Transcription

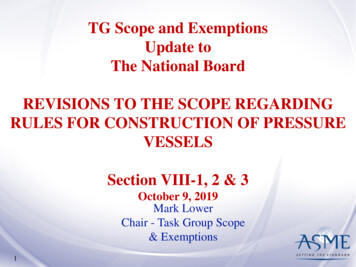

TG Scope and ExemptionsUpdate toThe National BoardREVISIONS TO THE SCOPE REGARDINGRULES FOR CONSTRUCTION OF PRESSUREVESSELSSection VIII-1, 2 & 3October 9, 2019Mark LowerChair - Task Group Scope& Exemptions1

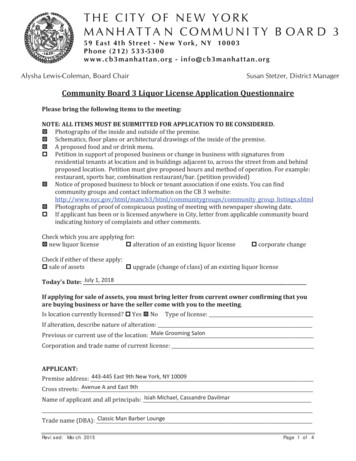

Quick Update Task Group meets on Monday evenings @6:00pm during CodeWeek– Teleconference available– Participation from regulators is highly desired Reaffirm proposals for Divisions 2 and 3– Custom engineered vessels, must identify jurisdictions– No public comments directed towards Division 2 or 3– BPV VIII Letter Ballot 19-2099 Jurisdictional rules vary and are not always consistent withASME VIII-1 exemptions– VIII-1, VIII-2, & VIII-3 Scope are not identical2

Focus of Public Comments Exemptions removed from the scope– U-1(c)(2)(f) – vessels containing water under pressure [ P 300 psi,T 210 F] Exemption commonly used for water side of shell and tube H/X– U-1(c)(2)(g) – hot water supply storage tank [heat input 200,000BTU/hr, T 210 F, volume 120 gallons]– U-1(c)(2)(i) – vessels having and inside diameter, with, height, orcross-section diagonal not exceeding 6 inches, with no limitation onlength of vessel or pressure Several codes and standards available to cover small diameterequipment (i.e. UL, ASHRAE) Public comments primarily from:– Heating, Ventilation, Air Conditioning, Refrigeration industry– Small, high pressure vessel industry (super high pressure but useDiv. 1)3

Scope RevisionsDivision 1 Modified Introductionto clarify scopeDivision 2 Definition of pressurevessel 15 psi threshold Modified/removedexemptions to the scopeIncluded NonmandatoryAppendix “Guidance forMandatory Applicationof Code Rules forPressure Vessels”Harmonize languagebetween Division 1 andDivision 2Modified Overview toclarify scope Definition of pressurevessel 15 psi threshold Modified/removedexemptions to the scopeIncluded NonmandatoryAnnex “Guidance forMandatory Applicationof Code Rules forPressure Vessels”Division 3 Added “U-1(c)(1)” to statejurisdiction has authority Modify language to statevessels exclusively in thescope of other Sections maynot be built to Division 3Focus of public comments4

Summary and Conclusions AHRI members are unanimously opposed to these scopechanges that apply to HVAC&R type equipment andcomponents. Existing standards have a convincing track record ofproviding safe products No information is available to indicate there are safetyrelated issues, no extension of BPVC is needed Risk of misinterpretation with other well-establishedgoverning standards adopted by the building codes Creates unnecessary uncertainty at the jurisdictional level

Recent Task Group Discussions How are requirements for HVAC industry flowed down? Vessel requirements in IBC (I-Codes) vary and differentthan many state requirements How do manufacturer’s comply with varied jurisdictionalrequirements? Is there any impact to removing scope exemptions fromVIII-2 & VIII-3?Why should ASME provide exemptions?6

ASME Section VIII, Divisions 1, 2 & 3Comparison of Construction StandardsMark LowerNational BoardOctober 9, 2019ORNL is managed by UT-Battelle LLC for the US Department of Energy

A brief introduction . SEC student background ASME Section VIII for almost 20 years– Subgroup General Requirements – past Chair– Task Group Scope and Exemptions - Chair– BPV VIII – Vice Chair “Day job” activities– Pressure systems SME– Established 1st FIA– DOT pipelines and facilities– Additive Manufacturing Demonstration Facility “printable” nuclear reactors Printed vehicles2Newest NBAdvisoryCommitteemember tothe BoT

Today’s Discussion ScopeFailure ModesMaterialsDesignJoiningNondestructive ExaminationPressure TestingOverpressure ProtectionFinal Thoughts

BPV VIII ScopeDivision 1(not so) Simple pressure vessel codeSeveral exclusions of vessel classes from ScopeMany jurisdictional requirements built aroundDivision 1 scope (although not the same as)Typically thought to be 3000psi (additionaldesign principles and construction practicesapply)Mass productionDivision 2Custom Engineered pressure vesselsSimilar (but not the same as) exemptions toDivision 12 vessel classesASME accepts responsibility for thetechnical excellence of any code it sponsorsand for its suitability as a basis forregulation. But ASME cannot itself regulateor enforce – a fact that needs constantly tobe remembered.ASME President L.N. RowleyMechanical Engineering Magazine, 19684

Division 3 - ScopeHigh PressureVessels Uses thick shelltheory INTENT - Generallyabove 10,000psi (nohard limits) Can’t assume planestrain Some exemptions, noexclusions Thin shell theory(Barlow’s formula)can give nonconservative results Small lab-type vesselshave relaxedrequirements Division 1 & 2applications for D/tratios do not apply5Scope:

U-Stamps Total number of U-Stamps – 5,665– U-1 Only84%– U-1 & U-215%– U-2 Only0.12%– U-1 & U-30.51%– U-3 Only0.14%U-1 and U-215%U-2 Only0%U-1 and U-31%U-3 Only0%U-1 Only84%6

Failure Modes Failure modes are organized into ce ASME does not provide rulesspecifically for the prevention ofservice-related failuresFailure modes (Category)Buckling (2,3)Plastic Collapse (1,2)Brittle Fracture (1,2,3)Creep (1,2,4)Ratcheting (2,4)Fatigue (2,4)Corrosion (1,2,4)7

MaterialsMaterial specifications provided in Section II & Code Cases. Only Code Casesspecifically identified as being applicable to the Section/Division may be used.Division 1: Few restrictions, impact testingrequired unless exempted (extensiveexemptions!)Carbonand LowAlloySteelsDivision 2: More restrictive on materials, similarexemptions on impact testing as VIII-1Graphite(Division 1Only)Division 3: Most restrictive on materials Fracture toughness testing for fracturemechanics evaluations CTOD for establishment of KIC and/or JIC8High AlloySteelsNonferrousCast Iron(Division 1Only)Clad andLinedCastDuctile Iron(Division 1Only)CodeCases**Only latest edition of Code Cases may beused, not allowed by all jurisdictions

Design FactorsPlasticCollapsePlasticCollapse1.5/SyD1 – 3.5D2 CL 1 - 3.0D2 CL 2 – 2.4D3 – 1.73FatigueDivision 1 – N/ADivision 2 & 3 2 on stress20 on cyclesBrittleFracture𝐾𝐾𝐼𝐼𝐼𝐼 𝜎𝜎2𝜋𝜋𝑎𝑎cLEFM criteria witha fracture margin(KIC/KIA) 1.8MinimumToughnessD1 - 15 ft-lbsD2 - 20 ft-lbsD3 - 20 ft-lbs?9CreepAllowable stresslimits based on: 100,000h stressrupture limits 10-7/h creepstrain rate

DesignDBRDBAExperimentalFatigueDivision 1XU-2(g)UG-101UG-22 [U-2(g)]Division 2XPart 5Annex 5-FRequired (unlessDivision 3XXLimitedRequiredexempted throughscreening)DBR: Prescriptive rules and closed-form solutions based on known allowable stress, loadingconditions and combinations, geometry, joint efficienciesDBA: Numerical stress analysis for protection against plastic collapse, local failure, buckling, & cyclicloading. Can only be used if the allowable stress is governed by time independent propertiesEXPERIMENTAL: Division 1 allows proof testing. Division 2 and Division 3 are similar, but Division 3 hastighter requirements for strain limits.FATIGUE: Not usually performed for Division 1 vessels as no criteria for cyclic service is provided.Division 3 requires surface finish correction factor for fatigue analysis10

Design Reports1 UDS2 MDRDesign basis documentfor vessel designContains the designcalculations and analysis tosupport final (as-built)construction All loading conditions May include operational andmaintenance Identifies jurisdictional authority Jurisdictional requirementsDivision 1Division 2Division 3a. “Neither required norprohibited” Mandatory Mandatory Certification required forClass 2 Certification requiredb. Nonmandatory AppendixKK11 Site specific environmental conditions

Material Joining*PRT certification to fabricate parts without design responsibilityWeldingBrazing See Section IX See Section IX Pressure and non-pressure parts “Welding” includes “brazing”requirements Division 2–More restrictive that VIII-1 in permittingprocesses, geometries, and PWHT Division 3Most restrictive in processes, geometries,& PWHT– Requirements for considering residualstress–12 VIII-1 Part UB Cannot be used for:–Lethal service–Unfired steam boilers–Direct firing*PWHT IMPORTANT TO MATERIALS JOINING INTEGRITY

Nondestructive ExaminationMethodsPersonnelQualificationsSection VSection VArticle 913CentralCertification Programs(ANSTACCP) RT UT MT PT VT LT ET AEAcceptanceCriteria“Essentially”identical Cracks, IF, IP Rounded Linear SurfaceConnected

NDE RequirementsDivision 1: May be exempted using extensive knock-down factors Supplemental/Contractual/Non-mandatoryDivision 2 Increase NDE for reduced design factor per Part 7 Both volumetric and surface examination required Harmonized with European practiceDivision 3 More stringent than Division 2 UT on all butt welds RT on all other welds Extensive use of surface examination including post-hydro14

Pressure TestingPrimary intent is to find gross design or fabrication issues and weld seam leaksDivision 1Division 2Division 3 Hydrostatic Hydrostatic Hydrostatic Min - 1.3*MAWP Max – Permanentdistortion Pneumatic Min – 1.1*MAWP Max – Permanentdistortion Vacuum Test Min - 1.25*MAWP Max – 0.95Pm Pneumatic Min – 1.15*MAWP Max – 0.80Pm Vacuum Test Min - 1.15*MAEWP Min - 1.25*MAWP Max – 0.95Pm Autofrettagevessels exempt Surface exam afterhydrotest MAEWP AND Leak test Code Cases Ultrasound (2324)In-service leak testing not allowed like B31 Codes15

Overpressure ProtectionDivisions 1 & 2Division 3 “pop action” relief devices for Responsibility of the user Identical requirements (Division 2references Division 1)pressures above 10k psi not readilyavailable Allows disk and holder to havedifferent manufacturers Added requirements for springs(gas has density of liquid. Spring hasdifferent requirement to hold valveopen) Different capacity certifications16

ASME Roles and QualificationsCertifying EngineerDesignersCertified Individuala. Attest in writing that theymeet the ASME Code ofEthics Manufacturer attests tocompetence Organization certifies theIndividual Qualified to performdesign for: Division 1b. 4 yrs experiencec. Chartered, registered, orlicensed within thejurisdiction where designtakes place or location ofinstallationDivision 2 & 317 General pressurevessels Heat exchangers Numerical analysis Miniature vessels (UM) Pressure relief devices(UV, UD) See also: ASME CA-1 Quick-actuatingclosures NB-383Division 2 & 3Division 1

Random Final Thoughts/Other Notables:1Exampleproblems forVIII-1 and VIII-2(PTB-3, PTB-4)2“CommonRules” to allowVIII-1 vessels toincorporate VIII2 DBR mentsfor U-2(g)1853VIII-2 Class 1eliminatescertification ofUDS and MDR4VIII-1 canobtainauthorization tofabricate VIII-2Class 1 vessels(CC 2891 exp 2020)Division 2provides latestcompleteupdate(VIII-2 Table E1.1)67Division 2requires“tuned” designto realizeefficiencies(Y/T 0.7)

Division 1 scope (although not the same as) Typically thought to be 3000psi (additional design principles and construction practices apply) Similar (but not the same as) exemptions to Division 1. 2 vessel classes. Mass production . ASME accepts responsibility for the technical excellence