Transcription

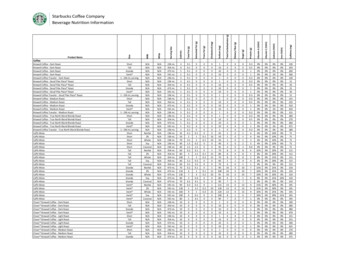

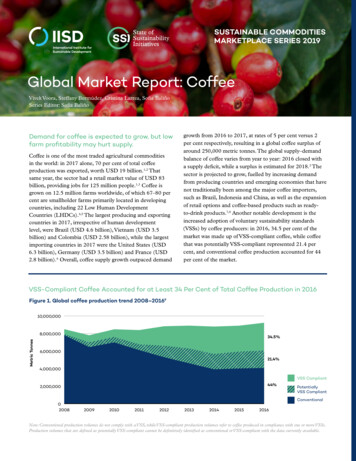

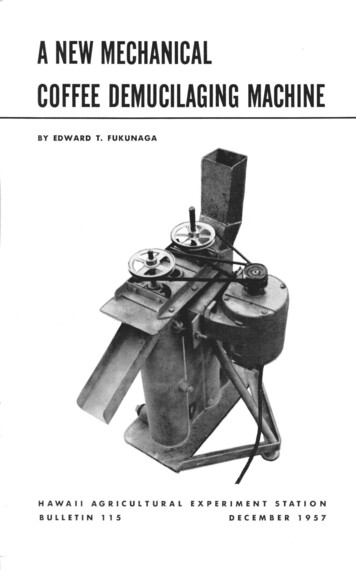

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 3 Issue 12, December-2014Processing and Drying of Coffee – A ReviewPayel GhoshDr. N. VenkatachalapathyResearch Scholar, Food Process Engineering Dept.Indian Institute of Crop Processing TechnologyThanjavur, IndiaAssociate Professor, Food Process Engineering Dept.Indian Institute of Crop Processing TechnologyThanjavur, IndiaAbstract— Coffee is one of the most popular beverages in theKeywords— Coffee, Processing,Mechanical Drying, Mechanical dryers1.Drying,INTRODUCTIONSun-drying,Fig 1.1 World Coffee Production [Source: Coffee Board of India; Database2013]This Coffee is one of the most popular beverages in theworld. Nearly 25 million farmers in 50 countries around theworld depend on coffee for a significant part of theirlivelihoods (Cague et al. 2009). The genus coffee belongs tothe botanical family of Rubiaceae and comprises more than90 different species (Davis, 2001). The characteristic, richand pleasant aroma and colour of coffee brews is a result ofcomplex processes leading from green coffee beans to thecup of coffee. One of the principal postharvest processes isdrying that gives rise to the formation of the characteristiccolour, flavour and taste of coffee brews. In 2010-11according to U.S. Department of Agriculture 12 milliontonnes of green coffee is produced.Coffee plants are grown in tropical and subtropicalregions of Central and South America, Africa, and South EastAsia, mainly in regions with temperate and humid climates(Schenker, 2000). Coffee cherries are harvested each yearwhen they are bright-red, glossy and firm. After removingthe outer hull, the seeds inside of the cherry are commonlycalled "green coffee beans". The quality of the green coffeebeans is dictated by a number of parameters, including beansize, colour, shape, method of drying, crop year, and presenceof defects (crack, withered bean, bean in parchment, mouldybean, etc.).IJERTV3IS120482Brazil is by far the largest grower and exporter of greencoffee beans in the world followed by Vietnam, Colombia,Indonesia, Ethiopia and India – producing nearly 2.5 milliontonnes of green coffee beans per year (Franca and Oliveira2009). Fig1.1 shows the main coffee producing countries aswell as their share in production.IJERTworld. One of the principle post-harvest technological processesis drying, giving rise to the formation of the characteristiccolour, flavour and taste of coffee brew. Conventionally thereare two types of drying techniques used in the coffee processing,(sun drying and mechanical drying). The initial moisturecontent of harvested coffee is about 55-60% and after dryinglowers the moisture content to around 12% (wb). Drying shouldbe uniform to obtain acceptable colour, size along with theremoval of pests for a longer safe storage. Since coffeeproduction is seasonal, traditional sun drying is quite tough.Unpredictable weather events can increase the moisture contentand the time taken for drying prolongs to about 7-21 days.There are several dryers available for coffee drying includingmechanical dryers as well as Combination of both solar dryerassisted with mechanical dryer. The new trend of coffee dryingis the microwave drying which retains the characteristics flavor.This is a novel try to share about various drying process indifferent countries throughout the world.2.COFFEE FRUIT AND MORPHOLOGYCoffee belongs to the botanical family Rubiaceae, whichhas some 500 genera and over 6,000 species Davis (2001).Most are tropical trees and shrubs that grow in the lowerstorey of forests.Other members of the familyinclude gardenias and plants that yield quinine and otheruseful substances, but Coffee is by far the most importantmember of the family economically.Table 2.1 – Botanical Characteristics of Coffee (Clifford etal., aLibericaAccording to Clifford et al (1985) Linnaeus firstdescribed coffee arabica in 1753. The best known varietiesare 'Typica' and 'Bourbon' but from these many differentstrains and cultivars have been developed, such as Caturrawww.ijert.org( This work is licensed under a Creative Commons Attribution 4.0 International License.)784

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 3 Issue 12, December-2014Table 2.2 - Basic differences between Arabica andRobusta are (Wrigley, 1988)(Brazil, Colombia), Mundo Novo (Brazil), Tico (CentralAmerica), the dwarf San Ramon and the Jamaican BlueMountain (Table 2.1). The average Arabica plant is a largebush with dark-green oval leaves. It is genetically differentfrom other coffee species, having four sets of chromosomesrather than two. In case of Arabica the fruits are oval andmature in 7 to 9 months (Table 2.2); they usually contain twoflat seeds (the coffee beans) - when only one bean develops itis called a peaberry. Since Arabica coffee is often susceptibleto attack by pests and diseases, resistance is a major goal ofplant breeding programs. Arabica coffee grown throughoutLatin America, in Central and East Africa, in India and tosome extent in Indonesia.The term 'Robusta' is actually the name of a widelygrown variety of this species. It is a robust shrub or smalltree growing up to 10 meters in height, but with a shallowroot system. The fruits are rounded and take up to 11 monthsto mature, the seeds are oval in shape and smaller than thoseof C. arabica (Table 2.2). Robusta coffee grown in West andCentral Africa, throughout South-East Asia and to someextent in Brazil, where it known as Conillon.RobustaDate species described17531895Time from flower toripe cherry9 months10-11 monthsRipe cherriesFallStayYield (kg beans/ha)1500-20002300-40000Optimum temperature(yearly average)15-24 C24-300 COptimal rainfall1500-2000mm2000-3000mmOptimum altitude1000-2000m0-700mCaffeine content ofbeans0.8-1.4%1.7-4%Shape of beanFlatOvalAccording to Avallone (1999) from a morphologicalperspective, the coffee cherry is an ellipsoidal fruit (about1x2 cm) with two curved sides on one side and flat by theother having an elliptical or egg geometry, flat-convex, with adivision on the flat surface (Dedecca, 1957). Measurescarried out on several seeds show that the grain has anaverage length of 10 to 18 mm and 6.5 to 9.5 mm of wide(Dedecca, 1957). Some species have smaller grains and C.ramenosa (5-7 mm long and 3 to 3.5 mm wide), while othershave larger grains and C. liberica. The proliferation of cellsduring fruit growth is limited because the thickness of themesocarp never exceeds 2 mm. The pericarp corresponds tothe fleshy part in drupes and its thickness varies from 1 to 1.7mm depending on the species of coffee. (Avallone, 1999).The endocarp, also called "parchment" is a hard, protectiveand woody tissue with lignified secondary walls of about110-150 μm of thickness (Avallone, 1999). Its functions arevaried: it was proposed that protects the coffee bean againstcertain enzymes (Avallone, 1999), and that it acts as aphysical barrier that limits the diffusion of certainbiochemical compounds from the pericarp (exocarp,mesocarp) and other tissues (Geromel et al., 2006; Avallone,1999).IJERTCoffee cherries are harvested when they becomebright-red, glossy, and firm, either by selective hand-pickingor non-selective stripping of whole branches or mechanicalharvesting. The hand-picking method is very timeconsuming, but it gives a superior product quality. Ripecherries will be available 9-11 months after flowering.ArabicaThe coffee fruit (also called berry or cherry) consistsof a smooth, tough outer skin or pericarp, usually green inunripe fruits, which turns to red-violet or deep red when ripe(Fig 2.1). The pericarp covers the soft yellowish, fibrous andsweet pulp or known as outer mesocarp. When the fruit isripe a thin hydrated slimy layer will be formed know asmucilage (also called pectin layer). Then there will be a thinendocarp, yellowish in color known as parchment.Underneath the parchment, the beans are covered in anotherthinner membrane, the silver skin (the seed coat). The silverskin covers the coffee seed or bean (Fig 2.2). Each cherrygenerally contains two coffee beans. If there is only one itassumes a rounder shape and it is known as pea-berry. (Belitzet al., 2009; Queiroz et al., 1998; Purseglove, 1974).Fig.2.1 Ripped and un-ripped CherryIJERTV3IS120482www.ijert.org( This work is licensed under a Creative Commons Attribution 4.0 International License.)785

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 3 Issue 12, December-2014(holding less than 10 acres), numbering 2,89,743 accountingfor 70 % of area under coffee and the rest cultivated in3,88,195 large holdings. Most of the coffee produced inIndia is exported and India has a share of 4.53% in the worldmarket. During 2012-13, world coffee production was 14,46, 11,000 bags (each bag contains 60 kg) and India’sproduction was 53, 03,000 bags where as India exported 2,98,063 tonnes of coffee. Indian coffee is exported to over 40countries but the top six markets are Russian federation, EUcountries like Italy, Germany, Belgium, Spain, Finland,Greece and USA accounting for 70% of Indian coffeeexports. The specialty coffee exports from India arecomprised of Malabar Monsoon Coffee, Mysore Nuggetsextra bold, Robusta Kapi Royale. Major ports of export areCochin, Chennai and Tuticorin. During recent years smallquantity of coffee from Indonesia and Vietnam are importedto India. Domestic consumption is mostly in the states ofTamilnadu and Karnataka.Fig.2.2 (a) Inner view of the CherryTable 2.3 - Top 10 countries in coffee production FAO(2012) reportS. NoIJERTFig.2.2 (b) Cherry with beans inside2.1 Coffee ProductionCoffee consumption takes place all the year around.However the production of coffee is seasonal. So long termstorage is necessary to maintain the better quality. About 60tropical and subtropical countries produce coffee extensively,being for some of them the main agricultural export product(Lashermes et al., 2008; Vieira, 2008). Most coffee beverageconsumed around the world is produced by the species Coffeaarabica (Arabica) and Coffea canephora (Robusta). Arabicais considered as the superior one due to its sensory propertiesand therefore it has a higher price in the international market(Gielissen et al., 2009). The top ten countries producingcoffee is shown in Table 2.3.India is the seventh largest producer of coffee in theworld. It produces both variety of coffee i.e. Arabica andRobusta. The bulk production taking place in the southernstates and most noted is Monsooned Malabar variety. Indiancoffee has created a niche for itself in the internationalmarket, particularly Indian Robusta which is highly preferredfor its good blending quality. Arabica coffee from India isalso well received in the international market.Coffee is one of the important plantation crops ofIndia cultivated in 4,15,341 hectares mainly in the southernstates of Karnataka (55.5%), Kerala (20.6%), Tamilnadu(7.6%) and to a small extent in other non-traditional and nonconventional areas such as Coastal tribal Andhra Pradesh andOrissa and North Eastern Region (14.9%). The production in2012-13 is estimated to be 3, 18,200 metric tonnes. Coffee inIndia is cultivated by a large number of small holdersIJERTV3IS120482Name of the 10Guatemala225,0002.2 Chemical Composition and Nutritional value of CoffeeGreen coffee beans are mainly composed, like mostplant tissues, by insoluble polysaccharides like cellulose andhemicellulose (50% w/w).They contain also solublecarbohydrates, such as the monosaccharaides fructose,glucose, galactose and arabinose, the oligosaccharidessucrose, raffinose and stachyose, and polymers of galactose,mannose, arabinose and glucose. Soluble carbohydrates actbinding aroma, stabilizing foam, sedimenting and increasingviscosity of the extract. In addition, non-volatile aliphaticacids (citric, malic and quinic acids) and volatile acids arealso present (such as acetic, propanoic, butanoic, isovaleric,hexanoic acids).Oils and waxes are also importantconstituents, accounting for 8 to 18% of the dry mass,together with proteins and free amino acids (9-12% w/w) andminerals (3-5% w/w). (Arya & Rao, 2007; Belitz et al., 2009;Clifford, 1985a; Gonzalez-Rios et al., 2007). Table 2.4 showsthe chemical composition of green Arabica and Robustabeans.www.ijert.org( This work is licensed under a Creative Commons Attribution 4.0 International License.)786

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 3 Issue 12, December-2014There are many compounds in coffee that are oftenthought to have implications upon human health. Theseinclude caffeine, micronutrients and chlorogenic acid. Thecoffee beverage is rich in biologically active substances suchas nicotinic acid, trigonelline, quinolinic acid, tanninc acid,pyrogolic acid and caffeine (Minamisawa et al., 2004).Sometimes coffee quality became low due to thehydrolysis of triacylglycerols (the major constituent of coffeelipid) releasing free fatty acids which are oxidized at the timeof storage. Multon et al (1973) reported that free amino acidsand sugars are degraded while lipids are oxidized andproduce off flavour at the end of the storage after drying.Table 2.4 - Chemical composition of green Arabica andRobusta coffee beans (g/100g)Arabica usta aces8 to 12traces8 to 12Fig 2.3. General scheme of coffee processing and preparation of greencoffee beans2.4.1 Dry cing sugarsother sugarsLipidsProteinsAmino acidsAliphatic acidsQuinic acidsChlorgenic acidsCaffeineTrigonellineMinerals (as oxideash)Volatile aromaWater.This is the simpler of the two methods and ispopular in Brazil to process Robusta coffee and in Sri Lankato process Arabica coffee. In case of dry processing coffeecherries are dried as such in the open yard until the moisturecontent reduce up-to 12% (wb). In this case one of the mostimportant processing is racking. The more number of rackinggives a uniform and better quality product2.3 Green Coffee ProcessingGreen coffee is produced either by dry processing orby wet processing. After harvesting, the coffee fruits areseparated from the pulp, which is carried out by dry or wetprocessing (Clarke & Macrae 1987; Illy & Viani 1995). Thedry process is simple and inexpensive. The whole cherriesare dried under the sun in open air, followed by the separationof the hull (dried pulp and parchment) for getting the greenbeans. On the contrary, the wet process requires more careand investment, but results in a superior coffee quality. In thewet process, the pulp of the coffee cherries, which is made upof exocarp and mesocarp, is removed mechanically, but theparchment remains attached to the beans. After drying eitherunder the sun or in a dryer, the parchment is removed toproduce the green coffee beans. Flow diagram for greencoffee processing is given in Fig 2.3.DryingThe coffee cherries are dried immediately afterharvest. This is usually sun drying on a clean dry floor or onmats. The bed depth should be less than 40mm and thecherries should be raked frequently to prevent fermentation ordiscoloration. However, there are problems associated withthis method. The most serious problem is dust and dirt blownonto the produce. Another problem is rainstorms often appear(even in the dry season) with very little warning, this cansoak the produce very quickly. Finally, labour has to beemployed to prevent damage or theft. Sun drying is thereforenot recommended.HullingThe dried cherry is then hulled to remove thepericarp. This can be done by hand using a pestle and mortaror in a mechanical huller. The mechanical hullers usuallyconsist of a steel screw, the pitch of which increases as itapproaches the outlet so removing the pericarp.CleaningThe hulled coffee is cleaned by winnowing.Defective beans are also removed. Sorting takes place bothin the producing and manufacturing countries to achieve highquality coffee beans, and is carried out by either mechanicalIJERTV3IS120482www.ijert.org( This work is licensed under a Creative Commons Attribution 4.0 International License.)787

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 3 Issue 12, December-2014or optical means. In the mechanical method, defective beansare hand-picked and fed into air classifiers (catadors) wherethey enter an adjustable rising current of air.2.4.2 Wet processingIn this method the cherry is squeezed in a pulpingmachine or pestle and mortar which removes the outer fleshymaterial (mesocarp and exocarp) leaving bean covered inmucilage. This mucilage is fermented and dispersed. Thebean is washed and dried.PulpingPulping involves the removal of the outer red skin(exocarp) and the white fleshy pulp (mesocarp) and theseparation of the pulp and beans. Immature cherries are hardand green and very difficult to pulp. If the coffee is to be wetprocessed, correct harvesting is essential. For small-scaleunits, the cherries can be pulped in a pestle and mortar, this isvery labour intensive. The two most common pulpers andmost suitable for small-scale units are the drum and the discpulpers.rather than slippery, the beans are ready. The beans shouldthen be washed immediately as 'off' flavours develop quickly.After fermentation, the coffee is known as'parchment coffee', since the seed retains its endocarp layer.It must be dried to about 10-12% (wb) moisture content toensure stability.DryingTo prevent cracking the coffee beans should be driedslowly to 10% moisture content (wet basis). Drying shouldtake place immediately after to prevent 'off' flavoursdeveloping. The same drying methods can be used for this asfor the dry processed coffee.HullingAfter drying the coffee should be rested for 8 hoursin a well-ventilated place. The thin parchment around thecoffee is removed either by hand, in a pestle and mortar or ina small huller.CleaningThe hulled coffee is cleaned by winnowing.Drum pulpersDisc pulpersThe same concept is involved with the disc pulper.The only difference is that rather than the cherries beingsqueezed between a breast plate and a drum, a disc with aroughened surface is used.Mucilage removalFermentation of the mucilage takes place in largetanks over 24 to 40 hours. However, the fermentationprocedure which results in the best quality, as well asallowing a reasonably convenient and rapid factory routine isthe two-stage 'dry' fermentation process (Wootton 1971).During the first stage the mucilage is degraded and during thesecond stage it is soaked in water for 24 to 48 hours.The amorphous gel of mucilage around the beanconsists of hemicelluloses, pectic substances and sugars andis insoluble in water. This can be removed by chemicalmethods, warm water or by an 'aqua pulper'. However, forsmall-scale units the only feasible method is fermentation.Fermentation involves the beans being placed in plasticbuckets or tanks and left until the mucilage has been brokendown. Natural enzymes in the mucilage and feasts; bacteriain the environment work together to break down themucilage. The coffee should be stirred occasionally and ahandful of beans should be tested by washing them in water.If the mucilage can be washed off and the beans feel grittyIJERTV3IS1204823.DRYING OF COFFEEDrying is one of the most important steps in the coffeeprocessing. The use of natural sun drying process of coffeein terraces is still very common among the coffee producershowever it requires high labour, it is a time requiringoperation and on dependency on the climatic conditions. Asthe coffee production increases the sun drying operation interraces happen to be problematic in terms of coffeeproduction operation and the mechanical drying becomes aneed due to the possibility of advancing the harvestingoperation, allowing to harvest better coffee in terms of qualityand quantity and make possible to destine usable areas forother activities.IJERTThis involves a rotating drum with a punched sheetsurface and adjustable breast plate between which the coffeecherries are pulped, the pulp and the beans separated. Thedistance between the drum and the breast plate has to beadjusted so that the pulp is removed without the beans beingdamaged. These can be manually operated or attached to atreadle or bicycle. For larger scale units, motorised drumpulpers are available.Drying is mainly concern for the degradation of themoisture content up to a certain limit12% (w.b). Dryingdiminishes the respiration rate of the product and increasesthe storage time with the minimum possible loss. If the beansare over dried it will be brittle in nature and if moisturecontent is more than safe storage moisture then there is aprobability of mould growth in the beans for furtherprocessing. Technical data of the post-harvest processing ofcoffee in both dry process and wet process is given in Table3.1.Conventionally there are 2 types of dryingtechniques used in the coffee processing that is sun dryingand mechanical drying. The initial moisture content of thecoffee is about 55-60% and after drying the final moisturecontent should be around 12% (wb) and the drying should beeven and homogenised to obtain the proper colour, size andto get rid of pests for the longer storage time. Generallycoffee beans can be stored almost for 8 months but the pestproblem and increase in moisture content during storageperiod are the problem.www.ijert.org( This work is licensed under a Creative Commons Attribution 4.0 International License.)788

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 3 Issue 12, December-2014Table: 3.1 Technical data of post-harvest processing (CIRAD CP)DRY PROCESSINGWET PROCESSINGPRODUCTS(at each stageMoistureof processing)content (%wb)ARABICAWeightBulk(in kg)density(kg/m2)ROBUSTAWeightBulk(in kg)density(kg/m2)PRODUCTS(in each stageMoistureof processing)content (%wb)ARABICAWeightBulk(in kg)density(kg/m2)Fresh 6846665DrycoffeecherryGreen resh cherryPulped cherryWet parchmentcoffeeDry parchmentcoffeeGreen Coffee1219.00250According to Muhidong et al. (2013) drying ofcoffee bean was performed under different air velocity (0.5,1.2, and 1.8 m/s) with a temperature of 47 0C. Among thevarious thin layer drying models Hii et al. model (2008) gavethe best fit with a R2 up to 0.99. It was also observed thatincreasing air velocity from 0.5 m/s to 1.8 m/s failed toimprove the drying rate considerably.IJERTThe study of the drying system, its design,optimization, its feasibility for an application for commercialuse could be obtained through the mathematical simulations.For simulation, which is based on principle of successive thinlayer drying, it is used a mathematical model that representssatisfactory the water loss during the drying process (Berbertet al., 1995); although the coffee thin layer drying curvesvary with the species, variety, environmental conditions andpost-harvest processing methods among others.It has been pointed out that beverages from coffeedrying processed by different methods have significantdifference (Selmar et al., 2006; Leloup et al., 2008). Coffeeproduced by the wet method has less body and higher acidity;it is also more aromatic than coffee produced by the drymethod, resulting in a higher acceptance by consumers. It iscurrently accepted that the metabolic reactions in the coffeefruits that occur during different types of processing canaffect the chemical composition of beans and thereby affectbeverage quality (Bytofet et al., 2005, 2007).Studies focusing on the coffee behaviour during thedrying process have been reported by several researchers.Corrêa et al. (2006) studied the drying characteristics andkinetics of coffee berry under the drying temperatures of 40 ,50 and 60 C. Corrêa et al. (2010) also observed themoisture sorption isotherms and isosteric heat of sorption ofcoffee in different processing levels. Coradi et al. (2007)tried to determine the effect of drying and storage conditionson the quality of natural and washed coffee. This researchemphasized the importance of the adequate storage besidesthe correct drying process to preserve coffee’s qualities.Ciro-Velásquez et al. (2010) conducted a numericalsimulation of thin-layer coffee drying by control volumes.Similar to Corrêa et al. (2006), this simulation also useddrying air temperatures of 40 , 50 and 60 C.In a study assessing intermittent drying ofparchment coffee, Martin et al. (2009) combined 12 hours ofdrying with 50º C heated air and 12 hours of rest andobserved a 24.56% reduction in effective drying time relativeto continuous drying.While drying of parchment coffee, Isquierdo et al.(2011), observed that interrupting the drying process whenthe moisture content was 24% (wet basis, w.b) with a restperiod of 2 to 12 days and later drying to 11% (w.b) resultedin lower values of potassium leaching and electricalconductivity and, consequently, greater integrity of thecellular membrane system of the beans compared to coffeesubjected to continuous drying to 11% (w.b).Afonso et al. (2003) studied the shrinkageevaluation of different coffee berries during the time ofdrying process. They concluded that moisture content in thecoffee berries affects its physical properties causingsignificant decrease in the superficial area, volume anddiameter during the drying process. Different variety ofcoffee has different shrinkage behaviour. The shrinkagebehaviour during the drying process was well explained by apolynomial model with a coefficient of determination greaterthan 90%.3.1 Sun drying or Natural DryingFresh coffee cherry assuming with a 4 to 6 cm layer2(25-30kg/m ) in the sun requires energy up-to the extent ofIJERTV3IS120482www.ijert.org( This work is licensed under a Creative Commons Attribution 4.0 International License.)789

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 3 Issue 12, December-2014about 17000 kJ/kg according to FAO research. Removal offruit tissues in the pulping step of wet-processing reduces thisenergy requirement by mechanically removing water and byremoving tissues that inhibit water loss. However, thedecision as to which processing system to apply is muchmore complex than mere consideration of drying efficiency.It depends from place to place. Previously it was consideredthat sun dried green coffee are the best in quality but now adays increase in the production and as a seasonal crop it isvery difficult to go for only sun drying method. Researchesalso proved that mechanically dried and the sun dried coffeeboth gives to some extent same quality. There are differenttypes of sun drying method (Fig 3.1).Drying ground is another mode of natural drying.Here the yard is usually made of concrete, tiles or asphaltwith a small slope (0.5-1%) to drain water. Depending onclimatic conditions, sun drying of coffee in patios takes from7 to15 days for parchment and from 12 to 21 days forcherries. Parchment requires more careful handling thancherry to avoid cracking and physical damage to the beans.Raking must be gentler. In tropical areas parchment is oftencovered during the hottest hours of the day to avoid crackingcaused by overheating.Rolz et al. (1969) reported on the use of fluidizedbeds in the drying of coffee cherries. They found that the bestquality coffee was obtained when drying was done in twostages, an initial period at a low temperature (20 C) followedby a longer one at a higher temperature (60 C).Some new technologies and dryers were inventedfor the better quality and uniform drying.S.S.SCoordinadora de Cafeticultores Yaxalwitz is an indigeneouscorporative society of small coffee growers. They developeda solar coffee dryer with low cost and easy to handle dryer inthe northern rainforest region of Mexico. It is very useful forthe rainforest communities where money and material arehard to obtain.Finzer et al (2001) conducted a study in Brazil withcoffee berries. They developed a vibratory bed dryer for thedrying of the berries and calculated the dispersion coefficientranged from 2.32 x 10-4 to 76.81 x 10-4 m2/s. The averagePeelet number was equal to 6.5.Reinato et al (2011) reported that quality of coffee,physico-chemical properties depends on the different types ofgrounds (earth, concrete and asphalt by products) used andthe thickness of layers. Washed parchment coffee dried inthin layer on concrete and asphalt surfaces gave the bestbeverage quality.Cunha M et al (2003) summarized that whencompared to conventional drying processes the developmentprocess of microwaves to pulped coffee cherries production,to reduce the drying time and to increase the industrial yieldand product quality was better. Two drying cycles weretested a) hot air drying conventional batch process using arotary dryer from 45-50 to 11-13% (wb) moisture product b)a two stage process, whereby the product was pre dried withhot air from 45-50 to 30% (wb), followed by the finalmicrowave and hot air drying stage, to reduce productmoisture from 30 to 11-13% (wb). The overall drying timewas reduced from 15 to 37.5 hours to about 10 hours,respectively. The sensory quality of the product wasevaluated by the "cup test", complemented by scanningelectronic microscope analyses (EMS) and showedsatisfactory results. A preliminary study of the economicaspects involved in up-grading an industrial scale coffeeprocessing line.IJERTDrying racks are used which makes the coffee clearand avoid contamination from the ground. Racks are alsomore exposed to wi

Coffee is one of the important plantation crops of India cultivated in 4,15,341 hectares mainly in the southern states of Karnataka (55.5%), Kerala (20.6%), Tamilnadu (7.6%) and to a small extent in other non-traditional and non-conventional areas such as Coastal tribal Andhra