house. Finally, 1 ft(0,3 m) above the point where the service line enters thehouse is a hose valve connection.To calculate the static water pressure available to the site, westart at point “A” where the water purveyor advises that wecan expect a static pressure in their main line of 111 psi (7,7bar). Point “B ” in this diagram is at the same elevation asthe main line and has the same 111 psi (7,7 bar) pressure.Point “C” is 3 ft (1 m) above the main and we wouldcalculate the pressure at point “C” as follows: 3 ft x .433 psi 1.299 psi (1 m 10 0,1 bar), or for simplification, 1.3 psi(0,1 bar). Since the supply source is from below, the 1.3 psi(0,1 bar) is a weight against the source pressure, so it is aloss. Therefore, the static pressure at point “C” is 111 psi – 1.3psi (7,7 bar – 0,1 bar) for a remainder of 109.7 psi (7,6 bar).Points “D” and “E,” which are on each side of the meter, areon the same elevation as point “C,” so they have the same109.7 psi (7,6 bar) static pressure. Between points “E” and“F” there is a 2 ft (0,5 m) rise in elevation that we calculateas follows to get a static pressure for point “F:”Understanding Basic Hydraulicspressure in the city main been low, say 40 psi (2,8 bar), thedesigner would adjust the design and equipment selectionto provide a system that operates correctly even with thelow service line pressure. In some instances, the waterpressure is too low for typical landscape irrigationrequirements and a booster pump will be necessary.If the water main was in a street higher than the site, all theelevation change coming down to the project would haveproduced pressure gains instead of losses. For example,had the main line been located 10 ft (3 m) above the site,the static pressure at the hose bib would have been:10 ft x .433 psi 4.33 psi 111 psi static pressure in the main line 115.33 psi static pressure at the valve(3 m 10 0,3 bar 7,7 bar static pressure in the main line 8,0 bar static pressure at the valve)To begin an irrigation system design you must have criticaldata or make critical assumptions about the water source.Static water pressure at the point-of-connection is anecessary part of the data needed to start an irrigationsystem design.2 x .433 psi .866 psi(0,5 10 0,05 bar)109.7 psi – .866 psi 108.8 psi, the static pressure remaining at point “F”.(7,6 bar – 0,05 bar 7,55 bar)Point “G,” the hose bib in the garage, is 1 ft (0,3 m) abovepoint “F,” for which we would calculate the static pressure bysubtracting .433 psi (0,03 bar) from the 108.8 psi (7,55 bar) atpoint “F” to determine there is approximately 108.36 psi(7,52 bar) at point “G.” A more direct way to calculate thestatic pressure for point “G” would be to multiply the6 ft rise in elevation by .433 psi (divide the 2 m rise by 10) andsubtract the 2.6 psi (0,2 bar) answer from 111 psi (7,7 bar) fora remainder of 108.4 psi (7,5 bar) in rounded numbers.The designer may choose to cut (or tap) into the serviceline anywhere between the meter and the house to start themain line for the irrigation system. (The location of the tapinto the service line may also be referred to as the point-ofconnection or POC.) At any point along the main line, thestatic pressure can be calculated.In this case, the designer will need to consider and controlthe high water pressure condition on this site. Had theFigure 4: Static water pressureA sound irrigation design cannot begin with subjectiveterms like “good pressure,” or “high pressure.” Whengathering information at a project site, a water pressurereading or valid pressure assumption is very important.In the previous example, the designer or other persongathering the site data could have measured the waterpressure with a pressure gauge rather than using the waterpurveyor’s estimate. However, it is important to design theirrigation system for the “worst case” pressure conditions.In most locales, the “worst case” situation will be on hotweekend days in the summer when a lot of people irrigateLandscape Irrigation Design Manual 5

Understanding Basic Hydraulicstheir lawns. The water purveyor probably uses a computermodel to predict the lower summer pressures in theirsystem, so they can provide data regardless of the season.The water purveyor may also be able to predict if pressuresmay change in the future.

psi, multiply the feet by .433 One foot of water .433 psi. For example, 200 ft of water height x .433 produces 86.6 psi at its base. (To convert meters of head to pressure in