Transcription

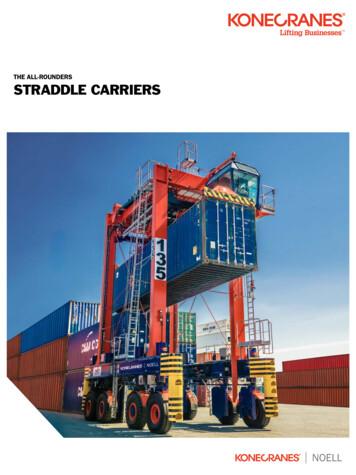

THE ALL-ROUNDERSSTRADDLE CARRIERS

2KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranesLOW SPECIFIC INVESTMENT COSTS, HIGH POTENTIAL FOR TERMINALSA GOOD PAY-OFFKonecranes is a leading supplier of cargo handlingsolutions for ports, terminals and industry. Our specialcompetence results from our many years of experiencein the development and production of Konecranes NoellStraddle Carriers and our intimate knowledge ofterminal processes.TWO MODEL HEIGHTS FOR VARIETY OF TASKSKonecranes Noell Straddle Carriers are universal machineswith low specific investment costs that make practically nodemands on the infrastructures in the terminals where theywill operate. They can be used for a wide variety of tasks,ranging from horizontal transport to stacking in the containerstack to loading and unloading of trains or road trucks.DYNAMICALLY EXPANDABLE CONCEPT FORTHE FUTUREKonecranes Noell Straddle Carriers are ideal for buildingand expanding entire fleets step-by-step to match yourneeds. The machines are designed to make versatileuse of terminal space. State-of-the-art control and driverassistance systems and their potential for semi or fullautomation make Konecranes Noell Straddle Carriers adynamic concept sure to be a success in the long term.1968: Pioneer of straddle carrier technology. Konecranes is one of the co-founders ofstraddle carrier technology. Our plant in Würzburg (Germany) is our competence centerfor design engineering and production. The excellent quality of Konecranes Noell StraddleCarriers also results from a high level of vertical integration.KONECRANES NOELL STRADDLE CARRIERSModelsDrive systemsDieselDieselhydraulic (H) electric (E)N SC 634 HN SC 644 HN SC 634 EN SC 644 EN SC 634 E ECON SC 644 E ECOMax. lifting capacities[t]Hybrid(E ECO) Stacking capabilities[9’6" high-cube container]5060*1-over-2 1-over-3 * In exceptional cases, maximum lifting capacity of 60t; actual lifting capacity dependent on spreader capacity Low specific investment costs Universal cargo handling machine with load capacities up to 60t Productive team of Konecranes Noell Straddle Carriers andKonecranes Noell Spreaders For building and expanding fleets step-by-step Especially eco-friendly drive variants Potential for semi and full automationRight choice for a variety of tasks: diesel-electricKonecranes Noell Straddle Carriers can be used fora wide variety of tasks in the container terminal likestacking high-cube containers.3

4KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersDIVERSE AREAS OF APPLICATION THROUGHOUT THE TERMINALMULTIFUNCTIONALKonecranes Noell Straddle Carriers are designedfor versatility. To cope with the different processesin day-to-day terminal operation, we have equippedthe machines with state-of-the-art technology.An application-oriented holistic system has beencreated, which allows you to face the challengesof today and tomorrow with confidence.1Horizontal transport: with fast and maneuverable Konecranes StraddleCarriers, you can move containers rapidly from A to B in your terminal.2Rail feeder and loader: if your terminal is connected to the rail network, themachines can bring containers safely to the train or even load them on to it.3Stacking in the container stack: depending on the model height, the straddlecarriers can stack containers quickly and economically, either 3 or 4 high.4Loading and unloading trucks: if trucks drive in and out of your terminal,Konecranes Noell Straddle Carriers are also the transport medium of choice.UNIVERSAL AND VERSATILE Number of machines and interfaces minimizedas all tasks are performed by one machine type Particularly easy implementation and enlargementof cargo handling fleet when required State-of-the-art assistance systems help to acceleratecargo handling The fleet management system always has a gripon the operating data1234Konecranes5

6KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranesKONECRANES NOELL STRADDLE CARRIER AT A GLANCEALL-ROUND WELL-BUILTPORTALThe design of Konecranes Noell Straddle Carriers takesits cue from conditions prevailing in the terminal. Theyare easily maneuverable and offer high travel speeds.Their light-weight, but adequately rigid and durablesteel structure and their low center of gravity provide ahigh degree of safety and convenience for the driver. Lightweight steel design with diagonal braces Yoke beam guided by low-maintenance sliding pads in the portal Spreader power and hydraulic supply via cable scissor armor cable chainThe slender portal and an all-round glazed cab offerdrivers the best possible view of the whole working areaat all times. In combination with the Konecranes NoellSpreader and the use of state-of-the-art components,the result is a highly cost-effective vehicle design.SPREADERSVETROCAB DRIVER’S CAB Large glass panels for goodall-round visibility Ergonomically designed, adjustable driverseat; electrically rotatableon request Clearly structured displays Second seat for training instructor (optional) Other cab models available Konecranes Noell Single-Lift and Twin-Lift Spreaders Patented modular twistlock mounting and locking Simple thanks to modern interface technology(CAN bus, corresponding to straddle carrier) Precise and fast thanks to smart sensor system and laser technology Soft landing function, automatic set-down function andlow-maintenance guidesTRAVEL GEAR Good load distribution thanks to eight individually steered wheelsDirect drive units thanks to wheel hub motors in four driven wheelsMaintenance-free three-phase motorsWheels individually steered by steering cylinders and rodsIndividual wheel suspension with maintenance-free spring systemLow tire wear thanks to electronic steering controlMain fuel tank easily accessible in the carriage beamCustomer-specific cab configurations possible.STAIRWAYS For easy and safe access to the driver’s caband machinery platform Second stairway (optional)Wheel hub motor7

8KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranesMACHINERY PLATFORM IN FOCUSEASILY ACCESSIBLEThe machinery platform of the Konecranes NoellStraddle Carrier is clearly structured. Its componentsare arranged for easy access in order to make serviceand maintenance quick and convenient.The use of durable components ensures long serviceintervals, which significantly contributes to the highavailability of Konecranes Noell Straddle Carriers.SWITCH CABINETSHOIST SYSTEM Contain the entire electrical equipmentand electronics All cabinets stainless steel, partiallyair-conditioned Maximum lifting capacity 60t Rope drums driven by centrallypositioned electric motor Maintenance-free three-phase motor Simple, clearly arranged and protectedrope guides up to the yoke beam Small number of rope pulleys for lowrope wear in operationThe diesel-generator set positioned at the center ofthe machinery platform can be fitted with a compartmentto reduce noise emissions from the machine if required.The hoist system of Konecranes Noell Straddle Carriersis positioned at the edge of the machinery platform tosave space. It consists of a centrally positioned electricmotor and two synchronized rope drums.BRAKE RESISTORS Both actuated and regulatedDRIVE UNITWALKWAYSHYDRAULICS MODULE High-performance diesel-generator set Sliding cover for easy maintenance access Amply dimensioned Supplies spreader, steering cylindersand brake system with hydraulic energy Compact construction, physicallyseparated from the diesel-generator set Driven by a separate shaft on generator9

10KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranes11ELECTRICAL DRIVE SYSTEMSEFFICIENT AND GREENKonecranes Noell Straddle Carriers can be equippedwith different drive systems. The diesel-electric driveis particularly energy efficient and environmentallycompatible, reducing operating costs and relievingterminals from exhaust emissions.HYBRID DRIVEWith their optional hybrid drive, Konecranes NoellStraddle Carriers have an even greater sustainableimpact. For in the hybrid drive, energy regenerated fromlowering and braking is stored in short-term electricalstorage modules (ECOCaps) and can be fed back intothe on-board power supply when needed.DIESEL-GENERATOR SET Power generation unit powers hoistand travel drives Lower pollution emissions due tolow fuel consumption Diesel engine available in the respectiveprescribed emission standards, currentlyEU Stage IIIA and IV (EPA Tier 3 and 4f) Easily accessible thanks to doublesliding housingENERGY SAVINGS OF UP TO 20%The benefits of the hybrid drive not only permit fuelsavings of up to 20%, depending on the operatingprofile of the vehicles, but equally protect the drivecomponents, as consumption peaks are no longerserved by the diesel-generator set, but from theECOCap storage. Engine operation optimized inthis way also ensures lower noise emissions for thedriver and the terminal thanks to smoother running.HYBRID DRIVE Second energy source: additional electrical short-termenergy storage unit (ECOCap module) Maintenance-free, high number of cycles and long service life Fuel savings of up to 20% depending on the operating profile Easy on all drive components Optimizes engine operation, ensures smooth running andminimizes noise emissionsELECTRICAL DRIVE SYSTEMS Highly-efficient and environmentally-friendlyRequire less energyMinimal emissionsThus a successful concept in the long termSecond energy source:ECOCap module.

12KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranesDIESEL-HYDRAULIC STRADDLE CARRIERSTHE PROVEN ALTERNATIVEIn addition to diesel-electric straddle carriers,Konecranes also offers you a diesel-hydraulic variantof straddle carriers tried and tested over many years.On diesel-hydraulic straddle carriers, both travel andhoist drives make use of powerful hydraulic motors.At the same time, terminal operators profit from comparablylow initial investments and little need for spare parts. Dieselhydraulic drive systems also offer benefits in terms of serviceas these machines are very easy to maintain.GOOD OPERATING CAPABILITIESAs far as their function, performance parameters and operatingcapabilities are concerned, these diesel-hydraulic straddlecarriers are a match for their diesel-electric counterparts.Like these, diesel-hydraulic straddle carriers can handlestacking heights of 3 and 4 containers.With all their features, the diesel-hydraulic machines areparticularly suited for terminals that are starting a step-by-stepgrowth phase and nevertheless need a highly productivemachine for the purpose: If, for example, you have organizedyour container handling with reach stackers up to now andwant to achieve higher stacking density in your yard and higherhandling efficiency, diesel-hydraulic straddle carriers fromKonecranes might be the right choice.MACHINERY PLATFORMHOIST SYSTEM Clear and structured machinery platformSo good visibility with ample spaceComponents easily accessible for service and maintenanceDiesel-pump set enclosed for reduction of noise emissions (optional)Konecranes Noell Straddle Carrierspowered by diesel-hydraulic drive formthe backbone of operations in manyhigh-performance terminals worldwide.Maximum lifting capacity 60tRope drums driven and synchronized by centrally positioned hydraulic motorHigh-performance hydraulic motorSimple and protected rope guides up to the yoke beamSmall number of rope pulleys for low rope wear in operationTRAVEL GEAR Good load distribution thanks to eight individually steered wheelsFour wheels driven by compact and powerful hydraulic motorsWheels individually steered by steering cylinders and rodsIndividual wheel suspension with maintenance-free spring systemLow tire wear thanks to electronic wheel alignment supervisionDIESEL-HYDRAULICKONECRANES NOELLSTRADDLE CARRIER Tried and tested on the market for decadesBackbone of operations in many terminalsAllow low initial investmentsFor improvement of stacking densityand handling efficiency in terminals13

14KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranes15FROM THE VETROCAB DRIVER’S CABBRIGHT OUTLOOKAs the interface between man and machine, our Vetrocabdriver’s cab holds the key to safe and productive straddlecarrier operation. Together with industrial designers,ergonomics experts and experienced straddle carrierdrivers, we have developed both the cab itself and theintuitive operating concept for you. The result: a cockpitthat is a pleasure to work in – so the driver haseverything under control.The large glass panels provide an excellent all-roundview and, together with the good noise insulation andthe clear arrangement of all the controls, provide a highdegree of convenience and safety. The driver’s seat,adjustable for individual body size, the flexibly adjustablepedals and a steering wheel adjustable in height anddistance turn the cockpit into a personal workplace.STATE-OF-THE-ART SAFETY ANDASSISTANCE SYSTEMSThe electronic stability assistant monitors the travelspeed of the Konecranes Noell Straddle Carrier in relationto the spreader position and its curve radius and, throughautomatic adjustment of the speed, ensures safe traveloperation of the Konecranes Noell Straddle Carrier.Clearly structured displays always showing current speedsand spreader position keep the driver informed.Drivers are also supported in their work by state-of-the-artassistance systems. These are partly standard andpartly optionally available, further enhancing productivityand safety in the terminal. Among other things, thestability displays, the automatic spreader positioningsystem (ASPS) and the CAN bus control system for boththe straddle carrier and the spreader functions helpto achieve improved deployment planning and moreeconomical operation.A cockpit that drivers like to work in: adjustable steering columns; electrically rotatabledriver seat, on request; adjustable pedals.High above the container stack: optimum view of the whole working area.Ideal arrangement: everything in the right place for maximum convenience and safety.

16KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranesWITH THE KONECRANES NOELL FLEET MANAGEMENT SYSTEMOPERATING DATA ON-LINEOur fleet management sytem recordsand transmits a variety of operating datato the terminal control center.The operational and health status data of vehicles canbe remotely monitored via the terminal WLAN networkusing the fleet management system (FMS) and can bedisplayed and recorded by software modules in accordancewith your needs. In addition, the system permits remotediagnoses to be carried out by Konecranes experts.The FMS has a modular structure, so the terminaloperator can adapt the system to its requirements.Depending on the module selected, the communicationof operating data, container handling rates or faultdiagnoses including single-value recording and monitoringof, for example, engine and electronic data, tirepressures or fluid levels is possible – both for individualvehicles and for entire straddle carrier fleets.FLEET MORE ECONOMICAL THROUGHDATA TRANSPARENCYThis data transparency makes the fleet more economical,as interventions can be planned much better in advanceand operating costs can be reduced by service adaptedto the local conditions. Diagnoses can also be carriedout more specifically and effectively, which results ina higher level of equipment ainerDataModuleTraceDataModuleOperating and health status data:operating data are displayed forthe driver on large and clearlystructured duleVersionDataModuleEverything at a glance: the data on the straddle carrier fleet are monitored in theterminal control Basic modulesAdd-on modules can be individually added and combinedKonecranes Noell Straddle Carriers equipped with our fleet management systemare provided with three basic modules. If necessary, terminal operators can upgradetheir FMS step-by-step.MODULAR FLEET MANAGEMENT SYSTEM Remote monitoring via terminal WLAN networkGradually adaptable to operating company requirementsData transparency makes the fleet more profitableGreater handling performance possibleInterventions can be planned better in advanceDeployment scheduling adjusted to service intervalsService costs can be significantly reduced17

18KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranesINCREASED HANDLING PERFORMANCE THROUGH AUTOMATED TERMINAL LOGISTICSA-STRADS MEETINGCHALLENGESQuick and economical loading and unloading of largecontainer vessels with ever increasing capacities demandnew technologies in terminal logistics in order to avoidoperational bottlenecks and to improve efficiency. Theseinclude the semi and full automation of Konecranes NoellStraddle Carrier fleets. orks even without a complete modification:Wthe control system of diesel-eletric KonecranesNoell Straddle Carriers is designed in such a waythat specific automated solutions can be addedwithout completely modifying existing machines.In addition to higher handling rates, the automation ofstraddle carriers (A-STRADs) also makes possible animprovement of safety and availability. Automation alsoensures the consistency and optimization of handlingprocesses, thus reducing fuel consumption and exhaustemissions, which has an overall positive effect on thecost-effectiveness and ecological balance of terminals.FROM MANUAL TO AUTOMATED OPERATIONThe control system of diesel-eletric Konecranes Noell StraddleCarriers is designed in such a way that specific automatedsolutions can be added without completely modifying existingmachines. These solutions permit the operators of existingterminals to convert currently manually operated equipmentto automated, unmanned A-STRAD machines. Similarly, anew terminal can start with manual equipment and, after asuccessful initial phase, can convert to automated operation.AUTOMATION WITH KONECRANES OPENS UP POTENTIALAs a pioneer and pacemaker in the automation of handlingprocesses, Konecranes has many years of experience in bothequipment technologies and associated management andnavigation software which are also used for A-STRAD solutions.Simulation and emulation of terminal processes gives terminaloperators a clear picture of handling performance, equipmentrequirements and development potentials before they committo any investments.STRADDLE CARRIERAUTOMATION (A-STRAD) Konecranes is a pioneer of automatedcontainer terminal solutions Technologies are well suited forstraddle carrier solutions Operation can start manually andbe automated later Permits higher handling speeds Provides enhanced safety and availability Reduces fuel consumption and exhaustgas emissionsHighest accuracy: laser technology positionsthe A-STRAD precisely above the container.19

KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersKonecranes21KONECRANES NOELL STRADDLE CARRIERSDATA AND DIMENSIONSN SC 634 HN SC 644 HN SC 634 E* N SC 644 E*ModelSpeedsN SC 634*N SC 644*12,50015,7009,10012,000300300Heights [mm]Lifting [m/min]– laden (40t)2020– laden (50t)1616– unladen2424– laden (40t)1820– laden (50t)1616– unladen2024243024– unladen30243024H2Weights [t]Maxium static wheel load15.415.916.3– unladen7.17.98.48.8Deadweight**6063677016.00 R25 or 480/95 R2516.00 R25 or 480/95 R258/48/4Caterpillar C13MTU (Daimler) 6 R 1100354 @ 1,800320 @ 1,700H3No. of wheels / drivenEnginesStandard diesel engine– Maximum power[kW @ rpm]– Maximum torque[Nm @ rpm]– Emission standardAlternative engine2,100 @ 1,4002,100 @ 1,800Stage IIIA (Tier 3)Stage IV (Tier 4 final)–H3Chassis clearance heightW1Inner chassis width3,4703,470W2Outer chassis width4,8704,8703,700Lengths [mm]L1Wheelbase, inner axles3,700L2Wheelbase, outer axles7,7007,700L3Total length9,300 – 10,3009,300 – 10,300Other dimensions [mm]R1Inside turning radius3,6003,600R2Outside turning radius9,3009,30020 / 30 / 40Spreader, single-lift[ft]20 / 30 / 40Spreader, twin-lift[ft]2 x 202 x 20S2Spreader side shift[mm] /- 300 /- 300S3Spreader swivel angle[ ] /- 6 /- 6[Nm @ rpm]–335 @ 1,800– Maximum torque[Nm @ rpm]–2,000 @ 1,300–Stage IIIA (Tier 3)750 or 1,500 (optional)750 or 1,500 (optional)* Figures applicable for H, E and E ECO.L1MTU (Daimler) 6 R 460 C– Maximum power– Emission standardMaximum stacking height under twistlocksS1Wheels and tiresTire sizeTotal heightH2Konecranes Noell SpreaderH3 H314.6H1 H130H2 H2– laden (30.5t)H1Traveling [km/h]– laden (60t)H1Widths [mm]Lowering [m/min]L1L1L2L2L2L3L3L3Illustration shows N SC 644 E Konecranes Noell Straddle Carrier.Fuel [l]Tank capacityS1* Figures also applicable for E ECO.** Depending on the configuration.S2 S2S2 S2S2W1 W1W2 W2On this page we have compiled the most importantdimensions, which apply for both diesel-electric anddiesel-hydraulic Konecranes Noell Straddle Carriers.You will also find the technical data for both machinetypes and heights of the 1-over-2 and 1-over-3 models.We shall be happy to send you further technical informationabout Konecranes Noell Straddle Carriers on request.Eco-friendly paintwork to your corporate specificationsThe Konecranes Noell Straddle Carrier and the Konecranes NoellSpreader are shown here in our standard colors. On request,Konecranes can supply you with straddle carriers paintedwith eco-friendly water-based paints in accordance with yourcorporate identity guidelines and marked with your own logos.R1R2R2S3 S3S2S1S3W1S1W220R2R1R1ECTLYPERFOur special brochure details thekey components, Konecranes NoellSingle-Lift and Twin-Lift Spreaders.D STRER ANSPRINTS NOELLRANEKONECDRATEINTEGERS FORSPREADS NOELLRANEKONECIERSCARRADDLE

22KonecranesKonecranes Noell Straddle CarriersKonecranes Noell Straddle CarriersGenerously dimensioned: the generously dimensioned machineryplatform provides ample space for all service and maintenance measures.KonecranesYOUR STRADDLE CARRIERS ARE IN THE BEST HANDS WITH USCOMPREHENSIVESERVICEDuring the development of our straddle carriers we werealready thinking about ease of maintenance. The robustmachines are user-friendly thanks to easily accessiblemaintenance points. Our expertise is based on a high levelof vertical integration and is complemented by the use ofcomponents from globally renowned manufacturers.WE MAINTAIN AVAILABILITYWe contribute to maintaining the availability of your straddlecarrier fleet. Our global service organization is local to you inall time zones, and offers you expertise in maintenance andrepair in combination with fast delivery of spare parts.WE MAINTAIN THE VALUE OVER MANY YEARSWe are the right choice to provide support for your straddlecarriers throughout their service life because we built them andtherefore know them best. With our comprehensive serviceportfolio, your straddle carriers remain state-of-the-art, theirservice life increases and they hold their value over many years.Service to meet your particular needs:full life cycle support by KonecranesDiagnoses: quick sensing and correction of faults thanks tosmart diagnostics systems.SERVICE-FRIENDLY Maintenance costs and wear are minimizedby the use of direct drive units and reliablehigh-grade components Quick correction of faults thanks to smartdiagnostics systems Ease of maintenance thanks to goodaccessibility to componentsManufactured with care: all mechanical, hydraulic and electricalcomponents have been arranged in a clear structure and with care.23

Konecranes is a world-leading group of Lifting Businesses , serving a broad range ofcustomers, including manufacturing and process industries, shipyards, ports and terminals.Konecranes provides productivity enhancing lifting solutions as well as services for liftingequipment of all makes. The Group has 18,000 employees at 600 locations in 50 countries.Konecranes is listed on Nasdaq Helsinki (symbol: KCR).are either registered trademarks or trademarks2017 2017 Konecranes. All rights reserved. 'Konecranes', 'Lifting Businesses' andof Konecranes.konecranes.com

Maintenance-free, high number of cycles and long service life Fuel savings of up to 20% depending on the operating profile Easy on all drive components Optimizes engine operation, ensures smooth running and minimizes noise emissions Second energy source: ECOCap module. 10 Konecranes K N S Criers K N S Criers Konecranes 11