Transcription

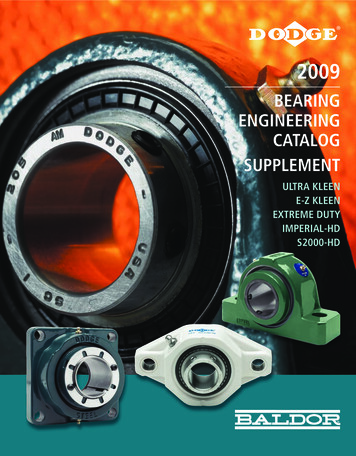

2009BEARINGENGINEERINGCATALOGSUPPLEMENTULTRA KLEENE-Z KLEENEXTREME DUTYIMPERIAL-HDS2000-HD

To receive a copy of the DODGE BearingEngineering Catalog, DODGE GearingEngineering Catalog or DODGE PowerTransmission Components Engineering Catalog,contact your local authorized DODGE Distributoror www.baldor.com.DODGE Products areManufactured inISO 9002 Certified PlantsMade in U.S.A.Prices and data indicated in this document are for your convenience and were correct at time of printing with theexception of clerical and/or printing errors. Possession of this document by any person or company is not to beconstrued as an offer to sell to him or to anyone else the goods listed herein at the prices stated.ALL DATA AND PRICES ARE SUBJECT TO CHANGE WITHOUT NOTICE and shall be subject to those prices in effectat time of shipments. All published and quoted prices are based upon the application of, and all sales are expresslysubject to, the Company’s Standard Terms and Conditions of Sales are available upon request. This documentsupersedes all previously published catalog/pricing documents.In illustrations throughout this catalog, safety guardshave been removed for photographic purposes.WARNINGThe information provided for Product Interchange in this catalog isfor use only as a general reference by persons qualified to recognizeunreasonable selection options. Products suggested as substitutesmay have dimensional, rating, pricing and other differences fromproducts to be replaced. This selection method must be used inconjunction with the applicable product catalog which containsimportant precautions and other pertinent information. 2009 Baldor Electric CompanyWARNING: Because of the possible danger to person(s) or property from accidents which may result from the improper use of products, it is important that correct procedures be followed:Products must be used in accordance with the engineering information specified in the catalog. Proper installation, maintenance and operation procedures must be observed. Theinstructions in the instruction manuals must be followed. Inspections should be made as necessary to assure safe operation under prevailing conditions. Proper guards and other suitablesafety devices or procedures as may be described or as may be specified in safety codes should be provided, and are neither provided by Baldor Electric nor are the responsibility of BaldorElectric. This unit and its associated equipment must be installed, adjusted and maintained by qualified personnel who are familiar with the construction and operation of all equipmentin the system and the potential hazards involved. When risk to persons or property may be involved, a holding device must be an integral part of the driven equipment beyond the speedreducer output shaft.

ULTRA KLEENCONTENTSTable of ContentsBall BearingFeatures/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2How to Order/Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5Easy Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6Selection/Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14Accessories (End Covers). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29E-Z KLEENULTRA KLEENFeatures/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30How to Order/Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36Easy Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38Selection/Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48Accessories (End Covers). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90EXTREME DUTYE-Z KLEENFeatures/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91Easy Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94Selection/Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96Accessories (End Covers). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129IMPERIAL-HDExtreme DutyFeatures/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131How to Order/Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136Dimensions & Part Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144S2000-HDFeatures/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173Dimensions & Part Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179Type E Steel Pillow Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193SAFS Steel Pillow Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202Part Number Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1210Part Number IndexIMPERIAL-HDS2000-HDRoller Bearing

FEATURES/BENEFITSULTRA KLEENULTRA KLEENPolymer and Stainless Steel Housed Mounted BearingsE-Z KLEENInsert: The Dodge ULTRA KLEEN features inserts made of 100% stainless steel and includes set screws positioned at65 degree angles to provide maximum locking force without compromising inner ring strength. The inserts each include astainless anti-rotation pin to prevent insert rotation in the housing under load which may cause premature bearing failure.Stainless inserts eliminate the possibility of contamination due to chipping and flaking, commonly found in inserts which arecoated with zinc or thin-dense chrome.Triple Lip SealRubberizedFlingerEXTREME DUTYIMPERIAL-HDSealing: Retaining lubrication and preventing contamination fromentering the bearing is critical in harsh environments. That is why Dodgehas developed the premium QuadGuard sealing system for maximumsealing effectiveness under these conditions. The seal includes twopatented features unique to Dodge bearings; these features are standardon the ULTRA KLEEN product. The first is a triple-lip seal designed tomaximize sealing and produce less drag than other multi-lip seals. TheDodge patented triple-lip design uses a mechanically retained seal withtwo contact points on the inner ring and one contact point riding againstthe flinger surface. Three points of contact maximize the ability of the sealto guard against contamination and to retain lubricants. The QuadGuardQuadGuardseal incorporates the industry’s first (and only) patented rubberized flinger.Maxlife CageSealing SystemThis flinger uses molded rubber toprovide additional protection fromcontaminants entering the bearing. The baffle design of the rubber on the externalsurface of the flinger enhances the removal of liquid as the flinger rotates. Greasechambers on the internal surface prevent lubricants from exiting the bearing duringoperation while allowing purging during re-lubrication. This superior design will increaseservice life in dirty environments thus leading to extended up-time for our customers.When used in conjunction with one another, the triple-lip seal and rubberized flingercreate a sealing system that is ideal for demanding environments.S2000-HDPART NUMBER INDEXRetainer: The Maxlife Cage is the product of extensive research and development in retainer technology and industryleading engineering. The cage features a two-piece design that creates a grease compartment around each of the rollingelements. These compartments allow balls to be constantly in contact with grease, so a good oil film will always exist toprevent wear and minimize friction and heat. The Maxlife cage reduces the relative motion between bearing componentsand grease which results in lower operating temperatures and extended life. The compartmental construction of the cagetends to hold in the grease and prevent it from being washed out in extremely wet or dirty conditions. This feature allowsthe bearing to be re-lubricated with less frequency than standard designs require, while extending bearing life.Lubrication: 100% filled with H1, food grade grease 2

ULTRA KLEENPolymer and Stainless Steel Housed Mounted BearingsULTRA KLEENFeatures/benefits— End covers availableEnd CoversAll Dodge EZ KLEEN and ULTRA KLEEN bearings include a housing groove to accept a snap-on polymer end cover. Thesedurable covers are easy to install and each is provided with a drain hole to prevent moisture from collecting inside the cover.The snap-on style of end cover incorporates an additional lip on the mounting surface for a rigid fit within the housing. Thistight fit creates a better seal prevents movement of the cover during operation and high-pressure cleaning. Dodge snap-onend covers provide positive sealing in wet environments and create safer working conditions by enclosing rotating shafts. 3EXTREME DUTYPart Number IndexS2000-HD Stainless— 204 to 208, 210 SeriesPillow BlockTwo-Bolt FlangeFour-Bolt FlangeNarrow Slot Take-UpWide Slot Take-UpTapped BaseFlange Bracket (no 208, 209)— 204-207 SeriesLight Duty Two-Bolt Flange, LFTLight Duty Three-bolt Flange, LF— 300 Series stainless steel castingIMPERIAL-HD Polymer— 204 to 210 Series (3/4” bore to 2”,20mm to 50mm)Pillow BlockTwo-Bolt FlangeFour-Bolt Flange— 204 to 207 Series (3/4” bore to 1-7/16”,20mm to 50mm)Tapped BaseFlange BracketWide Slot Take-Up— Solid cross-section base housings— No core cavities to trap contaminants— Anti-Microbial agent retards bacterial and fungal growth— All stainless hardware and fittings— Housing strength exceeds bearing static capacity— End covers availableE-Z KLEENHousings: The ULTRA KLEEN is available in a wide variety of both polymer andstainless housing designs.

Features/benefitsULTRA KLEENEZ Kleen-SC, DL, GT Ultra Kleen-SCEnd-Cover CapabilityEZ Kleen-SC, DL, GTUltra Kleen-SCStandard FeaturesSealingRetainerEnd-CoverGrooveSnap-OnEnd CoverTriple-Lip SealStainlessRubberizedFlingerMaxlifeCageXXXXXE-Z KLEENHousing Capability StainlessHousing EME XLFTXXXXXHousing Capability PolymerHousing 0-HDPART NUMBER INDEX 4

ULTRA KLEEN Polymer and Stainless Steel Housed Mounted BearingsHOW TO ORDERULTRA KLEENHOW TO ORDERNOMENCLATUREThere are two ways to specify DODGE ULTRA KLEEN ball bearings. Most of the product offerings have part numbers withlistings shown throughout this brochure. Use of part numbers ensures accurate order processing.E-Z KLEENWhen part numbers are not shown, the product may be specified by description or part name. This method is used whenordering units that include modifications or options. To order by description for options not covered by the nomenclature.NOMENCLATURE PSSModification Or Feature:SS Stainless Steel InsertLL Low torque labyrinth sealMOD ModifiedNL No Lube (sealed for life)P Polymer housingSH Stainless Steel HousingEXTREME DUTYP2B - SCHUEZ - 104SFirst digit Number of inchesSecond & third digits Number of sixteenths of an inch104 Indicates 1-4/16 or 1-1/4S Next smaller ring size. E.g. 1-1/4 206 would be written as 104SL Next larger ring size. E.g. 1/2 204 would be written as 008LIMPERIAL-HDShaft Size:Inches:Metric:First two digits number of millimetersM MetricHousing:SC Wide inner ring, normal duty, 65 setscrew lockingSuffixes to the above:EZ E-Z KLEEN/ULTRA KLEEN (used with polymer or stainless steel housed units)BEZ Low backing height pillow block, E-Z KLEEN/ULTRA KLEENUEZ higher back pillow block, E-Z KLEEN/ULTRA KLEEN (for interchangeability with competitivepillow blocks)Part Number IndexF2B 2 bolt flangeF4B 4 bolt flangeFB Flanged bracketINS InsertP2B Pillow block, 2 bolt baseTB Tapped base pillow blockWSTU Wide slot take-upNSTU Narrow slot take-upLF 3 bolt, light duty flangeLFT 2 bolt, light duty flangeS2000-HDBearing Type: 5

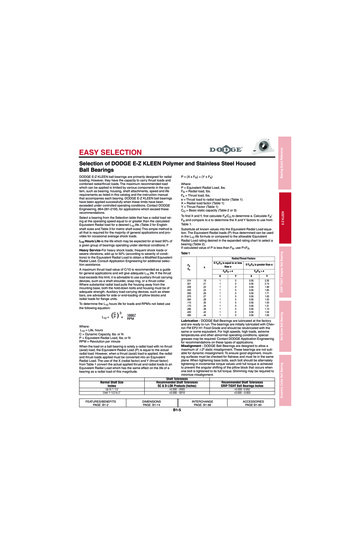

EASY SELECTIONULTRA KLEENSelection of DODGE ULTRA KLEEN Polymer and Stainless Steel HousedBall BearingsE-Z KLEENWhen the load on a ball bearing is solely a radial load withno thrust (axial) load, the Equivalent Radial Load (P) is equalto the actual radial load. However, when a thrust (axial)load is applied, the radial and thrust loads applied mustbe converted into an Equivalent Radial Load. Use X (radialfactor) and Y (thrust factor) from Table 1 to convert theactual applied thrust and radial loads to an Equivalent RadialLoad which has the same effect on the life of a bearing as aradial load of this magnitude.DODGE ULTRA KLEEN mounted ball bearings are primarilydesigned for radial loading. However, they have the capacityto carry thrust loads and combined radial/thrust loads.The maximum recommended load which can be appliedis limited by various components in the system, suchas bearing, housing, shaft attachments, speed and liferequirements as listed in this catalog and the instructionmanual that accompanies each bearing. DODGE ULTRAKLEEN ball bearings have been applied successfully whenthese limits have been exceeded under controlled operatingconditions. Contact DODGE Engineering for applicationswhich exceed these recommendations.Shaft TolerancesEXTREME DUTYSelect a bearing from the Selection Table that has a radialload rating at the operating speed equal to or greater thanthe calculated Equivalent Radial Load for a desired L10 life.This simple method is all that is required for the majority ofgeneral applications and provides for occasional averageshock loads.Recommended Shaft TolerancesSCUp to 1-1/2”Over 1-1/2 to 2” 0.000 -.0005 0.000 -.0010IMPERIAL-HDP XFR YFAWhere:P Equivalent Radial Load, lbs.FR Radial load, lbs.FA Thrust load, lbs.e Thrust load to radial load factor (Table 1)X Radial load factor (Table 1)Y Thrust Factor (Table 1)C0 Basic static capacity (Selection Table)L10 Hours Life-the life which may be expected for at least90% of a given group of bearings operating under identicalconditions.S2000-HDPART NUMBER INDEXHeavy Service-For heavy shock loads, frequent shock loadsor severe vibrations, add up to 50% (according to severityof conditions) to the Equivalent Radial Load to obtaina Modified Equivalent Radial Load. Consult ApplicationEngineering for additional selection assistance.A maximum thrust load value of C/10 is recommended asa guide for general applications and will give adequate L10life. If the thrust load exceeds this limit, it is advisable to useauxiliary thrust carrying devices, such as a shaft shoulder,snap ring, or a thrust collar. Where substantial radial loadpulls the housing away from the mounting base, both thehold-down bolts and housing must be of adequate strength.Auxiliary load carrying devices, such as shear bars, areadvisable for side or end-loading of pillow blocks and radialloads for flange units.To find X and Y, first calculate FA/C0 to determine e.Calculate FA/FR and compare to e to determine the X and Yfactors to use from Table 1.Substitute all known values into the Equivalent Radial Loadequation. The Equivalent Radial Load (P) thus determinedcan be used in the L10 life formula or compared to theallowable Equivalent Radial Load rating desired in theexpanded rating chart to select a bearing (Selection Table).To determine the L10 hours life for loads and RPMs not listeduse the following equation:L10 Normal Shaft SizeInches3)( CP ) ( 16,667RPMWhere:L10 Life, hoursC Dynamic Capacity, lbs. or NP Equivalent Radial Load, lbs. or Nn Revolutions per minute 6

Selection of DODGE ULTRA KLEEN Polymer and Stainless Steel HousedBall BearingsULTRA KLEENEASY SELECTIONIf FA/FR is equal to orless than eIf FA/FR is greaterthan eFA/FR .44FA/FR 31.551.451.311.151.041.00Misalignment - DODGE Ball Bearings are designed to allowa maximum of 2º static misalignment. These bearings arenot suitable for dynamic misalignment. To ensure goodalignment, mounting surfaces must be checked for flatnessand must lie in the same plane. When tightening base bolts,each bolt should be alternately tightening in incrementaltorque values until full torque is achieved to prevent theangular shifting of the pillow block that occurs when onebolt is tightened to its full torque. Shimming may be requiredto minimize misalignment.S2000-HDePart Number IndexFA/CoEXTREME DUTYLubrication - DODGE Ball Bearings are lubricated at thefactory and are ready to run. The bearings are initiallylubricated with an aluminum complex based, H1 FoodGrade grease and should be relubricated with the sameor some equivalent. For high speeds, high loads, extremetemperatures and other abnormal operating conditions,special greases may be required. Contact DODGEApplication Engineering for recommendations on thesetypes of applications.Radial/Thrust FactorsIMPERIAL-HDTable 1E-Z KLEENIf calculated value of P is less than FR, use P FR. 7

EASY SELECTIONULTRA KLEENTable 2: Easy Selection for Polymer and Stainless Housed ULTRA KLEENMounted Ball Bearings - Inch and MetricRingSize204E-Z KLEEN205EXTREME 35mmDynamicStaticCapacity C, Capacitylbs.C0, 45mm670738722101-15/16250mm67073872L10Life 6000010000020000300004000060000100000Allowable Equivalent Radial Load Rating (lbs.) at Various 31551465PART NUMBER INDEX* Slight interference fit required when operating on the right of the heavy line or in the shaded area. Piloted flange only 2334282482421382334282

Table 2: Easy Selection for Polymer and Stainless Housed ULTRA KLEENMounted Ball Bearings - Inch and 82396346314275232426372338295249426372338295249* Slight interference fit required when operating on the right of the heavy line or in the shaded area. Piloted flange only 10188751381211109681E-Z 00006000010000020000300004000060000100000Allowable Equivalent Radial Load Rating (lbs.) at Various RPM*EXTREME DUTY2067/815/16125mm2464L10Life HoursIMPERIAL-HD205DynamicStaticCapacity C, Capacitylbs.C0, lbs.S2000-HD204ShaftSizeSC1/25/83/413/1620mmPart Number IndexRingSizeULTRA KLEENEASY SELECTION

EASY SELECTIONULTRA KLEENULTRA KLEEN Polymer HousingsGeneral Resistance to Chemical Groups at Room Temperature (20 C/68 F)Chemical GroupCondition Or SubgroupResistance 1.00 1.00E-Z KLEENEXTREME DUTYInorganic Acids(non-oxidizing)concentrateddiluted (1:1)highly dilutedInorganic Acids(oxidizing)concentrateddiluted (1:1)highly diluted Organic Acidsconcentrateddiluted (1:1)highly diluted Basesconcentrateddiluted (1:1)highly diluted Salt Solutionsacidicneutralbasic oils and greases phenols -Halogenated Hydrocarbonsperhalogenatedpartially halogenated -Alcoholsmonovalentpolyvalent Aliphatic HydrocarbonsIMPERIAL-HDAromatic HydrocarbonsS2000-HDKetones Esters Ethers (1) except hydrofluoric acid( ) excellent resistance ( ) good-fair resistance ( - ) fair-poor resistance ( blank ) no data availablePART NUMBER INDEX 10

Chemical Resistance ChartChemical AgentSolution Conc.@ 23 C@ 60 C@ 80 C(73 F)(140 F)(175 HousingInsertHousing ULTRA KLEENEASY SELECTIONAcetic Acid5% Acetic Acid10% Acetic Acid20% - - Acetic Acid80% - - Acetic Acid100% Ammonium Chloride10%Ammonium Hydroxide10%Ammonium Hydroxideconc.Aniline - Benzene Bleaching Lye Brake Fluid Butane EXTREME DUTYAcetone B Butanol IMPERIAL-HD Butyl AcetateCCalcium Chloride5% Calcium Chloride10% Calcium Hydroxide10% Calcium Hypochlorite Carbon Disulphide Carbon Tetrachloride E-Z KLEENA Chloroform-Chromic Acid40% --Citric Acid10% Cottonseed Oil Cresol---S2000-HDCastor OilDetergents1% -Detergents25% -Dibutyl Phthalate Diesel Oil Dioxane Ethanol Ether (diethyl-) Ethyl Acetate Ethylene Dichloride-E ( ) excellent resistance ( ) good-fair resistance ( - ) fair-poor resistance ( blank ) no data available 11- Part Number IndexD

EASY SELECTIONULTRA KLEENChemical Resistance ChartChemical AgentSolution Conc.@ 23 C@ 60 C@ 80 C(73 F)(140 F)(175 HousingInsertHousingFFerrous Chloride5% E-Z KLEENFormic Acid5% Formic Acid90% --Freon 11 GGasoline EXTREME DUTYGlycerol (Glycerin) Glycol Grease HHeptane HexaneIMPERIAL-HD Hydrochloric Acid10% - --Hydrochloric Acid90%-----Hydrofluoric Acid5%-Hydrofluoric Acid50%-Hydrogen Peroxide3% Hydrogen Peroxide30% ----IJIsoamyle Alcohol Isopropanol KLKeroseneLithium Chloride 43% MS2000-HDMethanol Methylene Chloride- -Methyl Ethyl Ketone Methyl Salicylate Mineral Oil Motor Oils NPART NUMBER INDEXNitric Acid10% - - Nitric Acid40%-----Nitric Acid70%-----OOleic Acid100%Olive Oil Perchloroethylene Petroleum Ether -- PPhenolPhosphoric Acid3%( ) excellent resistance ( ) good-fair resistance ( - ) fair-poor resistance ( blank ) no data available 12

Chemical Resistance Chart@ 23 CChemical AgentSolution Conc.@ 60 C(73 F)@ 80 C(140 F)(175 HousingInsertHousingULTRA KLEENEASY SELECTIONPhosphoric Acid30% - - Phosphoric Acid85% - --Potassium Chloride10% 10% Potassium Hydroxide1%Potassium Hydroxide10%Potassium HydroxidePotassium Permanganate -------60%--10% P (Continued) S 1% Sodium Bicarbonate10% Sodium Bisulfate5% - -Sodium Bisulfite5% -Sodium Bisulfite10% - -Sodium Carbonate10% --Sodium Carbonate20% --Sodium Chloride10% Sodium Hydroxide1%-Sodium Hydroxide10%-Sodium Hydroxide60%-Sodium Hypochlorite5% Sodium Hypochlorite10% Sulfuric Acid3% - - Sulfuric Acid30% - --Sulfuric Acid98%----- - ------- -TTetrahydofuran Toulene Transformer Oil Trichlorethylene TriethylamineTurpentine VVaseline Vegetable Oils Water -White Spirits WXXyleneIMPERIAL-HD ( ) excellent resistance ( ) good-fair resistance ( - ) fair-poor resistance ( blank ) no data available 13S2000-HDSilicone FluidsSoap SolutionEXTREME DUTY Part Number IndexPotassium DichromateE-Z KLEENP (cont)

Selection/dimensionsULTRA KLEENULTRA KLEEN Mounted BearingsSCEZ PSS Normal Duty Polymer Housed Pillow BlocksE-Z KLEENEXTREME DUTYIMPERIAL-HDSeries204205206S2000-HD207208PART NUMBER INDEX209210ShaftSizeWith Stainless Steel InsertPartNo.DescriptionWeightlbskgDA136695 P2B-SCEZ-012-PSS0.6420 mm 136740 P2B-SCEZ-20M-PSS0.3029.4136696 P2B-SCEZ-100-PSS0.691-3/1625 mm 136741 P2B-SCEZ-25M-PSS0.3230.23/41BCmin.max.1-5/32 5-1/32 1-31/64 3-43/64 3-59/64127.837.793.399.65-1/2 1-31/64 3-31/32 7/8M1222.21/27/8130.240 mm 136744 P2B-SCBEZ-40M-PSS0.881-11/16 136702 P2B-SCEZ-111-PSS2.34 1-23/32 7-13/64 2-7/64 5-27/64 5-31/3245 mm 136745 P2B-SCEZ-45M-PSS1.0343.7183.01-15/16 136703 P2B-SCEZ-115-PSS2.651-3/48-1/16 2-23/64136986 P2B-SCEZ-200-PSS2.5850 mm 136746 P2B-SCEZ-50M-PSS1.3044.5204.8253.659.9 1410.71/22.08 1-11/16 7-13/64 2-7/64 5-7/64 5-41/642.3449/6423/32 3-57/64 1-27/32 1-7/80.74127694 P2B-SCEZ-112-PSS27/6423/3235 mm 136743 P2B-SCEZ-35M-PSS1-3/418.739/64 2-55/64 1-21/64 1-7/161/21.52129.647/6410.7231.68 1-17/32 6-35/64 1-7/8 4-13/16 .4166.7M1625.418.372.684.998.833.733.312.3136700 P2B-SCEZ-107-PSS183.03/81-5/16 27/6442.9136699 138.919/32R15.5136698 P2B-SCUEZ-104S-PSS136701 P2B-SCBEZ-108-PSS3/8M10M45/64 3-11/32 1-37/64 1-11/16 31/641-1/41-1/2L15.130 mm 136742 P2B-SCUEZ-30M-PSS116.9J23/321.13 1-25/64 6-5/16 1-25/32 4-39/64 4-57/6445.2H1/2136697 6.836.547.619.429/3249/64 4-11/64 2-3/64 1-15/16 19/32 1-3/3219.41065227/32 4-5/16 28.65459/64 4-9/16 2-7/162-1/419/32 1-5/3223.457.215.1115.961.929.4

ULTRA KLEENSelection/dimensionsULTRA KLEEN Mounted BearingsE-Z KLEENSCEZ SHSS Normal Duty Stainless Steel Housed Pillow Blocks205206206(SCU)207208208(SCB)210With Stainless Steel SCEZ-103-SHSS2.33 1-25/64 6-1/41-3/16 HSS2.44 1-25/64 .36 1-17/32 SS3.1935 08-SHSS4.39 CBEZ-108-SHSS3.93 15/16 00-SHSS5.0950 mm136854P2B-SCEZ-50M-SHS

The information provided for Product Interchange in this catalog is . the bearing to be re-lubricated with less frequency than standard designs require, while extending bearing life . Lubrication: 100% filled with H1, . manual that accompanies eac