Transcription

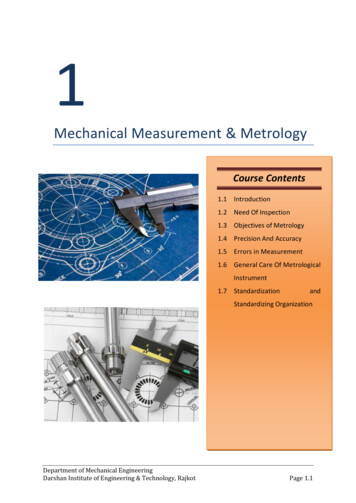

Metrology What is metrology?– It is the science of weights and measuresMEMS Metrology Refers primarily to the measurements of length,wetight, time, etc. Mensuration- A branch of applied geometryDr. Bruce K. GaleFundamentals of MicromachiningWhat is a Measurement A measurement is an act of assigning aspecific value to a physical variable The physical variable becomes themeasured variable Measurements provide a basis forjudgements about– Process information– Quality assurance– Process control– It measure the area and volume of solids fromlengths and angles It also includes other engineeringmeasurements for the establishment of aflat, plane reference surfaceMeasurable Parameters What do we want tomeasure? Length or distance Mass Temperature Elemental composition Viscosity Diplacements ordistortions Time essDepthIntensityetc.

Measurement Systems and ToolsComponents of a MeasuringSystem Measurement systems are important toolsfor the quantification of the physicalvariable Measurement systems extend the abilities ofthe human senses, while they can detect andrecognize different degrees of physicalvariables For scientific and engineering measurement,the selection of equipment, techniques andinterpretation of the measured data areimportantImportance of Metrology In human relationships, things must becounted and measured Metrology is an absolute necessity forhuman development– This necessity increased greatly with the adventof the industrial age As society develops further, metrology mustalso be refined furtherHow Important areMeasurements? Measurement is the language of science It helps us communicate about size, quantity,position, condition, time, etc. Simple measurement errors can cost a companya contract, work, jobs, and lots of money Three areas to which the basic principles ofmeasurement can be applied– Communication of the measurement– Act and application of the measurement– Codification of the measurement

Human Interaction inMeasurements Almost always require the use of vision– Other senses not always good at “measurement” Measurements usually require tools– They rely on the visual process What happens if object is too small to perceive?– At what size do things become to small to measure?– Handling and/or perception problems– Limits of vision/ perception without aid or assistanceWhat is Microsystem Metrology Measurement of physical dimensions ofmicrosystems or structures that are at thedimension scale below our ability to perceivewithout the help of measurements systems orinstruments Microsystems: IC, MEMS Microstructures: Line widths, film thickness,surface struture and roughness, step heights,particle size, atomic composition, defectinspections, etc Nanosystem metrology is emerging now!Where Metrology at the MicroLevel is Used Precision engineering and measurementsMicron and nano manufacturingResearch and developmentCalibration of instruments and standardsMEMS Measurement Statistics and probabilityStatistical process controlOptical microscopyScanning electron microscopy (SEM)Atomic force microscopy (AFM)Scanning tunneling microscopy (STM)Near- field microscopyLaser/ White light interferometryVideo MicroscopySurface ProfilerRoughness TesterEllipsometry

Statistics and Probability Statistical terms anddefinitions Infinite statistics Finite statistics Standard deviations Probability densityfunctions Confidence intervals Uncertainty analysis Error sources Bias and precisionerrors Error propagation Regression analysis Least squares methods Linear polynomials Student’s t-Test Single and multiplemeasurement errors Zero and higher orderuncertainties Correlation coefficientOptical Microscopy Light propagation and Snell’s lawMirrors, prisms, lenses and beam splittersImage formation, interference and diffractionSimple and compound microscopesMirror and thin lens equationsResolving power and resolutionAberrations and correctionsDepth of field and focusMeasurement on the optical microscopic scaleStatistical Process Control Concept of variation Importance of SPC inproduction processes Controlled anduncontrolled variation Common and specialcauses Control charts Statistical inference Running records Population parameters Control limits Subgroup average andrange Three sigma limits– Six now!Numerical Aperture

MEMS Optical Microscopy ProblemsScanning Electron Microscopy Used for observation, analysis, and measurement Can produce images over a wide range ofmagnifications– High magnification and great depth of field– High resolution (down to 2.5 nm) Can provide morphological, compositional, andphysical information 3D appearance of image Greater degree of freedomNear Field Scanning OpticalMicroscopy Used to get below the limits of “far-field diffraction” High resolution down to 50 nmNSOMImages using NSOMTip

SEM Components Electron gun assembly– Stable source of primary electrons Electromagnetic lenses and aperturesSEM Operation Small area irradiated by electrons E-beam can be static or swept Secondary and backscattered electrons detected– Focus electron beam Vacuum system– Allows passage of electrons withoutinterference Electron collector, display, and recorder Specimen stage– Goniometer stage Current in the focused e-beam determines magnitude ofemitted signals Size of focused beam determines the resolutionOpticalSEMComparison ofSystemsSEM Operation

Transmission ElectronMicroscopy (TEM) Only for thin materials Usually used to studycrystals Gives good informationon nanometer structureAtomic Force Microscopy Atomicallysharp tip Measuresminute atomicforces thatcause repulsion Can measureindividualatomsAFM Image of Silicon Silicon (111) plane- ridges 0.38 nm highScanningTunnelingMicroscopy

Scanning Tunneling Microscopy Sharp tip Tunneling currentor voltagemeasured Current increasesrapidly onapproach tosurface Atomic resolutionRoughness Step Tester (RST) Surface characterization Interference microscope Optical measurement ofsurfaceSurface Texture Definition– Repetitive or randomdeviation from nominalsurface that forms the 3-Dtopography of the surface Roughness– Closely spaced irregularities Waviness– Wider spaced irregularities(tool marks) Form– Does not contribute tosurface textureSurface Profiler Large tip scans across surfaceExcellent for measuring height of objectsSidewalls are not accurateVariation dependent on tip diameterVertical accuracy in angstroms

Ellipsometry Light is rotated as it passes through medium If dielectric constant is known, can be used tomeasure film thicknessInterferometry Reflected light waves interfere with each other Used to measure thickness of thin films ordeflections Interference occurs at different locations based onwavelengthCCD Cameras (Video Imaging)Thin FilmsChange Colors Charge Coupled Devices (CCD)– Metal - insulator - semiconductor devices(MIS)– Incident light generates charge on gate– Induced voltage causes charge separation CCD cameras are arrays of MISdevices– Can be 10 microns square– Charge collected and moved sequentiallyto edge of device– Dyes can be applied to transistor to detectcolors

MEMS Metrology Dr. Bruce K. Gale Fundamentals of Micromachining Metrology What is metrology? – It is the science of weights and measures Refers primarily to the measurements of length, wetight, time, etc. Mensuration- A branch of applied geometry – It meas