Transcription

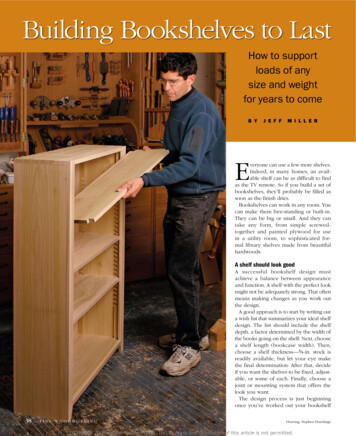

Building Bookshelves to LastHow to supportloads of anysize and weightfor years to comeB YJ E F FM I L L E REveryone can use a few more shelves.Indeed, in many homes, an available shelf can be as difficult to findas the TV remote. So if you build a set ofbookshelves, they’ll probably be filled assoon as the finish dries.Bookshelves can work in any room. Youcan make them free-standing or built-in.They can be big or small. And they cantake any form, from simple screwedtogether and painted plywood for usein a utility room, to sophisticated formal library shelves made from beautifulhardwoods.A shelf should look goodA successful bookshelf design mustachieve a balance between appearanceand function. A shelf with the perfect lookmight not be adequately strong. That oftenmeans making changes as you work outthe design.A good approach is to start by writing outa wish list that summarizes your ideal shelfdesign. The list should include the shelfdepth, a factor determined by the width ofthe books going on the shelf. Next, choosea shelf length (bookcase width). Then,choose a shelf thickness—3 4-in. stock isreadily available, but let your eye makethe final determination. After that, decideif you want the shelves to be fixed, adjustable, or some of each. Finally, choose ajoint or mounting system that offers thelook you want.The design process is just beginningonce you’ve worked out your bookshelf38FINE WOODWORKINGDrawing: Stephen HutchingsCOPYRIGHT 2006 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.

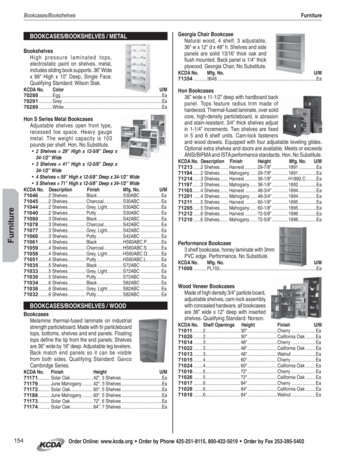

design “brief.” Now you must determineif your initial choices will be strongenough. If not, you’ll have to make somedesign changes. But before we get to that,it helps to understand how a shelf reactsto load.Sag is the main enemyAs the load on a shelf increases, the weighteventually reaches a point where the shelfbends, or sags. The same factors that affect appearance also affect shelf sag: thethickness, width, and length of the shelf;the wood species used; and the methodused to mount the shelf.As a general rule, our eyes won’t noticesag if it’s less than 1 32 in. (0.031 in.) perfoot. With time, even if the contents don’tchange, a shelf’s initial sag could increaseby 50% or more as the wood fibers “tire.”Wood engineers call this “creep.” To be onthe safe side, design shelves to limit anyinitial sag to no more than 0.02 in. per footunder a load of full-size books.In extreme cases (loading a bookcasewith your anvil collection, for example),shelves can deflect so much that the woodactually fails. This is not a common worry.More common, especially on long shelves,is that sag causes the effective length of theshelf to become shorter, causing it to slipoff the shelf supports. Or, too much weighton a long shelf can cause some adjustableshelf supports to crush the wood fibers inthe case sides. As a result, the supports tiltdownward.Design shelves for maximum loadYou don’t need to guess at how much a shelfis going to sag. The chart below provides aquick way to determine if your shelf will besag-free. If the chart doesn’t work for yourshelf, you can use the Sagulator, an onlineThe eye can detectprogram that makes it easy to determine sag.shelf sag as slight as1 32 in. per foot.Both the chart and the Sagulator assume unfixed shelf ends. Fixed ends sag less.The chart is easy to use. It provides themaximum shelf-weight limits (in pounds perfoot) and works for most designs. You need toA severely saggingknow the thickness of the shelf (¾ in. or 1 in.)shelf may slip offand its length (24 in., 30 in., 36 in., or 42 in.).supports.If the expected load exceeds theweight limit shown in thechart, you’ll have tomake compromises.To do that, usethe Sagulator(www.finewoodworking.com/sagulator).An answer of more than 0.02 in. per foot of shelfmeans you need to put less load on the shelf; use astronger wood; make the shelf thicker, wider, or shortMaterialer; or add wide edging. With the Sagulator, you canmakes a difference.Some shelf materials resistadjust those values and calculate a new sag number.SHELF WEIGHT LIMITSFixed or adjustableThe method used to mount a shelf affectshow much it will bend under a load. All elseequal, a fixed shelf will bend less than anadjustable shelf. That’s because on a wellsecured fixed shelf, the ends resist bothtilting and being pulled inward by the sag(see pp. 40-43 for fixed- and adjustableshelf options).Be aware that fixed shelves aren’t immune to failure. With enough weight (perhaps adding your spouse’s anvil collectionto your own on the same shelf) and itsconsequential sag, even fixed shelves canfail at the ends. When that happens, theshelf curves and effectively shortens, theends pull free, and everything can headsouth in a hurry.Jeff Miller builds furniture and teacheswoodworking in Chicago.sag better than others. Redoak is one of the better ones,eastern white pine less so.MDF makes a weaker shelf.Approximate shelf loads:Hardcover books (9 in. by 11 in.), 20 lb. per ft.Magazines (9 in. by 11 in.), 42 lb. per ft.(pounds per foot*)TYPESpeciesRED OAKPOPLAREASTERNWHITE PINEFIRPLYWOODMDFLENGTHThickness24 in.30 in.36 in.42 in.¾ in.4921951 in.116472312¾ in. with 2-in. edging112472112¾ in.4217841 in.101412010¾ in. with 2-in. edging97392010¾ in.3314631 in.7432158¾ in. with 2-in. edging7632148¾ in.321363¾ in. with 2-in. edging**9639189¾ in.9421¾ in. with 2-in. edging**7330147*Based on 11-in.-wide shelves **Edging is red oak; other edgings are the same wood as the shelf.www.finewoodworking.comMARCH/APRIL 2007COPYRIGHT 2006 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.39

Fixed shelves sag lessand strengthen the caseFixed shelves attach to the sides of a case with either wood joinery,hardware, or a combination of both. Unlike adjustable shelves, fixed shelveshelp strengthen the entire case. And because they are attached to the casesides, fixed shelves sag less.DADOStrength: GoodAppearance: Good (excellent if using astopped dado or if covered by a face frame)A dado joint effectively houses the ends ofthe shelf in a long notch, providing somemechanical strength. Because a dado jointproduces mostly end-grain surfaces, addingglue increases the strength only nominally.The attachment strength of a shelf can beimproved further by combining Confirmatscrews (see sidebar, right) with either a dadojoint or a rabbeted dado joint. The screwskeep the ends of the shelves in the dado, andthe dado adds extra shear strength.RABBETED DADOStrength: GoodAppearance: Good (excellent if using astopped dado or if covered by a face frame)A minor variation on the dado joint is torabbet the ends of the shelf to fit into anarrower dado. The main advantage is theability to fit the joint more easily, especiallyif the shelf thicknesses are inconsistent.This joint is useful when working withhardwood plywood, a material that typicallymeasures less than ¾ in. thick. In this case,a dado cut by making a single pass witha ¾-in.-dia. straight router bit ends up toowide. However, with a rabbeted dado, youcut a narrow dado first, then the rabbet for aperfect fit.Rabbeted dado starts with a dado. A T-square jig helps cuta dado across the side. The slot in the jig is just wide enough toaccept the bearing of a top-mounted bearing-guided straight bit.40FINE WOODWORKINGCONFIRMATSCREWS ADDSTRENGTHI’m not a fan of screwingshelves in place with thetypical tapered woodscrew.They rarely hold up longterm. That said, I have founda specialized screw thatworks much better. Calleda Confirmat screw, it has athick body with sharp, deepthreads. It’s mainly used withparticleboard, melamine,and MDF, but it also holdswell in solid wood. Whenused in a dado or a rabbeteddado, the joint strength isexcellent. Confirmat screwsrequire a pilot hole and ashank hole. A special bitis available that does thedrilling in one step (see“Sources,” p. 43).Mark and cut the rabbet. First, markthe rabbet location on the end of theshelf (left), then use a bearing-guidedrabbeting bit to cut the rabbet (above).Photos, except where noted: Tom Begnal; individual shelf and product shots: Michael PekovichCOPYRIGHT 2006 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.

BISCUITSStrength: FairAppearance: ExcellentIt’s easy to fix a shelf in place using abiscuit joiner. And, because the biscuitsare hidden when assembled, there is nojoinery, support parts, or hardware todistract the eye. Use at least twobiscuits on each end of the shelf. Add athird biscuit if there’s room. The jig shownat right is a good one to use here. Investa few minutes making it and you’ll berewarded many times over by the timesaved.SLIDING DOVETAILStrength: ExcellentAppearance: Very good (excellent ifstopped, or covered by a face frame)A sliding dovetail adds considerablemechanical strength, but sliding a10-in.-long dovetail into a tight-fitting slotbefore the glue sets up is a challenge.Using a fairly slow-setting epoxy glue willhelp considerably. Epoxy is a slippery gluethat helps get this type of joint togetherwithout excessive expansion and stress.See p. 74 to learn how to cut a slidingdovetail.JIG SPEEDSBISCUITINGA jig for cutting slots in thesides makes it easy to locateshelves accurately. The jighas just two parts: a cleatand a fence. The cleat keepsthe end of the fence squareto the side. Centerlines forthe slots are marked on theend of the fence. With eachnew set of shelf slots, thefence is crosscut to a shorterlength. Toss the jig whendone.SCREWED CLEATSStrength: Very goodAppearance: FairScrewed cleats let you add shelves withouttoo much fuss, but they come up a littleshort in the appearance department. Withthe exception of the hole closest to thefront, all of the holes in the shelf should beslotted to accommodate wood expansion.For the same reason, if you wish to gluethis joint, bear in mind that you shouldglue only the front inch or so.www.finewoodworking.comClamp and cut. Clampthe jig to the case. Cut oneset of slots, then use thejig to cut the same slotson the other side. Crosscutthe fence to the next shelfposition, and repeat until allslots are cut.MARCH/APRIL 2007COPYRIGHT 2006 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.41

Adjustable shelvesadd versatilityAdjustable shelves make it easy to change the spacing as needs change. But there isa structural cost: These shelves do nothing to hold the cabinet sides together. So, ontaller bookcases it’s a good idea to have one fixed shelf to help anchor the case sides.SHELF PINSStrength: Good (very good with sleeves)Appearance: GoodA JIG FOR PIN HOLESShelf pins come in a wide variety ofshapes, sizes, materials, and finishes.My favorites are the machined solidbrass ones from Lee Valley. I also likethe very small round pins by Häfele forsmaller cases. Shelf pins also comewith special clips for securing theshelves or for holding glass shelves.Sleeves are a great way to recover frompoorly drilled holes. Stamped sleeves(short tubes with a flared and roundedover end) tend to look like shoelaceeyelets when installed in a cabinet.Solid brass machined sleeves lookbetter, even though they accentuatethe row of holes in the case sidessomewhat. Some sleeves are threadedfor specially threaded shelf pins.Sleeve adds refinement andstrength. You can improve both theappearance and strength of a shelf pinsimply by slipping a brass sleeve intothe pin hole.HIDDENWIRESStrength: GoodAppearance: Very goodShelf-pin holes in a jiffy. Thanks to this shopmade jig, Miller quickly drills shelf-pin holesthat are the same depth and perfectly spaced.42FINE WOODWORKINGThese bent-wire supports fitinto holes drilled in the casesides. A stopped kerf cut inthe ends of the shelf slipsover the support, hiding thehardware. Structurally, thismeans the end of the shelf isthinner. This affects the shelf’sshear strength, but will havelittle effect on sag.Photos, facing page (right): Kelly J. DuntonCOPYRIGHT 2006 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.

WOODENSTANDARDSStrength: Very goodZIG-ZAG SUPPORTIN THREE STEPS1Appearance: Very goodWooden shelf standards havebeen around in various styles forgenerations. They are easy tomake and add an interesting lookto almost any bookcase. The styleshown in the top-left photo (I callit zig-zag) is one of the morecommon forms.Another style (I call it half-moon)is shown in the lower left photo.To make a pair, you’ll need a pieceof stock that’s at least double thewidth of each standard. Scribe alengthwise centerline along thestock, then lay out the shelf spacingby making a series of evenlyspaced marks along the centerline.Use a spade bit or a Forstner bitto drill a through-hole at eachmarked centerpoint. Finally, usinga tablesaw, rip the stock down themiddle. The net result is a pair ofstandards, each with a series of halfmoon shapes.Make the cleats just loose enoughto slip in and out with ease.METALSTANDARDS23Start with stock wide enough tomake four standards. Using thetablesaw, make a vertical cut ateach shelf location (1). An auxiliarymiter-gauge fence with a locationpin in front (much like a finger-jointjig) makes it easy to position thestock for subsequent cuts. Followwith 45º cuts (2) after relocating thelocation pin. Remove the triangularwaste piece, then clean theresulting flat with a chisel. Rip thestock to create four standards (3).Strength: Very goodAppearance: FairIt’s hard to beat metal shelf standardsfor ease of installation. Just run a pair ofdadoes down each side of the case, andnail, staple, or screw the shelf standardsinto place. Shelf supports usually justhook into place, although one newversion has brass support pins thatscrew into threaded holes in the brassstandards. In general, shelf standardsseem out of place on finer furniture.But they are great for utilitarian pieces,and even in larger bookcases, whereany support system will be pretty muchinvisible once the shelf is full of books.www.finewoodworking.comSOURCESO F S U P P LYHÄFELEwww.hafele.com; 800-423-3531LEE VALLEY/VERITASwww.leevalley.com; 800-871-8158MCFEELY’Swww.mcfeelys.com; 800-443-7937ROCKLERwww.rockler.com; 800-279-4441MARCH/APRIL 2007COPYRIGHT 2006 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.43

can make them free-standing or built-in. They can be big or small. And they can take any form, from simple screwed-together and painted plywood for use in a utility room, to sophisticated for-mal library shelves made from beautiful hardwoods. A shelf should look good A successful bookshelf design must achieve a balance between appearance