Transcription

DOCUMENT RESUMEED 322 361CE 055 483TITLEINSTITUTIONWelding Curriculum.Alaska State Dept. of Education, Juneau. Div. ofAdult and Vocational Education.PUB DATENOTEPUB TYPE8965p.EDRS PRICEDESCRIPTORSMF01/PC03 Plus Postage.*Competence; *Competency Rased Education; *CourseContent; Course Descriptions; *CurriculumDevelopment; *Educational Resources; Equipment; HandTools; Postsecondary Education; Skilled Occupations;State Curriculum Guides; Teacher Role; VocationalEducation Teachers; *Welding*AlaskaIDENTIFIERSGu.Ldes - Classroom Use - Guiues (For Teachers) (052)ABSTRACTThis competency-based curriculum guide is a handbookfor the development of welding trade programs. Based on a survey ofAlaskan welding employers, it includes all compet ncies a studentshould acquire in such a welding program. The handbook stresses theimportance of understanding the principles associated with thevarious elements of welding. Units begin with definitions of termsand principles so that students will have conceptual frameworks uponwhich they may develop a complete perspective for working in thefield. The handbook is or,anized in these seven sections: (1) theconcept of competency-based curriculum and the role of vocationaleducators in curriculum planning, implementation, and evaluation; (2)the scope and sequence of welding competencies; (3) coursedescriptions to assist school districts in developing theirvocational programs; (4) competencies and tasks for the followingsubjects--welding safety and health, tools and equipment, blueprintsand layouts, welding metallurgy, employability skills, oxyacetylenewelding and cutting, shielded metal arc and air carbon arc welding,gas metal and ilux core arc welding, crtungsten arc welding,special welding processes, and fabrication, repair, and riggingskills; (5) curriculum analysis matrices to be used to determinecompetencies for specific welding courses; (6) a sample skills cardfor evaluating and recording student progress; and (7) information onresources and specific materials available in Alaska and the rest ofthe nation, along with a suggested tools list and minimum tools andequipment needed. (KC)***Reproductions supplied by EDRS are the best that can be madefrom the original document.,**

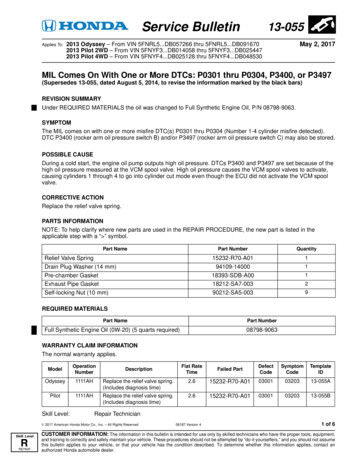

WeldingCurriculumU S DEPARTMENTOf (DUCATIONOffice of Educafionat Researchand ImprovementEDATIONAL RESOUrCESCENTER IERIC)INFORMATIONThis document Nes been .eoroduced asraceived from Me person or orgamtafionOriginating itC Woo, changes havebeen made to improirereproduction QualityPoints of v.ew or opomons stated o thmdocument do not necessafity represent officmIOE RI Dolman or poficy"PERMISSION TO REPRODUCE THISMATERIAL HAS BEEN GRANTED BY3111.--.40111ATO THE EDUCATIONAL RESOURCESINFORMATION CENTER (ERICL"Alaska Department of Education 19892

WeldingCurriculumState of AlaskaSteve Cowper, GovernorDeveloped by the:Alaska Department of EducationOffice of Aduit and Vocational EducationWilliam G. Demmert, CommissionerKaren Rya Is, Director,Office of Adult and Vocational EducationThis publication was prepared with the support of U.S. Depaitment ofEducation funds under the Carl Per Ida: Vocational Education Ad, P1.98524. Copies are available from the Alaska Department of Education, Officeof Adult and Vocational Education, Alaska Vocational Materials Lbrary,Box F, Juneau, Alaska 99811, (907)485-2980. This publication may beduplicated.Alaska Department of Educalion 19893

Table of ContentsForewordAcknowledgementsI.Introduction to Competency-Based CurriculumCompetency Based CurriculumCurriculum Delivery SystemsRole of Instructor in Curriculum Planning, Implementation,and EvaluationII.122Program Development7Scope of WeldingIII.Course DescriptionsIV.Competencies and Tasks811riSILLWaldloaraogaisnciesWelding Safety and HealthTools and EquipmentBlueprints and Layout/Specifications and CodeWelding MetallurgyEmployability Skills1519212325Agalladilt Weida !kW EaldinaramoloodesOxyacetylene Welding and Cutting (OAW & OFC.A)Shielded Metal Arc Welding (SMAW) andAir Cartoon Arc Welding (MC)Gas Metal and Flux Core Arc Welding (GMAW & FCAW)Gas Tungsten Arc Welding (GTAW)Special Welding Processes/TorhniquesFabrication and Repair and Rigging Skills313335373941V.Curriculum Analysis Matrices45VI.Sample Skills Card53VII.Suggested Resources574

The Alaska Department of Education is an equal opportunftlyemployer and will not dscriminah; in Depaitment employmentsupervision, practices, savices, or educational programs on thebasis of race, religion, color, national origin, age, sex, handicap,marital status, changes in marital status, pregnancy, parenthood,veteran's status, veteran's dsability or political affiliation.5

ForewordThis competency-based curriculum is designed to be a handbook for the welding trade. It includes allcompetencies a student will acquire in a welding program. Since the standards used to judge weld quaity arenational standards, articulation vigh post secondary programs could be arrangel through a testing processand college credit could be obtained. The welding program detailed in this cuniculum may also help studentsin entering an apprenticeship program. Welding Is a trade and a tool-one of the many tools of industry.Development of this handbook began with a survey of Alaskan welding employers. Their priorities regardingthe skills and knowledga students need to acquire to survive and thrive in the industry form the basis of thishandbook. For example, industrys emphasis on the importance of communication and personal skills isreflected in the empioyability skills unitThe handbook stresses the importance of understanding the principles associated with the various elementsof welding. Units begin with definition of terms and prindples so that students will have conceptual f rameworksto which they may add the details of various techniques. Theseven units, divided into competend es and tasks,are fundamental to welding. The competencies and tasks are presented so that instructors have theprerogative to detemine which aspectstheywantto teach In basic, intermediate, and advanced level courses.The following example demonstrates how this curriculum may be used and applied. Bill Johnson has beena vocational teacher at a rural Alaskan site for two years and he's very interested in initiating a program inwelding. He performs a needs assessment of his community and determines that a person who is able toweld aluminum skiffs would have a good chance of attaining employment. He also discovers that such weldingskills would have some direct application for personal uses in subsistence and other self-sufficiency activities.He looks at the Wekling Scope and Sequence to choose the processes which he will need to initiate a weldingcourse to attain skill in aluminum welding. Those areas would include Welding Safety and Health, Tools andEquipment, Empbyability Skills, GMAW & FCAW, GTAW and some Special Weiding Processes andIorWelding Metallurgy andlor Fabrication and Repair and ROging Skills. Hethentums to the Curriculum AnalysisMatrices and names his course (MWelding r) in the vertical column at the top of the page and reviews the listof competencies checking off those competencies he will teach in the course. It's that simple. Then he writesa course description (based on the samples In the Course Descriptions).Bill refers to the body of this book for the tasks involved in teaching those competencies. The competendesand tasks which compose the course depend on the location, the expertise of the instiuctor, time constraints,equipment available, and the project(s) to be undertaken, all of which may relate to the entry-level jobsavailable in the community. Bill reorders the competencies to fit his program. He uses the cross-referenceguides from the rqatrk to approach school administration about obtaining academic credit in given areas forthe class. In the Suggested Resources section he finds a Tools List and a list of Suggested Minimum Toolsand Equipment needed for the welding program. Bill writes for materials from several manufacturers andpublishers. Bill uses the sample skills cani, provided in the curriculum, as a model for developing other skillscards for evaluation of student's skills.If Bill Johnson's targeted skills involved stainless piping, he would of course pick other units, competenciesand tasks.A welding program focusing on basic welding skills without a specific skill area emphasis, will require aminimum of a two year course sequence to provide job training skills and preparation for post secondaryeducation.6II

ThabandbmkitatganIzestinimaramsecilanwSection I introduces the concept of corrpetency-based curriculum. Therole of vocational educators incurriculum planning, hriplementation, and evaluation is also included.Section II provides the scope and sequence of welding competencies.Section III contains course descriptions to assist school districts in developing theirSection IV presents the currimilum including the competencies and tasks torvocational programs.welding instruction.Section V provides curriculum analysis matrices to be used to determinecompetencies to be included inspecific welding courses.Section VI contains a sample sidlls card for evaluating and recording studentprogress.Section VII lists information on resources and specific materials available inA suggested tools list and minimum tools and equipment neededAlaska and the rest of the nation.for a welding program is included.It is recormended that all students participate in career awareness and explorationexperiences to help themunderstand the connection between school and work and make career plans.7ii

AcknowlAdgementsThis handbook reflects the competencies needed for entry-level employment as identified by Alaskan weklingprofessionals. Thanks and recognition go to the following technical committeemembers for their assistanceand cooperation:Alaska Welding Technologies, KetchikanFairbanks Machine and Steel, FairbanksFast Ed's Welding, JuneauNcgth Coast Welding, DillinghamPeninsula institute of Welding Technology, KenaiPhil's Welding, JuneauSmokeeter Sales and Service, AnchorageTech Welding Service, AnchorageA task force of welding educators helped to define the units, competencies and tasks, course descriptions,academic cross-credit, and scope and sequence forthe curriculum. The task force which met to finalize thishandbook deserves a great deal of credit for their hard work and valuable input:Gerald Park, instructor, University of Alaska AnchorageDwight Perkins, Business Manager, Plumbers and Pipefitters Union Local 262, JuneauSpecial thanks are due the following individuals for their assistance and review of this curriculum:Michael Anderson, Program Manager, Office of Adult and Vocatbnal Education, AlaskaDepartment of Education, JuneauDick Banta, Safety and Training Unit, ARCO Alaska , AnchorageDick Larson, Welding Instructor, University of Alaska-Southeast, JuneauBill Murray, Maintenance Supervisor, Prudhoe Bay, BP ExplorationRobert L. O'Brien, Manager, Technical Publications, American Welding Society, Miami, FloridaSam Rogers, Vocational Instructor, Northwest College, NomeWalter Ward, VocW anal instructor, Soidotna High School, SoldotnaSpecial appreciation is expressed to Richard Steele and Carin Smolln who coordinated the preparation andcompletion of this handbook, and to Mark Hanson, Associate Director of the South East Regional ResourceCenter, who administered this project.Special thanks are due South East Regional Resource Center employee Heidi Rocheleau who designed thegraphics for the handbook.Thanks also go to the National Network for Curriculum Coordination in Vocational and Technical Education(NNCCVTE) and participating states for providing resource materials which improved the quality of thishandbook and saved months of work.Finely, Virden Jackson, Curriculum Specialist for the Office of Adult and Vocational Education, must berecognized for designing the curriculum development process and for participating in every step of thehandbook's development ensuring that ft is a model Alaskan curriculum of the highest quality.Karen RyalsDirectorOffice of Adult and Vocational EducationAlaska Department of EducationNovomber 19898lii

IIntroduction toCompetency-BasedCurriculume

Competency-Based CurriculumVocational education should be directed toward the skills, knowledge, and attitudes needed for successfulemployment. Welding educators need to cordinually updale their curriculum in order to prepare students forcompetition in the job market.An effective method for delivering vocational education is through a competency-based curriculum. Thiscurriculum is based on an analysis of the key occupations in welding. Once a competency-based curriculumis set in place, student performance must be measured on levels of proficiency in those competencies. Thus,the critical features of competency-based education are:1)2)validating competencies to be included in the curriculum; andevaluation of student complency levels.This curriculum handbook sets direction for local curriculum developers.developing courses of study and lesson plans in local schools.It provides a framework forCurriculum Based On CompetenciesCompetence refers to the adequate pedomiance of a task. The task may be evaluated according to theperformance or process, the service, or both.Competency-Based Vocational Education consists of programs that derive their content from the tasksperformed in each occupationfpb and assess student performance on the basis of preset performancestandards.IIILearning materials define the competencies the student is to master, the criteria by which the student will beevaluated, and the conditions under which the evaluation will occur.Competency-based instruction places emphasis on the ability to do, as well as on learning how and why.Student performance and knowledge are individually evaluated against the stated criteria, ratherthan againstgroup norms.The competency process utilizes a checklist of attitudes, knowledge, and skills that are commonly needed byentry-level employees in welding occupations. In developing this curriculum handbook, a cross-section ofwelding professionals were asked to respond to a survey on the basis of needs within their own establishments.The survey results were summarized to determine which attitudes, knowledge, and skills were important tofirms in Alaska.Student Performance AssessmentA curriculum becomes competency-besed when students are assessed on the basis of their competence. Asample skills card is provided in this guide for teachers who wish to use them in assessing the competencylevels of their students. The card has four levels of proficiency which allow continued development of sidlis.The card can be used to monftor students' progress as they move between welding classes, between teachersand grade levels, and between school and work. The completed skills card is an important part of a placementportfolio when students begin their job search.10

MIMI/Curriculum Delivery SystemsVocational Student Leadership OrganizationsSome of the competelcies in this curfICUIUM guide cannot be fully met in traditionalclassroom and lab settings.The Vocational Industrial Clubs of America (VICA) Is a delivery system .vhichcan be integrated into theregular school program. Human relations skills as wel as job skills will be enhancedby student participationin VICA. VICA activities should complement instruction in the welding classroomand lab. They should beintegrated as a curriculum delivery system and not allowed to becomean extracurricular activity.Cooperative Work ExperienceSome of the competencies identified in this guide cannot be fully developed at a school site. A work stationin the community offers realistic experiences in fulfilling the program goals incareer de% Jpment and humanrelations. Cooperative Work Experience offers an excellent vehicle for the delivery ofinstruction. With welldeveloped training plant, teachers and employers can cooperate to prepare students for employment.Cooperative Wort Experience extends the instructional program beyond theavailability of equipment andinstructor time at the local achool. Teachers and employers must maintain regularcommunications to assurethat students are receiving a high quality experience.The Rural Student Vocational Program (RSVP) provides a two week full-time workexperience for studentsfrom rural areas where job stations are limited or non-existent.Job Training Partnership Act (JTPA) programs provide on-the-job experience to disadvantaged youthin bothurban and rural areas.Role of Instructor in Curriculum Planning,Implementation, and EvaluationThe vocational instructor fulfills many roles which include the following responsbilities:Prepares a written vocational program plan.Develops and maintains a written program philosophy with objectives that supportthe philosophy.Maintains a written list of competencies identified as needed for theprogram area.Devises and maintains a classroom management system for implementing thecurriculummaterials provided for the program area.Evaluates the curriculum content periodically to determine curriculum changes and updates.Thisincludes the involvement of the students (present and former), advisory committeemembers, andother perst MI.Selects units of instruction and lesson plans based on the competencies of the occupation.Provides appropriate instructional materials, supplies, and equipment for the studentsto use.Provides school guidance counselor with information and updates regarding implementationof thespecific curriculum.112

Reviews the instrucilonal materials to assure that they are free from sex bias and sex role stereotyping.Works with an advisory committee.Assists and/or serves as an advisor to the appropriate student organization related to the vocationalprogram area.Plans and arranges an appropriate classroom learning environment. This involves assisting students ofdifferent abilities to work at their own pace and in cases where remedial instruction is needed, securingadditional help for those students.Reinforces basic skills of reading, communication (written & oral) and computation through vocatic naleducation experiences.Helps determine what objective(s) should be established for handicapped students as a part of theindividual educational plan (IEP) development.Uses a grading procedure that is made available to all students at the beginning of their training.Sets an example for grooming and dress that Is generally found in the occupational area in buslness orindustry to enable students to establish appropriate standards.Benefits of the Competency-Based CurriculumCompetency-based vocational education offers several benefits to students:1.The competencies/tasks are directed to the student and provide measurable criteria for determining whenthe student has acquired the necessary knowledge and skills.2.Students receive realistic training for the job. They become competent in tasks that are relevant to theoccupation.3.Students know what is expected of them throughout the course. The competencies are made availableto them at the onset. They know what they will be doing and how well it rrust be done.4.Each student is individually responsible for completing each competency attempted in the curriculum.5.The basic thrust of the competency-based program is to evaluate students according to theiraccomplishment of tasks as they work up to individual capability. Students are not compared with otherstudents in their accomplishments because each is expected to work according to employmentstandards. Because of the various evaluation policies of different school systems, the ideal ofnot comparing students in determining grades is not always possible.123

IIProgramDevelopment13

Program DevelopmentThe format of this handbook was selected to aid adrrmistrators and teachers in concentrating on the sidllsneeded for vocational training. It will assist in selecting the array of units and the delivery system which tit theschool. This provides the flexbility of varying the course content to include the most valuable skills asappropriate for the scope and sequence. The primary importance is that students are able to securefoundation skills. Schools crn vary their delivery systems to maximize student opportunities by:1.Offering courses on alternate years or other planned sequences2.Offering two or more course-, in the same class3.Previding indWidualized materials and instructionA matrix is included in this guide for use in planning the courses to be offered and the) content of each course.The following chart shows the scope of welding competencies.or14

Scope of WeldingCertificationCertificationSpecial WeldingProcesses/TechniquesOxyacetyleneWelding & Cutting(OAW & OFC.A)Basic Welding CoreGas Metal (GMAW)& Flux Core ArcWe Ming (FCAW)15Safety and HealthTools and EquipmentBlueprints and Layout/Specifications and CodesWelding MetallurgyEmployability SkillsGas Tungsten ArcWelding (GTAW)Shielded MetalArc Welding (SMAW)& Air Carbon ArcCutting (AAC)r-11ficaii;4)Fabrication andRepair and RiggingSkillsCertification1k.6e

IIICourseDescriptions17

Course DescriptionsThete brief course descriptions provide a conceptual framework for the design and implementation of abalanced program in welding. Teachers can use these descriptions to organize course offerings in weldingeducation. Local schools will need to provide more definition regarding the content of their courses than isreflected in these general course descriptions.Use the curriculum analysis matrices to help build your own courses, depending on your school, location,equipment, and training of the instructor.Course:Length:Grades:WeldingOne semester9-12th gradesThis course covers the basic operations of welding including safety and health, tools and equipment,blueprints and layout/specifications and codes, welding metallurgy, and employability skills. Setup and weldquality will be stressed. There isn't any prerequisite for this course.Course:Length:Grades:Prerequisite:Welding IIone semester10th-12th grades or post secondaryWelding IThis course provides students with a review of welding techniques. They wine the basics of one or moreof the following: OAW, OFC.A, SMAW, AAC, GMAW, FCAW and GTAW. Students will complete advancedwelds and metal cutting with concentration on skills needr d in their communities. Students will utilize blueprintand layout skills. They will complete a fabrication or repair project or participate in Cooperative Education.The course will stress high standards of safety in the use and operation of welding equipment and ng IIIone semester11-12th grade or post secondaryWelding I and ilThis course includes a review of all of the skills learned in Welding I and II. Students will learn advancedtechniques of one or more of the following: OAW, OFC.A, SMAW, AAC, GMAW, FCAW, GTAW. Studerfswill complete advanced welds and metal cutting with concentration on skills needed in their communitielStudents will utilize blueprint and layout skills. Students will complete a fabrication or repair project orparticipate in Cooperative Education. Students will use riggingi skills as ng IVone semester11-12th grade or post secondaryWelding I, H, and illThis course includes a review of all of the skills learned in Welding I, II, and III. The course includes thecomprehensive study and application of blueprints and layout/specifications, codes, and fabrication, repair,and rigging skills. Students will complete advanced welds and metal cutting with concentration on skillsneeded in their communities. Opportunities will be provided for Cooperative Education programs. Studentswill prepare for certification in selected welding processes.48

IVCompetenciesand Tasksr-,-19i

Welding Safety and Health(A) indicates advanced competency or taskCompetency:Maintain a clean and safe shopTasks:Perform assigned shop cleanup dutiesKeep floors and workbenches clean and neatWipe oil and grease spots immedicelyStare materials, tools, and supplies in proper placesINspose of combustbie materialsStore oily rags in self-dosing metal containersPlace scrap materials in proper containersClean and replace tools to storage locationsKeep aisles, traffic areas, and exits free of materials and other debrisCompetency:Use general safety proceduresTasks:Follow safey rules fora. preventing firesb. using hand toolsc.operating equiprnentflammable metals and gasesavoiding electric shockf. handling containersg. toxic gases or displacement of breathing airIdentify ventilation procedures for the work areaidentify fire ham . In the shopIdentify the three components of the fire triangleDemonstrate the handling and safe storage of gasesDifferentiate among types and flammability of various gases in the shopFollow all rules for handling gas cylinders safelyIdentify different types and uses of fire extinguishers and other fire preventiondevicesFollow safe procedures in regards to fire prevention at all timusidentify safety procedures around radiation and other hazardous materials on thejob siteWear protective clothing and devices such as:a. safety glassesb. face shieldc. welding heimets/goggiesd. hand shieldse. ear protectionf. jacketsg. glovesh. bootsI.hair netj. fire-resistant apronMake sure clothing is free from oil and greaseIdentify safety procedures for different types of weldingIdentify proper procedures when moving or lifting heavy objects(A) kientify air cleaners for welding applications such as:a. direct capture air cleanersb. free hung air cleanersd.e.1520

Competency:Apply first aid skillsTasks:Demonstrate first aid for victims of electrical shockDemonstrate first aid for common welding injuries, especially bumsExplain ways to recognize shockDemonstrate the steps in treating shockUse first aid for eye injuryFollow other general guidelines for first aid emergenciesComplete a student safety pledge(A) Demonstrate the steps used in controlling bleedingCompetency:Use tools safelyTasks:Keep all tools sharp, clean, and in safe working orderDemonstrate use of tools in prescribed manner including:a. using proper tool for taskb. clamping projects securely before drilling or power grindingc. using correct speed for power tools and drill bits when workingwith metald. using properly sharpened tools and drill bitse. keeping all guards and safety devices in place and adjustedproPellYf. turning off all power before leaving a machine toolReport faulty shop tools and equipmentCompetency:Follow electrecal safety proceduresTasks:Explain rules and safety procedures for electric weldingLabel circuit breakersGround electrical equipment, explaining how and whyUse flexible extension cords and drop lightsIdentify electrical hazardsIdentify locations of all electrical equipment and power sourcesNever operate ungrounded equipmentNever arc weld or operate electrically powered equipment while Mt ridingon wet or damp floorsCompetency:Use safe welding proceduresTasks:Wear safety glasses and clothingNever weld, cut, or grind near flammable or explosive materialsKeep oll away from gas cylinders, regulators, connections and hosesKeep electrode holder away frorrwelding machine or gas WinderDo not cut or weld directly on concreteProperty purge barrels, drums or other containersCut into barvels, drums, or any containers that have been purgedNever ground elestrical equipment to a building member or a piece ofequipment attached to or part of a buildingNever engage In horseplay of any kindClean work carefullySecure tanksPlace work in jigs or other holding fixturesDo not weld near batteriesProtect wood or combustible materials from direct heat2118

Do not open an acetylene cyiinder valve near open flames orother welding and cutting and brazingShut off oxygen and acetylene at the cylinder valves when leavingthe areaoe(A) Competency:Follow OSHA and AWS guidelinesTasks:Explain purpose of Occupational Safety and Health Art (OSHA)Identify worker rights under OSHAExplain how to resolve hazardous and OSHA violationsIdentify employee rights according to OSHAMaintain records of work-related injuriesExplain how to report worker compensation claimsIdentify the role of the American Welding Society (AWS)identify AWS guidelines and publicationsinterpret Material Safety Data Sheets (MSDS's)Use color-coded signs to warn of danger

Tools and EquipmentCompetency:Tasks:Use welding hand toolsDemonstrate the use of welding hand tools such as:a. alignment toolsb. bevel squarec. chisels, punches, and pry barsd. combination squaree. dies and punchesf. driving and chipping toolsg. fliesh. fillet weld gaugeI.framing squarej. gaugesk. lacksI.jigm. manual cutting and shaping toolsn. measuring toolso. pliersp. positionersq. pulling and lifting toolsr. serni-precision measuring toolsS. turning tools and wrenchest. wire brushesu. work holding devicesFollow basic Ilan for safe use and maintenance of hand toolsMeasure parts with semi-precision measuring toolsInspect parts with precision measuring toolsMaintain and store toolsCompetency:Use welding shop power toolsTasks:Demonstrato welding power tools such as:a. air chiselb. beveling machinec. electric hammersd. hand oending brakese. hand grindersf. hydraulic shearg. mechanical shearh. metal-cutting band sawsI.non-destructive testingj. pedestal grinderk. pneumatic shearI.portable electric hand toolse. power squaring shearsP. power wire brushq. preheating andannealing equipmentr. rod ovens. sandblasting equipmentt. shears and nibblersU. spot welderV. turning rollsw. universal benderx. welding positionersy. wire feed mechanismsm. portable screenn. power press brakesFollow basic rules for safe use and maintenance of welding and shopequipment including:a. cleaningb. biowing dust out of welding machine with dean, dry airc. cheeking compressed gas systems fo

welding and cutting, shielded metal arc and air carbon arc welding, gas metal and ilux core arc welding, cr. . Bill refers to the body of this book for the tasks involved in teaching those competencies. The competendes and tasks which compose the course dependon the locatio