Transcription

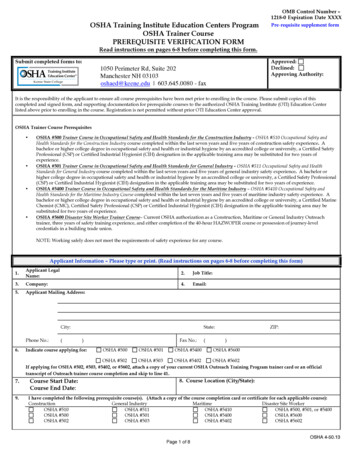

OSHA 3220-10N 2004

WORKER SAFETY SERIESWAREHOUSINGThink SafetyHazards & Solutions More than 145,000 people work in over 7,000warehouses. The fatal injury rate for the warehousingindustry is higher than the national averagefor all industries. Potential hazards for workers in warehousing: Unsafe use of forklifts; Improper stacking of products; Failure to use proper personal protectiveequipment; Failure to follow proper lockout/tagoutprocedures; Inadequate fire safety provisions; or Repetitive motion injuries.Warehouse operations can present awide variety of potential hazards forthe worker.For warehousing establishments, the10 OSHA standards most frequentlyincluded in the agency’s citationswere:1 . Forklifts2. Hazard communication3. Electrical, wiring methods4. Electrical, system design5. Guarding floor & wall openingsand holes6. Exits7 . Mechanical power transmission8. Respiratory protection9. Lockout/tagout10. Portable fire extinguishersOccupational Safety andHealth AdministrationU.S. Department of Laborwww.osha.govOccupational Safety andHealth Administration11

2WORKER SAFETY SERIESWAREHOUSINGDocksForkliftsHazard: Injuries happen here when forkliftsrun off the dock, products fall on employeesor equipment strikes a person.Solutions: Drive forklifts slowly on docks and dockplates; Secure dock plates and check to see if theplate can safely support the load; Keep clear of dock edges and never backup forklifts to the dock’s edge; Provide visual warnings near dock edges; Prohibit “dock jumping” by employees; Make sure that dock ladders and stairs meetOSHA specifications.Hazard: About 100 employees are killed and95,000 injured every year while operatingforklifts in all industries. Forklift turnoversaccount for a significant percentage of thesefatalities.Solutions: Train, evaluate and certify all operators toensure that they can operate forklifts safely; Do not allow anyone under 18 years old tooperate a forklift; Properly maintain haulage equipment,including tires; Before using a forklift, examine it for hazardous conditions which would make itunsafe to operate; Follow safe procedures for picking up,putting down and stacking loads; Drive safely, never exceeding 5 mph andslow down in congested areas or those withslippery surfaces;Occupational Safety andHealth AdministrationOccupational Safety andHealth Administration3

4WORKER SAFETY SERIESWAREHOUSINGConveyors Ensure that the operator wears a seatbeltinstalled by the manufacturer; Never drive up to a person standing in frontof a fixed object such as a wall or stackedmaterials; Prohibit stunt driving and horseplay; Do not handle loads that are heavier thanthe weight capacity of the forklift; Remove unsafe or defective trucks fromservice until the defect is properly repaired; Maintain sufficiently safe clearances foraisles and at loading docks or passageswhere forklifts are used; Ensure adequate ventilation either byopened doors/windows or using a ventilation system to provide enough fresh air tokeep concentrations of noxious gases fromengine exhaust below acceptable limits;Hazard: Workers can be injured when theyare caught in pinch points or in the in-goingnip points, are hit by falling products ordevelop musculoskeletal disorders associatedwith awkward postures or repetitive motions.Solutions: Inspect conveyors regularly; Ensure that pinch points are adequatelyguarded; Develop ways of locking out conveyors andtrain employees in these procedures; Provide proper lighting and working surfaces in the area surrounding the conveyor. Provide covers and/or guardrails to protectworkers from the hazards of open pits,tanks, vats and ditches; Train employees on the hazards associatedwith the combustion byproducts of forkliftoperation, such as carbon monoxide.Materials StorageHazard: Improperly stored materials may falland injure workers.Solutions: Stack loads evenly and straight; Place heavier loads on lower or middleshelves; Remove one object at a time from shelves; Keep aisles and passageways clear and ingood repair.Occupational Safety andHealth AdministrationOccupational Safety andHealth Administration5

6WORKER SAFETY SERIESWAREHOUSINGManual Lifting/HandlingHazard CommunicationHazard: Back injuries may occur fromimproper lifting or overexertion.Hazard: Chemical burns are possible if spillsof hazardous materials occur.Solutions:Solutions: Provide general ergonomics training andtask-specific training; Maintain a Material Safety Data Sheet(MSDS) for each chemical to which workersare exposed in the facility; Minimize the need for lifting by using gooddesign and engineering techniques; Lift properly and get a coworker to help ifa product is too heavy. Follow instructions on the MSDS for handling chemical products; Train employees on the risks of eachchemical being stored; Provide spill cleanup kits in any area wherechemicals are stored; Have a written spill control plan; Train employees to clean up spills, protectthemselves and properly dispose of usedmaterials; Provide proper personal protectiveequipment and enforce its use; Store all chemicals safely and securely; Store chemicals away from forklift trafficareas.Occupational Safety andHealth AdministrationOccupational Safety andHealth Administration7

8WORKER SAFETY SERIESWAREHOUSINGCharging StationsPoor ErgonomicsHazard: Fires and explosion risks are possibleunless proper guidelines are followed.Hazard: Improper lifting, repetitive motion orpoor design of operations can lead to musculoskeletal disorders in workers.Solutions: Prohibit smoking and open flames in andaround charging stations; Provide adequate ventilation to dispersefumes from gassing batteries; Ensure that fire extinguishers are availableand fully charged; Provide proper personal protectiveequipment such as rubber gloves and eyeand face protection; Properly position forklifts and apply brakesbefore attempting to change or chargebatteries; follow required procedures whenrefueling gas or propane fueled forklifts; Provide conveyors, overhead hoists orequivalent materials handling equipmentfor servicing batteries; Provide an eyewashing and safety showerfacility for employees exposed to batteryacids.Solutions: If possible, use powered equipment insteadof requiring a manual lift for heavy materials; Reduce lifts from shoulder height and fromfloor height by repositioning the shelf or bin; Ensure overhead lighting is adequate forthe task at hand; Provide employees with task-orientedergonomic training; Use your legs and keep your back in a natural position while lifting; Test the load to be lifted to estimate itsweight, size and bulk, and to determine theproper lifting method; Get help if the load exceeds the maximumweight a person can lift safely withoutassistance; Don’t twist while carrying a load, but shiftyour feet and take small steps in the direction you want to turn; Keep floors clean and free of slip and triphazards.Occupational Safety andHealth AdministrationOccupational Safety andHealth Administration9

10WORKER SAFETY SERIESWAREHOUSINGOther HazardsThink Safety ChecklistsInadequate fire safety provisions, improperuse of lockout procedures and failure to wearpersonal protective equipment also createhazards in the warehouse workplace.Employers should have an emergency planthat describes what is expected of employeesin the event of an emergency, including:The following checklists may helpyou take steps to avoid hazards thatcause injuries, illnesses and fatalities.As always, be cautious and seek helpif you are concerned about a potential hazard. Provisions for emergency exit locations andevacuation procedures;General Safety Procedures for accounting for all employeesand visitors; Location and use of fire extinguishers andother emergency equipment.Warehouse operations need a lockout/tagoutprogram to prevent equipment from beingaccidentally energized and injuring employees.Employees required to perform these operations should be trained and all employeesshould have a working knowledge of theprogram.Finally, management at warehouse operationsneeds to conduct a site hazard assessment todetermine what personal protective equipment(PPE) must be worn based on the hazardspresent and train warehouse employees onproper PPE selection, use and maintenance.11or open loading dock doors and Exposedother areas that employees could fall 4feet or more or walk off should be chainedoff, roped off or otherwise blocked.and aisles are clear of clutter, Floorselectrical cords, hoses, spills and otherhazards that could cause employees toslip, trip or fall.work practices are factored into Properdetermining the time requirements for anemployee to perform a task.performing physical work Employeeshave adequate periodic rest breaksto avoid fatigue levels that could result ingreater risk of accidents and reducedquality of work.employees receive general Newly-hiredergonomics training and task-specifictraining. The warehouse is well ventilated.are instructed on how to avoid Employeesheat stress in hot, humid environments.are instructed on how to work Employeesin cold environments. The facility has lockout/tagout procedures.Occupational Safety andHealth AdministrationOccupational Safety andHealth Administration

12WORKER SAFETY SERIESWAREHOUSINGMaterials Handling SafetyHazard Communication Safetyare appropriately marked and Theresufficiently safe clearances for aisles andat loading docks or passageways wheremechanical handling equipment is used.materials which might fall Loose/unboxedfrom a pile are properly stacked by blocking, interlocking or limiting the height ofthe pile to prevent falling hazards.containers, bundles, etc. are stored Bags,in tiers that are stacked, blocked, interlocked and limited in height so that theyare stable and secure to prevent slidingor collapse.areas are kept free from accumu Storagelation of materials that could lead to tripping, fire, explosion or pest infestations.vegetation is removed from Excessivebuilding entrances, work or traffic areasto prevent possible trip or fall hazardsdue to visual obstructions.and/or bumper blocks are provided Derailon spur railroad tracks where a rolling carcould contact other cars being worked onand at entrances to buildings, work ortraffic areas. Covers and/or guardrails are provided toprotect personnel from the hazards ofstair openings in floors, meter or equipment pits and similar hazards. Personnel use proper lifting techniques.and hoists for lifting materials/ Elevatorscontainers are properly used with adequate safe clearances, no obstructions,appropriate signals and directional warning signs.Occupational Safety andHealth Administration13hazardous materials containers Allare properly labeled, indicating thechemical’s identity, the manufacturer’sname and address, and appropriatehazard warnings.is an updated list of hazardous Therechemicals.facility has a written program that Thecovers hazard determination, includingMaterial Safety Data Sheets (MSDSs),labeling and training.is a system to check that each Thereincoming chemical is accompanied bya MSDS.employees are trained in the require Allments of the hazard communicationstandard, the chemical hazards to whichthey are exposed, how to read andunderstand a MSDS and chemical labels,and on what precautions to take toprevent exposure. All employee training is documented.outside contractors are given a com Allplete list of chemical products, hazardsand precautions.have been established to Proceduresmaintain and evaluate the effectivenessof the current program.use proper personal protective Employeesequipment when handling chemicals.chemicals are stored according to the Allmanufacturer’s recommendations andlocal or national fire codes.Occupational Safety andHealth Administration

14WORKER SAFETY SERIESForklift Safetyindustrial trucks (forklifts) meet Poweredthe design and construction requirementsestablished in American NationalStandard for Powered Industrial Trucks,Part II ANSI B56.1-1969.approval from the truck Writtenmanufacturer has been obtained for anymodifications or additions that affectthe capacity and safe operation of thevehicle.operation and maintenance Capacity,instruction plates, tags or decals arechanged to specify any modifications oradditions to the vehicle.and markings are in place Nameplatesand maintained in a legible condition.that are used in hazardous loca Forkliftstions are appropriately marked/approvedfor such use. facilities are provided Appropriatefor flushing and neutralizing spilledBattery charging is conducted only indesignated areas.electrolytes, for fire extinguishing, forprotecting charging apparatus fromdamage by trucks and for adequateventilation to disperse fumes fromgassing batteries. Conveyors, overhead hoists or equivalentmaterials handling equipment are providedfor handling batteries.batteries are properly Reinstalledpositioned and secured.tilters or siphons are used for Carboyhandling electrolytes.Occupational Safety andHealth AdministrationWAREHOUSINGare properly positioned and Forkliftsbrakes applied before workers start tochange or charge batteries. Vent caps are properly functioning.are taken to prevent smoking, Precautionsopen flames, sparks or electric arcs inbattery charging areas and during storage/changing of propane fuel tanks.and other metallic objects are kept Toolsaway from the top of uncovered batteries.of noxious gases and Concentrationsfumes are kept below acceptable levels.operators are competent to oper Forkliftate a vehicle safely as demonstrated bysuccessful completion of training andevaluation conducted and certified bypersons with the knowledge, training andexperience to train operators and evaluate their performance.training program content includes Theall truck-related topics, workplace-relatedtopics and the requirements of 29 CFR1910.178 for safe truck operation.training and evaluation is Refresherconducted whenever an operator hasbeen observed operating the vehicle inan unsafe manner or has been involvedin an accident or a near-miss incident.training and evaluation is Refresherconducted whenever an operator isassigned to drive a different type of truckor whenever a condition in the workplacechanges in a manner that could affectsafe operation of the truck.of each operator’s perfor Evaluationsmance are conducted at least once everythree years.Occupational Safety andHealth Administration15

16WORKER SAFETY SERIESengaging means are fully lowered, Loadwith controls neutralized, power shutoff and brakes set when a forklift is leftunattended. Operators maintain a safe distance fromthe edge of ramps or platforms whileusing forklifts on any elevated dock,platform or freight car.There is sufficient headroom for the forklift and operator under overhead installations, lights, pipes, sprinkler systems, etc.guards are provided in good Overheadcondition to protect forklift operatorsfrom falling objects.observe all traffic regulations, Operatorsincluding authorized plant speed limits.are required to look in the direc Driverstion of and keep a clear view of the pathof travel.run their trucks at a speed that Operatorswill permit the vehicle to stop in a safemanner.boards (bridge plates) are properly Docksecured when loading or unloading fromdock to truck. Stunt driving and horseplay are prohibited.loads are stable, safely arranged and Allfit within the rated capacity of the truck.fill fuel tanks only when the Operatorsengine is not running.parts of trucks are equivalent Replacementin terms of safety with those used in theoriginal design.are examined for safety before Trucksbeing placed into service and unsafeWAREHOUSINGWarehouse Safety &Health ResourcesMost resource materials can be foundon the OSHA website: www.osha.govMaterials HandlingMaterials Handling and StorageOSHA Publication 2236 (Revised 2002).559KB PDF, 40 pages.A comprehensive guide to hazards and safework practices in handling 6.pdfElectrical HazardsControl of Hazardous Energy (Lockout/Tagout)OSHA Publication 3120 (Revised 2002).174 KB PDF, 45 pages.This booklet presents OSHA’s general requirements for controlling hazardous energy duringservice or maintenance of machines or 0.pdfControlling Electrical HazardsOSHA Publication 3075 (Revised 2002).349KB PDF, 71 pages.This publication provides an overview of basicelectrical safety on the afety and Health Topics: Lockout/TagoutOSHA website index to information aboutlockout/tagout, including hazard recognition,compliance, standards and directives, ReviewCommission and Administrative Law JudgeDecisions, standard interpretations andCompliance Letters, compliance assistanceand energy/index.htmlor defective trucks are removed fromservice.Occupational Safety andHealth AdministrationOccupational Safety andHealth Administration17

18WORKER SAFETY SERIESEvacuation Plans and ProceduresAn eTool designed to help small, low-hazardservice or retail businesses implement an emergency action plan and comply with OSHA'semergency on/index.htmlFire SafetySafety and Health Topics: Fire SafetyOSHA website index to information on fire tmlFire Safety AdvisorOSHA's Fire Safety Advisor is an interactiveexpert software. It will help explain and applyOSHA's Fire Safety-related standards. It canbe used online or is available for tfirex.htmlForklift SafetySafety and Health Topics: PoweredIndustrial TrucksOSHA website index links to specific requirements and other Federal agency trialtrucks/index.htmlSample Daily Checklists for Powered Industrial pit/daily pit checklist.htmlPreventing Injuries and Deaths of WorkersWho Work Near ForkliftsNIOSH Alert Pub. No. 2001-109 (June 2001).This alert instructs workers in the steps they cantake to protect themselves near forklifts. It is alsoavailable as a downloadable PDF upational Safety andHealth AdministrationWAREHOUSINGProtecting Young Workers: ProhibitionAgainst Young Workers Operating ForkliftsOSHA Safety and Health Bulletin (2003), 4pages. Available as a PDF document, 109 ard CommunicationOSHA’s website index for resources on dcommunications/index.htmlMore Hazard CommunicationFrequently Asked Questions for HazardCommunication. OSHA, 6 rd Communication Standard.OSHA Fact Sheet (1993), 3 ocument?p table FACT SHEETS&p id 151Hazard Communication Guidelines forCompliance. OSHA Publication 3111 (2000), 112KB PDF, 33 pages.This document aids employers in understandingthe Hazard Communication standard and inimplementing a hazard communication pdfChemical Hazard Communication. OSHAPublication 3084 (1998), 248 KB PDF, 31 pages.This booklet answers several basic questionsabout chemical hazard a3084.pdfNIOSH Pocket Guide to Chemical Hazards.Handy source of general industrial hygieneinformation on several hundred chemicals/classes for workers, employers and occupational health lOccupational Safety andHealth Administration19

20WORKER SAFETY SERIESWAREHOUSINGErgonomicsWarehouse IndustrySafety and Health Topics: ErgonomicsOSHA website index to resources and publications on ex.htmlCooperative ProgramsGrocery Warehousing – ErgonomicsAn e-tool specific for warehousing operations inthe grocery rehousing/index.htmlPersonal Protective EquipmentSafety and Health Topics:Personal Protective EquipmentOSHA’s website index to hazard recognition,control and training related to personal protective iveequipment/index.htmlPersonal Protective Equipment. OSHAPublication 3151 (2004), 695KB PDF, 44 pages.Discusses equipment most commonly used forprotection for the head, including eyes and face,and the torso, arms, hands and feet. The use ofequipment to protect against life-threateninghazards is also 1/osha3151.htmlVoluntary Protection ProgramsNumerous VPP worksites that OSHArecognizes for their excellent safety and healthmanagement systems deal with the hazardsof warehousing and storage. These modelworksites are willing to share their expertiseand many are available to mentor otherbusinesses. For further information on howVPP participants can help you, contact the VPPManager in your OSHA Regional Office or theVoluntary Protection Programs Participants’Association, 7600-E Leesburg Pike, Suite 440,Falls Church, VA 22043, telephone (703) 7611146.Alliance ProgramAlliances enable organizations committed toworkplace safety and health to collaboratewith OSHA to prevent injuries and illnesses inthe workplace. A number of Alliances havean impact on the warehousing industry,including the following:Retail Industry Leaders AssociationThe OSHA Alliance with the Retail IndustryLeaders Association (RILA) is focused onOccupational Safety andHealth AdministrationOccupational Safety andHealth Administration21

22WORKER SAFETY SERIESWAREHOUSINGsharing safety and health best practices andtechnical knowledge, including ergonomics inretail warehousing and distribution facilities.NJ WarehouseOperation A Success StoryIndustrial Truck AssociationThe Industrial Truck Association (ITA) andOSHA also have an Alliance to promote thesafe operation of powered industrial trucksthrough training and outreach. The goal of theAlliance is to assist employers and employeesin reducing and preventing exposure topotential hazards associated with the use ofpowered industrial trucks in general, and inwarehouses in particular.International Warehouse Logistics AssociationOSHA and the International WarehouseLogistics Association (IWLA) work togetherto protect employees’ safety and health,including hard-to-reach youth workers. TheAlliance addresses materials handling, forkliftsafety, hazard communication and otherissues unique to the public warehouse industry.National Lumber and Building MaterialDealers AssociationOSHA has an Alliance with the NationalLumber and Building Material DealersAssociation (NLBMDA) to increase overallsafety awareness in that industry whilespecifically addressing recordkeeping issues,preventing forklift accidents and avoidinglifting strains.Occupational Safety andHealth AdministrationOSHA recommendations result inimmediate, high payoff for an EastCoast warehouse operation.Injury ReductionRecently, a New Jersey warehouse operationhad been averaging two back injuries amonth. After adopting several OSHArecommendations for reducing ergonomicrisk factors specific to their operations, thecompany reported zero back injuries.Boosting Morale & ProductivityAnd there was another benefit from adoptingOSHA’s recommendations. According to theMarlton, NJ OSHA area office, companysources reported that both the morale andproductivity of the company’s 50 warehouseemployees had subsequently increased.Ongoing HelpAs part of OSHA’s ongoing efforts to do abetter job in promoting workers’ safety andhealth, the agency has developed a programto help identify certain industries that haveexceptionally high injury rates. One of theseindustries is warehousing. By identifyingthese workplaces, OSHA is better able toassist businesses in reducing their high injuryrates. Through the Site Specific TargetingPlan, OSHA performs a comprehensiveevaluation of a workplace and, with the helpof its technical experts, helps the employerdevelop a plan for improving its employees’safety and health.Occupational Safety andHealth Administration23

24WORKER SAFETY SERIESWAREHOUSINGSpecific RecommendationsFeasible ControlsOSHA’s recommendations were developedspecifically for this New Jersey warehouseoperation by OSHA’s Salt Lake City TechnicalSupport Center following an inspection of the186,000 square foot facility under theagency’s Site Specific Targeting Plan whichincluded a comprehensive walkaround of theworkplace and a review of its injury records.In OSHA’s detailed evaluation, each hazardwas carefully described, including photographs illustrating the task to help clearlyshow the hazard. For each hazard, OSHAspecialists detailed several feasible controls.These were straightforward, easy-to-implement actions such as:Avoiding MSDs Providing stools or ladders to employees;OSHA compliance officers worked withexperts at the Salt Lake City Center to tailorspecific recommendations to address thepotential ergonomic risk factors theyobserved. Specialists at Salt Lake Cityanalyzed the warehouse’s various operationsand recommended 19 steps, known as“feasible controls,” that the employer couldtake to help employees to avoid musculosketal disorders (MSDs).Hazards IdentifiedSome of the hazards identified by OSHAincluded: Employees had to reach elevated anddistant locations in storage shelves toaccess materials; Adjusting the height of shelves; Reducing the depth of shelving; Raising loading heights; Evaluating the flow and volume of ordersso faster-moving products are placed oneasier-to-reach shelves.Also, OSHA’s evaluation report detailed a listof available resources, including on-siteconsultation visits, that the company coulduse in developing improved ways to preventinjuries.The company adopted 13 of the 19 feasiblecontrols that OSHA recommended. And theresult, thus far, speaks for itself: a perfect zerofor back injuries, improved productivity andhigher employee morale. Workers had to repeatedly bend to reachlow-level locations at floor level to accessmaterials; Employees were lifting and placing heavyboxes onto pallets placed on the floor; Employees were performing forceful fingertasks with their wrists in bent postureswhile pricing products at poorly designedworkstations.Occupational Safety andHealth AdministrationOccupational Safety andHealth Administration25

Occupational Safety andHealth AdministrationU.S. Department of Laborwww.osha.govOSHA’s role is to assure the safety and health ofAmerica’s workers by setting and enforcing standards; providing training, outreach and education;establishing partnerships; and encouraging continual improvement in workplace safety andhealth.This informational booklet provides a generaloverview of a particular topic related to OSHAstandards. It does not alter or determine compliance responsibilities in OSHA standards or theOccupational Safety and Health Act of 1970.Because interpretations and enforcement policymay change over time, you should consult currentOSHA administrative interpretations and decisionsby the Occupational Safety and Health ReviewCommission and the Courts for additional guidance on OSHA compliance requirements.This publication is in the public domain and maybe reproduced, fully or partially, without permission. Source credit is requested but not required.This information is available to sensory impairedindividuals upon request. Voice phone: (202) 6931999; teletypewriter (TTY) number: (877) 889-5627.

Occupational Safety and Health Administration Occupational Safety and Health Administration